Introduction: Navigating the Global Market for perspex clips

In the ever-evolving landscape of global trade, sourcing the right perspex clips can present significant challenges for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. As businesses increasingly rely on acrylic materials for displays, signage, and protective barriers, understanding the nuances of perspex clip procurement becomes crucial. This guide serves as a comprehensive resource, detailing the various types of perspex clips available, their applications across industries, and the factors that influence pricing and lead times.

International buyers face unique hurdles, from navigating language barriers to ensuring product quality and compliance with local regulations. By providing actionable insights on supplier vetting processes, this guide empowers businesses to make informed purchasing decisions that align with their operational needs. Whether you are in Nigeria seeking durable clips for retail displays or in Saudi Arabia looking for reliable suppliers to meet growing demand, this guide addresses your specific challenges.

Moreover, with an emphasis on cost analysis and performance metrics, buyers can streamline their procurement strategies and optimize their supply chains. As you explore this guide, you will gain the knowledge necessary to confidently navigate the global market for perspex clips, ensuring you select the best products for your business needs while fostering strong supplier relationships.

Understanding perspex clips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acrylic Panel Clips | Designed for 1/8″ or 3/8″ panels; clear acrylic | Retail displays, signage, exhibitions | Pros: Durable, aesthetically pleasing. Cons: Limited to specific panel thickness. |

| Sneeze Guard Clips | T-shaped or slide-on designs; accommodates various thicknesses | Healthcare, restaurants, retail | Pros: Versatile, easy to install. Cons: May not suit all display types. |

| Mirror Clips | Typically 1/8″ thick; includes necessary fasteners | Home décor, commercial spaces | Pros: Simple installation, cost-effective. Cons: Limited to mirror applications. |

| Sandwich Frame Clips | Holds two sheets of acrylic tightly together | Displays, information holders | Pros: Secure hold, enhances display quality. Cons: Requires specific frame types. |

| Custom Fabricated Clips | Tailored designs for unique applications | Specialized displays, custom projects | Pros: Fully customizable, meets specific needs. Cons: Higher cost and longer lead times. |

What Are Acrylic Panel Clips and Their Applications?

Acrylic panel clips are primarily used to secure acrylic sheets in various thicknesses, often 1/8″ or 3/8″. Their clear design allows for a seamless look, making them ideal for retail displays, signage, and exhibitions where aesthetics are paramount. When sourcing these clips, buyers should consider compatibility with the acrylic thickness and the overall design of their displays to ensure a cohesive presentation.

How Do Sneeze Guard Clips Function in Different Settings?

Sneeze guard clips come in various configurations, including T-shaped and slide-on designs, which accommodate multiple acrylic thicknesses. These clips are essential in healthcare, restaurants, and retail environments, providing safety and hygiene while maintaining visibility. B2B buyers should assess the installation ease and adaptability of these clips to different setups, ensuring they meet health and safety standards.

What Are the Advantages of Using Mirror Clips?

Mirror clips are specifically designed for securing mirrors, typically 1/8″ thick, and come with all necessary fasteners for installation. They are commonly used in home décor and commercial spaces, offering a simple and cost-effective solution. Buyers should evaluate the clip’s durability and ease of installation, particularly in high-traffic areas where mirrors are frequently used.

Why Choose Sandwich Frame Clips for Displays?

Sandwich frame clips are designed to hold two sheets of acrylic tightly together, ensuring a secure and polished look for displays and information holders. These clips enhance the overall quality of the presentation, making them suitable for trade shows and retail environments. When purchasing, buyers must consider the specific frame types they will be using, as compatibility is crucial for optimal performance.

What Are the Benefits of Custom Fabricated Clips?

Custom fabricated clips provide tailored solutions for unique display applications, allowing businesses to meet specific design and functionality requirements. While these clips can be more expensive and may have longer lead times, their adaptability makes them invaluable for specialized projects. B2B buyers should weigh the benefits of customization against budget constraints and project timelines to ensure a balanced decision.

Key Industrial Applications of perspex clips

| Industry/Sector | Specific Application of perspex clips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail Display | Supporting signage and promotional displays | Enhances visibility and engagement with customers | Ensure clips are compatible with various display materials and sizes. |

| Construction & Architecture | Securing acrylic panels in structures | Provides durability and aesthetic appeal in design projects | Focus on load-bearing capacity and weather resistance. |

| Healthcare | Mounting sneeze guards and protective barriers | Improves safety and hygiene in public spaces | Consider easy installation and maintenance requirements. |

| Automotive | Holding acrylic components in vehicle interiors | Enhances interior design while ensuring component stability | Look for UV resistance and temperature tolerance. |

| Art & Exhibition | Displaying artwork or photography securely | Protects valuable pieces while showcasing them effectively | Verify the clips’ weight capacity and material compatibility. |

How Are Perspex Clips Utilized in Retail Display Applications?

In the retail sector, perspex clips are essential for securing signage and promotional displays. They hold acrylic panels that feature product information or advertisements, enhancing visibility and customer engagement. For international buyers, especially in regions like Africa and South America, it’s crucial to source clips that accommodate different display sizes and materials. Quality assurance in terms of durability is vital, as these clips must withstand varied environmental conditions while maintaining aesthetic appeal.

What Role Do Perspex Clips Play in Construction and Architecture?

