Introduction: Navigating the Global Market for pfa sheet

Navigating the complexities of sourcing PFA sheets can be a daunting task for international B2B buyers, especially when dealing with the unique demands of diverse industries across Africa, South America, the Middle East, and Europe. As a highly versatile fluoropolymer, PFA (PerFluoroAlkoxy) is renowned for its exceptional chemical resistance and flexibility, making it an ideal choice for applications that involve aggressive and corrosive substances. However, understanding the nuances of this material, including its various types, applications, and sourcing considerations, is crucial for making informed purchasing decisions.

This comprehensive guide serves as an essential resource for B2B buyers seeking to demystify the global market for PFA sheets. We will explore the different grades and specifications of PFA, highlight its applications across industries such as pharmaceuticals, food processing, and chemical manufacturing, and provide key insights into supplier vetting processes. Additionally, we will discuss pricing strategies and cost considerations that can affect procurement decisions. By equipping buyers with the knowledge necessary to navigate this specialized market, this guide aims to empower businesses to make strategic choices that align with their operational needs and budget constraints. Whether you are in Brazil, Vietnam, or any other part of the world, understanding the intricacies of PFA sheet sourcing is vital for achieving your business goals.

Understanding pfa sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PFA Sheet | Transparent, flexible, high chemical resistance | Chemical processing, semiconductor industry | Pros: Excellent chemical resistance; Flexible. Cons: Higher cost compared to alternatives. |

| FDA-Compliant PFA | Meets FDA standards, suitable for food applications | Food processing, pharmaceuticals | Pros: Safe for food contact; High purity. Cons: Limited to specific applications. |

| Thermally Conductive PFA | Enhanced heat conductivity compared to standard PFA | Electronics, thermal management | Pros: Superior heat dissipation; Versatile. Cons: May be more expensive than standard options. |

| Colored PFA Sheet | Available in various colors for easy identification | Industrial applications, tubing systems | Pros: Aids in organization; Same chemical properties as standard PFA. Cons: Color may limit use in certain applications. |

| High-Performance PFA | Modified for greater tensile strength and clarity | Aerospace, high-stress environments | Pros: Enhanced durability; High clarity. Cons: May require specialized handling and processing. |

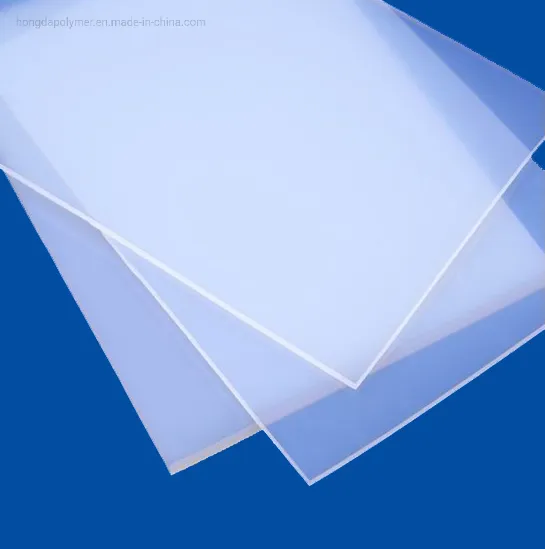

What Are the Characteristics of Standard PFA Sheets?

Standard PFA sheets are known for their transparency and flexibility, making them ideal for various industrial applications. They exhibit exceptional resistance to a wide range of chemicals, including acids and bases, which makes them suitable for use in chemical processing and the semiconductor industry. When considering a purchase, B2B buyers should evaluate the specific chemical resistance required for their applications, as well as the cost implications compared to alternatives like PTFE.

How Does FDA-Compliant PFA Differ from Other Types?

FDA-compliant PFA sheets are specifically designed to meet stringent food safety standards, making them suitable for applications in food processing and pharmaceuticals. These sheets ensure high purity and safety when in contact with food products. Buyers in the food industry should prioritize FDA compliance to avoid regulatory issues. However, the range of applications may be limited compared to standard PFA sheets.

What Are the Benefits of Thermally Conductive PFA Sheets?

Thermally conductive PFA sheets are engineered to provide enhanced heat conductivity, making them ideal for electronics and thermal management applications. This type of PFA can dissipate heat more effectively than standard options, which is crucial for maintaining the performance of sensitive electronic components. B2B buyers should consider the thermal management needs of their applications, although the cost may be higher than standard PFA.

Why Choose Colored PFA Sheets for Industrial Applications?

Colored PFA sheets offer the same chemical resistance as standard PFA but come in various colors, aiding in easy identification and organization in complex systems. This feature is particularly beneficial in industrial settings where multiple lines or types of tubing are used. While the color can enhance usability, buyers should consider whether the specific hue may restrict the sheet’s application in certain environments.

What Makes High-Performance PFA Sheets Stand Out?

High-performance PFA sheets provide enhanced tensile strength and optical clarity, making them suitable for demanding applications in aerospace and other high-stress environments. These sheets are designed for durability and reliability under challenging conditions. B2B buyers should assess their specific performance requirements and the potential need for specialized handling during processing, as this can impact overall costs and supply chain logistics.

