Introduction: Navigating the Global Market for phenolic laminate sheet

In the complex landscape of international trade, sourcing high-quality phenolic laminate sheets can present significant challenges for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Phenolic laminate sheets are renowned for their durability, chemical resistance, and versatility, making them a preferred choice in various industries, from electrical components to structural applications. However, navigating the intricacies of material specifications, supplier reliability, and regional compliance can be daunting.

This comprehensive guide is designed to empower B2B buyers by providing in-depth insights into the various types of phenolic laminate sheets available in the market, their specific applications, and crucial factors to consider when vetting suppliers. We will explore cost considerations, quality standards, and best practices for ensuring that your purchasing decisions align with your operational needs and budget constraints.

By equipping you with actionable strategies and a clear understanding of the phenolic laminate sheet market, this guide aims to facilitate informed purchasing decisions that drive efficiency and value in your business operations. Whether you are sourcing materials for manufacturing, construction, or specialized applications, understanding the nuances of phenolic laminate sheets will enhance your competitive edge in the global market.

Understanding phenolic laminate sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Canvas “C” Grade Phenolic | High impact strength, noise reduction, non-sparking | Gears, pulleys, rollers, explosion-proof parts | Pros: Durable, cost-effective; Cons: Limited electrical properties. |

| Linen “LE” Grade Phenolic | Fine-weave linen fabric, better machining capabilities | Precision parts, intricate shapes, gears | Pros: Excellent machinability, low noise; Cons: Higher cost than canvas grade. |

| G-10 Glass Epoxy Sheet | High mechanical strength, low moisture absorption | Electrical insulation, structural applications | Pros: Superior electrical properties; Cons: Limited temperature resistance. |

| Paper “Economy” Grade Phenolic | Lower resin content, suitable for low voltage applications | Electrical components, punch-through boards | Pros: Cost-effective; Cons: Poor performance in high humidity. |

| G-9 Glass-Melamine Laminate | Good moisture resistance, high surface finish | Countertops, decorative surfaces | Pros: Aesthetic appeal, durable; Cons: Less impact resistance compared to G-10. |

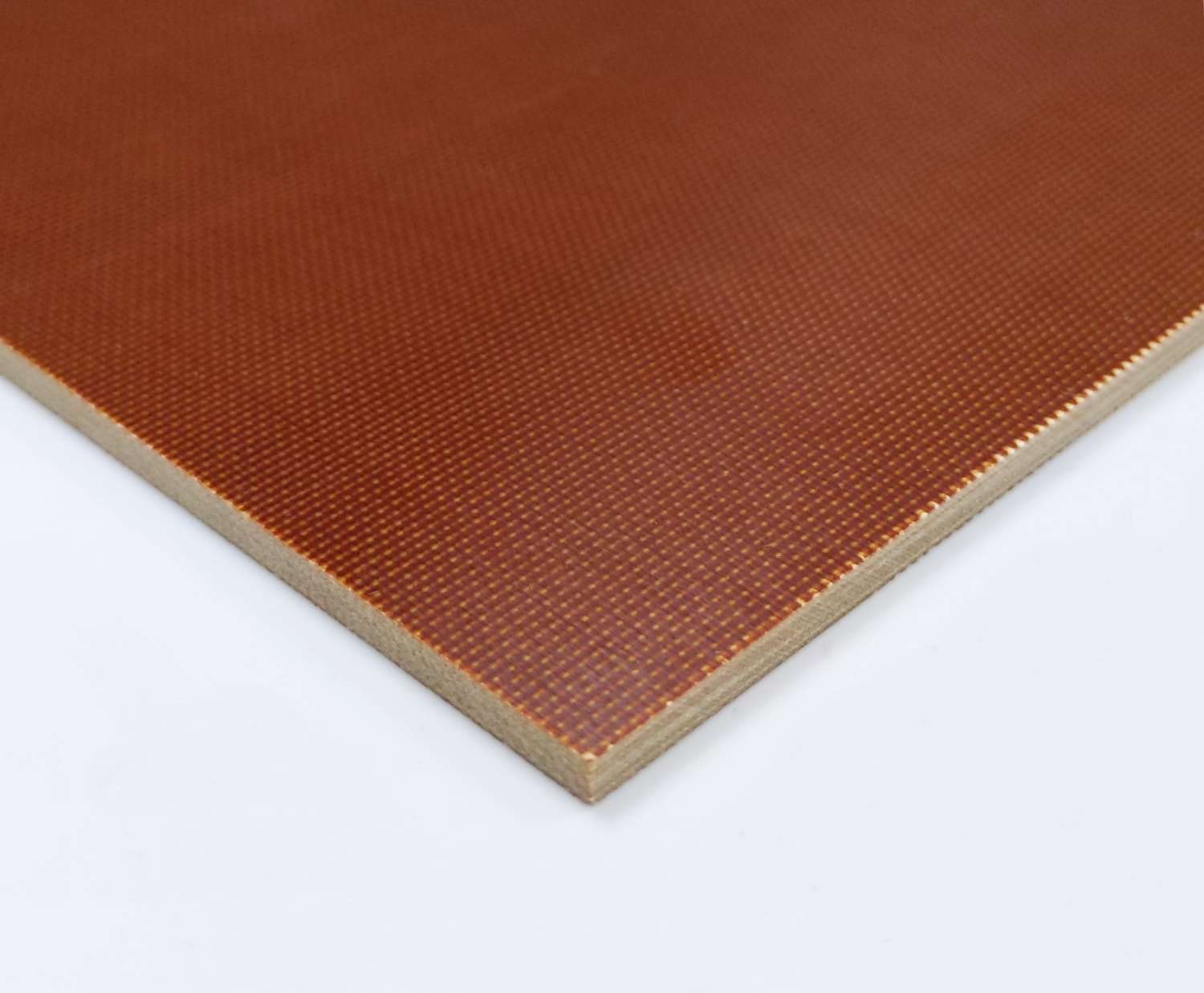

What Are the Key Characteristics of Canvas “C” Grade Phenolic Laminate Sheets?

