Introduction: Navigating the Global Market for peek plastic molding

In the competitive landscape of manufacturing, sourcing high-quality PEEK plastic molding components can pose significant challenges for international B2B buyers. As industries increasingly demand materials that offer exceptional strength, chemical resistance, and temperature performance, understanding the intricacies of PEEK (poly ether ketone) becomes crucial. This comprehensive guide is designed to navigate the global market for PEEK plastic molding, addressing key considerations such as types of PEEK materials, their diverse applications, and the critical factors for supplier vetting and cost assessment.

With an emphasis on practical insights, this guide empowers decision-makers from Africa, South America, the Middle East, and Europe—regions that are rapidly expanding their industrial capabilities. Buyers in countries like Saudi Arabia and Nigeria will find actionable information that demystifies the PEEK molding process, enabling them to make informed purchasing decisions that align with their operational needs. From understanding the unique properties of PEEK to optimizing the injection molding process, this resource equips buyers with the knowledge to select the right materials and suppliers, ultimately enhancing their product performance and market competitiveness.

By addressing the common pitfalls and best practices in PEEK plastic molding, this guide serves as a vital tool for businesses looking to leverage the advantages of this high-performance thermoplastic in their applications.

Understanding peek plastic molding Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PEEK Molding | Utilizes standard injection molding equipment; requires precise temperature control. | Aerospace, automotive, medical devices | Pros: High performance; versatile. Cons: Requires careful setup and monitoring. |

| PEEK Compression Molding | Involves pre-heating and compressing PEEK material; suitable for complex geometries. | Electrical components, specialized tooling | Pros: Excellent for intricate designs; reduced waste. Cons: Slower production rates. |

| PEEK Extrusion Molding | Continuous process; allows for longer parts and profiles; requires specialized equipment. | Industrial applications, piping systems | Pros: Cost-effective for large volumes; consistent quality. Cons: Limited to specific shapes. |

| PEEK Blow Molding | Creates hollow parts; involves air pressure to expand the material; suitable for specific applications. | Containers, medical devices | Pros: Lightweight and strong; efficient for hollow parts. Cons: Not suitable for all applications. |

| PEEK 3D Printing | Utilizes additive manufacturing techniques; allows for rapid prototyping and customization. | Prototyping, custom parts in aerospace | Pros: Flexible design options; quick turnaround. Cons: Potentially higher material costs. |

What are the Characteristics of Standard PEEK Molding?

Standard PEEK molding involves the use of conventional injection molding machines, which are adapted to reach the high processing temperatures required for PEEK. The process demands precise temperature control to ensure the material maintains its exceptional mechanical properties. This method is ideal for producing high-performance components used in industries such as aerospace and medical devices. Buyers should consider the initial setup costs and the need for skilled operators to manage the intricate parameters of the process.

How Does PEEK Compression Molding Differ?

PEEK compression molding is characterized by the pre-heating of the material followed by compression into molds. This method is particularly beneficial for creating complex geometries that may be challenging with standard molding techniques. It is commonly utilized for electrical components and specialized tooling. Buyers should weigh the advantages of intricate designs against the potentially slower production rates and the necessity for specialized molds.

What Are the Advantages of PEEK Extrusion Molding?

PEEK extrusion molding is a continuous process that allows for the production of longer parts and profiles. This technique is particularly suitable for industrial applications, such as piping systems, where consistent quality and cost-effectiveness are crucial. Buyers should consider that while extrusion is economical for large volumes, it limits the shapes that can be produced compared to other molding methods.

In What Scenarios is PEEK Blow Molding Used?

PEEK blow molding is utilized to create hollow parts by expanding the material using air pressure. This method is efficient for producing lightweight and strong components, such as containers and medical devices. Buyers should note that while this technique is effective for certain applications, it may not be suitable for all parts, and the design must accommodate the blow molding process.

How Does PEEK 3D Printing Benefit B2B Buyers?

PEEK 3D printing leverages additive manufacturing techniques to produce components rapidly and customize designs without the need for traditional molds. This method is particularly advantageous for prototyping and creating unique parts in industries like aerospace. However, buyers should be aware of potentially higher material costs and ensure that their applications justify the investment in this innovative technology.

Key Industrial Applications of peek plastic molding

| Industry/Sector | Specific Application of peek plastic molding | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Structural components and housings | High strength-to-weight ratio enhances performance | Compliance with aviation standards and certifications |

| Medical | Surgical instruments and implants | Biocompatibility and sterilization capabilities | FDA compliance and rigorous quality assurance processes |

| Oil and Gas | Seals, bearings, and valve components | Excellent chemical resistance and durability | Resistance to harsh environments and operational pressures |

| Automotive | Under-the-hood components | High thermal stability and lightweight design | Supplier reliability and ability to meet stringent safety standards |

| Electronics | Insulators and connectors | Superior electrical insulation properties | Material availability and compatibility with electronic applications |

How is PEEK Plastic Molding Used in Aerospace Applications?

In the aerospace sector, PEEK plastic molding is employed to create structural components and housings that require a high strength-to-weight ratio. These components can withstand extreme conditions, ensuring safety and performance during flight. For international buyers, especially from regions like Europe and the Middle East, sourcing PEEK materials that meet aviation standards is crucial. They must ensure that suppliers provide certifications and adhere to rigorous quality control measures to prevent failures in critical applications.

What Role Does PEEK Play in Medical Applications?