Key Industrial Applications of pfa sheet

| Industry/Sector | Specific Application of PFA Sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Processing | Lining for reactors and storage tanks | Protects equipment from corrosive chemicals, extending lifespan and reducing maintenance costs | Ensure compliance with local regulations and chemical compatibility |

| Pharmaceutical Manufacturing | Components in cleanroom environments | Maintains product integrity by preventing contamination, crucial for regulatory compliance | Verify FDA compliance and cleanroom certifications for materials |

| Food Processing | Non-stick surfaces for processing equipment | Enhances operational efficiency and product quality by preventing sticking and contamination | Sourcing from suppliers with food-grade certifications |

| Electronics | Insulation for wiring and components | Improves safety and performance in high-temperature and chemically aggressive environments | Consider thermal and electrical resistance requirements |

| Oil & Gas | Seals and gaskets in high-pressure systems | Provides reliable sealing to prevent leaks and ensure safety in demanding environments | Evaluate durability and compatibility with specific fluids |

How is PFA Sheet Utilized in Chemical Processing?

In the chemical processing industry, PFA sheets are commonly used as linings for reactors and storage tanks. Their exceptional resistance to a wide range of corrosive chemicals ensures that equipment remains intact and functional over time. This not only extends the lifespan of the equipment but also significantly reduces maintenance costs. For international buyers, particularly in regions like Africa and South America, it is crucial to source PFA sheets that comply with local chemical regulations and compatibility standards to ensure safe operations.

What Role Does PFA Sheet Play in Pharmaceutical Manufacturing?

PFA sheets are integral in pharmaceutical manufacturing, particularly in cleanroom environments where maintaining product integrity is essential. These sheets are used in various applications, from protective barriers to components in equipment, ensuring that contamination is minimized. For B2B buyers in Europe and the Middle East, sourcing PFA sheets that meet FDA compliance and possess cleanroom certifications is critical to adhere to stringent regulatory requirements, thereby safeguarding the quality of pharmaceutical products.

How Does PFA Sheet Enhance Food Processing?

In the food processing sector, PFA sheets serve as non-stick surfaces for various processing equipment. This feature not only improves operational efficiency but also enhances product quality by preventing sticking and contamination. Buyers in the food industry, especially in regions like Brazil and Vietnam, should prioritize sourcing from suppliers that offer food-grade certified PFA sheets, ensuring that materials are safe for direct food contact and comply with local health regulations.

Why is PFA Sheet Important in Electronics?

The electronics industry utilizes PFA sheets for insulation in wiring and components due to their excellent thermal and chemical resistance. This application is crucial for ensuring the safety and performance of electronic devices operating in high-temperature and chemically aggressive environments. International buyers should consider the specific thermal and electrical resistance requirements of their applications when sourcing PFA sheets, ensuring compatibility with their product designs.

How is PFA Sheet Used in Oil & Gas Applications?

In the oil and gas sector, PFA sheets are employed as seals and gaskets in high-pressure systems. Their durability and chemical resistance provide reliable sealing solutions that prevent leaks, which is essential for safety in demanding environments. B2B buyers in this industry should evaluate the durability and compatibility of PFA sheets with specific fluids and gases to ensure optimal performance and compliance with industry standards.

3 Common User Pain Points for ‘pfa sheet’ & Their Solutions

Scenario 1: Sourcing Quality PFA Sheets for Industrial Applications

The Problem: Many B2B buyers in industries such as pharmaceuticals and chemicals face significant challenges when sourcing PFA sheets. These materials are critical for applications that require high chemical resistance and purity. However, inconsistencies in quality and compliance with industry standards can lead to product failures, contamination issues, and costly downtime. Buyers often struggle to identify suppliers that provide reliable, FDA-compliant PFA sheets, leading to frustration and uncertainty in procurement processes.

The Solution: To ensure a reliable sourcing experience, buyers should prioritize suppliers with a proven track record in the industry. Look for certifications and compliance documentation, such as FDA approval or ISO certifications, to verify the quality of PFA sheets. Engaging in direct communication with suppliers about their manufacturing processes and quality control measures can provide deeper insights into their reliability. Additionally, requesting samples before placing larger orders can help assess material performance and suitability for specific applications. Leveraging supplier ratings and reviews can also guide buyers towards trusted sources.

Scenario 2: Understanding the Versatility of PFA Sheets in Diverse Industries

The Problem: A common pain point for B2B buyers is the lack of awareness regarding the versatility of PFA sheets across various applications. Buyers in sectors such as electronics, food processing, and laboratory environments often underestimate how PFA sheets can be tailored to meet specific needs. This oversight can result in choosing less suitable materials that do not provide the necessary resistance to chemicals or thermal stability, ultimately impacting performance and safety.

The Solution: To overcome this knowledge gap, buyers should invest time in researching the different properties of PFA sheets, such as their thermal stability, chemical resistance, and mechanical strength. Engaging with industry experts or attending webinars and workshops can help buyers gain insights into how PFA can be applied effectively in their specific contexts. Moreover, collaborating with suppliers to understand the specific grades and formulations of PFA available can lead to more informed decision-making. Buyers should also consider case studies or testimonials from other companies in similar industries to illustrate successful applications of PFA sheets.