Canvas “C” grade phenolic laminate sheets are known for their high impact strength and noise reduction capabilities. Composed of cotton canvas fabric infused with general-purpose phenolic resin, these sheets are easy to machine and can be utilized in explosion-proof environments due to their non-sparking nature. They are commonly used in manufacturing gears, pulleys, and rollers, making them a reliable choice for various mechanical applications. However, buyers should note that while they are durable and cost-effective, their electrical properties are not as robust compared to other grades.

How Does Linen “LE” Grade Phenolic Compare to Other Types?

Linen “LE” grade phenolic sheets are characterized by their fine-weave linen fabric, which provides enhanced machining capabilities compared to canvas grades. This material is quieter during operation and less abrasive than fiberglass alternatives, making it ideal for precision parts and intricate shapes. Common applications include fine-tooth gears and rollers. While these sheets offer excellent machinability and low noise, they tend to be more expensive than canvas grades, which may affect budget-conscious purchasing decisions.

Why Choose G-10 Glass Epoxy Sheet for Electrical Applications?

G-10 glass epoxy sheets are renowned for their high mechanical strength and low moisture absorption, making them suitable for a wide range of structural and electrical insulation applications. They combine woven glass fabric with epoxy resin, providing exceptional electrical properties even in humid conditions. Industries often utilize G-10 sheets for terminal boards and microelectronics. While they offer superior electrical insulation, buyers should consider their limited temperature resistance when selecting materials for high-heat applications.

What Are the Advantages and Disadvantages of Paper “Economy” Grade Phenolic Sheets?

Paper “economy” grade phenolic sheets are designed with a lower phenolic resin content, making them a cost-effective option for low-voltage electrical applications. These sheets are typically hot punched for various uses, such as electrical components and punch-through boards. Their affordability is a significant advantage; however, they are not suitable for high-humidity environments due to poor performance in moisture-laden conditions. Buyers should weigh the cost benefits against the limitations in application suitability.

What Makes G-9 Glass-Melamine Laminate a Good Choice for Decorative Surfaces?

G-9 glass-melamine laminate sheets are notable for their good moisture resistance and high surface finish, making them ideal for decorative surfaces such as countertops. These sheets combine aesthetic appeal with durability, suitable for both residential and commercial applications. However, while they are visually appealing and resistant to wear, they may not offer the same level of impact resistance as G-10 sheets. Buyers should consider the balance between aesthetics and mechanical performance when selecting G-9 for their projects.

Key Industrial Applications of phenolic laminate sheet

| Industry/Sector | Specific Application of phenolic laminate sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical & Electronics | Insulating components for circuit boards | High dielectric strength ensures reliability in performance | Ensure compliance with international electrical standards; consider moisture absorption rates. |

| Aerospace & Defense | Structural components in aircraft and military vehicles | Lightweight yet durable, reducing overall weight and enhancing fuel efficiency | Look for materials that meet stringent aerospace certifications and resistance to extreme temperatures. |

| Manufacturing & Machinery | Machine parts like gears, pulleys, and guides | Excellent wear resistance extends the lifespan of components | Consider the specific grade of phenolic laminate for machining capabilities and temperature tolerances. |

| Automotive | Brake pads and clutch disks | Provides high friction and thermal resistance, enhancing safety | Source phenolic laminates that meet automotive safety regulations and performance standards. |

| Construction & Building | Countertops and surface laminates | Durable and aesthetically pleasing, suitable for high-traffic areas | Evaluate chemical resistance and ease of maintenance for long-term usability in various environments. |

How is Phenolic Laminate Sheet Used in Electrical & Electronics Applications?

In the electrical and electronics sector, phenolic laminate sheets are commonly utilized for manufacturing insulating components in circuit boards. Their high dielectric strength is crucial for ensuring reliable performance in various electrical applications, particularly in environments prone to moisture. Buyers should prioritize materials that comply with international electrical standards and possess low moisture absorption rates to mitigate any risk of electrical failure.

What Role Does Phenolic Laminate Play in Aerospace & Defense?

In the aerospace and defense industries, phenolic laminate sheets are employed for structural components in aircraft and military vehicles. Their lightweight yet durable characteristics contribute to reducing overall vehicle weight, thereby enhancing fuel efficiency and performance. International buyers must consider sourcing materials that meet stringent aerospace certifications and can withstand extreme temperatures, ensuring both safety and reliability in critical applications.

Why are Phenolic Laminate Sheets Important in Manufacturing & Machinery?

Manufacturers often use phenolic laminate sheets to create machine parts such as gears, pulleys, and guides. These sheets offer excellent wear resistance, which significantly extends the lifespan of mechanical components and reduces maintenance costs. When sourcing for these applications, it is essential to select the appropriate grade of phenolic laminate that meets specific machining capabilities and temperature tolerances to ensure optimal performance.

How is Phenolic Laminate Utilized in Automotive Applications?

In the automotive sector, phenolic laminate sheets are vital for producing brake pads and clutch disks. Their properties provide high friction and thermal resistance, which are essential for enhancing vehicle safety and performance. Buyers in this field should ensure that the phenolic laminates sourced meet automotive safety regulations and performance standards to guarantee reliability under demanding conditions.

What Benefits Does Phenolic Laminate Offer in Construction & Building?

In construction, phenolic laminate sheets are widely used for countertops and surface laminates due to their durability and aesthetic appeal. They are particularly well-suited for high-traffic areas, providing a long-lasting surface that withstands wear and tear. When sourcing these materials, it is important to evaluate their chemical resistance and ease of maintenance, ensuring they remain functional and visually appealing over time.

3 Common User Pain Points for ‘phenolic laminate sheet’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Grade of Phenolic Laminate Sheet

The Problem: Many B2B buyers encounter challenges when choosing the appropriate grade of phenolic laminate sheet for their specific applications. With various options available, such as G-10, G-3, and linen grades, it can be overwhelming to determine which material offers the best performance in terms of strength, machinability, and thermal resistance. This confusion often leads to incorrect purchases, resulting in wasted resources and potential project delays.

The Solution: To effectively select the right grade, buyers should first assess their application requirements in detail. Consider factors such as temperature resistance, mechanical stress, and environmental conditions. For instance, G-10 glass epoxy laminate is ideal for high humidity and electrical insulation applications, while G-3 offers excellent mechanical properties in less demanding environments. Engaging with suppliers to obtain samples or technical data sheets can provide further clarity. Additionally, consulting with technical experts or utilizing online resources to compare properties can guide buyers in making informed decisions, ensuring they procure materials that align with their operational needs.

