Introduction: Navigating the Global Market for pcbway cnc cost

In today’s competitive landscape, understanding the intricacies of PCBWay CNC costs is crucial for international B2B buyers. Sourcing precision components and assemblies can be a daunting task, particularly for businesses operating in regions like Africa, South America, the Middle East, and Europe, including markets such as Saudi Arabia and Vietnam. The challenge lies not only in identifying reliable suppliers but also in navigating the complexities of pricing structures, which can vary significantly based on materials, manufacturing processes, and project specifications.

This comprehensive guide delves into the multifaceted world of PCBWay CNC costs, offering insights into various types of CNC services, including milling and turning, as well as applications across industries such as automotive, medical, and electronics. We will explore essential factors that influence costs, such as material selection, complexity of designs, and production volume. Additionally, we will provide practical tips for vetting suppliers to ensure quality and reliability, empowering buyers to make informed purchasing decisions.

By equipping B2B buyers with actionable knowledge about PCBWay CNC costs, this guide aims to demystify the procurement process, enhance cost-effectiveness, and ultimately support businesses in achieving their production goals. Whether you are looking to streamline your supply chain or enhance product quality, understanding these elements will provide a competitive edge in the global market.

Understanding pcbway cnc cost Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard CNC Milling | Utilizes 3-axis and 4-axis milling; versatile materials | Prototyping, low-volume production | Pros: Cost-effective, quick turnaround; Cons: Limited complexity in designs. |

| CNC Turning | Focus on cylindrical parts; high precision | Automotive, aerospace components | Pros: Excellent for round parts; Cons: Generally higher costs for complex shapes. |

| 5-Axis CNC Machining | Multi-directional machining; complex geometries | Medical devices, intricate components | Pros: High accuracy, complex shapes; Cons: Higher cost and longer lead times. |

| CNC Sheet Metal Fabrication | Combines cutting, bending, and assembly | Industrial machinery, enclosures | Pros: Versatile, suitable for various applications; Cons: Requires more setup time. |

| Rapid Prototyping | Fast production of prototypes; flexible materials | Product development, testing | Pros: Speedy iterations, cost-effective for small runs; Cons: May lack durability for final products. |

What Are the Key Characteristics of Standard CNC Milling for B2B Buyers?

Standard CNC milling is characterized by its use of 3-axis and 4-axis machines, making it suitable for a wide range of materials, including metals and plastics. This type of machining is particularly effective for creating prototypes and low-volume production runs. B2B buyers benefit from its cost-effectiveness and quick turnaround times, though they should be aware that designs may be limited in complexity compared to more advanced machining options.

How Does CNC Turning Meet the Demands of Precision Manufacturing?

CNC turning specializes in producing cylindrical parts with high precision, often utilized in industries such as automotive and aerospace. This process is ideal for creating components like shafts and fittings. Buyers appreciate the accuracy and repeatability of CNC turning; however, they may face higher costs for complex shapes that require additional machining processes.

Why Choose 5-Axis CNC Machining for Complex Projects?

5-axis CNC machining allows for multi-directional machining, making it capable of producing highly intricate geometries. This is especially beneficial for industries such as medical devices, where precision is paramount. While 5-axis machining offers exceptional accuracy and the ability to create complex shapes, B2B buyers should consider the higher costs and longer lead times associated with this advanced technology.

What Advantages Does CNC Sheet Metal Fabrication Offer?

CNC sheet metal fabrication combines cutting, bending, and assembly processes, making it versatile for various applications, particularly in industrial machinery and enclosures. This method is advantageous for producing parts that require strength and durability. While it provides flexibility, buyers should be mindful of potential setup times that could impact project timelines.

How Does Rapid Prototyping Facilitate Product Development?

Rapid prototyping focuses on quickly producing prototypes using flexible materials, making it ideal for product development and testing. This method allows for speedy iterations, enabling businesses to refine their designs before moving to full-scale production. While it is cost-effective for small runs, buyers should consider that prototypes may not always possess the durability required for final products, which could affect long-term performance.

Key Industrial Applications of pcbway cnc cost

| Industry/Sector | Specific Application of pcbway cnc cost | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom precision parts for vehicle components | Enhances performance and safety through high-quality parts | Material specifications, certifications, and lead times |

| Aerospace & Aviation | Manufacturing of lightweight structural components | Reduces weight and increases efficiency of aircraft designs | Compliance with industry standards and quality assurance |

| Medical and Dental | Production of medical devices and equipment | Ensures reliability and precision in life-saving devices | Regulatory compliance, biocompatibility of materials |

| Consumer Electronics | Prototyping for new electronic devices | Accelerates product development and market entry | Design flexibility, rapid prototyping capabilities |

| Robotics | Components for robotic systems | Supports innovation and efficiency in automation processes | Customization options and scalability in production |

In the automotive sector, PCBWay’s CNC machining services are vital for producing custom precision parts such as engine components, chassis elements, and electronic housings. These parts are crucial for enhancing vehicle performance and safety. International buyers should focus on material specifications and certifications to ensure compliance with regional automotive standards, along with understanding lead times to synchronize with production schedules.

