Introduction: Navigating the Global Market for pictures of bolts and nuts

Navigating the global market for pictures of bolts and nuts can be a daunting task for international B2B buyers, especially when sourcing high-quality images that accurately represent the variety and functionality of these essential fasteners. With diverse applications across industries—from construction and automotive to manufacturing—understanding the nuances of each type is crucial. This guide delves into a comprehensive array of images showcasing different styles, sizes, and materials of bolts and nuts, providing a visual reference that aids in informed decision-making.

In addition to exploring various types of fasteners, the guide offers insights on practical applications, supplier vetting processes, and cost considerations. As buyers from regions such as Africa, South America, the Middle East, and Europe (including countries like Nigeria and Vietnam) seek reliable suppliers and quality products, having access to accurate and informative visuals can significantly enhance their purchasing strategies.

By leveraging this resource, B2B buyers can streamline their sourcing process, ensuring they select the right fasteners for their projects while also establishing connections with trustworthy suppliers. This guide empowers international buyers to navigate the complexities of the market confidently, ultimately leading to more effective procurement practices and successful project outcomes.

Understanding pictures of bolts and nuts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hex Head Bolts | Hexagonal head, machine threads | Structural applications, machinery assembly | Pros: High strength, easy to install. Cons: Requires wrench for tight spaces. |

| Carriage Bolts | Smooth, large diameter head, square neck | Wood and plastic assembly, construction | Pros: Versatile, prevents pull-through. Cons: Limited to softer materials. |

| Flange Bolts | Round flange beneath the head | Metal-to-metal fastening | Pros: Distributes load evenly. Cons: Higher cost compared to standard bolts. |

| Plow Bolts | Square neck, flat head | Agricultural machinery, heavy equipment | Pros: High durability, prevents rotation. Cons: Specialized use may limit options. |

| Square Head Bolts | Square head for easy tightening | Electrical enclosures, tight spaces | Pros: Strong grip, easy to use. Cons: May not fit standard tools. |

What Are the Characteristics of Hex Head Bolts and Their B2B Suitability?

Hex head bolts are characterized by their hexagonal shape and machine threads, making them a popular choice for structural applications and machinery assembly. Their design allows for a secure grip and easy installation with a wrench, providing high strength for demanding applications. B2B buyers should consider the material and coating options available, as these can impact performance in various environments, particularly in industries requiring corrosion resistance.

How Do Carriage Bolts Serve Diverse B2B Applications?

Carriage bolts feature a smooth, large diameter head and a square neck designed to prevent rotation during tightening. This makes them ideal for assembling softer materials, such as wood and plastic, commonly found in construction and furniture applications. Buyers should assess the environmental conditions where these fasteners will be used, as factors like moisture and temperature can affect their longevity and performance.

What Advantages Do Flange Bolts Offer for Metal-to-Metal Fastening?

Flange bolts are distinguished by their round flange beneath the head, which distributes load effectively, making them suitable for metal-to-metal fastening. They are frequently used in automotive and heavy machinery applications where secure connections are critical. B2B buyers should weigh the cost against the benefits of improved load distribution and consider the specific requirements of their projects, including load-bearing capacities and material compatibility.

Why Are Plow Bolts Essential in Agricultural Machinery?

Plow bolts are designed with a square neck and flat head, making them ideal for use in agricultural machinery and heavy equipment. Their robust construction and ability to resist rotation during tightening ensure durability in demanding environments. When purchasing plow bolts, B2B buyers should consider the specific machinery requirements, including size and load specifications, to ensure optimal performance.

How Do Square Head Bolts Facilitate Assembly in Tight Spaces?

Square head bolts are designed for easy tightening with a wrench, making them particularly useful in electrical enclosures and other tight spaces. Their flat sides provide a strong grip, ensuring secure fastening in applications where visibility and accessibility may be limited. Buyers should evaluate the compatibility of square head bolts with their tools and consider the specific requirements of their projects to select the best fasteners for their needs.

Key Industrial Applications of pictures of bolts and nuts

| Industry/Sector | Specific Application of pictures of bolts and nuts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Project planning and material estimation | Accurate visualization aids in budgeting and sourcing | Quality standards, local availability, bulk pricing |

| Automotive | Design and assembly of vehicle components | Enhanced precision in design and manufacturing | Material specifications, compliance with safety standards |

| Manufacturing | Equipment maintenance and assembly line setup | Streamlined operations and reduced downtime | Durability, compatibility with existing systems |

| Aerospace | Component design and safety analysis | Ensures compliance with rigorous safety regulations | Certification requirements, supplier reliability |

| Marine | Shipbuilding and repair documentation | Facilitates efficient project management | Corrosion resistance, adherence to maritime standards |

How Are Pictures of Bolts and Nuts Used in the Construction Industry?

