Guide Contents

Project Insight: Passivating Stainless Steel

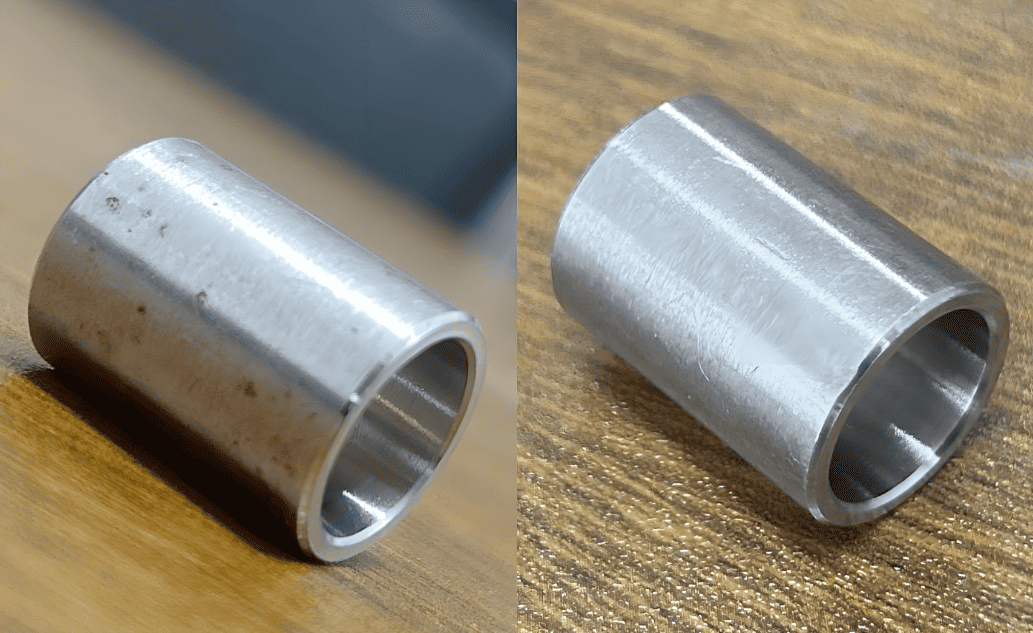

Manufacturing Insight: Passivating Stainless Steel

In product development, speed and precision aren’t just goals—they’re survival factors. For stainless steel components, passivation is the critical step that transforms raw parts into corrosion-resistant assets. But inconsistent processing can lead to premature failure, costly rework, and delayed launches. At Honyo Prototype, we’ve redefined this process through our digital manufacturing ecosystem—where AI-driven precision meets rapid turnaround to accelerate your path to market.

Why Precision Matters in Passivation

Incorrect acid concentration (20–50% nitric) or temperature (140–160°F) leaves passive layers incomplete, crippling corrosion resistance.

Overlooked pre-cleaning steps introduce surface contaminants that sabotage passivation effectiveness—especially critical for parts exposed to harsh environments (e.g., 800°C reducing furnaces).

Material-specific parameters (304 vs. 316 stainless) demand exact calibration. Manual processes risk human error, while inconsistent results compromise product longevity.

Speed as a Competitive Edge

Hardware startups face 6–8 week delays from traditional passivation outsourcing—derailing launch timelines and market opportunities.

Every day of prototyping delay costs startups $10K–$50K in lost revenue (industry benchmarks).

Fragmented workflows between suppliers create communication gaps and rework cycles.

Honyo’s Digital Manufacturing Edge

Online Instant Quote: Get real-time pricing and cost analysis for passivation within seconds. Our AI-powered tool calculates true costs—including hidden expenses like shipping, rework, and downtime—so you budget with confidence.

AI-Powered Platform: Auto-optimizes passivation parameters (acid type, concentration, temperature, duration) based on your part geometry, material grade, and application requirements. No guesswork. No compromises.

Fast Turnaround: 24–48 hour processing with end-to-end digital tracking. We compress lead times by 65% versus traditional suppliers—so your parts move from design to deployment faster than ever.

“In the race to market, precision isn’t optional—it’s the foundation of reliability. Our digital ecosystem ensures your stainless steel components meet exacting standards without slowing your innovation cycle.”

— Susan Leo, Founder of Honyo Prototype

Partner with us to turn your designs into resilient, production-ready reality—faster, smarter, and seamlessly integrated into your workflow. From prototype to volume production, Honyo is your one-stop digital manufacturing partner.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

AI-Powered Digital Platform

Online Instant Quote: Real-time pricing with AI-driven cost analysis—transparent breakdowns for labor, materials, and processing, no hidden fees

AI-Optimized Process Parameters: Dynamic adjustment of acid concentration (20–50% nitric acid), temperature (140–160°F), and duration tailored to your stainless steel grade

Seamless Workflow Integration: Upload CAD files, track production in real-time, and receive automated updates—all from a single platform

Scalable Production & Rapid Delivery

Any Volume, Any Stage: From 1 prototype to 10,000+ production parts with zero minimum order quantities (MOQs)

24–48 Hour Prototype Turnaround: Expedited shipping options for urgent projects—accelerate time-to-market without compromising quality

Real-Time Production Tracking: Monitor progress from passivation to delivery with live status updates

Precision Passivation & ISO-Certified Quality

Two-Step Corrosion-Resistant Process: Precision cleaning followed by controlled nitric acid bath optimized for 304, 316, and other alloys

ASTM A967 Compliance: Rigorous QC checks at every stage—ensuring peak corrosion resistance for industrial, medical, and aerospace applications