In the construction and architecture industries, perspex clips are used to secure acrylic panels in various structures, from office partitions to decorative facades. These clips provide a combination of durability and visual appeal, making them ideal for modern design projects. Buyers in the Middle East and Europe should focus on sourcing clips that meet specific load-bearing requirements and can resist harsh weather conditions, ensuring long-term performance without compromising safety.

How Are Perspex Clips Essential in Healthcare Settings?

Perspex clips are integral to mounting sneeze guards and protective barriers in healthcare environments, such as hospitals and clinics. These applications improve safety and hygiene, particularly in high-traffic areas. International B2B buyers, particularly from regions like Saudi Arabia, should consider sourcing clips that allow for easy installation and maintenance, as these factors can significantly impact the operational efficiency of healthcare facilities.

In What Ways Do Perspex Clips Enhance Automotive Interiors?

In the automotive industry, perspex clips are employed to secure acrylic components within vehicle interiors, contributing to both aesthetics and functionality. They ensure that elements such as dashboard panels and lighting fixtures remain stable during vehicle operation. Buyers from Europe and South America should prioritize sourcing clips that offer UV resistance and can withstand the varying temperatures experienced in different climates, ensuring longevity and performance.

How Are Perspex Clips Used in Art and Exhibition Displays?

Perspex clips are vital for securely displaying artwork and photography in galleries and exhibitions. They protect valuable pieces while providing a clean and professional presentation. B2B buyers in this sector should verify the weight capacity of the clips and ensure compatibility with various materials, as this can affect the overall display quality. Additionally, sourcing clips that are easy to install and adjust can enhance the efficiency of setting up exhibitions.

3 Common User Pain Points for ‘perspex clips’ & Their Solutions

Scenario 1: Sourcing Quality Perspex Clips for Diverse Applications

The Problem: B2B buyers often face the challenge of sourcing perspex clips that meet the specific requirements of their projects. For instance, a signage company in Nigeria might need clips that can securely hold heavy acrylic panels, while a retail display manufacturer in Brazil might require clips designed for lightweight materials. When suppliers fail to provide clear specifications or quality assurances, it results in wasted time and resources, leading to delays in project timelines and increased costs.

The Solution: To overcome sourcing challenges, buyers should establish clear specifications based on their project needs before reaching out to suppliers. This includes material thickness, weight capacity, and environmental considerations (e.g., UV resistance for outdoor use). Engaging with multiple suppliers and requesting samples can help assess quality and compatibility with specific applications. Furthermore, leveraging online platforms that specialize in B2B materials can provide access to a broader range of manufacturers, ensuring that buyers can compare options and make informed decisions. When placing orders, consider negotiating for bulk pricing or long-term contracts to secure better rates and maintain consistent supply.

Scenario 2: Ensuring Proper Installation of Perspex Clips

The Problem: Improper installation of perspex clips can lead to significant issues, such as panel instability or even breakage. A construction firm in Saudi Arabia working on a high-rise building may use perspex panels for architectural features. If the clips are not installed correctly, it can result in safety hazards and costly repairs. Additionally, many buyers lack the technical expertise to install these clips properly, leading to frustration and project setbacks.

The Solution: To mitigate installation issues, buyers should invest in comprehensive training for their installation teams. This can include workshops led by manufacturers that focus on best practices and the correct use of tools. Additionally, sourcing clips that come with detailed installation guides or video tutorials can significantly reduce errors. For projects with higher stakes, consider hiring professionals or consultants who specialize in acrylic installations. By ensuring that the right knowledge and techniques are applied, buyers can enhance the integrity and longevity of their installations.

Scenario 3: Adapting to Market Trends and Innovations

The Problem: The perspex clip market is constantly evolving, with new innovations and design trends emerging regularly. For instance, a marketing agency in Europe might find that their clients increasingly demand environmentally friendly materials and designs. Failing to adapt to these trends could result in losing competitive advantage or missing out on lucrative contracts.

The Solution: To stay ahead of market trends, B2B buyers should actively engage in industry networks and trade shows, which can provide insights into the latest innovations in perspex clips and related products. Subscribing to industry publications and following key influencers on social media can also offer valuable information on emerging trends. Additionally, consider collaborating with manufacturers who prioritize sustainability and innovation, as this can help align product offerings with market demands. By being proactive in research and development, buyers can position themselves as leaders in their respective markets, ensuring they meet client expectations and drive growth.

Strategic Material Selection Guide for perspex clips

What Are the Key Properties of Common Materials Used for Perspex Clips?

When selecting materials for perspex clips, understanding the properties and performance characteristics is crucial for ensuring product efficacy and longevity. Here are four common materials used in the manufacturing of perspex clips, each with unique advantages and limitations.

Acrylic

Acrylic is a widely used material for perspex clips due to its excellent clarity and strength. It has a good temperature resistance, typically ranging from -40°C to 90°C, making it suitable for various environments. Acrylic is also resistant to UV light, which helps prevent yellowing over time.

Pros: Acrylic is lightweight, easy to mold, and offers a high degree of transparency, making it aesthetically pleasing for display purposes. It is also relatively inexpensive compared to other materials.

Cons: While acrylic is durable, it can be prone to scratching and may not withstand extreme impacts as well as other materials like polycarbonate.