In the construction sector, pictures of bolts and nuts are critical for project planning and material estimation. They assist architects and engineers in visualizing how different fasteners fit into their designs, allowing for more accurate budgeting and sourcing of materials. For international buyers, especially in regions like Africa and South America, understanding local sourcing options and quality standards is essential to avoid delays and ensure compliance with construction regulations.

What Role Do Pictures of Bolts and Nuts Play in the Automotive Sector?

In the automotive industry, images of bolts and nuts are vital for the design and assembly of vehicle components. They help engineers ensure that specifications are met and that parts fit together correctly, ultimately enhancing the precision of manufacturing processes. For B2B buyers in Europe and the Middle East, it’s important to consider material specifications and compliance with safety standards to prevent costly recalls and ensure vehicle safety.

How Are Pictures of Bolts and Nuts Beneficial in Manufacturing?

Manufacturers rely on pictures of bolts and nuts for equipment maintenance and assembly line setup. High-quality visuals streamline operations by providing clarity on the types of fasteners needed, thus reducing downtime during maintenance. Buyers from regions like Vietnam should prioritize sourcing durable fasteners that are compatible with their existing systems, ensuring efficiency in production.

Why Are Pictures of Bolts and Nuts Important in Aerospace?

In aerospace, pictures of bolts and nuts are used extensively for component design and safety analysis. They facilitate compliance with rigorous safety regulations and standards that govern the industry. International buyers must focus on certification requirements and supplier reliability, as the stakes are high when it comes to safety in aviation.

How Do Pictures of Bolts and Nuts Aid Marine Applications?

In the marine industry, pictures of bolts and nuts play a crucial role in shipbuilding and repair documentation. They help project managers visualize fastener applications, ensuring efficient project management and adherence to maritime standards. Buyers should consider sourcing corrosion-resistant materials that meet industry specifications to prolong the lifespan of marine vessels.

3 Common User Pain Points for ‘pictures of bolts and nuts’ & Their Solutions

Scenario 1: Overwhelmed by Options for Bolts and Nuts Images

The Problem: B2B buyers often find themselves inundated with a vast array of images when searching for pictures of bolts and nuts. With thousands of stock photos available from various sources, it can be overwhelming to select images that accurately represent the specific types and applications they require. This confusion can lead to poor choices in visual marketing or product catalogs, potentially undermining the professionalism of their brand and complicating procurement processes.

The Solution: To effectively navigate this challenge, buyers should first define their specific requirements. This includes identifying the types of bolts and nuts relevant to their industry, such as hex bolts for construction or carriage bolts for woodworking. Once these parameters are established, utilizing specialized stock photo websites that allow for advanced filtering by type, size, or application can streamline the search process. Additionally, buyers should consider the context in which the images will be used—whether for technical documentation, marketing materials, or e-commerce platforms. By curating a focused collection of high-quality images that showcase the intended applications, B2B buyers can enhance their visual communications and ensure clarity in their offerings.

Scenario 2: Quality Concerns in Image Sourcing

The Problem: Another common pain point arises from the inconsistency in image quality across different stock photo platforms. Buyers may encounter images that are either too generic, poorly lit, or not representative of the true specifications of bolts and nuts, leading to misrepresentation in promotional materials. This inconsistency can damage the credibility of their brand and hinder effective communication with potential clients.

The Solution: To address quality concerns, B2B buyers should prioritize sourcing images from reputable stock photo providers known for their high standards. Researching user reviews and testimonials can offer insights into the reliability of image quality. Additionally, buyers can look for platforms that provide exclusive collections or partnerships with manufacturers, ensuring that the images are not only high-resolution but also accurately depict the products. Implementing a quality control process where images are vetted before use can further enhance the integrity of their visual assets. By investing time in sourcing quality images, buyers can strengthen their brand image and build trust with their audience.

Scenario 3: Misalignment of Visuals with Brand Messaging

The Problem: Many B2B companies struggle with aligning their chosen images of bolts and nuts with their overall brand messaging. For instance, a company that promotes sustainability may find generic images that do not convey their commitment to environmentally friendly practices. This misalignment can confuse potential customers and detract from the brand’s message, ultimately affecting sales and customer loyalty.

The Solution: To ensure that visuals reflect brand messaging effectively, buyers should develop a clear visual strategy that aligns with their core values and market positioning. This involves selecting images that not only showcase the products but also resonate with the brand’s identity. For example, if sustainability is a core value, sourcing images that highlight eco-friendly materials or manufacturing processes can reinforce this message. Collaborating with graphic designers to create customized visuals that integrate brand colors and themes can also provide a cohesive look. By taking a strategic approach to image selection, B2B buyers can enhance brand consistency and engage their target audience more effectively.

Strategic Material Selection Guide for pictures of bolts and nuts

What Are the Key Properties of Common Materials Used in Bolts and Nuts?

When selecting bolts and nuts for various applications, the choice of material is critical. Different materials offer unique properties that influence performance, durability, and suitability for specific environments. Here, we analyze four common materials: steel, stainless steel, aluminum, and brass.