PEEK is increasingly used in medical applications, particularly for surgical instruments and implants. Its biocompatibility and ability to withstand sterilization processes make it ideal for medical environments. Buyers from regions such as Africa and South America should prioritize suppliers who can guarantee FDA compliance and have robust quality assurance protocols in place. This ensures that the PEEK components will not only perform well but also meet the stringent health regulations required in the medical field.

How is PEEK Beneficial in Oil and Gas Applications?

In the oil and gas industry, PEEK plastic molding is utilized for seals, bearings, and valve components, where exposure to harsh chemicals and extreme temperatures is common. The exceptional chemical resistance and durability of PEEK help in reducing maintenance costs and downtime. For international buyers, especially in regions like Nigeria and Saudi Arabia, it is essential to consider suppliers who can provide materials specifically designed to withstand the challenging conditions of oil and gas operations, ensuring long-term reliability.

What Advantages Does PEEK Offer in Automotive Applications?

The automotive industry leverages PEEK for under-the-hood components due to its high thermal stability and lightweight characteristics. These properties contribute to improved fuel efficiency and overall vehicle performance. B2B buyers in Europe and the Middle East must focus on sourcing PEEK components from suppliers who can meet stringent safety and performance standards, ensuring that the materials used are not only reliable but also compliant with industry regulations.

How Does PEEK Enhance Electronics Manufacturing?

In electronics, PEEK is used for insulators and connectors, where its superior electrical insulation properties are critical. This application helps in preventing electrical failures and enhancing the longevity of electronic devices. Buyers from South America and Africa should ensure that their suppliers can provide PEEK materials that are readily available and compatible with various electronic applications, facilitating seamless integration into their manufacturing processes.

3 Common User Pain Points for ‘peek plastic molding’ & Their Solutions

Scenario 1: Ensuring Quality and Consistency in PEEK Parts

The Problem: B2B buyers often face challenges in achieving consistent quality in PEEK molded parts. Variability in the injection molding process can lead to defects, such as inconsistencies in mechanical properties or surface quality, which can affect performance in critical applications like aerospace or medical devices. These quality issues can lead to increased costs, rework, and even product recalls, impacting the buyer’s reputation and profitability.