Impact on Application: Acrylic clips are ideal for indoor applications where aesthetics are important, such as retail displays and signage.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is essential. Buyers should also consider the availability of acrylic in their region and potential import tariffs.

Polycarbonate

Polycarbonate is known for its exceptional impact resistance and durability, making it a preferred choice for high-stress applications. It can withstand temperatures ranging from -40°C to 120°C, providing versatility in various environments.

Pros: Polycarbonate is virtually unbreakable and offers excellent optical clarity. It is also resistant to UV radiation, making it suitable for outdoor applications.

Cons: The primary drawback is the higher cost compared to acrylic. Additionally, polycarbonate can be more challenging to work with during manufacturing due to its toughness.

Impact on Application: This material is particularly suitable for environments where safety is a concern, such as in schools or public spaces.

Considerations for International Buyers: Ensure that polycarbonate clips meet local safety standards. In regions like the Middle East, where temperatures can soar, polycarbonate’s heat resistance is a significant advantage.

Stainless Steel

Stainless steel clips are often used in applications requiring high strength and corrosion resistance. They can withstand extreme temperatures and are impervious to rust, making them suitable for outdoor and industrial environments.

Pros: Stainless steel offers unmatched durability and longevity, making it a cost-effective choice over time. Its resistance to corrosion is particularly beneficial in humid or saline environments.

Cons: The main disadvantage is the higher initial cost and weight compared to plastic alternatives. Additionally, stainless steel may not be suitable for applications where aesthetics are paramount.

Impact on Application: Stainless steel clips are ideal for heavy-duty applications, such as in construction or marine environments.

Considerations for International Buyers: Buyers should verify compliance with local regulations regarding metal materials. For instance, in Europe, adherence to RoHS standards is crucial.

Nylon

Nylon is a synthetic polymer known for its flexibility and strength. It performs well in a temperature range of -40°C to 120°C, making it suitable for various applications.

Pros: Nylon is lightweight, resistant to abrasion, and has good chemical resistance, which makes it versatile for different environments. It is also relatively inexpensive.

Cons: Nylon can absorb moisture, which may lead to dimensional changes over time. Additionally, it may not be as aesthetically pleasing as transparent materials.

Impact on Application: Nylon clips are often used in applications where flexibility and resistance to chemicals are necessary, such as in laboratories or industrial settings.

Considerations for International Buyers: Buyers should be aware of the specific grades of nylon that meet their application needs and any relevant compliance standards in their regions.

Summary Table of Material Selection for Perspex Clips

| Material | Typical Use Case for perspex clips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic | Indoor displays and signage | Lightweight and aesthetically pleasing | Prone to scratching | Low |

| Polycarbonate | High-stress environments (schools, public spaces) | Exceptional impact resistance | Higher cost and manufacturing complexity | Med |

| Stainless Steel | Heavy-duty applications (construction, marine) | Unmatched durability and corrosion resistance | Higher initial cost and weight | High |

| Nylon | Laboratories and industrial settings | Lightweight and chemically resistant | Moisture absorption can affect performance | Low |

This comprehensive material selection guide provides valuable insights for B2B buyers, enabling them to make informed decisions based on application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for perspex clips

What Are the Key Stages in the Manufacturing Process of Perspex Clips?

The manufacturing of perspex clips involves several critical stages that ensure product quality and functionality. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-grade acrylic, known for its clarity and strength. Suppliers often source raw materials from reputable manufacturers to ensure consistency. The acrylic sheets are then cut to specified dimensions, ensuring minimal waste and precise sizing for the final clips.

-

Forming Techniques: Once prepared, the acrylic is subjected to forming techniques such as injection molding or thermoforming. In injection molding, heated acrylic is injected into a mold to create the desired clip shape. Thermoforming involves heating the acrylic until pliable and then shaping it over a mold. Both methods require precision to maintain the integrity of the material and ensure that the clips can withstand their intended use.

-

Assembly: After forming, the clips may require assembly, especially if they consist of multiple components. This can involve attaching additional features such as rubber grips for better hold or adding fasteners. Automation is increasingly used in this stage to improve efficiency and reduce labor costs.

-

Finishing: The final stage includes surface finishing, which may involve sanding, polishing, or applying coatings to enhance durability and aesthetic appeal. Quality finishing not only improves the appearance of the clips but also their resistance to scratches and UV damage, which is crucial for outdoor applications.

How Is Quality Assurance Implemented in Perspex Clip Manufacturing?

Quality assurance (QA) is an essential aspect of perspex clip manufacturing, ensuring that products meet international standards and customer expectations. The following outlines the key elements of a robust QA process.

-

International Standards and Certifications: Manufacturers often adhere to international quality management standards such as ISO 9001, which focuses on consistent quality and customer satisfaction. Additional certifications like CE (Conformité Européenne) may be necessary for products sold within the European market, indicating compliance with health, safety, and environmental protection standards.

-

Quality Control Checkpoints: Throughout the manufacturing process, several quality control checkpoints are established:

– Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards. Any materials that do not meet quality benchmarks are rejected.

– In-Process Quality Control (IPQC): During production, random samples of clips are tested for dimensional accuracy and strength. This ensures that any deviations from the desired specifications are caught early.

– Final Quality Control (FQC): After production, a final inspection is conducted to verify that all clips conform to quality standards before packaging and shipping. -

Common Testing Methods: Various testing methods are used to validate the quality of perspex clips, including:

– Mechanical Testing: This assesses the strength and durability of clips under stress, ensuring they can withstand intended loads.