In aerospace and aviation, the demand for lightweight structural components has surged. CNC machining from PCBWay enables the production of intricate designs that contribute to weight reduction, thereby increasing fuel efficiency. Buyers in this sector need to ensure that their suppliers adhere to strict industry standards and have robust quality assurance processes in place to mitigate risks associated with component failure.

The medical and dental industries benefit significantly from PCBWay’s CNC capabilities, particularly in the production of precision medical devices and equipment. These components must meet stringent regulatory standards for reliability and biocompatibility. Buyers must prioritize sourcing from manufacturers that can demonstrate compliance with relevant certifications and offer transparency in their production processes to ensure safety and efficacy.

In the realm of consumer electronics, PCBWay’s CNC machining is essential for rapid prototyping of new electronic devices. This application allows businesses to accelerate product development cycles and achieve faster time-to-market. Companies should consider the design flexibility offered by PCBWay and the rapid turnaround times, which are crucial for maintaining competitive advantage in this fast-paced industry.

Lastly, in the robotics industry, PCBWay provides components that are integral to the development of advanced robotic systems. The precision and customization options available through CNC machining support innovations in automation and robotics. International buyers should evaluate the scalability of production and the ability of suppliers to meet specific design requirements, ensuring that they can keep pace with technological advancements in robotics.

3 Common User Pain Points for ‘pcbway cnc cost’ & Their Solutions

Scenario 1: Navigating Unpredictable CNC Cost Fluctuations

The Problem: B2B buyers often find themselves grappling with fluctuating costs associated with CNC machining services. This unpredictability can stem from various factors, including changes in material prices, labor costs, and even shipping expenses. For businesses in regions like Africa and South America, where economic instability can further complicate matters, having a clear understanding of CNC costs becomes vital for budgeting and project planning. The fear of unexpected expenses can hinder decision-making, causing delays in project timelines and impacting overall operational efficiency.

The Solution: To mitigate these cost fluctuations, buyers should leverage PCBWay’s online quoting tools, which allow for real-time pricing based on project specifications. By providing accurate details regarding materials, dimensions, and desired finishes, buyers can receive more reliable estimates. Additionally, establishing a long-term partnership with PCBWay can lead to negotiated rates or bulk discounts, providing stability in pricing. Engaging in regular communication with PCBWay representatives can also help buyers stay informed about potential price changes, enabling proactive financial planning.

Scenario 2: Understanding the Cost Breakdown of CNC Machining Services

The Problem: Many international B2B buyers struggle to comprehend the comprehensive breakdown of CNC machining costs, which can include factors such as material selection, machining complexity, and finishing processes. This lack of clarity can lead to misinformed decisions, where buyers may overlook essential aspects that could affect the quality and functionality of their products. Particularly in competitive markets, understanding these cost components is crucial for ensuring that budget allocations are appropriately managed.

The Solution: Buyers should request detailed quotes from PCBWay that clearly outline the cost components involved in their CNC machining projects. This can include line-item costs for materials, labor, and any additional services such as assembly or finishing. By doing so, buyers can gain insights into which aspects of the project may be driving up costs and make informed decisions about where to adjust specifications to stay within budget. Moreover, utilizing PCBWay’s resources, such as their FAQ sections and customer support, can provide further clarity on how to optimize designs for cost efficiency without compromising quality.

Scenario 3: Overcoming Shipping Costs and Delivery Time Challenges

The Problem: For international buyers, shipping costs and delivery timelines can pose significant challenges when sourcing CNC machined parts from PCBWay. Unexpected shipping fees can arise from customs duties or changes in shipping rates, and lengthy delivery times can lead to project delays. This is particularly problematic for businesses in regions like the Middle East and Europe, where timely product launches are critical for maintaining competitive advantage.

The Solution: To address these challenges, buyers should consider implementing a logistics strategy that includes detailed planning and contingency measures. This can involve selecting shipping options that provide the best balance between cost and delivery speed, potentially opting for consolidated shipments to reduce expenses. Additionally, buyers can engage with PCBWay’s logistics team to explore expedited shipping options or to understand regional customs requirements better. By establishing a clear timeline and maintaining open lines of communication with PCBWay, buyers can better anticipate costs and delivery times, ultimately leading to smoother project execution and enhanced satisfaction with the CNC machining process.

Strategic Material Selection Guide for pcbway cnc cost

What Are the Key Properties of Common Materials Used in PCBWay CNC Machining?

When selecting materials for CNC machining with PCBWay, it is essential to understand the properties and suitability of each option. Here, we analyze four common materials used in CNC applications, focusing on their performance characteristics, advantages and disadvantages, and considerations for international B2B buyers.

1. Aluminum

Key Properties: Aluminum is lightweight yet strong, with excellent thermal conductivity and corrosion resistance. It can withstand moderate temperatures, making it suitable for various applications.

Pros & Cons: The primary advantage of aluminum is its favorable strength-to-weight ratio, which allows for reduced overall product weight without sacrificing durability. However, it can be more expensive than other materials like plastics and may require specialized machining techniques to achieve precise finishes.