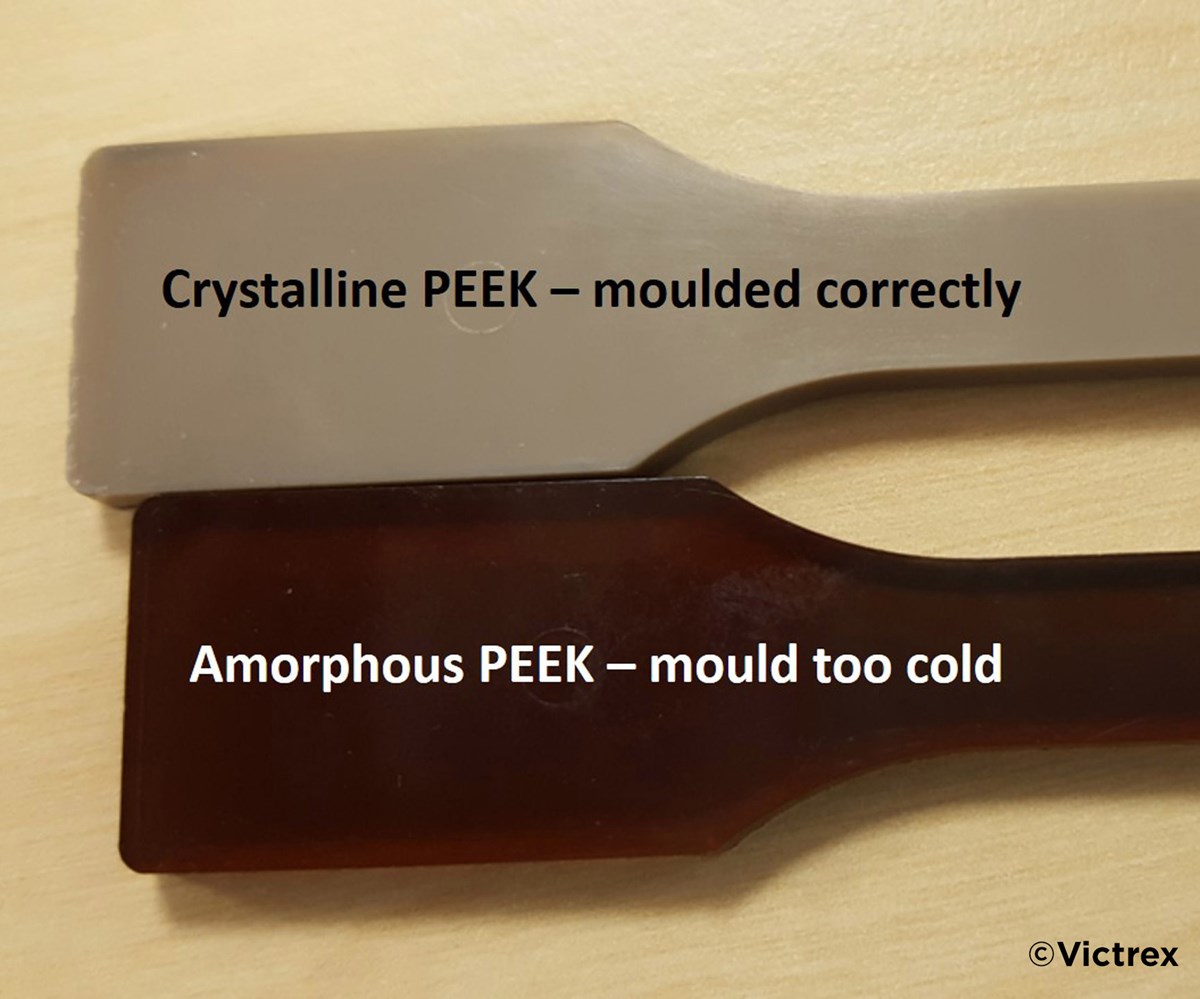

The Solution: To enhance the quality and consistency of PEEK parts, it’s essential to focus on the complete injection molding process. Start by selecting the right equipment and ensuring it is properly calibrated for PEEK’s high processing temperatures (350-400°C). Use high-quality molds with precise temperature control (170-200°C) to maintain the desired semi-crystalline state of PEEK during cooling. Implement strict cleanliness protocols to avoid contamination, which can manifest as defects in the final product. Regular maintenance and cleaning of machinery, along with using dedicated equipment for PEEK, can significantly reduce the risk of defects. Additionally, consider using in-line quality control measures, such as real-time monitoring of the injection process, to catch issues early and maintain high standards throughout production.

Scenario 2: Managing Production Costs with PEEK

The Problem: Many B2B buyers are concerned about the high costs associated with PEEK plastic molding. The material itself is expensive, and the specialized equipment and processes required can lead to significant overheads. This situation is particularly challenging for companies in competitive markets where pricing pressures are high, making it essential to find ways to manage production costs without sacrificing quality.

The Solution: To effectively manage production costs while using PEEK, buyers should optimize their design and manufacturing processes. Start by thoroughly analyzing the part design to reduce material waste and improve mold efficiency. Simplifying geometries can minimize the complexity of the mold, potentially reducing tooling costs. Furthermore, investing in advanced injection molding technology, such as machines with better thermal management capabilities, can lead to energy savings and lower operational costs over time. Buyers should also explore bulk purchasing agreements for PEEK material to negotiate better pricing. Lastly, collaborating with experienced suppliers can provide insights into best practices and innovative solutions that streamline production, ultimately lowering costs while maintaining the high performance PEEK is known for.

Scenario 3: Overcoming Technical Barriers in PEEK Molding

The Problem: Many B2B buyers new to PEEK injection molding encounter technical barriers that hinder their ability to effectively utilize this high-performance material. From understanding the specific drying requirements to managing the intricate cooling processes, these challenges can lead to frustration and underperformance of the molded parts, especially in demanding applications.

The Solution: Addressing technical barriers requires a comprehensive understanding of PEEK’s unique properties and processing requirements. First, ensure that PEEK is adequately dried before molding, as residual moisture can lead to defects. Implement a drying protocol using circulating ovens to achieve the recommended moisture content of less than 0.02%. Next, focus on the cooling process; maintain optimal mold temperatures to avoid quenching and ensure uniform crystallization. It’s also beneficial to consult with material suppliers or industry experts who can provide tailored advice and troubleshooting support. Training staff on best practices for handling and processing PEEK can further enhance their capabilities and confidence in working with this material. By investing in knowledge and resources, buyers can overcome technical challenges and fully leverage the advantages of PEEK in their applications.

Strategic Material Selection Guide for peek plastic molding

What Are the Key Properties of PEEK in Injection Molding?

PEEK (Polyetheretherketone) is a high-performance thermoplastic known for its exceptional mechanical properties, including high strength, stiffness, and chemical resistance. It can withstand temperatures up to 343°C and has a glass transition temperature around 143°C, making it suitable for demanding applications in industries such as aerospace, automotive, and medical. Its FDA compliance for food contact and sterilization capability further expands its usability in various sectors.

What Are the Pros and Cons of Using PEEK for Injection Molding?

Pros:

- Durability: PEEK exhibits excellent wear resistance and can endure harsh environments, making it ideal for long-lasting components.

- Chemical Resistance: It is inert to a wide range of chemicals, making it suitable for applications in corrosive environments.

- High-Temperature Performance: Its ability to maintain mechanical integrity at elevated temperatures is a significant advantage in high-stress applications.

Cons:

- Cost: PEEK is relatively expensive compared to other thermoplastics, which may limit its use in cost-sensitive applications.

- Manufacturing Complexity: The injection molding process for PEEK requires specialized equipment and precise control of processing conditions, increasing manufacturing complexity.

- Shrinkage: PEEK’s semi-crystalline nature leads to higher shrinkage rates, which can complicate mold design and part accuracy.

How Does PEEK Impact Application Compatibility?

PEEK’s unique properties make it compatible with various media, especially in industries requiring high-performance materials. For example, in the medical field, PEEK is used for surgical instruments and implants due to its biocompatibility and sterilization capabilities. In aerospace, its lightweight yet strong characteristics contribute to fuel efficiency and performance. However, the specific application must be assessed for compatibility with PEEK’s thermal and chemical properties to avoid degradation or failure.

What Should International B2B Buyers Consider When Selecting PEEK?

When sourcing PEEK for injection molding, international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider compliance with local and international standards such as ASTM, DIN, and JIS. Understanding the regulatory landscape is crucial, especially in sectors like medical and food processing. Additionally, buyers should evaluate the availability of specialized equipment and skilled labor in their region to ensure successful implementation of PEEK molding processes. Cost considerations, including material price and processing expenses, should also be factored into the decision-making process.

