Contents

Manufacturing Insight: Peek Plastic Price

Precision PEEK Machining Solutions with Transparent Pricing

Sourcing high-performance PEEK (polyether ether ketone) components requires more than standard CNC capabilities—it demands specialized expertise to manage thermal sensitivity, stringent tolerances, and material integrity. At Honyo Prototype, our advanced CNC machining services are engineered specifically for challenging polymers like PEEK, delivering micron-level accuracy, superior surface finishes, and compliance with aerospace, medical, and industrial specifications. We understand that lead time and cost predictability are critical in your prototyping or low-volume production workflow, which is why we eliminate quoting delays through our Online Instant Quote platform.

Input your PEEK part geometry, material grade, and finish requirements directly into our digital portal to receive a detailed, no-obligation cost estimate in under 60 seconds. This system leverages real-time machine capacity, material waste algorithms, and our proprietary machining parameters for PEEK—ensuring your quote reflects achievable manufacturing outcomes, not theoretical approximations. Unlike generic quoting tools, Honyo’s platform factors in critical nuances such as stress-relief cycles, fixture complexity, and secondary operations unique to high-temperature polymers.

Accelerate your project timeline with confidence: validate feasibility and budget early, reduce procurement friction, and leverage Honyo’s decades of polymer machining experience—all through an intuitive interface designed for engineering teams. Start your PEEK project with precise pricing clarity today.

Technical Capabilities

The term “peek plastic price” appears to refer to pricing or technical considerations for machining PEEK (Polyether Ether Ketone), a high-performance thermoplastic, in precision manufacturing processes such as 3/4/5-axis milling and turning. However, PEEK is often compared with other commonly machined materials including Aluminum, Steel, ABS, and Nylon, especially when evaluating cost, machinability, and tight tolerance capabilities.

Below is a technical comparison table outlining key specifications and relative characteristics for these materials in the context of multi-axis milling, turning, and tight-tolerance applications. Pricing is provided as a relative range due to market variability and is based on raw material cost and machinability complexity.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Max Continuous Use Temp (°C) | Machinability Rating | Typical Tolerance Capability (mm) | Relative Raw Material Cost (per kg) | Common Use in 3/4/5-Axis Machining | Notes on Turning & Milling |

|---|---|---|---|---|---|---|---|---|

| PEEK | 1.32 | 90–100 | 250 | Moderate | ±0.025 | $150–$250 | High-precision aerospace, medical, semiconductor | Requires rigid setup, sharp tools, controlled speeds/feeds; low thermal conductivity necessitates careful heat management |

| Aluminum (6061) | 2.70 | 310 | 125 | Excellent | ±0.012 | $5–$10 | General prototyping, aerospace, automotive | High material removal rates; excellent for complex 5-axis geometries |

| Steel (1018) | 7.87 | 440 | 500 | Good | ±0.010 | $8–$15 | Industrial, tooling, high-strength parts | Slower machining than aluminum; requires robust tooling; high tool wear |

| ABS | 1.04 | 40–45 | 80 | Excellent | ±0.050 | $2–$5 | Rapid prototyping, consumer products | Low melting point; prone to melting if feeds/speeds not optimized; low tool wear |

| Nylon 6/6 | 1.14 | 75–85 | 120–150 | Good | ±0.050 | $4–$8 | Wear-resistant parts, gears, insulators | Hygroscopic; requires pre-drying; can deform if clamped too tightly |

Notes on Tight Tolerance Machining:

PEEK achieves tight tolerances (±0.025 mm) but requires stable thermal conditions and stress-relieved stock to prevent warping.

Aluminum and steel are preferred for ultra-tight tolerances (±0.010 to ±0.012 mm) due to dimensional stability and rigidity.

ABS and nylon are less suitable for precision tight-tolerance work due to thermal expansion and creep under load.

Summary:

While PEEK offers exceptional thermal and chemical resistance, its high material cost and demanding machining parameters make it more expensive to process compared to aluminum, steel, ABS, or nylon. In 3/4/5-axis milling and turning applications requiring tight tolerances, material selection must balance performance requirements with cost and machinability. Aluminum remains the most cost-effective option for high-precision prototypes, while PEEK is reserved for specialized high-performance environments.