Scenario 3: Managing Cost and Budget Constraints When Purchasing PFA Sheets

The Problem: Cost management is a major concern for B2B buyers, particularly in regions where budgets are tight. PFA sheets are often perceived as expensive, and buyers may feel pressured to compromise on quality to meet budget constraints. This dilemma can lead to selecting inferior materials that do not perform adequately, resulting in increased long-term costs due to failures or replacements.

The Solution: Buyers should adopt a strategic approach to procurement by conducting a thorough cost-benefit analysis of different PFA sheet options. Instead of solely focusing on upfront costs, evaluate the total cost of ownership, including durability, maintenance, and potential downtime. Establishing long-term partnerships with suppliers can lead to negotiated pricing and bulk purchasing discounts. Additionally, exploring alternative grades of PFA that may offer a balance between performance and cost can be beneficial. Engaging in discussions with suppliers about customized solutions that fit budgetary constraints while still meeting application requirements can lead to more favorable outcomes.

Strategic Material Selection Guide for pfa sheet

What Are the Key Properties of PFA Sheets for B2B Buyers?

PFA (PerFluoroAlkoxy) sheets are highly valued in various industries due to their unique properties. They exhibit excellent chemical resistance, making them suitable for applications involving aggressive solvents, acids, and bases. PFA can withstand high temperatures, typically up to 260°C (500°F), without losing its structural integrity. Its low coefficient of friction enhances its suitability in applications where reduced friction is crucial. Additionally, PFA’s transparency allows for visibility of contents in tubing or containers, which can be beneficial in monitoring processes.

What Are the Pros and Cons of Using PFA Sheets?

Pros:

– Durability: PFA sheets are highly resistant to corrosion and degradation, ensuring a long service life even in harsh environments.

– Flexibility: Unlike PTFE, PFA is more flexible, making it easier to work with in various applications.

– Compliance: Many PFA products meet FDA and other international standards, making them suitable for food and pharmaceutical applications.

Cons:

– Cost: PFA sheets tend to be more expensive than other fluoropolymers like PTFE and FEP, which may impact budget-sensitive projects.

– Manufacturing Complexity: The processing of PFA can be more complex due to its unique properties, potentially leading to longer lead times.

How Does PFA Impact Specific Applications?

PFA sheets are particularly well-suited for applications in industries such as pharmaceuticals, food processing, and chemical manufacturing. Their high resistance to aggressive chemicals makes them ideal for lining tanks and pipes that handle corrosive substances. Additionally, their thermal stability allows for use in high-temperature environments, such as semiconductor manufacturing. International buyers should consider the specific media compatibility when selecting PFA sheets to ensure optimal performance in their applications.

What Should International B2B Buyers Consider When Selecting PFA Sheets?

When sourcing PFA sheets, international buyers, particularly from Africa, South America, the Middle East, and Europe, should pay attention to compliance with local and international standards. Common standards include ASTM, DIN, and JIS, which may dictate material properties and performance requirements. Understanding local regulations regarding chemical handling and safety can also influence material selection. Additionally, buyers should consider the availability of suppliers in their region to ensure timely delivery and support.

Summary Table of PFA Sheet Materials

| Material | Typical Use Case for PFA Sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PFA (Natural) | Chemical processing, semiconductor manufacturing | Excellent chemical resistance and flexibility | Higher cost compared to PTFE | High |

| PFA (FDA Compliant) | Food and pharmaceutical applications | Meets regulatory standards for safety | Limited color options may restrict branding | High |

| PFA (Thermally Conductive) | Applications requiring heat dissipation | Enhanced thermal conductivity for better heat management | More complex manufacturing process | Medium |

| PFA (Colored) | Identification in complex systems | Aids in organization and reduces contamination risk | Potentially higher cost due to coloring process | Medium |

This analysis provides a comprehensive overview of PFA sheets, emphasizing their properties, advantages, and considerations for international B2B buyers. Understanding these factors will assist buyers in making informed decisions that align with their specific needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pfa sheet

What Are the Key Manufacturing Processes for PFA Sheets?

PFA sheets, known for their chemical resistance and high-temperature stability, undergo a series of manufacturing processes that ensure their quality and suitability for various industrial applications. Understanding these processes is crucial for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, where demand for high-performance materials is growing.

How is Material Prepared for PFA Sheet Production?

The manufacturing process of PFA sheets begins with material preparation, where high-quality raw materials are sourced. The primary material, PerFluoroAlkoxy (PFA), is often derived from polymerization processes involving tetrafluoroethylene (TFE). This initial stage is critical as the purity and quality of the raw materials directly influence the performance characteristics of the final product.

Once the raw materials are selected, they undergo rigorous testing for impurities and consistency. These tests are crucial for ensuring that the PFA meets the specific requirements for chemical resistance and thermal stability. Buyers should inquire about the sourcing and testing practices of their suppliers to ensure that they are using high-grade materials.

What Forming Techniques Are Used to Create PFA Sheets?

The next stage involves the forming of PFA sheets, which can be achieved through various techniques including extrusion and molding.