Summary Table of PEEK Material Properties

| Material | Typical Use Case for peek plastic molding | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PEEK | Aerospace components, medical implants, and food processing equipment | Exceptional mechanical properties and chemical resistance | High cost and complex manufacturing process | High |

| PEEK GF30 | Gears, bearings, and high-load applications | Enhanced strength and stiffness due to glass fiber reinforcement | Increased brittleness and potential for higher wear rates | High |

| PEEK CF30 | Aerospace and automotive parts requiring lightweight and strength | Excellent thermal stability and reduced weight | Higher cost and processing challenges | High |

| PEEK HT | High-temperature applications in electronics and automotive | Superior heat resistance and dimensional stability | Limited availability and higher processing temperatures | High |

This analysis provides B2B buyers with essential insights into the strategic selection of PEEK materials for injection molding, emphasizing the importance of understanding material properties, application impacts, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for peek plastic molding

What Are the Key Stages in the Manufacturing Process of PEEK Plastic Molding?

The manufacturing process for PEEK plastic molding involves several critical stages that ensure the production of high-quality components. Understanding these stages is essential for B2B buyers looking to procure PEEK parts for various applications, including aerospace, automotive, and medical industries.

Material Preparation: How Is PEEK Polymer Prepared for Molding?

Before molding, PEEK resin must undergo thorough preparation to ensure optimal performance. The PEEK granules typically come dry but can absorb moisture from the atmosphere, which can negatively impact the molding process. Therefore, drying is crucial. Recommended drying involves placing the granules in circulating ovens at temperatures ranging from 150°C to 160°C for 2-3 hours. This process reduces the moisture content to below 0.02%, preventing defects such as bubbles or voids in the final product.

Forming: What Techniques Are Used in the Injection Molding of PEEK?

The forming stage involves injecting the prepared PEEK material into a mold. Key techniques include:

-

Injection Molding: PEEK is injected into a mold at high temperatures (typically between 350°C and 400°C) using standard injection molding machines. It is vital to maintain consistent processing temperatures to achieve the desired mechanical properties.

-

Gate Design: Using appropriately sized gates is critical, as PEEK exhibits higher shrinkage compared to other thermoplastics. Larger gates allow for better material flow and packing density, enhancing the final part’s strength and durability.

-

Temperature Control: Maintaining the right mold temperature (170°C to 200°C) is essential to ensure that the material crystallizes correctly, maximizing PEEK’s unique properties.

Assembly: How Are PEEK Components Assembled Post-Molding?

Post-molding assembly may involve secondary operations such as machining, drilling, or surface finishing to achieve precise dimensions or enhance surface properties. It is important to maintain cleanliness during assembly to avoid contamination, which can compromise the integrity of the parts. Dedicated equipment should be used for any regrinding of PEEK to prevent cross-contamination with other materials.

Finishing: What Finishing Techniques Are Commonly Used for PEEK Parts?

Finishing techniques can include polishing, coating, or applying surface treatments to improve the aesthetic or functional properties of PEEK components. The choice of finishing method often depends on the intended application, such as medical devices requiring sterilization or aerospace components needing specific surface characteristics.

What Quality Assurance Measures Are Essential in PEEK Plastic Molding?

Quality assurance is a critical component in the production of PEEK molded parts, ensuring that they meet international standards and specific industry requirements.

Which International Standards Are Relevant for PEEK Quality Assurance?

B2B buyers should ensure that their suppliers adhere to relevant international standards such as:

- ISO 9001: This standard focuses on quality management systems and is crucial for ensuring consistent product quality.

- CE Marking: Required for medical and certain industrial applications in Europe, indicating compliance with safety and performance requirements.

- API Standards: Relevant for components used in the oil and gas industry, ensuring that products meet rigorous industry specifications.

What Are the Key Quality Control Checkpoints During Manufacturing?

Implementing systematic quality control checkpoints is vital for maintaining product integrity. Key checkpoints include:

-

Incoming Quality Control (IQC): Inspecting raw materials for compliance with specifications before they enter the manufacturing process.

-

In-Process Quality Control (IPQC): Monitoring the molding process to ensure parameters remain within specified limits, thus preventing defects during production.

-

Final Quality Control (FQC): Conducting thorough inspections and testing of finished components to verify that they meet design specifications and quality standards.

What Common Testing Methods Are Used to Ensure PEEK Quality?

Common testing methods for PEEK components include:

- Mechanical Testing: Evaluating tensile strength, elongation, and hardness to ensure that the components can withstand their intended applications.

- Thermal Analysis: Assessing properties such as melting point and glass transition temperature to confirm that the material performs under expected temperature ranges.

- Chemical Resistance Testing: Ensuring that the PEEK components can withstand exposure to various chemicals, particularly for applications in the medical and aerospace sectors.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers:

-

Audits: Conducting regular audits of the supplier’s manufacturing facilities can provide insight into their adherence to quality standards and practices.

-

Quality Reports: Requesting detailed quality reports, including inspection results and compliance certifications, can help buyers evaluate the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of the manufacturing process and quality assurance practices, ensuring compliance with both international standards and specific industry requirements.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

-

Regional Compliance: Different regions may have varying compliance requirements. Understanding local regulations and standards is essential for ensuring that products can be legally marketed and used.

-

Cultural Sensitivity: Engaging with suppliers that understand and respect cultural differences can facilitate smoother communication and collaboration, especially when discussing quality expectations.

-

Documentation and Traceability: Maintaining clear documentation and traceability throughout the supply chain is crucial for addressing any quality issues that may arise post-purchase.