– Environmental Testing: Clips may be subjected to UV exposure or temperature variations to evaluate their performance in different conditions.

– Dimensional Inspection: Precision instruments are used to ensure that clips meet specified dimensions and tolerances.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial. Here are actionable steps to ensure that suppliers maintain high-quality standards.

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control measures in place. During these audits, buyers can review documentation, observe operations, and assess the overall environment.

-

Requesting Quality Reports: Suppliers should be able to provide detailed quality reports that outline their QA processes, testing methodologies, and results. These documents can provide insight into the supplier’s commitment to quality and compliance with relevant standards.

-

Third-Party Inspections: Engaging a third-party inspection agency can provide an unbiased evaluation of the supplier’s quality control measures. These agencies can conduct random inspections, verify compliance with international standards, and provide certification if the supplier meets the necessary criteria.

-

Understanding Certification Nuances: Buyers should familiarize themselves with the specific certifications relevant to their markets. For instance, products sold in Europe may require CE marking, while those in certain industries might need API certification. Understanding these nuances helps buyers ensure compliance and avoid potential market access issues.

How Do International Standards Affect the Manufacturing of Perspex Clips?

International standards play a significant role in the manufacturing of perspex clips, shaping processes and influencing buyer expectations. Adhering to these standards not only ensures product quality but also fosters trust in supplier relationships.

-

Market Access: Compliance with international standards often determines a product’s eligibility for entry into various markets. For example, perspex clips sold in Europe must meet CE requirements, which can be a barrier for non-compliant products.

-

Consumer Confidence: Products that meet recognized standards are more likely to gain consumer trust. Buyers are increasingly looking for suppliers that can demonstrate adherence to international quality standards, as it reflects a commitment to excellence.

-

Risk Management: By following established standards, manufacturers can mitigate risks associated with product failure. This is particularly important for clips used in safety-critical applications, where reliability is paramount.

Conclusion

Manufacturing perspex clips involves a meticulous process that combines advanced techniques with stringent quality assurance measures. For international B2B buyers, understanding these processes is key to ensuring they partner with reliable suppliers who can meet their quality expectations. By taking proactive steps to verify supplier practices and familiarizing themselves with relevant standards, buyers can navigate the complexities of global trade with confidence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘perspex clips’

In the competitive landscape of B2B procurement, sourcing perspex clips requires a strategic approach to ensure quality, compatibility, and cost-effectiveness. This guide outlines essential steps to help buyers navigate the process successfully.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it is critical to establish the specific requirements for your perspex clips. Consider factors such as the thickness of the panels they will hold, the type of installation (e.g., wall-mounted or freestanding), and the material properties (e.g., clear acrylic versus polycarbonate). Clearly defined specifications will help you communicate effectively with potential suppliers and avoid compatibility issues down the line.

Step 2: Research the Market

Conduct thorough market research to identify potential suppliers of perspex clips. Utilize industry-specific platforms, trade shows, and online directories to gather a list of manufacturers and distributors. Pay attention to reviews and testimonials from other buyers in your region, as this can provide insights into the supplier’s reliability and product quality.

Step 3: Evaluate Supplier Certifications

When selecting a supplier, it’s essential to verify their certifications and compliance with international standards. Look for ISO certifications or other quality assurance credentials that demonstrate their commitment to manufacturing excellence. This step is crucial to mitigate risks associated with product defects and ensure that the clips meet safety and performance requirements.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the perspex clips to evaluate their quality firsthand. Examine the clips for durability, finish, and ease of installation. Testing samples will help you identify any potential issues early on and ensure that the product aligns with your expectations.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, it’s time to negotiate terms and pricing. Discuss bulk order discounts, payment terms, and lead times to ensure that you receive the best deal possible. Keep in mind that a lower price should not compromise quality; prioritize suppliers who offer a balance of cost-effectiveness and product reliability.

Step 6: Assess Shipping and Logistics

Consider the logistics involved in sourcing perspex clips, especially if you are importing them from a different country. Evaluate shipping options, delivery times, and any potential customs duties that may apply. Choosing a supplier with efficient logistics can significantly reduce lead times and enhance your overall procurement experience.

Step 7: Establish a Long-Term Relationship

Finally, aim to build a long-term relationship with your chosen supplier. Consistent communication and feedback can foster trust and lead to better terms in future transactions. A reliable supplier can become a valuable partner in your business, helping you keep pace with evolving needs and market demands.

By following this checklist, B2B buyers can streamline their procurement process for perspex clips, ensuring they secure high-quality products that meet their specific needs while also optimizing costs.

Comprehensive Cost and Pricing Analysis for perspex clips Sourcing

What Are the Key Cost Components in Sourcing Perspex Clips?

When considering the sourcing of perspex clips, understanding the cost structure is vital for B2B buyers. The main cost components include:

-

Materials: The primary material for perspex clips is acrylic, which varies in quality and price. High-quality, UV-resistant acrylic may incur higher costs but offers better durability and aesthetic appeal.

-

Labor: Labor costs encompass the wages for workers involved in manufacturing, assembly, and quality control. Regions with lower labor costs can provide a competitive edge, but this must be balanced with the quality of craftsmanship.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, rent, and administrative expenses. Efficient production processes can reduce overhead, impacting overall pricing.