How Does Steel Perform as a Material for Bolts and Nuts?

Steel is one of the most widely used materials for bolts and nuts due to its excellent strength and versatility. It typically has a high tensile strength, making it suitable for applications requiring robust fastening solutions. Steel bolts can withstand high temperatures and pressures, making them ideal for heavy-duty applications. However, standard steel is prone to corrosion, which can limit its use in harsh environments unless treated or coated.

Pros: High strength, cost-effective, widely available.

Cons: Susceptible to rust without protective coatings, heavier than alternatives.

Impact on Application: Suitable for automotive, construction, and machinery applications where strength is paramount.

Considerations for International Buyers: Compliance with ASTM standards is common, and buyers should consider local corrosion resistance needs, especially in humid or coastal regions.

What Advantages Does Stainless Steel Offer for Bolts and Nuts?

Stainless steel is known for its corrosion resistance, making it an excellent choice for outdoor or marine applications. It maintains its strength at elevated temperatures and offers good ductility, which allows for flexibility during installation. However, stainless steel can be more expensive than regular steel, and its manufacturing process is more complex.

Pros: Excellent corrosion resistance, aesthetic appeal, maintains strength in high temperatures.

Cons: Higher cost, potential galling issues when used with other metals.

Impact on Application: Ideal for applications in food processing, pharmaceuticals, and marine environments where hygiene and corrosion resistance are critical.

Considerations for International Buyers: Familiarity with DIN and JIS standards is essential, as different regions have varying grades of stainless steel.

Why Is Aluminum Considered for Bolts and Nuts?

Aluminum is lightweight and resistant to corrosion, making it suitable for applications where weight savings are crucial. It has a lower tensile strength compared to steel, which may limit its use in heavy-load applications. Aluminum bolts are often used in aerospace, automotive, and electronic applications due to their lightweight nature.

Pros: Lightweight, excellent corrosion resistance, good thermal and electrical conductivity.

Cons: Lower strength compared to steel, more expensive than standard steel.

Impact on Application: Best suited for applications where weight reduction is essential, such as in aerospace and automotive industries.

Considerations for International Buyers: Compliance with aerospace standards (like AS9100) may be necessary, especially for buyers in the aerospace sector.

What Role Does Brass Play in the Selection of Bolts and Nuts?

Brass is a copper-zinc alloy known for its excellent machinability and resistance to corrosion. It is often used in applications requiring electrical conductivity and low friction. However, brass is not as strong as steel and is typically used in low-stress applications.

Pros: Good corrosion resistance, excellent electrical conductivity, easy to machine.

Cons: Lower tensile strength, higher cost compared to steel.

Impact on Application: Commonly used in plumbing, electrical fittings, and decorative applications.

Considerations for International Buyers: Understanding local standards for electrical applications is crucial, as brass is often used in electronic components.

Summary Table of Material Selection for Bolts and Nuts

| Material | Typical Use Case for pictures of bolts and nuts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, construction | High strength | Susceptible to corrosion | Low |

| Stainless Steel | Food processing, marine applications | Excellent corrosion resistance | Higher cost | High |

| Aluminum | Aerospace, automotive | Lightweight | Lower strength | Medium |

| Brass | Plumbing, electrical fittings | Good machinability | Lower tensile strength | Medium |

This strategic material selection guide provides insights for international B2B buyers, helping them make informed decisions based on application needs, material properties, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for pictures of bolts and nuts

What Are the Key Stages in the Manufacturing Process of Bolts and Nuts?

Manufacturing bolts and nuts involves several critical stages that ensure the final product meets the required specifications and quality standards. The typical stages include:

-

Material Preparation: The process begins with selecting high-quality raw materials, typically steel or other alloys. These materials are sourced from certified suppliers to ensure they meet the necessary mechanical and chemical properties. The materials are then cut into appropriate lengths and shapes for further processing.

-

Forming: This stage involves shaping the raw materials into the desired forms. Common techniques include cold heading and forging, which involve compressing the metal to create the basic shape of the bolts and nuts. Cold heading is particularly effective for creating complex shapes with minimal waste, while forging enhances the strength of the materials.

-

Assembly: Once formed, the components are assembled. This may involve threading the bolts and nuts, which is typically done using precision machinery to ensure uniformity and adherence to specified tolerances. Automated systems can significantly increase the efficiency and accuracy of this process.

-

Finishing: The final stage includes surface treatments such as coating, plating, or anodizing to enhance corrosion resistance and aesthetic appeal. Common finishing processes include hot-dip galvanizing and electroplating. These treatments not only improve durability but also comply with international standards for fasteners.

How Do Quality Assurance Processes Ensure High Standards for Bolts and Nuts?

Quality assurance (QA) is integral to the manufacturing of bolts and nuts, ensuring that products meet both international and industry-specific standards. Key components of QA include:

-

International Standards Compliance: Manufacturers often adhere to ISO 9001, which outlines requirements for a quality management system. This standard emphasizes continuous improvement and customer satisfaction, crucial for international trade. Other relevant certifications may include CE marking for European markets and API standards for oil and gas applications.