End-to-End Traceability: Full documentation of material specs, process parameters, and test results for regulatory and quality assurance needs

Materials & Surface Finishes

Material Options & Finishes

Material & Finish Portfolio

Metals:

Stainless Steel: 303, 304, 316, 17-4PH, 410

Aluminum: 6061, 7075, 2024

Titanium: Grade 5 (Ti-6Al-4V)

Carbon Steel: 1018, 1045

Copper Alloys: C110, C101

Plastics:

ABS, Nylon (PA6, PA66), POM (Acetal), PC, PTFE, PET

Surface Finishes:

Anodizing (Type II, III), Powder Coating, Electroplating (Nickel, Zinc), Polishing (Bead Blasted, Mirror), Passivation (Stainless Steel Only), Laser Etching, Paint

Optimizing Stainless Steel for Passivation

Passivation is a critical process exclusive to stainless steel, removing free iron and enhancing corrosion resistance through a protective oxide layer. Here’s how to choose the right grade and process for your application:

Grade Selection Guide:

304 Stainless Steel: Ideal for general-purpose use (e.g., medical devices, food processing). Standard nitric acid bath (20–50% concentration, 140–160°F). Cost-effective for prototypes and low-corrosion environments.

316 Stainless Steel: Best for marine, chemical, or high-corrosion settings. Requires precise acid concentration and temperature adjustments due to molybdenum content—Honyo’s AI dynamically optimizes parameters to prevent pitting.

410 & 17-4PH: Martensitic grades needing citric acid passivation for optimal results. Avoid high-sulfur grades like 303 for critical corrosion resistance.

Critical Pre-Process Step:

Our automated cleaning system eliminates oils, contaminants, and machining residues before acid baths—ensuring maximum passivation effectiveness. Overlooked by competitors, but foundational to Honyo’s zero-defect quality.

Why Honyo Wins:

✅ Online Instant Quote: Upload your CAD file and get real-time passivation pricing in seconds—our cost calculator factors in labor, capital, and job size for accurate savings vs. outsourcing. No hidden fees.

✅ AI-Powered Process Optimization: Machine learning analyzes part geometry, material, and environmental requirements to recommend the most efficient passivation method—cutting costs by up to 30% while maximizing corrosion resistance.

✅ 24-48 Hour Turnaround: Integrated digital manufacturing ecosystem processes passivation in record time—prototypes ready in 1 day, production runs in 5–7 days. No third-party handoffs.

Pro Tip: For extreme environments (e.g., 800°C reducing furnaces), pair 316 or 17-4PH with Honyo’s specialized passivation protocol to prevent scaling and maintain structural integrity under thermal stress.

Honyo Prototype’s One-Stop Solution: From design validation to passivated parts—all under one roof. Leverage our digital ecosystem to eliminate supply chain friction and accelerate time-to-market. Get your instant quote today.

From Quote to Part: Our Process

How It Works: From CAD to Passivated Part

Step 1: Upload Your CAD File

Drag-and-drop interface for seamless submission of STEP, STL, or native CAD files

AI instantly extracts material specs, geometry, and passivation requirements

No manual data entry – just upload and go

Step 2: Instant AI-Powered Quote

Real-time cost analysis with transparent breakdown (material, processing, shipping)

Built-in cost savings calculator compares in-house vs. outsourced expenses

See potential savings of up to 40% with zero capital investment in equipment

No hidden fees – all costs visible before you commit

Step 3: Expert DFM Analysis for Optimal Passivation

Engineers review design for passivation readiness (surface prep, geometry, material grade)

Identify and fix potential issues like trapped air pockets or uneven acid exposure

Receive actionable feedback in <24 hours – revise and requote instantly

Step 4: Precision Production & Seamless Delivery

Automated passivation process using ASTM A967-compliant nitric acid baths (20-50% concentration, 140–160°F)

Tailored to your stainless steel grade for maximum corrosion resistance

Track your order in real-time; delivered in 3–5 business days

Why Honyo?

As part of our Digital Manufacturing Ecosystem, we eliminate third-party dependencies. From prototype to production, you get a single-point solution with end-to-end transparency – so you focus on innovation, not logistics.

Start Your Project with Honyo

Start Your Project with Honyo: Precision Passivation, Zero Hassle

Why Choose Honyo for Stainless Steel Passivation?

AI-Powered Cost Calculator: Instantly compare in-house vs. outsourced passivation costs with real-time data. Eliminate guesswork and maximize savings.

Precision Process Control: Industry-standard nitric acid passivation (20%-50% concentration, 140°F-160°F) with meticulous cleaning and acid bath steps for maximum corrosion resistance.

One-Stop Digital Manufacturing Ecosystem: Seamlessly integrate passivation with CNC machining, 3D printing, and surface finishing—no vendor coordination headaches.

48-Hour Fast Turnaround: Accelerate your timeline with rapid processing and shipping, without sacrificing quality or compliance.

How It Works in 3 Simple Steps

Upload & Analyze: Submit CAD files via our AI platform for instant technical review and cost estimation.

Optimize & Confirm: Receive a detailed quote with process recommendations—adjust parameters in real-time for optimal results.

Deliver & Scale: Get certified parts delivered in 48 hours, with scalable solutions for prototype to full production.

Ready to Boost Your Component Performance?

Founder Susan Leo and our engineering team are ready to help. Contact us today for an instant quote:

📧 [email protected] | 📞 +86 139 2843 8620

📍 Visit our Shenzhen/Dongguan facilities to see our digital manufacturing ecosystem in action.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.