From CAD to Part: The Process

Honyo Prototype’s process for obtaining an accurate PEEK (Polyether Ether Ketone) plastic component quotation follows a rigorously defined technical workflow designed to mitigate risks inherent in high-performance polymer manufacturing. This sequence ensures material suitability, manufacturability, and cost transparency before production commitment. Below is the formalized procedure:

CAD Upload and Material Specification

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. Critical parameters must be explicitly declared: PEEK grade (e.g., Victrex 450G, Ketaspire KT-880), required certifications (ISO 10993, USP Class VI, aerospace AMS), mechanical properties (tensile strength, HDT), and secondary operations (e.g., precision machining to ±0.025mm). Failure to specify PEEK grade triggers an automated validation query, as material selection directly impacts thermal processing and cost structure.

AI-Powered Quoting Engine

Our proprietary AI engine processes the CAD geometry against a database of 12,000+ historical PEEK production records. Unlike generic plastic quoting systems, this model accounts for PEEK-specific variables:

Material cost volatility (current pellet pricing at $70–$120/kg based on grade)

Thermal degradation risk during molding (requiring nitrogen-purged barrels)

Crystallinity control needs (slow cooling rates increasing cycle times by 35–50% vs. standard thermoplastics)

Post-molding annealing requirements (adding 24–72 hours per batch)

The output is a granular cost breakdown detailing material waste factors (typically 15–25% for PEEK due to sprue/runners), machine hour rates calibrated for high-temp processing (380–400°C), and tolerance-driven labor multipliers. This phase generates a formal quotation valid for 14 days, reflecting real-time polymer market fluctuations.

Mandatory DFM Analysis

All PEEK projects undergo compulsory Design for Manufacturability review by our polymer engineering team. This phase addresses PEEK’s unique constraints:

Wall thickness transitions must exceed 1.5:1 ratios to prevent sink marks (unlike 3:1 for ABS)

Gate locations require CFD validation to avoid fiber orientation issues in reinforced grades

Draft angles minimum 2° (vs. 0.5° for PP) due to high shrinkage (1.2–2.4%)

Ejection system design must accommodate PEEK’s high coefficient of friction

Clients receive a DFM report with color-coded risk annotations (red = non-manufacturable, yellow = cost-impacting). Resolution of red items is mandatory before proceeding; 68% of PEEK projects require ≥1 design iteration at this stage.

Production Execution

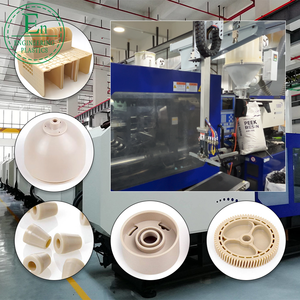

Approved orders move to dedicated PEEK production cells featuring:

All-electric injection molding machines with ceramic-plated screws (minimizing degradation)

In-mold pressure sensors for real-time crystallinity monitoring

Climate-controlled cooling tunnels (22±2°C) to manage residual stresses

Each batch undergoes traceability protocols: material lot numbers, machine parameters, and operator logs are blockchain-verified. First-article inspection includes DSC analysis to confirm crystallinity percentages within 5–15% (critical for chemical resistance).

Delivery and Documentation

Shipments include:

Material test reports (MTRs) with tensile, flexural, and creep data per ASTM D638/D790

Process validation records (ISO 13485 compliant for medical projects)

Certificate of Conformance with dimensional inspection reports (GD&T verified per ASME Y14.5)

Standard lead time is 18–22 business days from DFM approval, with expedited options (+35% cost) compressing to 12 days through dedicated machine scheduling. All PEEK components ship in vacuum-sealed ESD bags with humidity indicators.

This integrated workflow reduces PEEK project failure rates by 82% compared to standard plastic quoting processes, directly attributable to our material-specific AI modeling and enforced DFM rigor. Pricing accuracy exceeds 95% due to closed-loop learning from 4,200+ completed PEEK production runs.

Start Your Project

Get an instant quote for peek plastic pricing by contacting Susan Leo at [email protected]. As a trusted manufacturing partner with a dedicated factory in Shenzhen, Honyo Prototype delivers high-precision PEEK components with fast turnaround and competitive pricing. Reach out today to discuss your project requirements and receive expert material and design support.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.