Impact on Application: Aluminum is widely used in automotive and aerospace applications due to its lightweight nature and ability to withstand environmental stressors. Its compatibility with various coatings also enhances its usability in different media.

Considerations for International Buyers: Buyers from regions like the Middle East and Europe should ensure compliance with local standards, such as ASTM or DIN, particularly for aerospace and automotive components.

2. Stainless Steel

Key Properties: Stainless steel is known for its high strength, durability, and excellent corrosion resistance, particularly in harsh environments. It can withstand high temperatures and pressure, making it suitable for demanding applications.

Pros & Cons: The main advantage of stainless steel is its longevity and resistance to rust and corrosion. However, it is heavier than aluminum and generally more costly, which can impact budget considerations for projects.

Impact on Application: This material is ideal for medical devices, industrial machinery, and food processing equipment, where hygiene and durability are critical.

Considerations for International Buyers: Compliance with health and safety standards is crucial, particularly for buyers in the medical and food industries. Understanding the specific grades of stainless steel required for different applications is also essential.

3. POM (Polyoxymethylene)

Key Properties: POM, also known as acetal, is a high-performance engineering plastic known for its excellent dimensional stability, low friction, and high wear resistance. It can operate effectively within a temperature range of -40°C to 100°C.

Pros & Cons: POM is lightweight and cost-effective, making it an attractive option for various applications. However, it is less suitable for high-temperature environments and can be less durable than metals.

Impact on Application: POM is commonly used in precision parts, gears, and automotive components, where low friction and high wear resistance are necessary.

Considerations for International Buyers: Buyers should be aware of the different grades of POM and their specific applications. Ensuring compliance with local environmental regulations regarding plastic materials is also vital.

4. FR4 (Fiberglass Reinforced Epoxy)

Key Properties: FR4 is a composite material made of woven fiberglass cloth and epoxy resin. It has excellent electrical insulation properties, high mechanical strength, and good thermal stability.

Pros & Cons: The primary advantage of FR4 is its excellent electrical insulating properties, making it ideal for PCB applications. However, it can be more brittle than metals, which may limit its use in high-stress applications.

Impact on Application: FR4 is predominantly used in electronics and electrical applications, including circuit boards and insulation components.

Considerations for International Buyers: Buyers should ensure compliance with international standards for electrical materials, such as UL certification, particularly in regions with strict safety regulations.

Summary Table of Material Selection for PCBWay CNC Cost

| Material | Typical Use Case for pcbway cnc cost | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace, automotive components | Lightweight and strong | Higher cost and machining complexity | Medium |

| Stainless Steel | Medical devices, industrial machinery | Excellent corrosion resistance | Heavier and generally more costly | High |

| POM | Precision parts, gears | Low friction and cost-effective | Less durable in high temperatures | Low |

| FR4 | Electronics, circuit boards | Excellent electrical insulation | Brittle under stress | Medium |

Understanding the properties, advantages, and limitations of these materials will enable B2B buyers to make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pcbway cnc cost

What Are the Key Stages in PCBWay’s CNC Manufacturing Process?

Understanding the CNC manufacturing process at PCBWay is vital for international B2B buyers looking to optimize their procurement strategies. The manufacturing process typically involves several stages: material preparation, forming, assembly, and finishing.

Material Preparation

The first step involves selecting the right materials for the CNC machining process. PCBWay offers a variety of materials, including metals like aluminum and stainless steel, as well as engineering plastics like POM and nylon. This stage includes verifying the material specifications to ensure they meet the project requirements. Suppliers often use advanced tools to analyze material properties and ensure consistency.

Forming

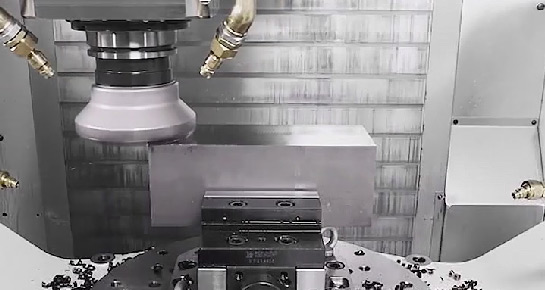

During the forming stage, CNC machines utilize various techniques such as milling, turning, and drilling to create the desired shapes and features of the components. PCBWay employs 3-axis, 4-axis, and full 5-axis machining capabilities, which allows for complex geometries and high precision. The choice of machining technique is determined by the design specifications and the material being used. This stage is critical for achieving the desired tolerances and surface finishes.

Assembly

In the assembly phase, components are put together to form the final product. PCBWay offers various assembly services, including through-hole and surface mount technology (SMT) assembly. This stage may involve the integration of different components, including PCBs, which are often assembled in conjunction with CNC machined parts. Proper assembly is crucial to ensure functionality and reliability, especially for applications in sectors like automotive and aerospace.

Finishing

Finally, the finishing stage includes surface treatments and coatings that enhance the appearance and durability of the parts. PCBWay provides a range of finishing options, including anodizing, painting, and bead blasting. This step not only improves aesthetics but also adds functional properties, such as corrosion resistance. The choice of finishing technique is often dictated by the end-use of the product.