By understanding the manufacturing processes and quality assurance measures involved in PEEK plastic molding, B2B buyers can make informed decisions and ensure that they procure high-quality components that meet their specific needs and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘peek plastic molding’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure PEEK plastic molding services. PEEK, or polyetheretherketone, is a high-performance thermoplastic known for its exceptional strength, chemical resistance, and versatility across various industries. Following this checklist will ensure that you make informed decisions, enabling you to source high-quality PEEK components that meet your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to outline your technical requirements for the PEEK components you need. This includes dimensions, tolerances, and intended applications. A clear understanding of your specifications helps suppliers provide accurate quotes and ensures that the final products meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in PEEK plastic molding. Look for manufacturers with a proven track record in your industry, as they will better understand your unique challenges and requirements. Utilize online directories, industry forums, and trade shows to gather a list of potential candidates.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers hold relevant certifications, such as ISO 9001 for quality management and any industry-specific certifications (e.g., FDA compliance for medical applications). Certifications indicate a commitment to quality and regulatory compliance, which is critical when working with advanced materials like PEEK.

Step 4: Request Samples and Review Prototypes

Before making a large commitment, request samples or prototypes of the PEEK components. This step is vital to assess the quality of the supplier’s work and ensure that the materials used meet your specifications. Pay attention to the finish, dimensional accuracy, and any specific properties relevant to your application.

Step 5: Discuss Molding Parameters and Capabilities

Engage in detailed discussions with suppliers about their molding capabilities, including equipment used, processing temperatures, and drying procedures. Understanding their technical capabilities will help you gauge whether they can meet your production needs effectively. Key parameters to discuss include:

– Drying Procedures: Ensure they can achieve the low moisture content required for PEEK processing.

– Temperature Control: Confirm that they can maintain the necessary temperatures throughout the molding process.

Step 6: Inquire About Lead Times and Production Capacity

Clarify the supplier’s lead times and production capacity to ensure they can meet your project timelines. Understanding their production schedule will help you plan your supply chain effectively and avoid potential disruptions. Consider suppliers that offer flexibility in scaling production to accommodate future demands.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful partnership. Ensure that the supplier has established channels for ongoing communication, including dedicated account managers or project liaisons. Clear communication will facilitate quick problem resolution and ensure that any adjustments to your order are handled efficiently.

By following this checklist, B2B buyers can navigate the complexities of sourcing PEEK plastic molding services, ensuring they partner with suppliers capable of delivering high-quality, reliable products that align with their business needs.

Comprehensive Cost and Pricing Analysis for peek plastic molding Sourcing

What Are the Key Cost Components in PEEK Plastic Molding?

When sourcing PEEK plastic molding, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: PEEK resin is significantly more expensive than conventional thermoplastics due to its superior properties such as chemical resistance and high thermal stability. Prices can vary based on the grade of PEEK and market fluctuations. Typically, the material cost can represent up to 40-60% of the total production cost.

-

Labor: Skilled labor is essential for the precise handling and molding of PEEK, which can be challenging due to its processing requirements. Labor costs will depend on local wage standards and the complexity of the molding process, accounting for about 15-25% of total costs.

-

Manufacturing Overhead: This includes indirect costs such as utilities, maintenance of equipment, and depreciation. Overhead can contribute 10-20% to the overall cost, depending on the efficiency of the production facility.

-

Tooling: Tooling costs for PEEK molding can be substantial due to the need for specialized molds that can withstand high processing temperatures and pressures. Initial tooling investments can range from a few thousand to tens of thousands of dollars, depending on the complexity and size of the part.

-

Quality Control (QC): Given PEEK’s application in critical industries like aerospace and medical, rigorous QC measures are mandatory. This could add another 5-10% to the cost, factoring in testing and certification processes.

-

Logistics: Transporting PEEK components can be costly, especially for international shipping. Costs will vary based on distance, volume, and the chosen Incoterms. It’s crucial to factor these logistics costs into the total pricing.

-

Margin: Suppliers will typically include a profit margin of around 10-30% on top of the total cost, which can vary based on the supplier’s market position and the competitive landscape.

What Factors Influence Pricing for PEEK Plastic Molding?

Several factors can influence the pricing of PEEK plastic molding, particularly in international markets.

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs due to economies of scale. Minimum order quantities (MOQs) can vary by supplier, impacting pricing flexibility.

-

Specifications and Customization: Unique specifications or custom designs can increase costs due to the need for specialized tooling or processes. Buyers should clearly communicate their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Higher quality materials or those with specific certifications (e.g., FDA compliance) may come at a premium. Ensure that suppliers provide necessary documentation to justify these costs.

-

Supplier Factors: The supplier’s reputation, location, and capabilities can affect pricing. Established suppliers with proven track records may charge more but could offer better reliability and quality.

-

Incoterms: Choosing the right Incoterms can significantly impact the total cost, as they dictate the responsibilities for shipping, insurance, and tariffs. Buyers should be well-versed in these terms to avoid hidden costs.

What Are the Best Buyer Tips for Negotiating PEEK Plastic Molding Prices?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider the following strategies to maximize cost-efficiency:

-

Negotiate Terms: Engage in discussions to negotiate pricing based on volume commitments or long-term contracts, which can lead to favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial prices; consider the total cost of ownership, which includes maintenance, durability, and lifecycle costs of PEEK components.

-

Understand Pricing Nuances: Be aware of the specific pricing structures in different regions, as currency fluctuations and local market conditions can impact costs.

-

Leverage Multiple Quotes: Obtain quotes from multiple suppliers to compare prices and services. This competitive approach can help secure better deals.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing, priority service, and improved communication.

Disclaimer for Indicative Prices

Prices for PEEK plastic molding can vary widely based on numerous factors. Buyers are encouraged to obtain precise quotes from suppliers to ensure accurate budgeting and financial planning.