-

Quality Control Checkpoints: Effective QA incorporates multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial step involves inspecting raw materials upon receipt to verify their compliance with specifications.

– In-Process Quality Control (IPQC): During production, regular inspections are conducted to monitor processes and identify any deviations from standards.

– Final Quality Control (FQC): At the end of production, finished products undergo rigorous testing and inspection to ensure they meet predefined criteria. -

Common Testing Methods: Several testing methods are employed to verify the quality of bolts and nuts, including:

– Tensile Testing: Measures the strength and ductility of materials.

– Hardness Testing: Assesses the material’s resistance to deformation.

– Dimensional Inspection: Verifies that products meet specified measurements.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are effective strategies:

-

Supplier Audits: Conducting audits of suppliers can provide firsthand insight into their manufacturing processes and quality management systems. This includes evaluating their adherence to international standards and their internal QA protocols.

-

Requesting Quality Reports: Buyers should request documentation that demonstrates compliance with quality standards, including test reports, certifications, and inspection records. This information helps assess the reliability of the supplier’s quality assurance processes.

-

Third-Party Inspections: Engaging third-party inspection services can provide an objective evaluation of the supplier’s products. These services can conduct inspections at various stages of production, ensuring that the products meet the required standards before shipment.

What Are the Specific Quality Control and Certification Nuances for International B2B Buyers?

Navigating the nuances of quality control and certification is particularly important for B2B buyers from diverse markets. Here are some considerations:

-

Regional Standards Compliance: Different regions may have specific standards and regulations governing the manufacturing of fasteners. Buyers should familiarize themselves with these requirements to ensure compliance and avoid potential legal issues.

-

Cultural Differences in Quality Expectations: Understanding the cultural context of suppliers can help buyers set realistic expectations regarding quality. For instance, suppliers in developing regions may have different approaches to quality control compared to those in more industrialized nations.

-

Language Barriers: Effective communication is crucial for ensuring that quality standards are understood and met. Buyers should consider working with suppliers who can provide documentation and support in their preferred language.

-

Logistical Considerations: International shipping can impact the quality of products. Buyers should ensure that suppliers have robust packaging and handling processes to protect the integrity of bolts and nuts during transit.

Conclusion

For international B2B buyers, understanding the manufacturing processes and quality assurance measures related to bolts and nuts is essential for making informed purchasing decisions. By grasping the key stages of manufacturing, the importance of quality control, and how to verify supplier standards, buyers can ensure they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pictures of bolts and nuts’

In the competitive landscape of B2B procurement, sourcing high-quality images of bolts and nuts is essential for marketing, product catalogs, and technical documentation. This guide offers a structured approach to help international buyers effectively find and secure the right visuals for their needs.

Step 1: Identify Your Specific Needs

Before diving into the sourcing process, clarify the types of images you require. Consider the context in which these images will be used, such as product listings, educational materials, or marketing campaigns.

– Types of images: Decide between stock photos, custom images, or technical illustrations.

– Image quality: Specify whether you need high-resolution images for print or lower quality for digital use.

Step 2: Research Reliable Sources

Conduct thorough research to identify reputable platforms that offer stock images of bolts and nuts. Popular platforms include iStock, Shutterstock, Adobe Stock, and free sources like Unsplash and Pixabay.

– Check user reviews: Look for platforms with positive feedback from previous users to ensure reliability.

– Understand licensing agreements: Ensure that the images you choose come with appropriate usage rights that align with your intended application.

Step 3: Evaluate Image Quality and Relevance

When selecting images, assess their quality and relevance to your specific applications. High-resolution images with clear details are crucial for technical and marketing purposes.

– Zoom capabilities: Ensure that the images maintain clarity when zoomed in, especially for intricate parts of the bolts and nuts.

– Diversity of images: Look for various angles, settings, and types of bolts and nuts to cover all potential uses.

Step 4: Verify Licensing and Usage Rights

Before finalizing your selection, review the licensing terms associated with each image. This step is critical to avoid legal issues and ensure you have the right to use the images as intended.

– Commercial use: Confirm that the license allows for commercial use if you plan to use the images in a business context.

– Attribution requirements: Check if the images require attribution or have any restrictions on modifications.

Step 5: Request Custom Images if Necessary

If stock images do not meet your specific requirements, consider commissioning a photographer or graphic designer to create custom visuals. This option can provide tailored images that perfectly fit your brand’s needs.

– Provide detailed briefs: Clearly outline your expectations, including angles, lighting, and specific features of the bolts and nuts you want to highlight.

– Negotiate pricing and timelines: Ensure you agree on costs and delivery schedules to avoid misunderstandings.

Step 6: Test and Use the Images Effectively

Once you have acquired the images, test them in your intended formats to ensure they meet your expectations. This includes checking how they look in print or on various digital platforms.