-

Extrusion: This is the most common method for producing PFA sheets. The prepared PFA material is heated until it becomes pliable and is then forced through a die to create sheets of desired thickness and dimensions. This process allows for uniform thickness and excellent surface finish.

-

Molding: In some cases, especially for thicker sheets or specific geometries, molding techniques may be employed. This involves placing the PFA material into a mold and applying heat and pressure to shape it. This method is particularly effective for creating complex designs or thicker components.

Both methods require precise control of temperature and pressure to avoid degradation of the polymer. B2B buyers should ask suppliers about their manufacturing methods to ensure they align with their quality and performance requirements.

How Are PFA Sheets Finished for Optimal Performance?

After forming, the sheets undergo finishing processes to enhance their surface quality and performance characteristics. This may include:

-

Trimming and Cutting: Sheets are trimmed to specified dimensions, ensuring they meet the exact requirements of the buyer. This is often done using CNC machines for precision.

-

Surface Treatment: Depending on the application, surface treatments may be applied to enhance properties such as adhesion or to improve the surface finish. This could involve polishing or applying coatings that improve performance in specific environments.

-

Quality Inspection: Each batch of finished PFA sheets undergoes quality control checks to verify that they meet the required specifications. This includes visual inspections and dimensional checks.

B2B buyers should request information on the finishing processes used by suppliers, as these can significantly affect the performance of PFA sheets in their applications.

What Quality Assurance Measures Are Essential for PFA Sheets?

Quality assurance is critical in the production of PFA sheets, especially when dealing with industries that require stringent compliance with international standards.

Which International Standards Are Relevant for PFA Sheet Quality Assurance?

The production of PFA sheets typically adheres to several international quality standards, including:

-

ISO 9001: This standard outlines the requirements for a quality management system, ensuring that organizations consistently meet customer and regulatory requirements.

-

CE Marking: For products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

-

API Standards: In industries such as oil and gas, adherence to American Petroleum Institute (API) standards is crucial for ensuring materials can withstand harsh conditions.

Buyers should ensure that their suppliers are compliant with these standards, as it provides assurance of the product’s quality and reliability.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control in the manufacturing of PFA sheets involves several checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality criteria.

-

In-Process Quality Control (IPQC): During the manufacturing process, checks are performed to monitor critical parameters such as temperature and pressure, ensuring they remain within acceptable limits.

-

Final Quality Control (FQC): After the production of PFA sheets, a final inspection is conducted to verify that the finished products meet the required specifications. This includes dimensional checks and testing for chemical resistance.

For B2B buyers, understanding these checkpoints can help in assessing supplier reliability and the overall quality of the products they procure.

How Can B2B Buyers Verify Supplier Quality Control?

Ensuring that suppliers maintain robust quality control measures is essential for B2B buyers. Here are some ways to verify supplier QC:

-

Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and quality assurance practices. This can help identify any potential issues before they affect product quality.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the results of various inspections and tests conducted throughout the manufacturing process.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices and product quality. This is particularly important for international transactions where buyers may not have direct oversight.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Variations in manufacturing standards and practices across different countries can affect the quality and reliability of products.

Buyers should be aware of:

-

Cultural Differences: Different countries may have varying approaches to quality assurance and compliance. Building strong relationships with suppliers and understanding their operational practices can help mitigate risks.

-

Regulatory Requirements: Different regions may impose specific regulatory requirements for materials, especially in industries like pharmaceuticals or food processing. Buyers should ensure that their suppliers can meet these local regulations.

-

Communication: Clear and consistent communication with suppliers is essential to address any quality concerns and ensure that expectations are aligned.

By being proactive in their approach to quality assurance, B2B buyers can secure high-quality PFA sheets that meet their specific needs and regulatory requirements, ultimately supporting their operational success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pfa sheet’

In the competitive landscape of sourcing PFA sheets, a structured approach is essential for international B2B buyers. This guide provides a step-by-step checklist to help you navigate the procurement process efficiently, ensuring that you acquire the right product from a reliable supplier.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for your PFA sheets. Consider factors such as dimensions, thickness, and compliance with industry standards (e.g., FDA compliance for food applications). Providing precise specifications helps suppliers understand your needs and reduces the risk of receiving unsuitable products.

Step 2: Research and Identify Suppliers

Conduct thorough research to identify potential suppliers of PFA sheets. Look for manufacturers with a solid reputation in the industry, focusing on those with experience in your specific application area. Utilize online platforms, trade shows, and industry directories to compile a list of reputable suppliers.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify that potential suppliers hold relevant certifications. Look for certifications such as ISO 9001 for quality management and FDA compliance if applicable. These certifications indicate a supplier’s commitment to quality and regulatory standards, which is crucial for maintaining the integrity of your operations.

Step 4: Request Samples

Once you have shortlisted suppliers, request samples of their PFA sheets. Evaluating samples allows you to assess the material’s quality, flexibility, and resistance to chemicals firsthand. Ensure that the samples meet your defined specifications and are suitable for your intended application.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing and payment terms. While cost is a significant factor, consider the overall value, including the quality of the product and the supplier’s reliability. Look for any hidden costs such as shipping or handling fees that could impact your budget.