-

Tooling: The cost of molds and tools required for producing specific designs of perspex clips can be significant. Custom designs will require initial investments in tooling, which can be amortized over larger production runs.

-

Quality Control (QC): Ensuring that products meet specified standards incurs costs related to inspections and testing. Buyers should prioritize suppliers with stringent QC processes to minimize defects.

-

Logistics: Transportation costs can vary widely based on shipping methods, distances, and whether the supplier offers DDP (Delivered Duty Paid) or EXW (Ex Works) terms. These factors influence the overall cost of acquiring perspex clips.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the margin expectations can aid buyers in negotiations.

How Do Price Influencers Affect the Cost of Perspex Clips?

Several factors can influence the pricing of perspex clips, including:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs. Suppliers may set Minimum Order Quantities (MOQs) that can significantly affect pricing. Buyers should assess their needs to negotiate favorable terms.

-

Specifications/Customization: Custom designs or specific color requirements can increase costs. Buyers should clarify their specifications upfront to receive accurate quotes.

-

Materials: The choice of materials impacts the price. For instance, opting for recycled acrylic may offer cost savings but could compromise on quality.

-

Quality and Certifications: Suppliers offering certified products (e.g., ISO 9001) may charge a premium. Certifications often indicate higher quality and reliability, which can be critical in certain applications.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record may command higher prices but can offer better service and quality assurance.

-

Incoterms: Understanding shipping terms is essential. Incoterms dictate who bears the cost and risk at various stages of transportation, which can affect the total cost of ownership.

What Tips Can Help Buyers Negotiate Better Pricing for Perspex Clips?

To achieve cost efficiency when sourcing perspex clips, consider the following buyer tips:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially if you can commit to larger orders. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Assess Total Cost of Ownership: Evaluate not just the purchase price but also logistics, potential tariffs, and the cost of quality. Sometimes a higher initial price can lead to lower overall costs if the product is more durable.

-

Understand Pricing Nuances for International Sourcing: For buyers in Africa, South America, the Middle East, and Europe, currency fluctuations, import duties, and shipping times can significantly affect costs. Factor these into your budget and timelines.

-

Consider Supplier Location: Sourcing from suppliers closer to your location can reduce shipping costs and lead times. Evaluate the trade-offs between price and logistical convenience.

-

Request for Quotations (RFQ): When dealing with multiple suppliers, issuing an RFQ can streamline the process and provide a clearer picture of the market rate for perspex clips.

Disclaimer on Indicative Prices

The prices mentioned throughout this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific order requirements. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing perspex clips With Other Solutions

Exploring Alternative Solutions to Perspex Clips for B2B Buyers

In the competitive landscape of acrylic and display solutions, understanding the alternatives to perspex clips is vital for making informed purchasing decisions. While perspex clips offer a reliable method for securing acrylic panels, there are several alternatives that businesses can consider based on their specific requirements such as performance, cost, and ease of use. This analysis compares perspex clips with two notable alternatives: T-shaped gripper connectors and acrylic mirror clips.

| Comparison Aspect | Perspex Clips | T-Shaped Gripper Connectors | Acrylic Mirror Clips |

|---|---|---|---|

| Performance | High durability for acrylic panels | Good for securing multiple panels | Suitable for lightweight applications |

| Cost | Low-cost, typically $0.45 each | Moderate, around $25.40 for a pack of 6 | Very low, approximately $2.99 for a pack of 6 |

| Ease of Implementation | Simple installation process | Requires some assembly | Easy to install, includes all fasteners |

| Maintenance | Minimal, occasional cleaning | Low, durable materials | Low, but may require replacement if damaged |

| Best Use Case | Ideal for display applications | Best for sneeze guards or dividers | Suitable for mirrors or lightweight displays |

What Are the Advantages and Disadvantages of T-Shaped Gripper Connectors?

T-shaped gripper connectors serve as a versatile solution for securing acrylic sheets, particularly in sneeze guard applications. They excel in stability and can hold multiple panels securely, making them ideal for environments that require robust barriers, such as retail and healthcare settings. However, these connectors often come at a moderate cost, which could be a consideration for budget-conscious businesses. Their installation may require additional assembly time compared to perspex clips, which could affect project timelines.

Why Consider Acrylic Mirror Clips as an Alternative to Perspex Clips?

Acrylic mirror clips are another viable option, particularly for lightweight applications like mirrors or decorative displays. Their cost-effectiveness is a significant advantage, making them attractive for businesses looking to minimize expenses. Installation is straightforward, as they come with all necessary fasteners. However, they may not be suitable for heavier panels or high-traffic environments where durability is crucial. This could limit their application in more demanding settings compared to perspex clips or gripper connectors.

Conclusion: How Should B2B Buyers Decide on the Best Solution?

When selecting the right solution for securing acrylic panels or displays, B2B buyers should carefully evaluate their specific needs. Factors such as the weight of the panels, the environment in which they will be used, and budget constraints all play a critical role in the decision-making process. While perspex clips provide a reliable and cost-effective option, alternatives like T-shaped gripper connectors and acrylic mirror clips may offer better performance or cost savings depending on the application. Ultimately, understanding the strengths and weaknesses of each alternative will empower buyers to choose the most suitable solution for their business needs.