– Seek feedback: Share the images with your team or stakeholders to gather input on their effectiveness.

– Optimize for SEO: If using online, optimize image file names and alt text for search engines to enhance visibility.

Step 7: Maintain an Organized Digital Library

As you accumulate images, establish an organized digital library. This will make it easier to access and manage your visuals in the future.

– Categorize images: Sort images by type, usage, or project to streamline retrieval.

– Regularly update: Periodically review your library to remove outdated images and add new ones as your needs evolve.

By following these steps, B2B buyers can effectively source high-quality pictures of bolts and nuts that meet their specific requirements while ensuring compliance with legal and branding standards.

Comprehensive Cost and Pricing Analysis for pictures of bolts and nuts Sourcing

When sourcing pictures of bolts and nuts for B2B needs, understanding the cost structure and pricing dynamics is essential. This analysis will cover the key components influencing the costs, the factors affecting pricing, and offer practical tips for buyers, particularly those operating in diverse international markets.

What Are the Key Cost Components in Sourcing Pictures of Bolts and Nuts?

-

Materials: The primary cost driver in sourcing images relates to the quality of the photographs. High-resolution images, especially those featuring various types and specifications of bolts and nuts, often incur higher licensing fees. Stock images from established platforms may vary based on exclusivity, resolution, and the rights associated with usage.

-

Labor: The expertise of photographers and graphic designers plays a significant role in the overall cost. Professional photographers with experience in industrial photography may charge premium rates for their services, particularly if they are capturing specialized or custom images.

-

Manufacturing Overhead: While not directly applicable to image sourcing, any associated costs with image production, such as studio rental or equipment depreciation, can influence the final pricing of images.

-

Tooling: For custom images, the cost of specific tools or props used in the photography session can be a factor. For instance, if a unique setup is required to showcase a particular type of bolt or nut, that can add to the overall expense.

-

Quality Control (QC): Ensuring that images meet specific standards and specifications may involve additional QC processes, particularly when images are intended for high-stakes B2B marketing materials.

-

Logistics: While logistics primarily concern physical goods, in the context of digital images, it refers to the distribution and delivery mechanisms. Secure transfer methods or platforms that ensure image integrity may incur additional fees.

-

Margin: Suppliers will typically include a margin in their pricing structure to cover overhead and profit. This margin can vary based on the supplier’s market position and competition.

What Influences Pricing for Pictures of Bolts and Nuts?

-

Volume/MOQ (Minimum Order Quantity): Discounts are often available for bulk purchases. Buyers looking for a large volume of images can negotiate lower per-image prices.

-

Specifications and Customization: Custom images tailored to specific requirements can significantly increase costs. The more specialized the request, the higher the price is likely to be.

-

Materials and Quality Certifications: Images that require specialized photography equipment or editing software can also add to the overall cost. High-quality images often come with certifications that can be beneficial for marketing purposes.

-

Supplier Factors: The reputation and location of the supplier can influence costs. Established platforms may charge more due to their extensive libraries and better quality assurance processes.

-

Incoterms: While typically associated with physical goods, understanding the terms of service and licensing agreements for digital images is crucial. Different licensing terms can impact the overall cost and usage rights.

How Can Buyers Negotiate and Ensure Cost Efficiency?

-

Leverage Negotiation: Always be prepared to negotiate pricing, especially for bulk orders. Highlighting your potential for repeat business can incentivize suppliers to offer better rates.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term value of the images, including potential usage across multiple projects. Investing in high-quality images may yield better returns in brand perception and marketing effectiveness.

-

Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, consider currency fluctuations and import duties that may affect overall costs. Utilizing local suppliers can mitigate these issues, making sourcing more economical.

-

Disclaimer for Indicative Prices: It’s important to understand that prices can fluctuate based on market conditions, supplier changes, and specific project requirements. Always seek updated quotes and clarify licensing terms before finalizing purchases.

By understanding these cost structures and pricing influencers, B2B buyers can make informed decisions when sourcing pictures of bolts and nuts, ultimately leading to better procurement strategies and enhanced business outcomes.

Alternatives Analysis: Comparing pictures of bolts and nuts With Other Solutions

Exploring Alternatives to Pictures of Bolts and Nuts in B2B Applications

In the realm of industrial fasteners and components, visual representation plays a crucial role in decision-making. While pictures of bolts and nuts serve as a fundamental tool for buyers and suppliers, various alternatives can enhance understanding and selection. This analysis compares the effectiveness of visual imagery against two viable alternatives: 3D modeling software and physical samples.

