Contents

Manufacturing Insight: Performance Machining Services

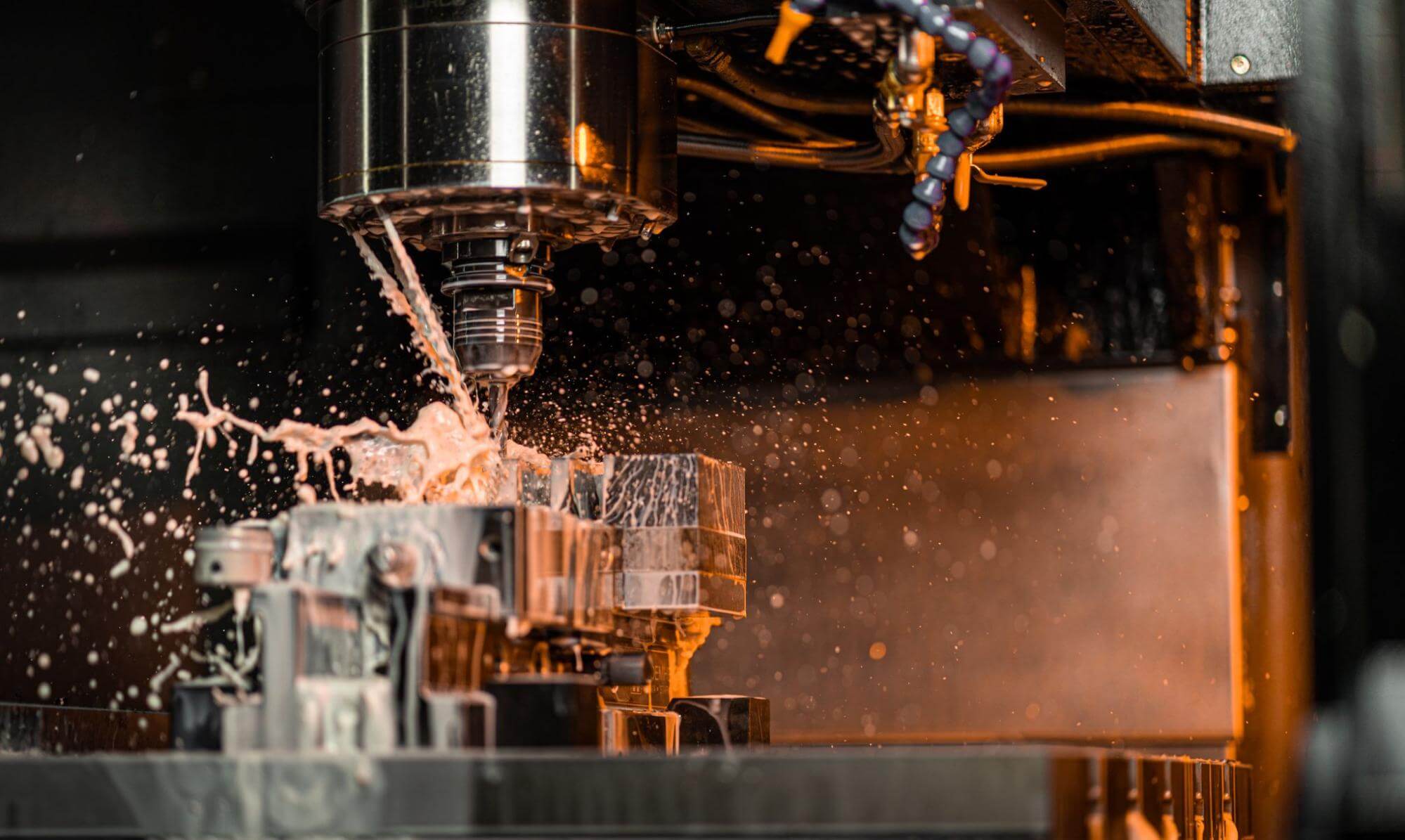

Precision Performance Machining for Demanding Applications

Honyo Prototype delivers advanced CNC machining services engineered to meet the rigorous demands of aerospace, medical, and industrial clients requiring uncompromising precision and repeatability. Our multi-axis milling and turning capabilities consistently achieve tight-tolerance geometries down to ±0.0002 inches across complex components, utilizing high-rigidity machines with proven process control for mission-critical applications. We machine everything from aluminum and titanium to exotic alloys and high-performance polymers, ensuring material integrity and dimensional stability through optimized toolpaths and in-process inspection.

Every project leverages our AS9100-certified quality management system, with full traceability from raw material to final assembly. This commitment to technical excellence eliminates costly rework and accelerates time-to-market for prototyping and low-volume production runs. To streamline your procurement workflow, Honyo provides an Online Instant Quote platform where engineers upload CAD files and receive detailed pricing within hours—not days—enabling faster decision-making without sacrificing technical validation.

Accelerate your next development cycle with machining performance that matches your engineering standards. Submit your design for an immediate quote today.

Technical Capabilities

Performance machining services at Honyo Prototype are engineered to deliver precision, repeatability, and high-quality surface finishes across complex geometries. Our capabilities span 3, 4, and 5-axis CNC milling, CNC turning, and tight-tolerance machining, supporting a broad range of industrial applications in aerospace, medical, automotive, and robotics.