How Does PCBWay Ensure Quality Control Throughout the Manufacturing Process?

Quality assurance is a cornerstone of PCBWay’s CNC manufacturing process, ensuring that products meet international standards and client expectations. B2B buyers must understand the various quality control mechanisms in place.

Relevant International Standards

PCBWay adheres to ISO 9001, a widely recognized standard for quality management systems. Compliance with this standard ensures that the manufacturing processes are efficient and that products are consistently produced to meet customer requirements. Additionally, industry-specific certifications like CE and API are relevant for buyers in sectors such as medical, aerospace, and automotive.

Quality Control Checkpoints

Quality control is conducted at several checkpoints throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to verify they meet specified requirements.

- In-Process Quality Control (IPQC): Continuous monitoring is carried out during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A comprehensive inspection is performed on finished products before they are dispatched to clients.

Each checkpoint is designed to identify potential issues, ensuring that only products that meet quality standards are delivered.

Common Testing Methods

PCBWay employs various testing methods to validate product quality, including:

- Automated Optical Inspection (AOI): Used to check for defects in soldering and component placement.

- Electrical Testing: Ensures that the electrical performance of the assembled PCBs meets specifications.

- X-ray Inspection: Utilized for complex assemblies to verify hidden solder joints and connections.

- Impedance Control Testing: Particularly important for high-frequency applications.

These methods not only help in maintaining quality but also in building trust with international clients.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers like PCBWay is essential to mitigate risks.

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. Buyers should request documentation of previous audits and any corrective actions taken. An on-site visit can also provide a firsthand view of the operational environment and quality practices.

Requesting Quality Reports

Buyers should ask for detailed quality assurance reports, including inspection and testing results. These reports should outline the methodologies used and any deviations from expected standards. This transparency helps in assessing the reliability of the supplier’s quality control processes.

Utilizing Third-party Inspection Services

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These services can conduct inspections at various stages of production and provide a comprehensive report to the buyer. This is particularly useful for buyers who may not be able to travel to the supplier’s location.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control in an international context is crucial for B2B buyers. Different regions may have varying standards and expectations regarding quality.

Cultural and Regulatory Differences

Buyers must be aware of the cultural and regulatory differences that may affect quality standards. For instance, European buyers may have stricter regulations compared to those in Africa or South America. Understanding these differences is vital for aligning expectations and ensuring compliance.

Language Barriers and Communication

Effective communication is essential for ensuring that quality standards are understood and met. Language barriers can complicate this process, making it important for buyers to establish clear lines of communication with suppliers. Utilizing professional translators or bilingual staff can help mitigate misunderstandings.

Leveraging Technology for Quality Assurance

Technology can play a significant role in enhancing quality control. Buyers can utilize digital platforms for real-time tracking of production processes and quality metrics. This not only helps in monitoring supplier performance but also fosters transparency.

By understanding the manufacturing processes and quality assurance practices at PCBWay, B2B buyers can make informed decisions that enhance their procurement strategies and ensure product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pcbway cnc cost’

To effectively navigate the procurement process for PCBWay CNC services, this checklist will guide you through essential steps that ensure you secure the best value and quality for your investment.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your project requirements. This includes dimensions, tolerances, material types, and any specific features necessary for your CNC machined parts. Having precise specifications helps suppliers provide accurate quotes and reduces the likelihood of errors during production.

Step 2: Research PCBWay’s CNC Capabilities

Investigate the range of CNC machining services offered by PCBWay. Familiarize yourself with their capabilities in milling, turning, and materials used, such as aluminum or stainless steel. Understanding their strengths allows you to align your project needs with their expertise, ensuring optimal results.

Step 3: Obtain Detailed Quotes

Request detailed quotes from PCBWay, ensuring they include a breakdown of costs associated with materials, labor, and additional services like assembly or finishing. Compare these quotes with those from other suppliers to gauge competitiveness. Pay attention to any hidden fees that may affect your overall budget.

Step 4: Evaluate Lead Times and Production Schedules

Discuss estimated lead times for your project with PCBWay. Understanding their production capacity and timelines is crucial for planning your project milestones. Ensure they can meet your deadlines without compromising quality, as delays can impact your supply chain and project deliverables.

Step 5: Verify Quality Assurance Processes

Inquire about PCBWay’s quality control measures. Look for certifications such as ISO 9001 or specific industry standards relevant to your sector. A robust quality assurance process ensures that the parts produced meet your specifications and function as intended.

Step 6: Assess Communication and Support Services

Evaluate the level of customer support PCBWay offers. Effective communication is vital for addressing any concerns or adjustments during the manufacturing process. Ensure they have responsive support channels, such as online chat or dedicated account managers, to facilitate smooth interactions.

Step 7: Review Customer Feedback and Case Studies

Research customer reviews and case studies related to PCBWay’s CNC machining services. This feedback provides insights into their reliability, product quality, and customer satisfaction. Engaging with previous clients can also reveal valuable information about potential challenges or advantages in working with them.

By following this checklist, you can streamline your sourcing process and enhance your chances of selecting the right CNC machining partner for your needs.