Essential Technical Properties and Trade Terminology for perspex clips

What Are the Essential Technical Properties of Perspex Clips?

Understanding the technical properties of perspex clips is vital for B2B buyers to ensure they select the right products for their applications. Here are some critical specifications to consider:

-

Material Grade

Perspex clips are typically made from high-quality acrylic or polycarbonate materials. The grade of the material affects the clip’s durability, transparency, and resistance to UV light and impacts. Selecting the appropriate material grade is essential for applications requiring long-term use or exposure to harsh environments. -

Thickness Compatibility

Most perspex clips are designed to fit specific thicknesses of acrylic panels, commonly ranging from 1/8 inch to 3/8 inch. This specification ensures that the clips securely hold the panels without causing damage. Buyers should confirm the thickness of their acrylic sheets to avoid compatibility issues. -

Load-Bearing Capacity

The load-bearing capacity indicates how much weight the clip can support without breaking or deforming. This property is crucial for applications where clips are used to hold multiple sheets or heavy displays. Buyers should assess their needs carefully to choose clips that will maintain structural integrity under expected loads. -

Finish and Clarity

The finish (e.g., clear, frosted) of the perspex clips can influence aesthetics and visibility. A clear finish is often preferred in retail and display applications to maintain a sleek look. Understanding the finish options can help buyers select clips that align with their brand image and display requirements. -

Temperature Resistance

Different applications may expose perspex clips to varying temperatures. Knowing the temperature resistance of the clips can help buyers avoid issues like warping or melting in high-heat environments, ensuring the longevity of their displays. -

Tolerances

Tolerances refer to the allowable variations in dimensions during manufacturing. Tight tolerances are crucial in applications requiring precision, such as in modular display systems. Buyers should inquire about tolerances to ensure compatibility with their systems and avoid installation issues.

What Trade Terminology Should B2B Buyers Know About Perspex Clips?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some commonly used terms related to perspex clips:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components that are used in another company’s end products. Understanding this term is important for buyers looking to source perspex clips that will be integrated into larger display systems or products. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budgeting and inventory management, as it helps buyers determine if they can meet the supplier’s requirements without overcommitting. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For B2B buyers, crafting a clear RFQ can facilitate better negotiations and help in comparing different suppliers effectively. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is vital for B2B buyers dealing with suppliers across borders, as they clarify who is responsible for shipping, insurance, and tariffs. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the products. Knowing the lead time is essential for planning and ensuring that products are available when needed, especially in time-sensitive projects. -

Bulk Pricing

Bulk pricing refers to discounted rates offered for large orders. Buyers should inquire about bulk pricing options when purchasing perspex clips to optimize costs, especially if they require a significant quantity for large-scale projects.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions regarding their purchases of perspex clips, ensuring that they meet their specific application needs while also navigating the complexities of international trade effectively.

Navigating Market Dynamics and Sourcing Trends in the perspex clips Sector

What Are the Current Market Dynamics and Key Trends in the Perspex Clips Sector?

The perspex clips market is experiencing robust growth driven by several global factors, particularly in the B2B space. The increasing demand for acrylic displays in retail environments, coupled with the rise in modular and customizable display solutions, has fueled the need for high-quality perspex clips. Markets in Africa, South America, the Middle East, and Europe are particularly vibrant, as businesses seek innovative ways to enhance customer engagement and product visibility.

Technological advancements are reshaping sourcing strategies, with digital platforms facilitating easier access to suppliers and improved supply chain management. B2B buyers are now leveraging data analytics to forecast demand accurately, thus optimizing inventory levels. Emerging trends such as the integration of IoT in display systems are also influencing the design and functionality of perspex clips. For instance, smart displays that can adjust based on customer interactions are becoming more common, driving the need for versatile and durable clip solutions.

Moreover, the impact of e-commerce cannot be overlooked. As more businesses transition to online platforms, the demand for secure and reliable packaging solutions, including perspex clips for product displays, is on the rise. This shift is particularly evident in regions like Nigeria and Saudi Arabia, where e-commerce is rapidly expanding. International B2B buyers must stay abreast of these trends to remain competitive and meet changing consumer expectations.

How Does Sustainability Influence Sourcing Decisions for Perspex Clips?

Sustainability is no longer a buzzword; it is a core consideration for B2B buyers in the perspex clips sector. The environmental impact of acrylic production, including carbon emissions and plastic waste, has led many businesses to seek sustainable alternatives. Ethical sourcing practices are increasingly important, as companies aim to build trust and transparency with their customers.

B2B buyers are encouraged to prioritize suppliers who offer eco-friendly materials and adhere to stringent environmental standards. Certifications such as ISO 14001 for environmental management systems and the use of recycled or recyclable materials can serve as indicators of a supplier’s commitment to sustainability.

Additionally, there is a growing market for bioplastics and other sustainable materials that can be used in the production of perspex clips. By choosing these materials, companies not only reduce their environmental footprint but also appeal to an increasingly eco-conscious consumer base. This shift towards sustainability can enhance brand reputation and foster long-term customer loyalty.

What Is the Historical Context of Perspex Clips in B2B Markets?

The evolution of perspex clips can be traced back to the broader development of acrylic materials in the mid-20th century. Initially used for windows and safety glasses, acrylic quickly gained popularity in various applications, including signage and displays. The introduction of perspex clips allowed for a more seamless integration of acrylic in display systems, providing businesses with an efficient way to showcase products.