Scenario 2: Managing Supply Chain Disruptions

The Problem: International buyers, especially in regions like Africa and South America, often face supply chain disruptions due to geopolitical issues, shipping delays, or fluctuating demand. This unpredictability can lead to extended lead times for phenolic laminate sheets, jeopardizing project timelines and increasing costs. Consequently, businesses may struggle to meet customer demands or fulfill contractual obligations, which can damage their reputation and financial standing.

The Solution: To mitigate these risks, buyers should diversify their supplier base and explore local manufacturers or distributors in their region. This strategy not only reduces dependency on international suppliers but can also decrease shipping times and costs. Establishing strong relationships with multiple suppliers allows for quicker responses to market changes. Additionally, utilizing inventory management software can help buyers forecast demand more accurately and maintain optimal stock levels, ensuring they have the necessary materials on hand to avoid project delays.

Scenario 3: Ensuring Safe Handling and Compliance

The Problem: The handling of phenolic laminate sheets presents safety challenges, particularly due to sharp edges and the potential for injury. Buyers often overlook the importance of safe handling practices, which can lead to accidents in the workplace. Furthermore, compliance with safety regulations and standards can be a concern, especially in industries such as construction and manufacturing where safety is paramount.

The Solution: To enhance safety, it is crucial for buyers to implement comprehensive training programs for employees on the proper handling of phenolic laminate sheets. This training should cover the use of personal protective equipment (PPE), safe lifting techniques, and the correct handling procedures to minimize injury risks. Additionally, suppliers should provide clear safety information and guidelines for their products. Buyers can also ensure compliance with industry standards by regularly reviewing safety regulations and integrating them into their operational protocols. By prioritizing safety and compliance, businesses can create a safer work environment and reduce the likelihood of accidents, ultimately enhancing productivity and employee morale.

Strategic Material Selection Guide for phenolic laminate sheet

What Are the Key Properties of Common Phenolic Laminate Sheet Materials?

Phenolic laminate sheets are engineered composites that offer a variety of properties depending on the reinforcement materials used. The most common types include Canvas “C” Grade, Linen “LE” Grade, G-10 Glass Epoxy, and Economy Paper Grade. Each has distinct characteristics that influence their performance in various applications.

Canvas “C” Grade Phenolic Laminate

Canvas “C” Grade phenolic laminate is made from cotton canvas fabric reinforced with general-purpose phenolic resin. This material is known for its high impact strength and excellent machinability, making it suitable for mechanical components such as gears and pulleys. It operates effectively in environments where noise reduction is essential and is non-sparking, which is critical for explosion-proof applications.

Pros: High durability, good machinability, and cost-effective.

Cons: Limited electrical properties compared to other grades; may not perform well in high-humidity conditions.

Impact on Application: Ideal for mechanical parts in dry environments but less suitable for sensitive electrical applications.

International Considerations: Buyers should ensure compliance with local standards such as ASTM for mechanical properties, especially in regions like Europe and the Middle East where regulations can be stringent.

Linen “LE” Grade Phenolic Laminate

Linen “LE” Grade phenolic laminate features a fine-weave linen fabric that provides superior machining capabilities. This grade is often used for applications requiring intricate shapes and finer details, such as precision gears and guides. It offers excellent noise reduction and is also non-sparking, making it suitable for hazardous environments.

Pros: Exceptional machining capabilities and higher temperature resistance.

Cons: Higher cost compared to Canvas “C” Grade and may absorb moisture over time.

Impact on Application: Suitable for precision components in both mechanical and electrical applications, but moisture absorption can be a concern in humid climates.

International Considerations: Compliance with JIS standards may be necessary for buyers in Asia, while European buyers may focus on DIN standards.

G-10 Glass Epoxy Laminate

G-10 Glass Epoxy laminate is a high-performance material made from woven glass fabric and epoxy resin. It is recognized for its excellent electrical properties and mechanical strength, making it ideal for applications in electronics and electrical insulation. G-10 can withstand higher temperatures and has low moisture absorption, contributing to its durability.

Pros: Superior electrical insulation, high mechanical strength, and excellent dimensional stability.

Cons: More expensive than other phenolic grades and can be more challenging to machine.

Impact on Application: Perfect for electrical components, printed circuit boards, and high-humidity environments.

International Considerations: Buyers should verify compliance with IEC standards for electrical applications, particularly in regions like Africa and South America where electrical safety is paramount.

Economy Paper Grade Phenolic Laminate

Economy Paper Grade phenolic laminate is a cost-effective option that utilizes paper as a base material. It is primarily used in low-voltage electrical applications where high humidity resistance is not a requirement. This laminate offers fair electrical properties in dry conditions but is not suitable for high-stress applications.

Pros: Low cost and lightweight, making it suitable for budget-sensitive projects.

Cons: Limited mechanical and electrical properties; not suitable for humid environments.

Impact on Application: Best for low-demand electrical applications but should be avoided in moisture-prone areas.

International Considerations: Buyers should consider local standards for electrical insulation, particularly in humid regions.

Summary Table of Phenolic Laminate Sheet Materials

| Material | Typical Use Case for phenolic laminate sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Canvas “C” Grade | Gears, pulleys, and mechanical parts | High durability and machinability | Limited electrical properties | Medium |

| Linen “LE” Grade | Precision gears and intricate components | Exceptional machining capabilities | Higher cost and moisture absorption | High |

| G-10 Glass Epoxy | Electrical components and circuit boards | Superior electrical insulation | More expensive and difficult to machine | High |

| Economy Paper Grade | Low-voltage electrical applications | Cost-effective for budget projects | Limited mechanical properties | Low |

This strategic material selection guide provides valuable insights into the properties, advantages, and limitations of various phenolic laminate sheets, enabling international B2B buyers to make informed purchasing decisions tailored to their specific needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for phenolic laminate sheet

What Are the Main Stages in the Manufacturing Process of Phenolic Laminate Sheets?