Comprehensive Cost and Pricing Analysis for pcbway cnc cost Sourcing

What Are the Key Cost Components in PCBWay CNC Pricing?

When evaluating PCBWay’s CNC machining costs, several critical components contribute to the overall pricing structure. These include:

-

Materials: The choice of materials significantly impacts cost. Common options like aluminum and stainless steel tend to be more affordable, whereas specialized materials such as titanium or engineering-grade plastics can escalate expenses.

-

Labor: Skilled labor is essential in CNC machining. The labor cost typically reflects the complexity of the machining processes and the expertise required, particularly for custom projects.

-

Manufacturing Overhead: This encompasses costs associated with running machinery, facility expenses, and utility costs. Efficient operations can lead to lower overhead, which can be beneficial for pricing.

-

Tooling: Tooling costs can vary based on the complexity of the design. Custom tooling or modifications may incur additional charges, while standard tools can help keep costs manageable.

-

Quality Control (QC): Ensuring high-quality output often requires additional inspection and testing processes, which can add to the overall cost. Certifications and compliance with industry standards further influence QC expenses.

-

Logistics: Shipping costs, which can vary based on the destination and shipping method, are crucial for international buyers. The choice of Incoterms can also affect logistics costs, impacting the final price.

-

Margin: Suppliers typically factor in a profit margin on top of their costs, which varies based on market demand and competitive pricing.

How Do Price Influencers Affect PCBWay CNC Costs?

Several factors influence the pricing of CNC machining services at PCBWay:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to reduced per-unit costs. Understanding the MOQ can help buyers optimize their orders to achieve better pricing.

-

Specifications and Customization: Custom designs with intricate specifications generally incur higher costs. Simpler designs may benefit from standardized pricing, making them more cost-effective.

-

Material Selection: The choice of materials not only influences the price but also impacts production time and quality. Evaluating alternatives can lead to significant savings.

-

Quality and Certifications: Buyers requiring specific certifications (e.g., ISO compliance) may face higher costs due to the additional processes involved in meeting these standards.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers like PCBWay may charge a premium for their recognized quality and service.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is vital for cost management. Different terms can lead to significant variations in total landed costs.

What Buyer Tips Can Help Optimize PCBWay CNC Costs?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance cost-efficiency:

-

Negotiate Effectively: Engage in discussions about pricing, especially for larger orders. Many suppliers are open to negotiation, particularly if they see potential for long-term business.

-

Assess Total Cost of Ownership (TCO): Look beyond initial costs. Consider factors such as shipping, potential tariffs, and the long-term durability of the product, which can influence overall expenses.

-

Leverage Bulk Orders: If feasible, consolidate orders to take advantage of economies of scale. This can significantly reduce per-unit costs.

-

Evaluate Alternative Materials: Explore various material options that meet your project requirements but may be more cost-effective.

-

Stay Informed on Pricing Trends: Keep abreast of market trends affecting CNC machining costs, including fluctuations in material prices and labor rates, which can aid in timing your purchases effectively.

Conclusion

Understanding the intricate cost structure and pricing dynamics of PCBWay’s CNC machining services is essential for B2B buyers aiming to make informed purchasing decisions. By considering the outlined cost components, price influencers, and strategic buyer tips, businesses can optimize their sourcing strategies and achieve better value in their CNC projects. Note that the prices mentioned are indicative and may vary based on specific project requirements and market conditions.

Alternatives Analysis: Comparing pcbway cnc cost With Other Solutions

Exploring Alternative Solutions to PCBWay CNC Cost

In the realm of CNC machining, businesses often seek the most efficient and cost-effective solutions for their manufacturing needs. While PCBWay offers competitive pricing and a wide range of services, exploring alternatives can provide valuable insights into achieving the best results for specific projects. Below, we compare PCBWay CNC cost against two viable alternatives: traditional CNC machining services and 3D printing technologies.

| Comparison Aspect | Pcbway Cnc Cost | Traditional CNC Machining | 3D Printing |

|---|---|---|---|

| Performance | High precision; 3-5 axis | Very high precision; 3-5 axis | Varies by technology; generally lower than CNC |

| Cost | $257 – $334 per project | $300 – $500 per project | $100 – $300 per project |

| Ease of Implementation | User-friendly online quoting | Requires direct interaction and quotes | Generally straightforward, with online services available |

| Maintenance | Low maintenance | Moderate; requires skilled operators | Low; less mechanical wear |

| Best Use Case | Prototyping & small batches | Large-scale production & complex parts | Rapid prototyping & design iterations |

Detailed Breakdown of Alternatives

Traditional CNC Machining

Traditional CNC machining often involves more manual oversight and direct interaction with service providers. This method excels in producing high-precision components, particularly for complex geometries that require tight tolerances. However, it can be more expensive, with project costs ranging from $300 to $500, depending on the complexity and materials used. The need for skilled operators can also complicate the implementation process, potentially leading to longer lead times. While it is ideal for large-scale production, businesses may find it less flexible for rapid prototyping compared to PCBWay.