We specialize in machining a variety of materials including aluminum, steel, ABS, and nylon, ensuring optimal toolpath strategies and parameter selection for each material type. Our equipment operates under strict environmental controls and is calibrated regularly to maintain tolerances as tight as ±0.0002″ (5 µm).

Below is a detailed overview of our performance machining capabilities:

| Capability | Specification |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including mill-turn with live tooling) |

| Tolerance Range | Standard: ±0.001″ (25 µm); Tight Tolerance: ±0.0002″ to ±0.0005″ (5–12 µm) |

| Positional Accuracy | ±0.0001″ (2.5 µm) on 5-axis platforms with laser probing and in-process inspection |

| Surface Finish | As low as 8 µin Ra (0.2 µm Ra) achievable via fine tooling and optimized parameters |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, stainless 303/316), ABS, Nylon (6 & 66), and other engineering plastics |

| Max Work Envelope (5-Axis) | 24″ × 36″ × 24″ (610 × 914 × 610 mm) |

| Spindle Speed | Up to 24,000 RPM for high-speed aluminum and plastic machining |

| Tooling & Probing | Automatic tool changers (ATC), in-process touch probes, and on-machine measurement for first-article validation |

| Fixturing | Custom modular and vacuum fixturing for delicate or complex components |

| Quality Control | CMM inspection, optical comparators, and GD&T-compliant reporting available |

All processes follow ISO-compliant workflows with full traceability, first-article inspection reports (FAIR), and PPAP documentation upon request. Our technical team collaborates directly with clients to optimize designs for machinability while meeting stringent performance and tolerance requirements.

From CAD to Part: The Process

Honyo Prototype delivers accelerated performance machining services through a rigorously defined workflow engineered for precision, speed, and manufacturability. Our process eliminates traditional bottlenecks while maintaining strict adherence to aerospace, medical, and industrial-grade quality standards. Below is the technical execution of each phase:

CAD Upload and Validation

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid) via our ISO 27001-certified portal. Our system performs automated geometry validation against minimum feature size thresholds (0.05 mm for micro-machining, 0.1 mm for standard performance parts), wall thickness checks, and material compatibility screening. All data undergoes AES-256 encryption with client-controlled access permissions, ensuring intellectual property protection throughout the workflow.

AI-Powered Quoting Engine

Within 60 minutes of CAD validation, our proprietary AI quoting system generates a comprehensive cost and lead time analysis. Unlike rule-based competitors, our AI cross-references 12.7 million historical machining datasets to predict:

Machine-hour optimization based on 5-axis vs. Swiss-type lathe selection

Material waste reduction through nesting algorithms

Secondary operation sequencing (e.g., heat treatment before precision grinding)

The quote includes granular cost breakdowns for setup, material surcharges (e.g., Inconel 718 vs. 7075-T6 aluminum), and tolerance-driven labor multipliers. Clients receive real-time scenario modeling for ±0.005 mm vs. ±0.025 mm tolerance impacts on cost and delivery.

Engineering-Driven DFM Analysis

Our AS9100D-certified manufacturing engineers conduct mandatory Design for Machinability reviews using Siemens NX CAM simulation. This phase identifies and resolves performance-critical issues:

Eliminating non-manufacturable radii in turbine blade contours

Redesigning deep cavity toolpaths to prevent chatter at >50,000 RPM spindles

Recommending alternative materials for thermal stability (e.g., switching 6061-T6 to 2024-T3 for aerospace brackets)

Clients receive annotated CAD markups with GD&T validation against ISO 1101 standards and a formal DFM report detailing cost/time savings. Average DFM cycle time: 4 business hours.

Precision Production Execution

Approved designs move to our climate-controlled machine floor featuring:

Makino a51nx 5-axis mills (±0.002 mm repeatability)

DMG MORI CTX beta 1250 turning centers

Hardinge Super-Precision grinders for mirror finishes

All performance parts undergo in-process CMM verification at 20% completion intervals. Critical features (e.g., hydraulic valve seats) receive 100% laser interferometer validation. Material traceability is maintained via blockchain-logged heat numbers with full MTR documentation.

Certified Delivery and Documentation

Shipments include:

First Article Inspection reports per PPAP Level 3

Certified material test reports with lot-specific chemistry

3D scan deviation maps against nominal CAD

ISO 17025-accredited calibration certificates for all measuring equipment

Global delivery options include DHL Express with real-time GPS tracking and customs clearance support. Typical lead time from CAD upload to delivery: 5-12 business days for complex performance components.

Performance Machining Capabilities Summary

| Parameter | Standard Capability | High-Performance Tier |

|———————|———————|————————|

| Tolerance | ±0.025 mm | ±0.002 mm |

| Surface Finish (Ra) | 0.8 μm | 0.05 μm |

| Max Work Envelope | 1000 x 500 x 400 mm | 500 x 300 x 250 mm |

| Material Range | Aluminum to Tool Steel | Titanium, Inconel, CFRP |

This integrated workflow reduces time-to-prototype by 40% versus conventional methods while ensuring zero non-conformances in mission-critical applications. All processes are audited to AS9100 Rev D and IATF 16949 standards with full FAI traceability.

Start Your Project

For precision performance machining services tailored to demanding applications, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen delivers high-accuracy components with fast turnaround and strict quality control. Partner with Honyo Prototype for reliable, scalable machining solutions engineered to perform.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.