The manufacturing process of phenolic laminate sheets involves several critical stages, each designed to ensure the final product meets the high-performance standards expected in various industrial applications. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage involves selecting high-quality raw materials, typically consisting of a phenolic resin combined with reinforcing fibers such as glass or cotton. The resin is usually in liquid form and is blended with these fibers to create a composite material. This mixture is then subjected to processes such as drying and grinding to achieve the desired consistency and properties. The preparation phase is crucial as it determines the mechanical and thermal characteristics of the final product.

How Is the Forming Process Conducted for Phenolic Laminate Sheets?

Once the materials are prepared, they undergo a forming process, which typically employs techniques like hot pressing. In this stage, the prepared composite is placed in a mold, and heat and pressure are applied to cure the resin, solidifying the laminate into the desired thickness and shape. This step not only enhances the material’s strength but also influences its electrical and thermal insulating properties. The precision of the forming process is vital, as it directly impacts the final product’s dimensional stability and performance.

What Is Involved in the Assembly and Finishing Stages?

After forming, the sheets may require additional assembly, particularly if they are intended for complex applications. This could involve laminating multiple layers or integrating other materials to enhance specific properties. The finishing stage includes cutting, sanding, and surface treatments to achieve the required finish and tolerances. This stage is essential for ensuring that the sheets meet customer specifications and are ready for end-use applications.

What Quality Assurance Standards Are Relevant for Phenolic Laminate Sheets?

Quality assurance in the manufacturing of phenolic laminate sheets is critical to ensure product reliability and performance. International standards such as ISO 9001 provide a framework for consistent quality management practices. Additionally, industry-specific certifications, such as CE marking for compliance with European safety standards and API specifications for the oil and gas industry, play a significant role in assuring product quality.

How Are Quality Control Checkpoints Established?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process. Key QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations or defects early, allowing for immediate corrective actions.

- Final Quality Control (FQC): This final inspection ensures that the finished product meets all specifications before it is shipped to customers.

What Common Testing Methods Are Used in Quality Assurance?

Several testing methods are employed to verify the quality of phenolic laminate sheets. Common tests include:

- Mechanical Testing: Evaluates tensile strength, compressive strength, and impact resistance to ensure the material can withstand its intended applications.

- Thermal Testing: Assesses the heat resistance and thermal stability of the laminate, ensuring it can perform under varying temperature conditions.

- Electrical Testing: Measures dielectric strength and insulation resistance, crucial for applications in electrical and electronic components.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying supplier quality control is paramount. Here are some actionable steps:

- Conduct Supplier Audits: Regular audits can help assess a supplier’s adherence to quality standards and manufacturing practices. This can include reviewing their quality management systems and production processes.

- Request Quality Reports: Suppliers should provide detailed QC reports that outline their testing methodologies, results, and compliance with relevant standards.

- Engage Third-Party Inspection Services: Utilizing independent inspection agencies can provide an unbiased assessment of the supplier’s quality practices and product reliability.

What Are the Quality Control Nuances for International Buyers?

When sourcing phenolic laminate sheets internationally, buyers should be aware of certain nuances in quality control:

- Cultural Differences in Quality Standards: Different regions may have varying expectations regarding quality assurance. Buyers must ensure that suppliers understand and meet the specific standards required in their target markets.

- Regulatory Compliance: Depending on the country of import, additional certifications or testing may be necessary to comply with local regulations. Buyers should verify that their suppliers are familiar with these requirements.

- Supply Chain Transparency: A transparent supply chain enhances trust and allows buyers to trace the quality of materials back to their source. It’s essential to inquire about the suppliers’ practices for ensuring material integrity throughout the supply chain.

Conclusion: Ensuring Quality in Phenolic Laminate Sheets Manufacturing

Understanding the manufacturing processes and quality assurance measures for phenolic laminate sheets is vital for B2B buyers looking to source reliable materials. By focusing on each stage of production, adhering to international standards, and implementing robust quality control practices, manufacturers can deliver products that meet the rigorous demands of various industries. For buyers, verifying these processes and standards with suppliers will ensure they receive high-quality materials that align with their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘phenolic laminate sheet’

Introduction

This practical sourcing guide is designed to assist B2B buyers in effectively procuring phenolic laminate sheets. By following this step-by-step checklist, you can ensure that you make informed decisions, select high-quality materials, and establish reliable supplier relationships that meet your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clarify your specific requirements for phenolic laminate sheets. This includes understanding the intended application, such as electrical insulation or structural components, and determining the necessary properties like heat resistance, moisture absorption, and mechanical strength.

– Consider: The grade of phenolic required (e.g., G-10 for high humidity environments or Canvas “C” for mechanical applications).

– Document: All specifications clearly to communicate effectively with potential suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in phenolic laminate sheets. Look for companies with a proven track record in your industry, particularly those that serve regions similar to yours, such as Africa, South America, or the Middle East.

– Utilize: Online directories, trade shows, and industry forums to gather a list of potential suppliers.

– Check: Reviews and testimonials to assess supplier reliability and product quality.

Step 3: Evaluate Supplier Certifications

It’s crucial to verify the certifications of your potential suppliers. Certifications can indicate compliance with international standards and quality assurance processes, ensuring that the phenolic laminate sheets meet safety and performance requirements.

– Look for: ISO certifications, industry-specific standards (like NEMA), and any other relevant quality certifications.

– Request: Documentation to validate these certifications before proceeding with any orders.

Step 4: Request Samples

Before making a large purchase, always request samples of the phenolic laminate sheets. This allows you to assess the material’s quality and suitability for your specific applications firsthand.

– Examine: The physical properties, such as texture, flexibility, and thermal resistance.

– Test: The samples in your operational environment to ensure they meet your functional requirements.

Step 5: Compare Pricing and Terms

Once you have identified suitable suppliers, compare their pricing structures and payment terms. Be mindful that the cheapest option may not always provide the best value, so consider the overall quality and service.

– Analyze: Total cost of ownership, including shipping and potential tariffs, especially for international transactions.

– Negotiate: Terms that align with your budget while ensuring quality and reliability.

Step 6: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear channels for discussing technical specifications, order updates, and any potential issues that may arise.