3D Printing

3D printing technology offers a distinct advantage in terms of cost-effectiveness, with projects typically ranging from $100 to $300. This method is particularly advantageous for rapid prototyping, allowing for quick design iterations without the need for expensive tooling. However, the performance can vary significantly based on the 3D printing technology used; for instance, FDM (Fused Deposition Modeling) may not provide the same level of precision as CNC machining. Additionally, while 3D printing reduces mechanical wear and maintenance requirements, it may not be suitable for high-stress applications or parts requiring specific mechanical properties.

Conclusion: Choosing the Right Solution for Your B2B Needs

For B2B buyers, selecting the right manufacturing solution depends on a variety of factors, including budget, project scale, and desired precision. PCBWay’s CNC services are particularly well-suited for businesses looking for a balance between cost and quality, especially for prototyping and small batch production. However, for those requiring high precision for complex designs, traditional CNC machining may be the better option despite its higher costs. On the other hand, for rapid prototyping and iterative design processes, 3D printing offers a cost-effective and flexible alternative. Ultimately, understanding these alternatives allows businesses to make informed decisions tailored to their specific manufacturing requirements.

Essential Technical Properties and Trade Terminology for pcbway cnc cost

Understanding the essential technical properties and trade terminology associated with PCBWay’s CNC machining costs is vital for international B2B buyers. This knowledge not only aids in cost estimation but also enhances communication with suppliers, ensuring that buyers receive the best value for their investments.

What Are the Key Technical Properties Influencing PCBWay CNC Costs?

-

Material Grade

– The choice of material significantly affects the cost of CNC machining. Common materials include aluminum, stainless steel, and various plastics. Each material has different mechanical properties, costs, and suitability for specific applications. For instance, aluminum is often favored for its lightweight and excellent machinability, while stainless steel is chosen for its strength and corrosion resistance. Understanding the material requirements is crucial for selecting the right option that aligns with project budgets and performance expectations. -

Tolerance

– Tolerance refers to the allowable deviation from specified dimensions. In CNC machining, tighter tolerances often lead to higher costs due to the increased precision required during manufacturing. Typical tolerances can range from ±0.1 mm to ±0.005 mm. For B2B buyers, knowing the required tolerance levels is essential, as it directly impacts both the price and the functionality of the final product. Striking a balance between necessary precision and cost-efficiency is key. -

Surface Finish

– The surface finish is another critical property that influences CNC machining costs. Different finishes, such as anodizing, bead blasting, or painting, can enhance aesthetics and corrosion resistance but also add to the overall expense. Buyers should evaluate whether a specific finish is necessary for their application or if a standard finish suffices, allowing for cost savings without compromising quality. -

Quantity and Complexity

– The complexity of the design and the quantity of parts required play a significant role in determining costs. More complex geometries may require advanced machining techniques or longer processing times, increasing labor and material costs. Additionally, larger order quantities can lead to economies of scale, reducing the per-unit cost. Buyers should assess their needs carefully to optimize both design and order size for cost-effectiveness. -

Lead Time

– Lead time refers to the time required from order placement to delivery. Shorter lead times often come at a premium, as they may require expedited processing and resources. Understanding the trade-off between lead time and cost is crucial for B2B buyers, especially when timing is critical for project deadlines.

What Are the Common Trade Terms Related to PCBWay CNC Costs?

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts or equipment that may be marketed by another company. In the context of CNC machining, OEMs often work with suppliers like PCBWay to fabricate components that are part of larger systems. Understanding OEM relationships can help buyers navigate sourcing and pricing strategies effectively. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects both inventory management and cash flow. Knowing the MOQ can help buyers plan their purchases and avoid excess inventory costs. -

RFQ (Request for Quotation)

– An RFQ is a document used to invite suppliers to bid on specific products or services. For CNC machining, submitting an RFQ to PCBWay allows buyers to receive detailed quotes based on their project specifications, enabling informed decision-making. -

Incoterms (International Commercial Terms)

– Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify shipping, insurance, and tariffs, which can significantly impact overall costs. Familiarity with Incoterms can help buyers manage logistics and avoid unexpected expenses. -

CNC (Computer Numerical Control)

– CNC technology automates the control of machining tools via computer programming. Understanding CNC processes and capabilities helps buyers appreciate the complexity and precision available, ultimately influencing their design choices and budget considerations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing CNC machining services from PCBWay, ensuring they optimize their costs while meeting project requirements.

Navigating Market Dynamics and Sourcing Trends in the pcbway cnc cost Sector

What Are the Current Market Dynamics and Key Trends Affecting PCBWay CNC Costs?

The global landscape for CNC machining is rapidly evolving, driven by technological advancements and increasing demand for precision manufacturing. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can provide competitive pricing without compromising quality. Key trends include the rise of online CNC machining services that offer instant quotes, enabling buyers to make faster procurement decisions. The use of advanced materials, such as aluminum and high-performance plastics, is also on the rise, as manufacturers look to enhance product durability and performance.