Comparison Table

| Comparison Aspect | Pictures of Bolts and Nuts | 3D Modeling Software | Physical Samples |

|---|---|---|---|

| Performance | Good for visual reference | Excellent for detailed analysis and customization | Excellent tactile experience, but limited in availability |

| Cost | Low (often free or nominal) | Moderate to high (software licenses may be expensive) | High (shipping and handling costs) |

| Ease of Implementation | Easy to access and share | Requires training and software setup | Requires physical logistics and inventory management |

| Maintenance | No maintenance needed | Requires software updates and training | Requires inventory management and storage |

| Best Use Case | Quick reference for selection | Complex projects needing detailed specifications | Quality assurance and physical verification |

Detailed Breakdown of Alternatives

3D Modeling Software

3D modeling software offers a comprehensive approach to visualizing nuts and bolts. This technology allows users to manipulate designs, view parts from multiple angles, and even simulate assembly processes. The main advantages include detailed analysis and the ability to customize components for specific applications. However, the initial investment in software and the learning curve for employees can be considerable. This method is particularly beneficial for engineers and project managers who need precision and adaptability in their designs.

Physical Samples

Physical samples provide the most tangible experience, allowing buyers to assess the quality and fit of bolts and nuts firsthand. This approach is invaluable for ensuring that the chosen fasteners meet specific project requirements. However, it can be costly due to shipping and handling, especially when dealing with large orders or international suppliers. Moreover, managing an inventory of physical samples can complicate logistics and increase overhead costs. Physical samples are best suited for situations where quality assurance is paramount, such as in critical construction or manufacturing projects.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between pictures of bolts and nuts, 3D modeling software, and physical samples, B2B buyers should consider their specific requirements. For quick visual references and low-cost solutions, pictures remain effective. In contrast, 3D modeling software is ideal for complex projects requiring detailed specifications and adaptability. Physical samples are essential for quality assurance but come with higher costs and logistical challenges. Ultimately, the right choice will depend on the project scope, budget constraints, and the level of detail needed for successful implementation.

Essential Technical Properties and Trade Terminology for pictures of bolts and nuts

What Are the Key Technical Properties of Bolts and Nuts in B2B Purchasing?

When sourcing bolts and nuts, several technical properties are crucial for ensuring the right fit and functionality for industrial applications. Understanding these specifications can significantly impact purchasing decisions and overall project success.

1. Material Grade

Material grade indicates the quality and properties of the bolt or nut, typically categorized by standards such as ASTM or ISO. Common grades include ASTM A307 for general use and ASTM A325 for structural applications. The material affects strength, corrosion resistance, and suitability for specific environments. B2B buyers must consider the material grade to ensure the fastener can withstand operational demands, thus preventing costly failures and replacements.

2. Thread Type and Pitch

The thread type (e.g., UNC, UNF, Metric) and pitch (the distance between threads) are vital in determining compatibility with nuts and other fasteners. Incorrect thread specifications can lead to improper assembly, which compromises safety and performance. Understanding these elements is essential for buyers to ensure that the fasteners will fit perfectly with existing components and meet engineering specifications.

3. Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions. It is critical for ensuring that bolts and nuts fit together without excessive play or binding. For example, tighter tolerances are often required in precision applications, while looser tolerances may suffice in less critical settings. B2B purchasers should evaluate tolerance levels to maintain assembly integrity and performance under load.

4. Coating and Finish

The coating or finish applied to bolts and nuts, such as zinc plating or black oxide, affects corrosion resistance and aesthetics. For industries operating in harsh environments, selecting the right finish is essential for longevity and performance. Buyers should assess their environmental conditions and choose finishes that align with their operational needs.

5. Load Rating

The load rating specifies the maximum load a bolt or nut can safely handle. This is critical for applications where safety is paramount, such as in construction or machinery. Understanding load ratings helps B2B buyers select the appropriate fasteners for their projects, minimizing the risk of failure under stress.

What Are Common Trade Terms in the Bolt and Nut Industry?

In the B2B landscape, familiarity with industry terminology is crucial for effective communication and negotiation. Here are some common trade terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of bolts and nuts, understanding whether a supplier is an OEM can inform buyers about the quality and reliability of the products offered. OEM parts often meet stringent quality standards, making them a preferred choice.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is important for buyers to know as it can affect inventory management and cost efficiency. Understanding MOQ helps businesses plan their purchases effectively and avoid overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing for specific quantities of products. This is a critical step in the procurement process, allowing buyers to compare prices and terms from various suppliers. Crafting a detailed RFQ can lead to better pricing and service agreements.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that outline the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk transfer, and delivery obligations, ensuring smoother transactions and reducing disputes.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is crucial for project planning and ensuring that materials are available when needed. Buyers should factor in lead times when negotiating contracts and setting project timelines.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing bolts and nuts, leading to more successful procurement and project outcomes.

Navigating Market Dynamics and Sourcing Trends in the pictures of bolts and nuts Sector

What Are the Key Market Trends Influencing the Pictures of Bolts and Nuts Sector?

The global market for bolts and nuts, alongside their corresponding images, is experiencing significant growth driven by several factors. Industrialization in emerging markets, particularly in Africa, South America, and parts of Europe and the Middle East, is a primary driver. As construction and manufacturing industries expand, the demand for reliable fasteners is surging. Additionally, technological advancements in manufacturing processes, such as automation and precision engineering, are enhancing the quality and variety of bolts and nuts available, making them more accessible to international buyers.