– Utilize: Email, phone calls, and project management tools to maintain ongoing dialogue.

– Document: All communications to ensure clarity and accountability on both sides.

Step 7: Conduct a Final Review Before Order Confirmation

Before placing your order, conduct a final review of all details, including specifications, pricing, delivery timelines, and contractual obligations. This step is crucial to avoid any misunderstandings or errors that could impact your operations.

– Confirm: That all parties are aligned on expectations and responsibilities.

– Clarify: Any remaining questions or concerns to ensure a smooth procurement process.

By following this structured approach, you can streamline your procurement of phenolic laminate sheets, ensuring that you select the best materials for your business needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for phenolic laminate sheet Sourcing

What Are the Key Cost Components in Phenolic Laminate Sheet Sourcing?

When sourcing phenolic laminate sheets, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of resin and reinforcement material significantly affects pricing. For instance, G-10 glass epoxy laminate tends to be more expensive due to its superior mechanical and electrical properties compared to economy grades.

-

Labor: Labor costs can vary based on the region of production and the complexity of the manufacturing process. Skilled workers may command higher wages, particularly for custom or specialized products.

-

Manufacturing Overhead: This includes costs related to facilities, equipment maintenance, and utilities. Manufacturers with advanced machinery may have higher overhead costs, which can be reflected in the pricing.

-

Tooling: Custom tooling for unique specifications can add a significant upfront cost. Buyers should consider whether the tooling cost will be amortized over a large volume of orders.

-

Quality Control (QC): Ensuring the phenolic laminate sheets meet industry standards requires investment in QC processes. These costs are often integrated into the final pricing.

-

Logistics: Transportation and handling costs vary widely depending on the shipping method and distance. Incoterms play a crucial role in determining who bears these costs, impacting the overall price.

-

Margin: Suppliers typically add a profit margin that can vary based on market conditions, supplier reputation, and the competitiveness of the niche.

How Do Price Influencers Impact Phenolic Laminate Sheet Costs?

Several factors influence the pricing of phenolic laminate sheets, particularly for international buyers:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Minimum Order Quantities (MOQs) can also affect pricing flexibility.

-

Specifications and Customization: Custom specifications, such as thickness, color, or specific properties (e.g., flame resistance), can increase costs. Standardized products usually have a lower price point.

-

Materials and Quality Certifications: Premium materials with certifications (e.g., ISO standards) command higher prices. Buyers should weigh the benefits of certified materials against their budget constraints.

-

Supplier Factors: Reputation, reliability, and geographical location of suppliers can affect pricing. Established suppliers may offer better quality assurance, but at a higher price.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) influences total costs, including shipping, insurance, and customs duties. Understanding these terms can help buyers manage costs effectively.

What Are the Best Negotiation and Cost-Efficiency Tips for Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management are vital:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, operational costs, and potential downtime associated with lower-quality materials.

-

Be Transparent About Your Needs: Clearly communicating your requirements can help suppliers provide more accurate quotes, reducing the risk of unexpected costs later in the process.

-

Leverage Market Research: Understanding current market trends and competitor pricing can strengthen your negotiation position. Suppliers are more likely to offer competitive pricing when they know you are informed.

-

Consider Long-term Relationships: Establishing a long-term partnership with suppliers can lead to better pricing and terms over time. Regular purchases may allow for bulk discounts and priority service.

-

Explore Alternative Suppliers: If pricing seems too high, consider sourcing from different regions or suppliers. Emerging markets may offer competitive pricing due to lower labor and overhead costs.

Final Thoughts on Phenolic Laminate Sheet Pricing

While pricing for phenolic laminate sheets can vary significantly based on numerous factors, a thorough understanding of the cost structure and price influencers will empower international buyers to make informed decisions. Always approach sourcing with a strategic mindset, balancing cost against quality and suitability for your specific applications.

Alternatives Analysis: Comparing phenolic laminate sheet With Other Solutions

Understanding Alternative Solutions to Phenolic Laminate Sheets

When considering materials for industrial applications, it’s crucial to explore various alternatives to phenolic laminate sheets. These alternatives may offer distinct advantages or drawbacks depending on specific project requirements, such as performance characteristics, cost-effectiveness, and application suitability. Below, we compare phenolic laminate sheets with two viable alternatives: fiberglass reinforced plastic (FRP) and high-density polyethylene (HDPE).

| Comparison Aspect | Phenolic Laminate Sheet | Fiberglass Reinforced Plastic (FRP) | High-Density Polyethylene (HDPE) |

|---|---|---|---|

| Performance | High strength, excellent dielectric properties, and good resistance to heat and chemicals. | Superior tensile strength and impact resistance; can be tailored for specific applications. | Good chemical resistance and flexibility; less rigid than phenolic. |

| Cost | Generally cost-effective for high-performance applications. | Higher initial cost but can be economical for large-scale applications due to durability. | Typically lower cost, especially for bulk applications. |

| Ease of Implementation | Requires specialized cutting and machining tools; can be complex to fabricate. | Can be molded into complex shapes but also requires skilled labor for installation. | Easy to handle and fabricate; can be welded or heat-sealed. |

| Maintenance | Low maintenance but may require periodic inspection for wear. | Low maintenance; resistant to corrosion and wear. | Minimal maintenance; easy to clean and resistant to staining. |

| Best Use Case | Ideal for electrical insulation, gears, and components needing high durability. | Best for structural applications, marine environments, and when high strength is required. | Suitable for storage tanks, piping, and applications requiring flexibility. |

In-Depth Analysis of Alternatives

Fiberglass Reinforced Plastic (FRP)

FRP is a composite material made from a polymer matrix reinforced with fibers, typically glass. It boasts superior tensile strength and impact resistance, making it an excellent choice for demanding applications. However, the initial costs can be higher than those of phenolic laminate sheets. FRP is also versatile and can be molded into complex shapes, which is beneficial for custom applications. The downside is that the installation process can require skilled labor, potentially increasing overall project costs.

High-Density Polyethylene (HDPE)

HDPE is a thermoplastic known for its strength, chemical resistance, and flexibility. It is generally more affordable than both phenolic laminate sheets and FRP, making it a popular choice for bulk applications. Its ease of fabrication allows for quick installation and minimal downtime in production environments. However, while HDPE is resistant to many chemicals, it does not have the same level of rigidity or heat resistance as phenolic laminate sheets, which may limit its use in high-performance settings.