Moreover, the emergence of Industry 4.0 technologies, including automation and data analytics, is transforming how CNC machining services operate. These technologies not only optimize production efficiency but also allow for real-time tracking of costs, leading to more transparent pricing models. As international trade barriers are gradually reduced, B2B buyers are exploring sourcing from a wider array of suppliers, including those in emerging markets. This diversification not only mitigates risks but also allows for cost comparisons that can lead to more favorable pricing.

How Can Sustainability and Ethical Sourcing Influence PCBWay CNC Costs?

As businesses worldwide become more environmentally conscious, sustainability is becoming a pivotal factor in sourcing decisions. B2B buyers are increasingly evaluating suppliers based on their environmental impact and commitment to ethical practices. For the PCBWay CNC cost sector, this translates into a demand for eco-friendly materials and processes. Buyers are keen to partner with manufacturers who utilize ‘green’ certifications and demonstrate compliance with sustainability standards.

The choice of materials plays a crucial role in this context. Suppliers that offer recyclable or biodegradable options can significantly enhance their appeal to eco-conscious buyers. Moreover, ethical sourcing practices, such as fair labor conditions and transparent supply chains, are becoming critical considerations. By prioritizing sustainability, companies not only reduce their ecological footprint but also strengthen their brand reputation, making them more attractive to potential clients. This shift toward sustainability can lead to an initial increase in costs; however, the long-term benefits, including customer loyalty and market differentiation, often outweigh these initial investments.

What Is the Evolution of CNC Machining and Its Relevance for B2B Buyers?

The history of CNC machining dates back to the 1950s when the first numerical control machines were developed. This technology has since evolved dramatically, transitioning from simple automated tools to sophisticated multi-axis machines capable of intricate designs. For B2B buyers, understanding this evolution is crucial as it highlights the increasing precision and efficiency that modern CNC machining offers.

Today, CNC machining is a cornerstone in various industries, including automotive, aerospace, and consumer electronics. The advent of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software has further revolutionized the process, allowing for rapid prototyping and shorter lead times. These advancements mean that B2B buyers can expect not only high-quality products but also a faster turnaround, which is essential in today’s fast-paced market. As international markets continue to expand, the importance of leveraging advanced CNC machining capabilities will only grow, making it a vital consideration for businesses looking to stay competitive.

In summary, as the PCBWay CNC cost sector evolves, B2B buyers must navigate these market dynamics while aligning their sourcing strategies with sustainability practices and technological advancements. Understanding these factors will enable them to make informed decisions that ultimately enhance their operational efficiency and product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of pcbway cnc cost

-

How do I calculate the total cost of CNC machining with PCBWay?

To calculate the total cost of CNC machining with PCBWay, consider factors such as material type, complexity of the design, size of the part, and finishing options. Use PCBWay’s online quoting tool to input your specifications, which will provide an instant estimate. Additionally, consider shipping costs, which may vary based on your location in Africa, South America, the Middle East, or Europe. Always account for potential tariffs or customs fees that may apply to international shipments. -

What materials are available for CNC machining at PCBWay?

PCBWay offers a wide range of materials for CNC machining, including various metals like aluminum, stainless steel, and brass, as well as plastics such as ABS, nylon, and PTFE. The choice of material affects not only the cost but also the properties of the final product, such as strength, weight, and durability. For specific applications, ensure you select a material that meets industry standards and requirements for your target market. -

What are the minimum order quantities (MOQs) for CNC machining at PCBWay?

PCBWay typically does not enforce strict minimum order quantities for CNC machining, allowing for flexibility in orders. However, larger quantities can lead to cost savings per unit due to economies of scale. If you require a small batch for prototyping, PCBWay is equipped to handle those needs, making it suitable for startups and businesses testing new designs before mass production. -

What payment terms does PCBWay offer for international buyers?

PCBWay provides several payment options, including credit cards, PayPal, and bank transfers. For international buyers, it is essential to confirm the accepted payment methods, as some may incur additional fees or exchange rates. Generally, a deposit may be required before production, with the balance due upon completion. Always discuss payment terms upfront to avoid any misunderstandings during the transaction. -

How does PCBWay ensure quality assurance in CNC machining?

PCBWay implements a comprehensive quality assurance process that includes design rule checks, automated optical inspection (AOI), and rigorous testing protocols. Each project undergoes a quality control review before shipment, ensuring that parts meet specified tolerances and standards. International buyers should inquire about specific QA measures relevant to their industry, especially for sectors like aerospace or medical, where compliance is critical. -

What shipping options are available for international orders from PCBWay?

PCBWay offers various shipping methods for international orders, including express options like DHL, FedEx, and UPS, as well as standard shipping services. Delivery times and costs will vary based on the chosen method and destination. For buyers in Africa, South America, the Middle East, or Europe, it is advisable to select a shipping option that balances speed and cost-effectiveness, considering any potential customs delays. -

Can I customize my CNC machining order with PCBWay?

Yes, PCBWay allows for extensive customization of CNC machining orders, including design modifications, material selection, and finishing options. When placing an order, provide detailed specifications and any CAD files to ensure accurate production. Collaborating with PCBWay’s engineering team can further refine your design to meet specific functionality or aesthetic requirements, which is particularly beneficial for unique projects or niche markets. -

How do I vet PCBWay as a reliable supplier for CNC machining?