Step 6: Check References and Reviews

Before finalizing your supplier choice, check references and read reviews from other clients. Engaging with previous customers can provide insights into the supplier’s reliability, customer service, and product performance. This step helps mitigate risks associated with supplier selection.

Step 7: Negotiate Contract Terms

Once you have selected a supplier, negotiate the contract terms to ensure favorable conditions. Discuss lead times, return policies, and warranties. A well-defined contract protects your interests and sets clear expectations for both parties, paving the way for a successful partnership.

By following this checklist, B2B buyers can streamline their sourcing process for PFA sheets, ensuring they make informed decisions that align with their operational needs. Prioritizing quality, reliability, and compliance will facilitate smoother procurement and enhance overall business performance.

Comprehensive Cost and Pricing Analysis for pfa sheet Sourcing

When analyzing the cost and pricing structure for PFA sheets in a B2B context, several components and influencing factors come into play. Understanding these can help international buyers make informed decisions.

What Are the Key Cost Components in PFA Sheet Pricing?

The primary cost components associated with PFA sheets include:

-

Materials: The raw materials for PFA, primarily PerFluoroAlkoxy resin, represent a significant portion of the cost. Prices can vary based on the supplier and market demand for fluoropolymers.

-

Labor: Labor costs encompass the workforce involved in manufacturing, quality control, and logistics. Labor rates can differ significantly by region, impacting overall pricing.

-

Manufacturing Overhead: This includes the indirect costs of production such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can lower overhead costs, benefiting buyers.

-

Tooling: Custom tooling for specific applications can add to the initial costs. Buyers may need to consider whether the long-term benefits of custom tooling outweigh the upfront expenses.

-

Quality Control (QC): Ensuring that PFA sheets meet industry standards involves rigorous quality control processes. Certification costs, such as FDA compliance for certain applications, can also influence pricing.

-

Logistics: Shipping and handling costs vary based on the supplier’s location and the destination. International shipping may involve additional fees, taxes, and tariffs.

-

Margin: The supplier’s profit margin can fluctuate based on competition, market conditions, and perceived value of the product. Understanding the supplier’s pricing strategy can provide negotiation leverage.

How Do Volume and Customization Affect PFA Sheet Pricing?

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact unit pricing. Bulk purchases typically yield lower per-unit costs, making it advantageous for buyers with large-scale needs.

-

Specifications and Customization: Customized PFA sheets tailored to specific dimensions or properties (e.g., thickness, color, or chemical resistance) often incur higher costs. Buyers should weigh the need for customization against standard options.

-

Material Quality and Certifications: Higher-grade materials and certifications can command premium prices. Buyers in regulated industries should prioritize suppliers that provide comprehensive certification documentation.

-

Supplier Factors: Supplier reputation, reliability, and service quality can affect pricing. Established suppliers may charge more but offer better reliability and service.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) dictate responsibilities for shipping, insurance, and tariffs, influencing overall costs. Understanding these terms is crucial for international transactions.

What Are Some Effective Buyer Tips for Negotiating PFA Sheet Prices?

-

Negotiate Wisely: Leverage volume commitments and long-term contracts to negotiate better pricing. Suppliers may offer discounts for repeat business or larger orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also shipping, storage, and potential waste or defects. A lower upfront cost may lead to higher TCO if quality is compromised.

-

Understand Pricing Nuances for International Buyers: When sourcing from different regions, be aware of currency fluctuations, import regulations, and potential trade tariffs. These factors can significantly impact final costs.

-

Research and Compare Suppliers: Take the time to compare multiple suppliers to understand market pricing. This research can provide leverage in negotiations and help identify the best overall value.

Conclusion

Navigating the cost structure and pricing of PFA sheets requires a comprehensive understanding of various components and influencing factors. By considering these elements and employing strategic negotiation tactics, international B2B buyers can secure favorable pricing while ensuring the quality and suitability of their PFA sheet purchases. Prices may vary widely, so it is essential to engage with multiple suppliers and remain informed about market trends to make the most cost-effective decisions.

Alternatives Analysis: Comparing pfa sheet With Other Solutions

Introduction: Understanding Alternative Solutions to PFA Sheets

In the quest for effective materials in industrial applications, businesses often seek alternatives to common solutions such as PFA sheets. While PFA (PerFluoroAlkoxy) offers exceptional chemical resistance and flexibility, various alternatives can meet similar needs depending on specific operational requirements, budget constraints, and application scenarios. This section compares PFA sheets against two viable alternatives: PTFE (Polytetrafluoroethylene) sheets and FEP (Fluorinated Ethylene Propylene) sheets, providing insights to help international B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | PFA Sheet | PTFE Sheet | FEP Sheet |

|---|---|---|---|

| Performance | High chemical resistance, flexible, and optically clear | Excellent chemical resistance, high thermal stability | Good chemical resistance, lower melting point than PTFE |

| Cost | Higher cost (approx. $36.42 for 12″ x 12″) | Generally lower cost (approx. $25 for 12″ x 12″) | Moderate cost (approx. $30 for 12″ x 12″) |

| Ease of Implementation | Easy to fabricate and mold | Requires specialized cutting tools | Easy to fabricate and weld |

| Maintenance | Low maintenance required | Low maintenance required | Low maintenance required |

| Best Use Case | Ideal for high-purity applications and flexible tubing | Suitable for high-temperature applications and non-stick surfaces | Great for applications needing clarity and moderate temperature resistance |

Detailed Breakdown of Alternatives

PTFE Sheets: A Cost-Effective Solution

PTFE sheets are widely recognized for their excellent chemical resistance and thermal stability. They are often less expensive than PFA sheets, making them an attractive option for businesses with budget constraints. However, while PTFE is robust, it lacks the flexibility of PFA, which may limit its application in certain scenarios requiring bending or shaping. Additionally, PTFE can be more challenging to cut and mold, requiring specialized tools for fabrication.