Making the Right Choice for Your B2B Needs

Selecting the appropriate material for your application involves evaluating specific project requirements against the strengths and weaknesses of each option. Phenolic laminate sheets are ideal for high-performance environments where electrical insulation and durability are paramount. In contrast, FRP may be more suited for structural applications requiring superior strength, while HDPE offers cost-effective solutions for projects where flexibility and chemical resistance are essential. By carefully analyzing these alternatives, B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for phenolic laminate sheet

What Are the Key Technical Properties of Phenolic Laminate Sheets?

Phenolic laminate sheets possess several essential properties that make them suitable for a variety of industrial applications. Understanding these properties can help B2B buyers make informed decisions when sourcing materials for their projects.

-

Material Grade

Phenolic laminates come in various grades such as G-10, G-11, and C-grade, each offering different mechanical and electrical properties. For instance, G-10 is known for its excellent electrical insulation and mechanical strength, making it ideal for electrical applications. Selecting the right grade is crucial for ensuring product performance and compliance with industry standards. -

Tensile Strength

This property measures the material’s ability to withstand pulling forces without breaking. High tensile strength is critical in applications where the laminate will be subjected to stress and strain, such as in gears and structural components. A higher tensile strength often translates to greater durability and longevity, which is a key consideration for B2B buyers looking to minimize replacement costs. -

Thermal Resistance

Phenolic laminates exhibit exceptional thermal resistance, allowing them to maintain structural integrity at elevated temperatures. For example, G-10 can withstand temperatures up to 284°F (140°C). This property is vital for applications in high-heat environments, such as electrical insulation and thermal barriers, where material failure could lead to significant operational disruptions. -

Moisture Absorption Rate

The moisture absorption rate indicates how much water a material can absorb over time. Low moisture absorption is a desirable trait in phenolic laminates, as it helps maintain dimensional stability and prevents degradation. For instance, G-10 has a moisture absorption rate of only 0.15%, making it suitable for use in humid environments, which is particularly relevant for buyers in tropical regions. -

Dielectric Strength

This property refers to the material’s ability to act as an electrical insulator. High dielectric strength is essential for applications in electrical and electronic components, where insulation failure can lead to short circuits and equipment damage. Phenolic laminates provide excellent dielectric properties, making them a preferred choice for manufacturers of electrical components.

What Are Common Trade Terms Related to Phenolic Laminates?

Understanding industry-specific jargon is crucial for navigating the procurement process effectively. Here are some common trade terms relevant to phenolic laminate sheets:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. B2B buyers often deal with OEMs when sourcing phenolic laminates for integration into their products, making it essential to understand OEM specifications and requirements. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This is a critical factor for buyers, as it affects inventory management and overall project costs. Understanding the MOQ can help buyers negotiate better terms and ensure they meet production needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For buyers, an RFQ is an essential tool for comparing offers and ensuring they receive the best value for their procurement needs. -

Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms can help B2B buyers mitigate risks and avoid misunderstandings related to shipping costs, delivery timelines, and liability. -

Lead Time

Lead time refers to the period from the placement of an order to its delivery. Understanding lead times is crucial for buyers to align their production schedules and manage inventory effectively. Longer lead times can impact project timelines, making it essential for buyers to account for this in their planning.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their decision-making processes and ensure they select the right phenolic laminate sheets for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the phenolic laminate sheet Sector

What Are the Current Market Dynamics and Key Trends Influencing Phenolic Laminate Sheets?

The global market for phenolic laminate sheets is driven by several factors, including the increasing demand for high-performance materials in various industries such as automotive, aerospace, and electrical insulation. The durability and excellent mechanical properties of phenolic laminates make them an attractive alternative to traditional materials like aluminum and steel. Additionally, the growth of emerging economies in Africa and South America is propelling demand, as these regions invest in infrastructure development and industrialization.

Among the current B2B tech trends, the adoption of digital supply chain solutions is noteworthy. Many buyers are now leveraging online platforms for sourcing, enabling them to compare suppliers, check product specifications, and obtain quotes rapidly. This trend is particularly beneficial for international buyers from regions such as the Middle East and Europe, where efficient sourcing can significantly impact project timelines and costs. Moreover, the integration of advanced manufacturing technologies, such as CNC machining and additive manufacturing, is enhancing the customization capabilities of phenolic laminate products, catering to specific industry requirements.

Emerging trends also include a focus on lightweight materials and composites, which align with global efforts to reduce energy consumption in transportation and construction sectors. As a result, manufacturers are innovating with phenolic formulations that offer improved weight-to-strength ratios, making them increasingly relevant for applications in high-performance sectors.

How Are Sustainability and Ethical Sourcing Shaping the Phenolic Laminate Sheet Market?

Sustainability has become a pivotal concern in the procurement of phenolic laminate sheets, with buyers increasingly prioritizing suppliers that adhere to environmentally responsible practices. The production of phenolic materials can have environmental impacts, particularly concerning waste management and the use of non-renewable resources. Therefore, it is essential for B2B buyers to engage with suppliers who can demonstrate sustainable practices throughout their manufacturing processes.

The importance of ethical supply chains is also gaining traction, as companies face pressure to ensure that their sourcing strategies align with corporate social responsibility goals. This includes verifying that materials are sourced from suppliers who uphold labor rights and environmental standards. Certifications such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) certification for wood-based products can serve as indicators of a supplier’s commitment to sustainability.

In the phenolic laminate sector, innovations in ‘green’ materials, such as bio-based phenolic resins, are emerging as viable alternatives. These materials not only reduce reliance on fossil fuels but also offer comparable performance characteristics, making them attractive for environmentally conscious buyers. By choosing sustainably sourced phenolic laminate sheets, B2B buyers can significantly minimize their ecological footprint while still meeting their operational needs.

What is the Brief Evolution and Historical Context of Phenolic Laminate Sheets?

