Contents

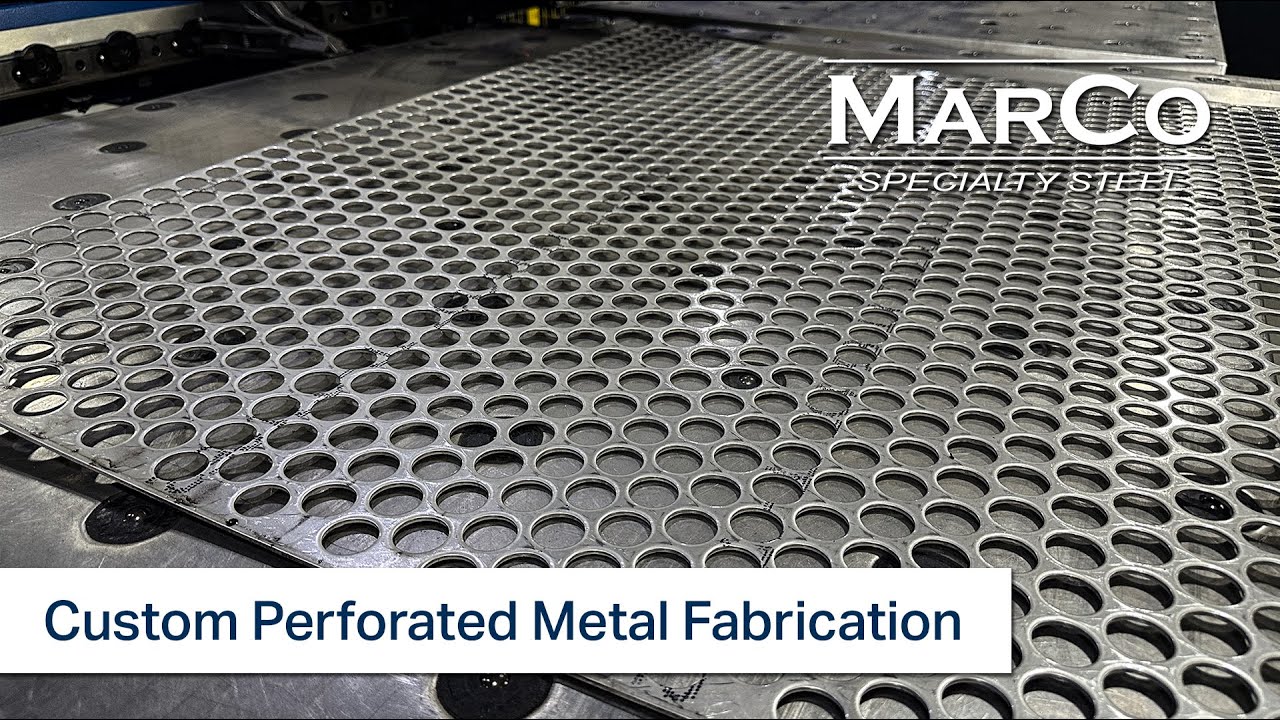

Manufacturing Insight: Perforated Steel Sheet

Precision Perforated Steel Sheet Solutions from Honyo Prototype

Honyo Prototype delivers engineered excellence in perforated steel sheet fabrication, serving demanding industrial applications where precision, structural integrity, and consistent performance are non-negotiable. Our advanced sheet metal fabrication capabilities encompass CNC punching, laser cutting, and precision bending, enabling the production of complex perforation patterns—from standard grids to custom geometries—with tight tolerances across diverse steel grades and thicknesses. We understand that perforated components critical to filtration, ventilation, acoustics, or safety guarding require meticulous material selection, deburring, and finishing to meet functional and regulatory requirements. Beyond core fabrication, Honyo integrates secondary processes like welding, plating, and powder coating under one roof, ensuring seamless project execution from prototype to volume production.

Accelerate your procurement cycle with Honyo’s Online Instant Quote platform. Upload your DXF/DWG files or technical specifications to receive a detailed, transparent cost assessment within hours—not days—empowering faster design validation and project initiation. Our engineering team stands ready to collaborate on optimizing perforation layouts for manufacturability, cost efficiency, and end-use performance. Partner with Honyo Prototype for perforated steel solutions built on decades of metalforming expertise and digital-driven responsiveness.

Technical Capabilities

Perforated steel sheet fabrication involves precise laser cutting, bending, and welding processes tailored to material properties. While “perforated steel sheet” typically refers to steel, similar perforation techniques apply across materials such as aluminum, ABS, and nylon—though process parameters vary significantly due to differences in thermal conductivity, tensile strength, and melting behavior.

Laser cutting is the preferred method for creating accurate perforation patterns with clean edges. Bending must account for material ductility and springback, especially in metals. Welding is generally applicable only to metallic substrates (steel and aluminum), while thermoplastics like ABS and nylon are joined via adhesives or mechanical fastening due to their low melting points and poor weldability.