Emerging B2B tech trends, including e-commerce platforms for industrial supplies and digital marketplaces, are reshaping how buyers source fasteners. These platforms not only simplify the procurement process but also facilitate access to a wider range of high-quality images and detailed specifications of bolts and nuts, enabling informed decision-making. Moreover, the rise of data analytics is allowing suppliers to predict trends and optimize inventory based on demand forecasts, which is crucial for meeting the needs of diverse markets.

Another notable trend is the increasing importance of customization. Buyers are seeking tailored solutions that meet specific project requirements, leading manufacturers to offer more bespoke products. This trend is particularly relevant in sectors such as construction, automotive, and aerospace, where precision and reliability are paramount.

How Is Sustainability Shaping the Sourcing of Bolts and Nuts?

Sustainability has emerged as a critical consideration in the sourcing of bolts and nuts. The environmental impact of manufacturing processes, including resource extraction and energy consumption, is prompting businesses to seek more sustainable practices. Ethical sourcing is becoming a priority, with buyers increasingly demanding transparency in the supply chain. This includes knowing the origin of materials and the environmental practices of manufacturers.

To address these concerns, many suppliers are adopting ‘green’ certifications and utilizing eco-friendly materials in their products. Certifications such as ISO 14001 (Environmental Management) and the use of recycled metals are becoming standard practices for reputable manufacturers. By prioritizing sustainability, companies not only enhance their brand reputation but also cater to a growing segment of environmentally conscious consumers and businesses.

Furthermore, ethical supply chains are not just about compliance but also about fostering long-term relationships with suppliers who share similar values. As buyers from Africa, South America, and Europe become more aware of the social and environmental implications of their purchasing decisions, they are likely to prefer suppliers who demonstrate a commitment to sustainable practices.

What Is the Historical Context of the Bolts and Nuts Sector?

The evolution of bolts and nuts dates back to ancient civilizations, where rudimentary fastening methods were used for construction and machinery. However, the modern era of fasteners began during the Industrial Revolution, which saw significant advancements in manufacturing techniques and materials. The introduction of standardized sizes and grades of bolts and nuts revolutionized the industry, allowing for mass production and widespread application across various sectors.

In recent decades, the focus has shifted towards enhancing the performance and durability of fasteners through innovations in materials science and engineering. This evolution has been critical in meeting the demands of modern industries, where reliability and safety are paramount. As the market continues to grow, the historical advancements in bolts and nuts not only provide a foundation for current trends but also set the stage for future innovations that will further enhance the sector’s capabilities.

By understanding these dynamics, B2B buyers can navigate the complexities of sourcing bolts and nuts effectively, ensuring they make informed decisions that align with both their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of pictures of bolts and nuts

-

How do I choose the right supplier for pictures of bolts and nuts?

To select a reliable supplier, consider their industry experience, portfolio quality, and customer reviews. Verify that they specialize in industrial imagery, as this ensures a better understanding of your needs. Request samples to gauge image quality and ensure the supplier can meet your specific requirements. Additionally, check for certifications and compliance with international standards, especially if you’re sourcing from different regions. -

What is the best platform for sourcing high-quality images of bolts and nuts?

Platforms like Adobe Stock, Shutterstock, and iStock offer extensive collections of high-quality images of bolts and nuts. These platforms allow you to filter images based on various criteria, ensuring you find the right visuals for your marketing or product documentation. Evaluate licensing options to ensure they fit your usage needs, whether for commercial or editorial purposes. -

How can I ensure the images I purchase are exclusive or unique?

To secure exclusive or unique images, consider negotiating a custom licensing agreement with the supplier. This might involve commissioning a photographer to create tailored images specifically for your brand. Additionally, explore platforms that offer exclusive content or limited licenses, ensuring that the images won’t be widely distributed among competitors. -

What are the typical payment terms for international image sourcing?

Payment terms vary by supplier but commonly include options like upfront payment, installment plans, or payment upon delivery. It’s crucial to clarify these terms before finalizing your order, especially for international transactions where currency exchange and transfer fees may apply. Ensure that the payment method is secure and offers buyer protection. -

What minimum order quantities (MOQ) should I expect when sourcing images?

Most image suppliers do not have a strict MOQ for purchasing stock images, as they often operate on a pay-per-image basis. However, if you are looking for custom photography, suppliers may have MOQs based on the project scope. Discuss your needs with the supplier to understand any potential volume discounts or packages available. -

How can I verify the quality of images before purchasing?

Before making a purchase, request a portfolio or sample images from the supplier. Pay attention to resolution, clarity, and detail, as these factors significantly impact the final output. Many platforms also allow you to preview images at full resolution. Consider conducting a test purchase for a single image to evaluate the quality and suitability for your projects. -

What are the logistics involved in sourcing images internationally?