The development of phenolic laminate sheets dates back to the early 20th century when phenolic resins were first synthesized by Belgian chemist Leo Baekeland. Initially used for electrical applications due to their excellent insulating properties, phenolic laminates have evolved significantly over the decades. The introduction of various reinforcement materials, such as glass and cotton fabrics, has expanded their applications across multiple industries.

Over time, advancements in manufacturing techniques have allowed for greater customization and improved performance characteristics of phenolic sheets. Today, they are not only utilized in electrical insulation but also in aerospace, automotive, and construction sectors, thanks to their lightweight and durable nature. As industries continue to seek high-performance materials, phenolic laminate sheets are positioned to remain a critical component in modern manufacturing and construction processes.

Frequently Asked Questions (FAQs) for B2B Buyers of phenolic laminate sheet

-

How do I choose the right phenolic laminate sheet for my application?

Selecting the appropriate phenolic laminate sheet hinges on several factors, including the specific application requirements, mechanical properties, and environmental conditions. For instance, G-10 glass epoxy sheets are ideal for electrical insulation due to their excellent dielectric strength, while canvas phenolic sheets are suitable for mechanical applications due to their high impact resistance. Evaluate the load-bearing capacity, temperature resistance, and moisture absorption of the various grades to ensure optimal performance in your intended use. Consulting with suppliers can also provide insights tailored to your unique needs. -

What are the key properties of phenolic laminate sheets?

Phenolic laminate sheets are renowned for their high strength, stiffness, and durability. They exhibit excellent dielectric properties, making them suitable for electrical applications. Additionally, these sheets are lightweight, resistant to corrosion, and possess good dimensional stability. The ability to withstand high temperatures (up to 284°F for G-10) and low moisture absorption further enhances their suitability for various industrial applications, from electrical insulators to mechanical components. -

What minimum order quantities (MOQ) should I expect when sourcing phenolic laminate sheets?

Minimum order quantities for phenolic laminate sheets can vary significantly between suppliers. Typically, MOQs may range from 50 to 100 sheets, depending on the grade and thickness required. Some manufacturers may offer flexibility for smaller orders, especially if the product is readily available in stock. It’s advisable to discuss your specific needs with suppliers and inquire about any potential for lower MOQs or bulk purchasing discounts. -

What payment terms are commonly available for international B2B transactions?

Payment terms in international trade can differ by supplier and region. Commonly accepted methods include wire transfers, letters of credit, and payment upon delivery. Some suppliers may offer net 30 or net 60 terms, allowing buyers to pay within 30 or 60 days after receipt of goods. Always clarify payment conditions before placing an order and ensure they align with your financial processes to avoid any disruptions. -

How do I ensure quality assurance (QA) when sourcing phenolic laminate sheets?

To guarantee quality assurance, request detailed specifications and certifications from your supplier, such as ISO 9001 or other relevant quality standards. Implement a thorough inspection process upon receiving materials, checking for defects, dimensional accuracy, and material properties. Additionally, consider establishing a long-term relationship with suppliers that have a proven track record in quality assurance, as this can enhance consistency and reliability in your sourcing process. -

What are the logistics considerations for importing phenolic laminate sheets?

When importing phenolic laminate sheets, consider shipping methods, lead times, and customs regulations specific to your country. Air freight may offer faster delivery, but sea freight is often more economical for larger shipments. Ensure that you comply with import regulations, including any necessary documentation like certificates of origin and material safety data sheets (MSDS). Partnering with a logistics expert can streamline the process and help navigate potential challenges. -

Can phenolic laminate sheets be customized for specific applications?

Yes, many suppliers offer customization options for phenolic laminate sheets. This may include variations in thickness, size, and even specific resin types to meet unique application requirements. When discussing customization, provide detailed specifications regarding mechanical properties, colors, and any particular performance criteria necessary for your application. Collaborating closely with your supplier can lead to tailored solutions that enhance product performance. -

What are the common applications for phenolic laminate sheets in various industries?

Phenolic laminate sheets are utilized across diverse sectors, including electrical, automotive, and aerospace. Common applications include electrical insulators, switch bases, and terminal boards in electrical engineering. In manufacturing, they are used for gears, pulleys, and mechanical components due to their high wear resistance. Additionally, the construction industry employs phenolic sheets for countertops and cabinetry, leveraging their durability and aesthetic appeal. Understanding the range of applications can help you identify potential uses in your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Phenolic Laminate Sheet Manufacturers & Suppliers List

1. Professional Plastics – Laminated Phenolic Sheets

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: This company, Professional Plastics – Laminated Phenolic Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Electrowind – CE Canvas Cotton-Cloth Reinforced Phenolic Laminate 1/2 Thick

Domain: electro-wind.com

Registered: 1999 (26 years)

Introduction: {“thickness”:”.500″ (1/2″ thick)”,”material”:”CE Canvas Cotton-Cloth Reinforced Phenolic Laminate”,”temperature_rating”:”130°C”,”color”:”natural”,”dimensions”:”48″W x 48″L”,”part_number”:”CE.500″,”manufacturer”:”Electrowind”,”features”:”NEMA grades C and CE, cost-effective, easily machined, medium-weave canvas, known for mechanical properties”,”applications”:”Electrical applications, general purpo…