Alternatives Analysis: Comparing peek plastic molding With Other Solutions

Exploring Alternatives to PEEK Plastic Molding

In the world of advanced manufacturing, selecting the right material and method for plastic molding is crucial for achieving optimal performance and cost-effectiveness. PEEK plastic molding is renowned for its high strength, stiffness, and chemical resistance, making it a preferred choice in various demanding applications. However, there are alternative solutions that may better suit certain applications or budget constraints. This analysis compares PEEK plastic molding with two viable alternatives: Ultem (Polyetherimide) and traditional thermoplastics like ABS (Acrylonitrile Butadiene Styrene).

| Comparison Aspect | Peek Plastic Molding | Ultem (Polyetherimide) | Traditional Thermoplastics (ABS) |

|---|---|---|---|

| Performance | Excellent mechanical properties, high thermal stability, and chemical resistance | High thermal stability, good electrical properties, limited chemical resistance | Good impact resistance, lower thermal stability, and less chemical resistance |

| Cost | Higher material and processing costs | Moderate to high cost | Low material cost, widely available |

| Ease of Implementation | Requires specialized equipment and expertise | Requires specific processing conditions but generally easier than PEEK | Simple processing with standard equipment |

| Maintenance | Low maintenance if properly processed | Low maintenance if conditions are met | Moderate maintenance; prone to wear and tear |

| Best Use Case | Aerospace, medical devices, and oil & gas applications | Electronics, automotive, and industrial components | Consumer products, toys, and low-stress applications |

In-Depth Look at Alternatives

What are the Advantages and Disadvantages of Ultem (Polyetherimide)?

Ultem is a high-performance thermoplastic similar to PEEK but offers a slightly different set of properties. It is known for its high thermal stability and excellent electrical insulating properties, making it ideal for applications in the electronics and automotive sectors. However, Ultem does not match PEEK’s chemical resistance, which limits its use in environments exposed to aggressive chemicals. Additionally, while Ultem is easier to process than PEEK, it still requires careful handling to avoid defects during molding.

How Do Traditional Thermoplastics Like ABS Compare?

Traditional thermoplastics, such as ABS, are widely used due to their low cost and ease of processing. They offer good impact resistance and are suitable for a variety of applications, particularly in consumer goods and toys. However, ABS does not possess the high-temperature resistance or chemical stability of PEEK or Ultem, making it less suitable for demanding environments like aerospace or medical fields. Additionally, while the lower cost is appealing, the long-term durability and performance may not justify the initial savings in high-stress applications.

Making the Right Choice for Your Needs

When choosing between PEEK plastic molding and its alternatives, B2B buyers should consider several factors, including the specific application requirements, budget constraints, and processing capabilities. PEEK is unmatched for performance in high-stress environments, but if cost is a primary concern or the application does not require extreme properties, alternatives like Ultem or traditional thermoplastics may provide adequate performance at a lower price point. Assessing these factors will help buyers select the most suitable solution for their manufacturing needs.

Essential Technical Properties and Trade Terminology for peek plastic molding

What Are the Key Technical Properties of PEEK Plastic Molding?

Understanding the technical properties of PEEK (Polyether Ether Ketone) is crucial for B2B buyers, especially when evaluating its suitability for specific applications. Here are some essential specifications:

-

Material Grade

PEEK is available in various grades, including unfilled and filled versions. The choice of grade affects mechanical properties, thermal stability, and chemical resistance. For instance, Victrex PEEK 450G is known for its high strength and ductility, making it ideal for demanding environments like aerospace and medical applications. Selecting the correct grade ensures optimal performance and longevity of the final product. -

Tensile Strength

This property measures how much force a material can withstand while being stretched or pulled before breaking. PEEK typically exhibits a tensile strength of around 98 MPa, making it suitable for applications requiring high mechanical performance. Understanding tensile strength helps manufacturers design components that can endure operational stresses, reducing the risk of failure. -

Flexural Modulus

The flexural modulus indicates a material’s stiffness when subjected to bending. PEEK’s flexural modulus is approximately 3.8 GPa, which signifies its resistance to deformation. This property is vital for applications like gears and bearings, where maintaining shape under load is essential. -

Melting Point

PEEK has a high melting point of about 343°C, allowing it to maintain structural integrity in high-temperature environments. This makes it suitable for industries like aerospace, automotive, and oil and gas, where components are exposed to extreme conditions. Knowing the melting point is crucial for manufacturers to ensure that the material will perform adequately in its intended application. -

Drying Temperature and Time

Proper drying of PEEK granules is critical to prevent moisture-related defects during molding. The recommended drying conditions are typically 150°C for 3 hours or 120°C for 5 hours. This specification is essential for ensuring the quality of the molded parts, especially in high-performance applications where defects can compromise safety and functionality.

What Are Common Trade Terminology and Their Importance in PEEK Plastic Molding?

Familiarity with industry jargon is vital for effective communication and decision-making in the B2B sector. Here are several key terms related to PEEK plastic molding:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of PEEK molding, understanding OEM relationships can help buyers identify reliable suppliers and quality assurance practices, which are critical for maintaining product standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to plan their purchasing strategies and inventory management, especially when dealing with specialized materials like PEEK, which may not be readily available in small quantities. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price proposals from suppliers. It is a critical tool for buyers to compare costs and services when sourcing PEEK components. Understanding how to effectively prepare and respond to RFQs can lead to better pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers to understand shipping costs, risk management, and delivery timelines when importing PEEK products from different regions. -

Mold Shrinkage

This term refers to the reduction in size of a molded part as it cools and solidifies. PEEK typically exhibits about 1% shrinkage. Understanding mold shrinkage is important for accurate part dimensions and ensuring that the final product meets design specifications. -

Processing Temperature

This term indicates the temperature range required to mold PEEK effectively, typically between 350°C and 400°C. Knowledge of processing temperatures is essential for selecting appropriate machinery and ensuring the quality of the molded parts.