FEP Sheets: A Versatile Option

FEP sheets provide a balance between performance and cost, offering good chemical resistance and a lower melting point than PTFE. They are easy to fabricate, making them suitable for various applications, including electrical insulation and corrosion-resistant linings. However, FEP sheets may not withstand as high temperatures as PFA or PTFE, which could be a limiting factor in high-heat industrial settings. Their optical clarity also makes them a preferred choice for certain applications where visibility is crucial.

Conclusion: Making the Right Choice for Your Business Needs

When selecting a material for industrial applications, B2B buyers must consider their specific needs, including performance requirements, budget, and ease of implementation. PFA sheets stand out for high-purity applications due to their flexibility and chemical resistance, but alternatives like PTFE and FEP offer viable options depending on the context. By weighing the pros and cons of each alternative, businesses can make informed decisions that align with their operational goals and budget constraints, ensuring optimal performance and cost-effectiveness in their projects.

Essential Technical Properties and Trade Terminology for pfa sheet

What Are the Key Technical Properties of PFA Sheets?

PFA (PerFluoroAlkoxy) sheets are recognized for their unique properties that make them suitable for a variety of industrial applications. Understanding these properties is crucial for B2B buyers when selecting materials for specific needs.

-

Chemical Resistance

PFA sheets exhibit exceptional resistance to a wide range of chemicals, including acids, bases, and solvents. This property is vital for industries such as pharmaceuticals and chemical processing, where materials frequently come into contact with aggressive substances. Selecting PFA ensures that equipment remains intact and operational, minimizing downtime and maintenance costs. -

Temperature Tolerance

PFA can withstand high temperatures, typically up to 260°C (500°F). This thermal stability is essential for applications involving heat exposure, such as in food processing or semiconductor manufacturing. Buyers must consider temperature limits to ensure that the material chosen will not degrade or lose its properties in their specific operational conditions. -

Low Friction Coefficient

With a low coefficient of friction, PFA sheets are ideal for applications where sliding or moving parts are involved. This characteristic helps reduce wear and tear on machinery, increasing longevity and performance. Industries that rely on precise movement, such as robotics or conveyor systems, will benefit significantly from this property. -

Optical Clarity

PFA sheets are transparent, allowing for visual inspection of processes where material flow or chemical reactions need monitoring. This feature is particularly useful in laboratory settings or any application where visibility is critical. B2B buyers should consider optical clarity when selecting materials for applications requiring monitoring without interruption. -

FDA Compliance

Certain PFA grades are FDA compliant, making them suitable for food contact applications. This compliance is critical for companies in the food and beverage industry, ensuring that materials meet safety and regulatory standards. Understanding compliance can facilitate smoother regulatory approvals and enhance product marketability.

What Are Common Trade Terms Associated with PFA Sheets?

Familiarity with industry terminology can significantly ease communication between buyers and suppliers, helping ensure clarity in transactions.

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help identify reliable sources for PFA sheets that meet specific manufacturing standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it can impact budgeting and inventory management. Knowing the MOQ helps in planning purchases effectively, especially for smaller companies or startups. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It is an essential step in the procurement process, allowing buyers to compare pricing and terms before making a decision. A well-prepared RFQ can lead to more favorable pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers to avoid misunderstandings related to shipping, insurance, and delivery responsibilities. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is received. Knowing the lead time is essential for effective supply chain management, helping businesses plan their production schedules and inventory levels accordingly. -

Tolerances

Tolerance refers to the allowable deviation from a specified dimension or property. Understanding tolerances is crucial for ensuring that PFA sheets meet the required specifications for fit and function in their intended applications. Buyers should always confirm tolerances to avoid issues during installation or operation.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions regarding PFA sheets, ensuring their applications are successful and efficient.

Navigating Market Dynamics and Sourcing Trends in the pfa sheet Sector

What Are the Global Drivers Impacting the PFA Sheet Market?

The PFA sheet market is experiencing robust growth driven by several global factors. First, the increasing demand for high-performance materials in industries such as pharmaceuticals, chemicals, and food processing is propelling the adoption of PFA sheets. Their excellent chemical resistance and thermal stability make them ideal for handling aggressive substances and high-temperature applications. Additionally, the growing trend towards automation in manufacturing processes is fostering a need for advanced materials that can withstand rigorous operational conditions.