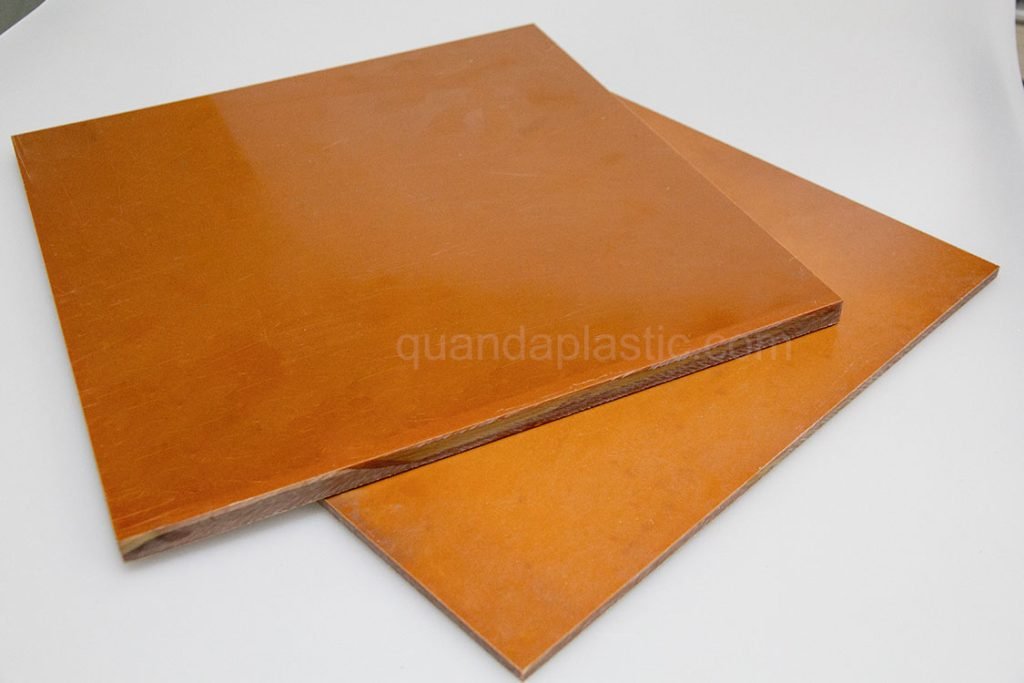

3. Interstate Plastics – G-3 Glass Phenolic Laminate

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: G-3 Sheet | G3 Glass Phenolic Laminate – Dimensions: 24x24x0.500 inches. Color: Amber/brown. Material: Woven glass fabric reinforced with phenolic resin. Features: Excellent tensile, compressive, impact, and flexural strengths at high temperatures. Applications: Used for acid-resistant gaskets, seals, grommets, oven internal parts, and structural applications. Compliance: Meets Mil-I-24768/18, Typ…

4. Piedmont Plastics – Phenolic Industrial Laminate

Domain: piedmontplastics.com

Registered: 1996 (29 years)

Introduction: Phenolic is a durable industrial laminate used for various applications including terminal boards, antenna insulators, printed circuit boards, washers, spacers, cams, and inserts. Key features include:

– Easy to bond and machine

– Chemical resistant

– Good dimensional stability

– Excellent electrical insulation

– High temperature and impact resistant

– Stain, wear, and abrasion resistant

– …

5. FUTAMURA – Taiko Lite Paper-based Phenolic Laminated Sheet (FL-100)

Domain: futamura.co.jp

Introduction: Phenolic Laminated Sheets from FUTAMURA CHEMICAL are used as insulation and structural materials in electric components and machines. Key products include:

1. **Taiko Lite Paper-based Phenolic Laminated Sheet (FL-100)**:

– JIS Standard: PL-PEV

– Features: Superb electrical characteristics and processability

– Applications: Electromechanical components (switchboards, circuit breakers, …

6. Interstate Am – Phenolic Sheet & Rod

Domain: interstateam.com

Registered: 2022 (3 years)

Introduction: Phenolic Sheet & Rod: High strength composite materials for custom parts, high speed bearings, electrical applications, and more. Known for rigidity and variable properties depending on base material and resin type. Highlights include strong and stiff, great dielectric strength, low moisture absorption, lightweight, and good machinability. Applications include printed circuit boards, electrical in…

7. {product_details: MSC Direct – Industrial Supplies}

Domain: mscdirect.com

Registered: 1996 (29 years)

Introduction: CRITICAL: You MUST output ONLY the JSON object, with no other text, commentary, or markdown formatting. The entire response must be a single, valid JSON object like this: {“product_details”: “string”}. If no info is found, use an empty string for the value.

8. KMAC Distribution – Thermoset Plastic Phenolic Laminates

Domain: kmac-distribution.com

Registered: 2006 (19 years)

Introduction: Thermoset Plastic Phenolic Laminates, Sheets, Rods:

– Characteristics: Uniformly dense, structurally strong, lightweight, moisture resistant, durable, high mechanical and electrical insulating properties.

– Forms Available: Sheets, rods, tubes, angles.

– Grades: G10, FR4, G11, FR5, G7, G5/G9, X/XX/XXX Paper, C/CE Canvas, L/LE, G3.

– G10/FR4: High pressure composite laminate, excellent insulato…

9. QUANDA Plastic – Phenolic Laminates

Domain: quandaplastic.com

Registered: 2009 (16 years)

Introduction: Phenolic Laminates are part of QUANDA Plastic’s product offerings. They include various types of sheets such as Ketonolic® Bakelite Sheet, Ketonolic® FR4 Sheet, Ketonolic® G10 Sheet, Ketonolic® G11 Sheet, and Ketonolic® GPO-3 UPGM203 Sheet. These laminates are used in diverse applications across industries such as aerospace, defense, transportation, and heavy equipment manufacturing. They are know…

10. Surface Materials – Solid Phenolic Laminate

Domain: surfacematerials.com

Registered: 1999 (26 years)

Introduction: Solid Phenolic – Lab Designs Laminate is a premium laminate surface designed for durability and versatility in various settings including kitchens, bathrooms, bar tops, and tabletops. It is a high-pressure structural laminate made from multiple layers of kraft paper fused together under extreme heat and pressure, resulting in a virtually indestructible sheet. The laminate is manufactured with high…

Strategic Sourcing Conclusion and Outlook for phenolic laminate sheet

In the evolving landscape of industrial materials, phenolic laminate sheets stand out due to their exceptional strength, durability, and versatility. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of phenolic products is crucial. These materials not only offer cost-effective solutions for various applications but also deliver superior performance in demanding environments.

Strategic sourcing of phenolic laminate sheets enables businesses to leverage their mechanical and insulating properties while ensuring compliance with industry standards. By establishing strong relationships with reliable suppliers, buyers can secure high-quality materials that meet specific operational needs, ultimately enhancing productivity and reducing downtime.

Looking ahead, the demand for phenolic laminates is poised for growth as industries increasingly prioritize sustainability and performance. Buyers are encouraged to explore innovative sourcing strategies and engage with manufacturers that offer tailored solutions. By investing in high-quality phenolic products, businesses can position themselves for success in an increasingly competitive marketplace. Embrace the potential of phenolic laminate sheets to drive your operations forward.