To vet PCBWay as a reliable supplier, consider reviewing their certifications, customer testimonials, and case studies relevant to your industry. Additionally, inquire about their manufacturing capabilities, lead times, and experience with international shipping. Engaging in direct communication with their customer service can also provide insights into their responsiveness and willingness to support your specific needs, ensuring they align with your business standards and expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Pcbway Cnc Cost Manufacturers & Suppliers List

1. CNC Machining – Cost-Effective Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: CNC machining services for steel plates; initial quote of 70 USD raised to over 300 USD after manual review and shipping costs; looking for cheaper alternatives; components include linear rails and ballscrews; suggestions for temporary plates using plywood or 3D printing; consideration of laser/water cutting for cost savings; inquiry about local makerspaces or manual mills for one-off parts; menti…

2. PCBWay – Coaxial Hotend Assembly

Domain: hackaday.io

Registered: 2014 (11 years)

Introduction: PCBWay CNC fabrication costs range from USD $257.69 to $334.08 depending on the specifications. The project involves creating a coaxial hotend assembly, with quotes provided for different configurations: $334.08 for a complete assembly, $277.52 for the main block without assembly, and $257.69 for an aluminum version. The project also considers the addition of components costing approximately £70 (…

3. PCBWay – CNC Machining Services

Domain: lets-talk-about.tech

Registered: 2020 (5 years)

Introduction: PCBWay offers CNC machining services, specializing in creating parts from various materials, including aluminum. They support file formats such as .step, *.stp, *.x_t, *.iges, and *.sldprt for CNC milling. Customers can choose from about 25 surface finish options, with anodized blue being one of the choices. The typical build time for aluminum parts is 13-15 days, and PCBWay processes 2100 orders …

4. EEVBlog – CNC Machining Services

Domain: eevblog.com

Registered: 2009 (16 years)

Introduction: CNC machining service for private projects, primarily for metal parts, often CNC milled. Users have experience with PCBway, noting satisfaction with quality but high shipping costs (around $35 to Europe). A recent order included a shaft made of mild steel, 25mm diameter, 102mm length, weighing 370g, costing $48 each (ordered 2). Alternative services mentioned include China-machining.com ($29 per p…

5. AnyPCBA – Key Cost Factors

Domain: anypcba.com

Registered: 2023 (2 years)

Introduction: Key factors influencing PCBWay cost include board dimensions, layer count, material choices, surface finish, via types and density, solder mask and silkscreen, and minimum trace and spacing widths. PCBWay’s prototype pricing structure is designed for initial design iterations, with costs affected by quantity, board dimensions, layer count, material type, surface finish, copper weight, solder mask …

6. JLCPCB – CNC Machining Service

Domain: circuits-diy.com

Registered: 2019 (6 years)

Introduction: JLCPCB’s CNC Machining Service: 1. Precision and Accuracy: ±0.05 mm tolerance. 2. Material Variety: Metals (aluminum, copper, stainless steel) and plastics. 3. Integration with PCB Services: Combines CNC machining with PCB manufacturing. 4. Low-Cost Options: Affordable for prototypes and low-volume production. 5. Extensive CNC Machining Capabilities: Maximum part size of 1000800550 mm. 6. Superior…

7. Seeed Studio – PCB Manufacturing & Assembly

Domain: seeedstudio.com

Registered: 2008 (17 years)

Introduction: This company, Seeed Studio – PCB Manufacturing & Assembly, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. PDI – PCB-50 CNC Milling Prototyping System

Domain: pdi3d.com

Registered: 2008 (17 years)

Introduction: {“Product Name”: “PC Board CNC Milling Prototyping System”, “Model”: “PCB-50”, “Retail Price”: “$13,995.00”, “Sale Price”: “$11,495.00”, “Lease Price”: “$240/month”, “Availability”: “In Stock”, “Key Features”: [“Automated PC Board CNC Milling System”, “Unattended Operation with Automatic Tool Changer”, “Automatic Tool Measurement”, “Automatic Tool Breakage Sensing”, “Advanced Surface Detection”, “…

Strategic Sourcing Conclusion and Outlook for pcbway cnc cost

In the dynamic landscape of CNC machining, understanding the cost structure at PCBWay provides significant strategic advantages for international B2B buyers. The typical CNC machining costs range from approximately $257 to $334, influenced by factors such as material choice, complexity, and additional services like assembly. This insight allows companies to better budget their projects and negotiate effectively, ensuring they receive optimal value for their investment.

Strategic sourcing is essential for businesses aiming to enhance operational efficiency and reduce costs. By leveraging PCBWay’s competitive pricing and extensive capabilities, buyers from regions such as Africa, South America, the Middle East, and Europe can access high-quality manufacturing solutions tailored to their specific needs.

Looking ahead, the demand for precision engineering and rapid prototyping is poised to grow, making it crucial for businesses to stay ahead of market trends. International buyers are encouraged to engage with PCBWay’s services, explore customized solutions, and take advantage of the latest technologies in CNC machining. Embrace this opportunity to streamline your supply chain and enhance your product offerings in a rapidly evolving global market.