By grasping these properties and terms, B2B buyers can make informed decisions when sourcing PEEK plastic components, ensuring they meet their specific application requirements.

Navigating Market Dynamics and Sourcing Trends in the peek plastic molding Sector

What Are the Key Market Dynamics and Trends Affecting PEEK Plastic Molding?

The global market for PEEK plastic molding is experiencing significant growth, driven by increasing demand from industries such as aerospace, automotive, medical, and oil and gas. These sectors are seeking materials that can withstand extreme conditions, and PEEK’s exceptional mechanical properties, including high strength, thermal stability, and chemical resistance, make it an ideal choice. B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of several key trends influencing sourcing decisions.

One notable trend is the shift towards advanced manufacturing technologies, such as additive manufacturing and automation in injection molding processes. These technologies not only enhance production efficiency but also improve the precision and quality of PEEK components. Additionally, the rise of digital platforms for sourcing and supply chain management is making it easier for international buyers to connect with suppliers, compare prices, and access technical data.

Emerging markets, particularly in Africa and South America, are witnessing an uptick in the adoption of high-performance polymers like PEEK as industries modernize and seek to compete globally. This presents opportunities for B2B buyers to establish partnerships with local suppliers who can meet their specific needs. Furthermore, navigating trade regulations and tariffs will be crucial for international buyers, especially in the context of fluctuating geopolitical conditions.

How Does Sustainability Impact Sourcing in the PEEK Plastic Molding Sector?

Sustainability is becoming a critical consideration for B2B buyers in the PEEK plastic molding sector. The environmental impact of plastic production, including energy consumption and waste generation, is prompting companies to seek more sustainable practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint and employing ethical sourcing methods.

Ethical supply chains are essential, as they ensure that materials are obtained responsibly and contribute to social well-being. Buyers should look for suppliers who adhere to international environmental standards and possess certifications such as ISO 14001, which focuses on effective environmental management systems. Additionally, exploring options for recycled or bio-based PEEK materials can further enhance sustainability efforts.

Investing in green certifications and materials not only helps in complying with regulations but also appeals to environmentally conscious consumers. B2B buyers should engage with suppliers who can provide transparency regarding their sourcing practices and the lifecycle impact of their products. This proactive approach not only fosters brand loyalty but can also lead to long-term cost savings through efficient resource management.

What Is the Historical Context of PEEK Plastic Molding in B2B Markets?

PEEK (polyether ether ketone) was first developed in the 1970s and has since evolved into a crucial material in various high-performance applications. Initially utilized in aerospace and industrial sectors, its unique properties have expanded its use in medical devices, automotive components, and electronic applications. Over the decades, advancements in molding technologies and processing techniques have made PEEK more accessible and cost-effective for B2B buyers.

As industries continue to innovate, the demand for PEEK is likely to grow, driven by its ability to meet stringent performance requirements. The historical context of PEEK highlights its adaptability and the ongoing need for high-performance materials in increasingly demanding applications. Understanding this evolution can help international buyers appreciate the material’s capabilities and make informed sourcing decisions that align with their business objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of peek plastic molding

-

How do I solve issues with PEEK plastic molding defects?

To resolve defects in PEEK plastic molding, it’s crucial to analyze the injection molding process carefully. Common issues include improper drying of PEEK granules, inadequate temperature control, and contamination. Ensure PEEK is dried to less than 0.02% moisture content and maintain processing temperatures between 350-400°C. Additionally, keep all equipment clean to avoid contamination, and consider the size of the gates used in the mold—larger gates often help reduce defects by ensuring better material flow. -

What is the best application for PEEK plastic molding?

PEEK is ideal for applications in demanding industries such as aerospace, automotive, medical, and oil and gas due to its high strength, stiffness, and excellent chemical resistance. It is commonly used for manufacturing components like bearings, gears, surgical instruments, and manifolds. When selecting PEEK for your application, consider factors like temperature requirements, mechanical load, and exposure to chemicals to ensure optimal performance. -

What should I look for in a PEEK plastic molding supplier?

When vetting suppliers for PEEK plastic molding, assess their experience and specialization in high-performance thermoplastics. Review their production capabilities, quality assurance processes, and certifications relevant to your industry standards. It’s also beneficial to check customer testimonials and case studies. Additionally, inquire about their ability to customize solutions, including mold design and production volume, to meet your specific needs. -

What are the typical minimum order quantities (MOQs) for PEEK plastic molding?

Minimum order quantities for PEEK plastic molding can vary significantly based on the supplier and the complexity of the components. Generally, MOQs may range from a few hundred to several thousand units. It’s advisable to discuss your project requirements directly with suppliers to understand their MOQs, as many are willing to accommodate smaller orders for prototype runs or initial projects to build a long-term partnership. -

What payment terms should I expect when sourcing PEEK plastic molding?

Payment terms for PEEK plastic molding can vary based on the supplier’s policies and your business relationship. Common terms include net 30, net 60, or upfront payments for new customers. Some suppliers may offer discounts for early payments or bulk orders. Establishing a clear agreement regarding payment terms before placing an order is crucial to ensure mutual understanding and avoid potential disputes. -

How can I ensure quality assurance (QA) in PEEK plastic molding?