Emerging B2B technologies are also reshaping sourcing strategies. The rise of digital procurement platforms facilitates better access to suppliers and enhances transparency in the supply chain. Buyers from regions such as Africa, South America, the Middle East, and Europe are leveraging these platforms to compare prices, specifications, and supplier reliability. Moreover, the integration of data analytics into procurement processes is enabling businesses to forecast demand more accurately and optimize inventory management, ultimately leading to cost savings.

What Are the Current and Emerging Sourcing Trends in the PFA Sheet Sector?

International B2B buyers are increasingly focused on sourcing PFA sheets from suppliers who offer customization options. Tailored solutions not only meet specific application requirements but also enhance operational efficiency. Furthermore, the trend toward local sourcing is gaining traction, particularly in regions like Brazil and Vietnam, where reduced lead times and lower shipping costs are critical for maintaining competitive advantage.

Sustainability considerations are driving a shift towards suppliers that prioritize ethical sourcing practices. Buyers are more likely to partner with manufacturers who demonstrate a commitment to environmental responsibility and sustainability in their production processes. This trend is particularly relevant in Europe, where regulations around environmental compliance are becoming stricter.

How Does Sustainability Impact the Sourcing of PFA Sheets?

The environmental impact of PFA sheets is a significant consideration for B2B buyers today. As industries strive to reduce their carbon footprint, the importance of sustainable and ethical supply chains cannot be overstated. Manufacturers are being held accountable for the environmental effects of their production methods, and buyers are increasingly evaluating suppliers based on their sustainability credentials.

The use of ‘green’ certifications and materials is becoming essential in the PFA sheet sector. Certifications such as ISO 14001 indicate that a supplier adheres to rigorous environmental management standards. Buyers should actively seek out manufacturers who offer eco-friendly alternatives or engage in recycling programs, as these initiatives not only support sustainability but can also enhance a company’s reputation and marketability.

What is the Historical Context of PFA Sheets in B2B Applications?

PFA sheets have evolved significantly since their introduction, primarily driven by advancements in polymer chemistry. Initially developed for their non-stick properties, PFA has expanded its applications beyond cookware to include critical industrial uses. Over the years, the material has gained a reputation for its superior chemical resistance and flexibility, making it a preferred choice for high-stakes environments such as semiconductor manufacturing and pharmaceuticals.

The development of PFA sheets has been marked by continuous innovation, leading to enhanced properties such as increased tensile strength and thermal stability. This evolution not only reflects advancements in material science but also highlights the growing demand from international markets for reliable and effective materials that can meet stringent regulatory standards. As industries continue to evolve, PFA sheets are poised to play an increasingly vital role in a variety of applications, offering both performance and sustainability benefits.

Frequently Asked Questions (FAQs) for B2B Buyers of pfa sheet

-

How do I determine the appropriate PFA sheet thickness for my application?

When selecting the thickness of PFA sheets, consider the specific application requirements, including the type of chemicals being handled, temperature conditions, and mechanical stresses. Thicker sheets offer greater strength and durability, making them suitable for high-pressure environments. Conversely, thinner sheets may suffice for less demanding applications. Always consult with your supplier to ensure that the chosen thickness aligns with your operational conditions and safety standards. -

What is the best application for PFA sheets in industrial settings?

PFA sheets are ideal for applications involving aggressive chemicals, high temperatures, and environments sensitive to contamination. They are commonly used in the pharmaceutical, food processing, and semiconductor industries due to their excellent chemical resistance and non-stick properties. When evaluating specific applications, consider factors such as exposure to solvents, required durability, and compliance with industry regulations to determine the best fit. -

What are the key factors to consider when sourcing PFA sheets internationally?

When sourcing PFA sheets internationally, assess the supplier’s reputation, compliance with quality standards, and delivery capabilities. Verify certifications, such as FDA compliance for food-grade applications, and ensure they can meet your specific requirements regarding customization and minimum order quantities (MOQs). Additionally, consider the supplier’s logistics capabilities, including shipping times and costs, especially if you are operating in regions like Africa or South America, where logistics can be complex. -

What customization options are available for PFA sheets?

Many suppliers offer customization options for PFA sheets, including variations in size, thickness, and color. Some manufacturers can also provide specific surface treatments or cutting services to meet unique application needs. Before placing an order, communicate your requirements clearly to the supplier and inquire about their capabilities and lead times for customized products. -

What minimum order quantities (MOQs) should I expect when purchasing PFA sheets?

Minimum order quantities for PFA sheets can vary significantly between suppliers. Some manufacturers may have low MOQs for standard products, while others might require higher quantities for custom orders. It’s essential to discuss your needs with potential suppliers and negotiate MOQs that align with your purchasing strategy, especially if you are operating on a tight budget or project timeline. -

What payment terms are typically offered by PFA sheet suppliers?

Payment terms can differ widely among suppliers, often influenced by the buyer’s creditworthiness and the supplier’s policies. Common terms include upfront payments, partial payments upon order confirmation, or net payment terms (e.g., net 30 or net 60). When negotiating, be clear about your financial processes and explore options that can help manage cash flow, such as letter of credit or installment payments. -

How do I ensure quality assurance when sourcing PFA sheets?