Over the decades, advancements in manufacturing techniques have led to the development of more durable and versatile clips, catering to a wide range of applications in retail, corporate, and industrial settings. Today, perspex clips are essential components in modern display solutions, reflecting the ongoing innovation within the industry and the rising demand for aesthetic and functional design. As the market continues to evolve, understanding this historical context can help B2B buyers make informed sourcing decisions that align with current trends and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of perspex clips

-

How do I select the right perspex clips for my application?

Selecting the right perspex clips involves understanding the specific thickness and type of acrylic panels you are using. For instance, if you’re working with 1/8″ panels, ensure the clips are compatible with that thickness. Additionally, consider the clip design; some clips are better for applications requiring frequent access, while others are designed for stability. Consulting with suppliers about your specific needs and the intended use will ensure you choose the most suitable clips for your project. -

What are the advantages of using perspex clips compared to traditional materials?

Perspex clips offer several advantages, including durability, lightweight construction, and aesthetic appeal. Unlike metal clips, perspex clips do not corrode and are less likely to scratch or damage your acrylic panels. They provide a cleaner look for displays and are often easier to install and adjust. Their versatility makes them suitable for various applications, from retail displays to protective barriers, enhancing both functionality and presentation. -

What is the typical minimum order quantity (MOQ) for perspex clips?

The minimum order quantity for perspex clips can vary significantly between suppliers. Generally, you can expect MOQs to range from 100 to 1,000 units, depending on the manufacturer and the specific product. For bulk orders, many suppliers offer discounts, which can be beneficial for businesses looking to source large quantities. It’s advisable to communicate directly with suppliers to negotiate favorable terms based on your specific needs. -

What customization options are available for perspex clips?

Customization options for perspex clips often include size, color, and branding. Some manufacturers can produce clips in different thicknesses or styles to meet specific project requirements. Additionally, you may request branding options, such as adding your company logo or colors to the clips. Engaging with suppliers early in the design process can help you explore these options and ensure the final product aligns with your branding and operational needs. -

How can I verify the reliability of a perspex clip supplier?

To verify the reliability of a perspex clip supplier, start by checking their reputation through online reviews and testimonials. Request references from other clients and evaluate their experience with the supplier. Additionally, assess their production capabilities, quality control processes, and compliance with international standards. A reliable supplier should also provide clear communication and be responsive to inquiries, which are crucial for a successful B2B partnership. -

What payment terms should I expect when purchasing perspex clips internationally?

Payment terms for international purchases of perspex clips typically vary by supplier but may include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers will require a deposit upfront, especially for custom orders. It’s essential to clarify these terms before placing an order and ensure they align with your business’s cash flow and financial policies. Additionally, consider any potential currency exchange risks in your negotiations. -

What are the shipping options for perspex clips when sourcing internationally?

When sourcing perspex clips internationally, shipping options usually include air freight, sea freight, and express courier services. Air freight is faster but more expensive, while sea freight is more economical for large orders but takes longer. Express courier services offer a balance between speed and cost for smaller shipments. It’s advisable to discuss shipping preferences with your supplier and consider factors such as delivery time, cost, and customs clearance when making your decision. -

How do I ensure quality assurance for perspex clips from international suppliers?

To ensure quality assurance for perspex clips, request samples before placing a large order. This allows you to assess the material quality, durability, and fit for your application. Additionally, inquire about the supplier’s quality control processes, certifications, and inspection procedures. Establishing clear specifications and conducting regular audits or inspections during production can also help maintain quality standards. Building a strong relationship with your supplier will facilitate better communication regarding quality expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Perspex Clips Manufacturers & Suppliers List