To ensure quality assurance in PEEK plastic molding, request detailed quality control processes from your supplier. These should include regular inspections during the production process, adherence to ISO standards, and documentation of material certifications. Consider asking for samples or conducting third-party audits to evaluate the supplier’s capabilities. Establishing a clear QA plan with specific metrics will help monitor product quality throughout the manufacturing process. -

What logistics considerations should I be aware of when sourcing PEEK plastic molding internationally?

When sourcing PEEK plastic molding internationally, consider logistics factors such as shipping costs, customs duties, and delivery times. Work with suppliers who have experience in international shipping and can provide guidance on documentation required for customs clearance. Additionally, evaluate shipping methods—air freight is faster but more expensive, while sea freight is cost-effective but slower. Planning for potential delays and maintaining clear communication with your supplier can help ensure timely delivery. -

What are the common challenges faced in PEEK plastic molding and how can they be mitigated?

Common challenges in PEEK plastic molding include material degradation, incorrect processing temperatures, and contamination. To mitigate these issues, ensure that your equipment is properly maintained and that the PEEK material is adequately dried before processing. Implement strict cleanliness protocols in the production area to prevent contamination, and monitor temperature control closely to avoid thermal degradation. Collaborating with experienced suppliers can also provide valuable insights into best practices for overcoming these challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Peek Plastic Molding Manufacturers & Suppliers List

1. Proto Labs – PEEK Injection Molding

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: PEEK Injection Molding offers high strength, stiffness, and chemical resistance. PEEK (poly ether ketone) is a high-performance thermoplastic that is FDA compliant for food contact and can be sterilized for medical applications. Key benefits include good strength and stiffness, high ductility, and chemical resistance. Material properties include: Tensile Strength (Yield) of 98 MPa, Tensile Elongat…

2. Ensinger – PEEK Plastic Injection Molding

Domain: ensingerplastics.com

Registered: 2015 (10 years)

Introduction: Ensinger is one of the largest PEEK processors globally, with over three decades of experience in PEEK plastic injection molding, producing more than 50 million components annually at four global production sites. They specialize in customized high-performance PEEK parts for various industries, including medical, aerospace, automotive, semiconductor, and electronics. Ensinger offers tailored PEEK …

3. Ensinger – PEEK Thermoplastic Solutions

Domain: ensinger-pc.com

Registered: 2015 (10 years)

Introduction: PEEK (Polyetheretherketone) is a high-performance thermoplastic used in medical and pharmaceutical applications. Key features include:

– Unreinforced grades offer high elongation and toughness.

– Excellent chemical and hydrolysis resistance, comparable to PPS, with higher temperature capabilities.

– V-O flammability rating allows continuous use up to 480°F in hot water/steam without loss of pro…

4. VEM Tooling – PEEK Solutions

Domain: vem-tooling.com

Registered: 2005 (20 years)

Introduction: PEEK (Polyether ether ketone) is a high-performance thermoplastic known for its versatility and mechanical properties. It is resistant to gamma radiation and sterilization processes like autoclaving, making it ideal for medical device manufacturing. PEEK is categorized into four major types: Natural PEEK (general-purpose, wear-resistant), GF30 PEEK (30% glass fiber, increased strength and stabilit…

5. Aline Components – PEEK Plastic Material

Domain: alinecomponents.com

Registered: 2000 (25 years)

Introduction: PEEK Plastic Material – High-performance, high-temperature thermoplastic. Excellent strength-to-weight characteristics. Maintains integrity at higher temperatures than other thermoplastics. Environmentally friendly alternative to metals. Used in applications like bearings, pistons, pumps, and gears. Offers corrosion resistance and durability. Aline Components provides custom injection molding serv…

6. Molding Dynamics – PEEK Solutions

Domain: moldingdynamics.net

Registered: 2004 (21 years)

Introduction: Polyetheretherketone (PEEK) is a versatile engineered thermoplastic material known for its strength and suitability as a metal replacement. Key characteristics include high heat resistance, low moisture absorption, high tensile strength, tolerance to gamma radiation, chemical resistance, fatigue and stress-crack resistance, creep resistance, and low levels of toxic gas emissions. PEEK can be reinf…

Strategic Sourcing Conclusion and Outlook for peek plastic molding

Why Is Strategic Sourcing Crucial for PEEK Plastic Molding?

In the rapidly evolving landscape of high-performance materials, strategic sourcing of PEEK (polyetheretherketone) offers significant competitive advantages for international B2B buyers. The exceptional mechanical properties, chemical resistance, and temperature stability of PEEK make it an ideal choice for applications across industries such as aerospace, medical, and energy. By investing in the right suppliers and technologies, businesses can enhance product quality, reduce lead times, and minimize costs.

How Can International Buyers Benefit from PEEK Plastic Molding?

For buyers from Africa, South America, the Middle East, and Europe, understanding the unique characteristics of PEEK and the specific requirements for successful injection molding is vital. Prioritizing equipment compatibility, material cleanliness, and optimal processing conditions will ensure the production of defect-free components that meet stringent industry standards. Emphasizing these factors can streamline production processes and foster long-term partnerships with reliable suppliers.

What’s Next for Your PEEK Sourcing Strategy?

As global demand for high-performance polymers continues to rise, now is the time to refine your sourcing strategies for PEEK plastic molding. Engage with suppliers who understand your market’s specific needs and are equipped to provide tailored solutions. By taking proactive steps today, your organization can secure a robust supply chain that not only meets current demands but is also prepared for future innovations in PEEK applications.