To ensure quality assurance when sourcing PFA sheets, request detailed product specifications and certifications from suppliers. It’s advisable to conduct third-party quality inspections or audits, especially for large orders. Additionally, consider ordering samples before committing to larger quantities to assess the material’s performance in your specific application. Building a solid relationship with your supplier can also facilitate better communication regarding quality expectations. -

What logistical considerations should I keep in mind when importing PFA sheets?

When importing PFA sheets, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Coordinate with your supplier to understand shipping timelines and ensure that all necessary documentation is prepared for customs clearance. Additionally, factor in local regulations regarding the importation of materials in your industry. Working with a reliable freight forwarder can help streamline the process and mitigate potential delays or complications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Pfa Sheet Manufacturers & Suppliers List

1. Acme Plastics – PFA Sheets and Rods

Domain: acmeplastics.com

Registered: 1997 (28 years)

Introduction: PFA (PerFluoroAlkoxy) is a transparent, chemical and solvent resistant material. It is commonly used in applications requiring high purity and resistance to aggressive chemicals. PFA is available in sheets and rods, and is suitable for various industries including chemical processing, pharmaceuticals, and food processing.

2. Curbell Plastics – PFA Sheets and Rods

Domain: curbellplastics.com

Registered: 2000 (25 years)

Introduction: PFA (perfluoroalkoxy) is a tough, flexible fluoropolymer used for flexible tubing and fluid processing equipment. It is characterized by chemical resistance, high purity, and low stiffness. Available products include PFA sheets and rods in various sizes and specifications. Specific products include:

– PFA Rod, White (Natural), Daikin Neoflon® 450HP, FDA Compliant, (0.5 in x 6 ft)

– PFA Rod, White …

3. FluoroStore – PFA Standard Tubing

Domain: fluorostore.com

Registered: 2010 (15 years)

Introduction: [{‘name’: ‘PFA Standard Tubing’, ‘price’: ‘$1.59 per foot’, ‘description’: ‘PFA is resistant to more chemically aggressive and abrasive environments than FEP and PTFE. It is preferred in contamination sensitive applications.’}, {‘name’: ‘H2 PFA Thermally Conductive / Anti-Stat Tubing’, ‘price’: ‘$1.85 per foot’, ‘description’: ‘A proprietary material, H2 PFA tubing from Fluorotherm has almost 3x h…

4. Boedeker – PFA Perfluoroalkoxy Plastic Solutions

Domain: boedeker.com

Registered: 1997 (28 years)

Introduction: PFA Perfluoroalkoxy Plastic Sheet, Rod & Tube

5. Professional Plastics – LAM PFA-LT Film

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: LAM PFA-LT is a high-performance fluoropolymer film known for its excellent chemical resistance, high-temperature stability, and low friction properties. It is suitable for various applications including electrical insulation, chemical processing, and food processing. The product is available in various thicknesses and widths to meet specific customer requirements.

6. Polymer Plastics – PFA Sheet and Rod

Domain: polymerplastics.com

Registered: 1997 (28 years)

Introduction: Product: Perfluoroalkoxy/PFA Sheet and Rod

Material: PFA (Perfluoroalkoxy)

Properties: Melt-processable, similar to PTFE, low coefficient of friction, non-reactive, softer than PTFE, melts at 305 °C, higher flex life than FEP, superior electrical properties compared to PTFE and FEP.

Applications: Used in plastic lab ware, tubing for corrosive processes, sheet linings for chemical equipment, replac…

7. Interstate Plastics – PFA – M High Service Temperature Sheet

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: PFA – M (FM4910) High Service Temperature Sheet

– Material: Copolymer plastic sheet made from tetrafluoroethylene and perfluorinated methyl vinyl ether

– Maximum Service Temperature: 425°F

– Features:

– Excellent stress crack resistance

– Extremely smooth surface

– Reduces caking of solids

– Easy to clean

– Purity: Exceeds that of PVDF

– Applications: Used in a wide range of applications …

8. Analytical Sales – HTeChem Assembly PFA Sheet

Domain: analytical-sales.com

Registered: 1996 (29 years)

Introduction: PFA Sheet for HTeChem Assembly (701025) – Analytical Sales and Services, Inc.

Strategic Sourcing Conclusion and Outlook for pfa sheet

In conclusion, strategic sourcing of PFA sheets offers significant advantages for international B2B buyers, particularly in industries requiring high-performance materials resistant to aggressive chemicals and extreme temperatures. PFA’s unique properties, including its flexibility, transparency, and high chemical resistance, make it an optimal choice for applications in pharmaceuticals, food processing, and semiconductor manufacturing.

Understanding the nuances between different fluoropolymers, such as PFA compared to PTFE and FEP, enables buyers to make informed decisions that align with their operational needs. By establishing relationships with reliable suppliers who can provide tailored PFA solutions, businesses can enhance their production efficiency and reduce risks associated with material failures.

Looking ahead, the demand for PFA sheets is expected to grow as industries increasingly prioritize safety and sustainability. Buyers from regions like Africa, South America, the Middle East, and Europe are encouraged to leverage this opportunity by exploring diverse sourcing options and engaging with manufacturers who can meet their specific requirements. Investing in high-quality PFA materials today will pave the way for future innovation and competitiveness in global markets.