Below is a comparative technical specification table for perforated sheet fabrication across materials:

| Parameter | Steel (Mild/Carbon) | Aluminum (e.g., 5052, 6061) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (Polyamide, e.g., PA6) |

|---|---|---|---|---|

| Laser Cutting Compatibility | Excellent | Excellent | Good (low power, controlled speed) | Fair (prone to melting/charring) |

| Typical Laser Type | Fiber Laser | Fiber Laser | CO₂ Laser | CO₂ Laser |

| Minimum Feature Size | 1.0 mm | 1.2 mm | 1.5 mm | 2.0 mm |

| Edge Quality After Cutting | Smooth, minimal dross | Smooth, oxide layer possible | Slight melting, requires post-process | Moderate charring, burr risk |

| Bending Capability | High (with tooling) | High (springback ~2–3%) | Limited (brittle, stress cracking) | Moderate (tough but elastic) |

| Minimum Bend Radius (2mm) | 2.0 mm | 3.0 mm | Not recommended | 4.0 mm (preheating advised) |

| Welding Process | MIG, TIG, Spot Welding | TIG, MIG (with shielding gas) | Not weldable (thermoplastic) | Not weldable (fusion issues) |

| Joining Alternatives | — | — | Adhesives, snap-fits, screws | Adhesives, rivets, press-fit |

| Thermal Sensitivity | Low | Medium | High | High |

| Typical Thickness Range | 0.8 – 6.0 mm | 1.0 – 5.0 mm | 1.5 – 4.0 mm | 2.0 – 5.0 mm |

| Surface Finish Options | Galvanized, Powder Coat | Anodized, Painted | Painted, Textured | Natural, Oiled |

Notes:

Steel and aluminum sheets are most suitable for full fabrication cycles involving cutting, forming, and welding.

ABS and nylon are generally limited to laser cutting and mechanical assembly; they are not recommended for bending or welding in perforated configurations due to deformation and structural integrity concerns.

For thermoplastics, optimized laser parameters (lower power, higher speed) are critical to minimize heat-affected zones.

This data supports process selection in prototyping and low-volume production at Honyo Prototype, ensuring material-appropriate manufacturing methods are applied.

From CAD to Part: The Process

Honyo Prototype Perforated Steel Sheet Manufacturing Process

Our end-to-end process for perforated steel sheet fabrication ensures precision, efficiency, and compliance with engineering specifications. The workflow begins with your CAD submission and concludes with certified delivery, integrating AI-driven validation and rigorous engineering oversight at each stage.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SolidWorks) via our secure customer portal. For perforated sheets, we require complete geometric definitions of the hole pattern—including hole size, pitch, stagger, edge margins, and any non-standard shapes. Acceptable file formats ensure dimensional accuracy; PDFs or 2D sketches are insufficient due to tolerance dependencies in perforation tooling. Material specifications (grade, thickness, finish) must accompany the CAD data to enable immediate feasibility assessment.

AI-Powered Quoting Engine

Uploaded files enter our AI quoting system, which autonomously analyzes geometric complexity, material utilization, and process constraints. For perforated sheets, the AI cross-references hole patterns against our tooling library (e.g., standard round, slotted, or custom dies) to flag conflicts like minimum hole-to-edge distances below 1.5× material thickness or patterns exceeding press capacity. Real-time cost drivers include sheet nesting efficiency, secondary operations (e.g., bending), and material waste. Quotes are generated within 2 business hours, with clear annotations for non-compliant features requiring DFM intervention.

Engineering-Driven DFM Review

All perforated sheet projects undergo mandatory DFM validation by our manufacturing engineering team. We assess hole pattern stability under shear forces, burr directionality requirements, and tooling wear implications for high-volume runs. Critical checks include:

Verification of hole alignment tolerances (±0.1mm typical) against material springback

Confirmation of minimum web width between holes (≥0.8× material thickness)

Evaluation of nesting efficiency to minimize raw material waste

Identification of potential deformation risks during perforation (e.g., thin sections near edges)

Clients receive a formal DFM report with actionable recommendations—such as adjusting hole spacing or switching to laser perforation for intricate geometries—before proceeding to production.

Precision Production Execution

Approved designs move to our dedicated perforation line, utilizing hydraulic punch presses (up to 200-ton capacity) or fiber laser systems for complex patterns. Steel sheets are clamped under tension to prevent distortion during punching. In-process quality checks include:

First-article inspection of hole diameter, pitch, and positional accuracy (CMM verification)

Burr height measurement (max 10% of material thickness per ISO 13715)

Material flatness validation post-perforation (≤0.5mm/m deviation)

For multi-step projects, secondary operations like bending or welding occur in climate-controlled cells to maintain dimensional stability. All perforated sheets undergo deburring and cleaning before final inspection.

Certified Delivery Logistics

Finished parts undergo final QA against ASME Y14.5 tolerances, with material test reports (MTRs) and perforation pattern validation certificates provided. Perforated sheets are interleaved with kraft paper and secured in custom crating to prevent surface damage during transit. Delivery includes:

Digital inspection reports with GD&T callouts

Nesting layout documentation for material traceability

Shipping confirmation with real-time tracking

Standard lead time is 7–10 business days from DFM approval; expedited options are available for urgent requirements.

This structured workflow ensures perforated steel components meet functional and aesthetic requirements while minimizing rework risks. Contact our engineering team to discuss pattern-specific constraints or request a DFM template for perforation projects.

Start Your Project

Looking for high-quality perforated steel sheets for your next project? Contact Susan Leo at [email protected] to discuss your requirements and get expert support from our engineering team.

Honyo Prototype operates a state-of-the-art manufacturing facility in Shenzhen, ensuring precision fabrication, fast turnaround times, and strict quality control for all perforated metal products. Whether you need custom hole patterns, specific materials, or large-volume production, we deliver reliable solutions tailored to your application.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.