When sourcing images from international suppliers, consider shipping logistics if physical media is involved. However, most images are delivered digitally, which simplifies the process. Ensure that you understand the file formats, resolution requirements, and any potential digital rights management (DRM) restrictions that may affect your use of the images. -

How do I handle quality assurance (QA) for images sourced from suppliers?

Implement a QA process that includes reviewing images for technical quality, relevance, and compliance with your brand guidelines. Create a checklist that assesses aspects such as resolution, color accuracy, and composition. Engage your team to evaluate the images in context, ensuring they align with your project objectives before final approval and usage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Pictures Of Bolts And Nuts Manufacturers & Suppliers List

1. Adobe Stock – Nut Bolt Images

Domain: stock.adobe.com

Registered: 1986 (39 years)

Introduction: Nut Bolt影像 – 瀏覽164,965個素材庫相片、向量圖和影片 | Adobe Stock。可找到的內容包括:影像、影片、音訊、範本、3D模型等。可免費試用以獲得10張影像或1部影片,並解鎖超過2億個資產。特定模型包括Wide, open bolt、Hex bolt、Metal nut等,影片格式為4K HD。

2. iStock – Nuts and Bolts Images

Domain: istockphoto.com

Registered: 2000 (25 years)

Introduction: This company, iStock – Nuts and Bolts Images, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Shutterstock – Bolts and Nuts Collection

Domain: shutterstock.com

Registered: 2003 (22 years)

Introduction: This company, Shutterstock – Bolts and Nuts Collection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Getty Images – Nut Bolt Stock Photos

Domain: gettyimages.com

Registered: 1999 (26 years)

Introduction: 2,939 Nut Bolt Stock Photos, High-Res Pictures, and Images available on Getty Images. Options include nut bolt clipart, screw nut bolt stock images, and various sizes and resolutions for projects.

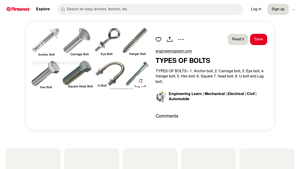

5. Pinterest – Types of Bolts

Domain: ca.pinterest.com

Registered: 2009 (16 years)

Introduction: Types of Bolts: 1. Anchor bolt, 2. Carriage bolt, 3. Eye bolt, 4. Hanger bolt, 5. Hex bolt, 6. Square head bolt, 7. U-bolt, 8. Lag bolt.

6. Unsplash – Nuts and Bolts

Domain: unsplash.com

Registered: 2013 (12 years)

Introduction: Nuts and bolts, screw, bolt, machine, construction, nut, grey metal, thread, macro, tool, steel, detail.

7. Freepik – Nut Bolt Graphics

Domain: freepik.com

Registered: 2010 (15 years)

Introduction: This company, Freepik – Nut Bolt Graphics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Helix Steel – Bolts, Nuts & Washers

Domain: helixsteel.ph

Introduction: 40+ Different Types of Bolts and Nuts and Washers including: 1. Carriage Bolts – Simple installation, smooth large diameter head, square neck. 2. Flange Bolts – Round flange under head, distributes load. 3. Plow Bolts – Square neck, flat head, used in heavy machinery. 4. Hex Head Bolts – Hexagonal heads, machine threads, used with nut and washer. 5. Square Head Bolts – Large flat sides, used in re…

9. Vecteezy – Nuts and Bolts Stock Photos

Domain: vecteezy.com

Registered: 2007 (18 years)

Introduction: Nuts And Bolts Stock Photos, Images and Backgrounds for Free Download; 1,698 high resolution, royalty free stock photos and pictures matching Nuts And Bolts; Related searches include bolt, nut, construction, screw, tool, nail, hardware, steel, metal, repair work, nail head, rivet, equipment, industry; Keywords: nuts and bolts background, bolt, nut, construction, screw, tool, nail, hardware, steel,…

Strategic Sourcing Conclusion and Outlook for pictures of bolts and nuts

In navigating the complex landscape of bolts and nuts sourcing, international buyers must prioritize strategic sourcing to enhance their procurement processes. By understanding the vast array of fasteners available, from carriage bolts to hex head screws, buyers can make informed decisions that align with their specific application needs. High-quality images of these components not only assist in identifying the right products but also facilitate better communication with suppliers, ensuring that expectations are clearly set.

The strategic sourcing of bolts and nuts extends beyond mere procurement; it encompasses supplier relationship management, quality assurance, and cost-efficiency. Buyers in regions such as Africa, South America, the Middle East, and Europe should leverage online resources and stock photo libraries to visualize and compare products effectively. This approach not only streamlines the selection process but also enhances the overall quality of projects through better material choices.

Looking ahead, the demand for customized and high-performance fasteners is expected to rise. International buyers are encouraged to embrace innovative sourcing strategies and to stay abreast of market trends to remain competitive. Engage with suppliers today to explore the vast potential of high-quality bolts and nuts, ensuring your projects are built on a foundation of reliability and excellence.