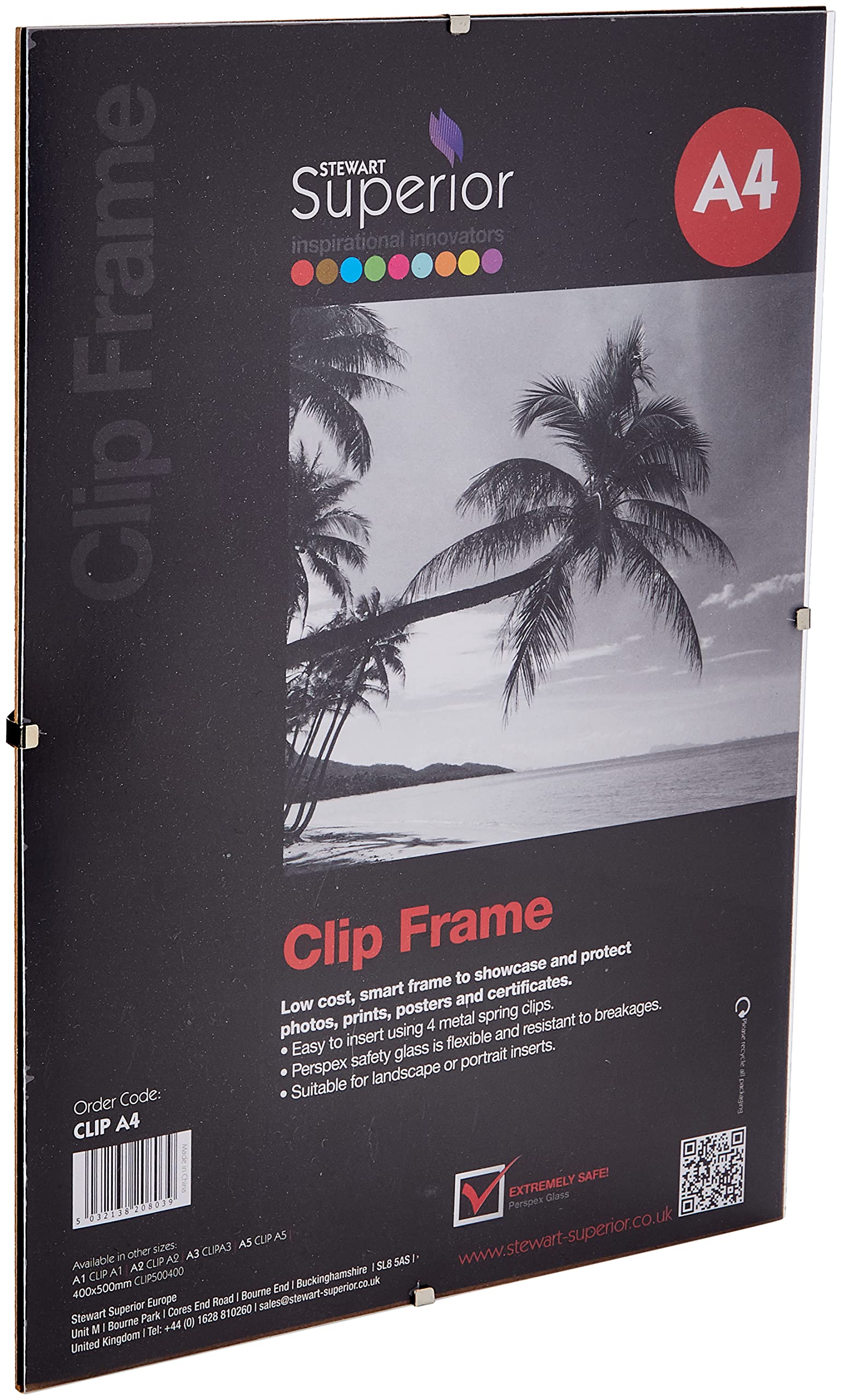

1. Tap Plastics – Swiss Framing Clips

Domain: tapplastics.com

Registered: 1999 (26 years)

Introduction: Swiss Framing Clips are designed for easy and secure mounting of pictures and artwork. They are made from durable materials, ensuring long-lasting use. The clips are available in various sizes to accommodate different frame dimensions. Ideal for both professional and DIY projects, these clips provide a clean and modern look for displaying your favorite images.

2. Shop Pop Displays – Sneeze Guard Clips & Accessories

Domain: shoppopdisplays.com

Registered: 2014 (11 years)

Introduction: Sneeze Guard Clips, Brackets & Accessories include various products designed for sneeze guards and plexiglass shields. Key features include: Economy options, Ships Flat design, suitable for placement in Cubicles, Desks, and Floor Standing. Price ranges from $25.00 to $170.00, with specific items like T Shaped Gripper Connectors available in packs of 6 for $25.40.

3. Wonton in a Million – Acrylic Clips

Domain: wontoninamillion.com

Registered: 2015 (10 years)

Introduction: Product: Acrylic Clips

Availability: In stock (3), Out of stock (1)

Price: $6.00 each for available clips

Products:

– Soupy Acrylic Clip (MISC021)

– Dawn Tot Acrylic Clip (MISC020)

– Bolo Bob Acrylic Clip (MISC069)

– Wonton Acrylic Clip (MISC018) – Sold Out

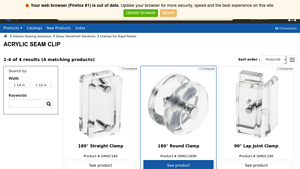

4. Richelieu – Acrylic Seam Clip

5. Lollipop Ins – Custom Acrylic PP Clip

Domain: lollipopins.com

Registered: 2022 (3 years)

Introduction: {“product_name”: “Custom Acrylic Pp Clip”, “regular_price”: “$0.60 USD”, “sale_price”: “$0.60 USD”, “unit_price”: “per”, “availability”: “Sold out”, “quantity_in_cart”: 0, “customer_reviews”: {“average_rating”: 0, “total_reviews”: 0}}

Strategic Sourcing Conclusion and Outlook for perspex clips

In conclusion, strategic sourcing of perspex clips presents significant advantages for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. By leveraging bulk purchasing agreements and establishing strong supplier relationships, businesses can achieve cost efficiencies and ensure consistent quality in their projects. The versatility of perspex clips, from display solutions to protective barriers, positions them as essential components across various industries, including retail, construction, and healthcare.

As buyers evaluate their sourcing strategies, it is crucial to consider the full range of applications for perspex clips and the specific needs of their markets. Engaging with suppliers who offer customizable solutions and reliable logistics will further enhance operational efficiency.

Looking ahead, the demand for innovative display and protective solutions is expected to grow, driven by evolving consumer preferences and regulatory changes. Now is the time for B2B buyers to proactively seek partnerships with reputable manufacturers and distributors of perspex clips. By doing so, they can position themselves at the forefront of market trends and capitalize on emerging opportunities. Embrace the potential of strategic sourcing to drive your business forward.