Introduction: Navigating the Global Market for parts of a robotic arm

In today’s rapidly evolving industrial landscape, sourcing high-quality parts of a robotic arm can pose significant challenges for international B2B buyers. Companies across Africa, South America, the Middle East, and Europe are increasingly turning to robotic automation to enhance productivity and efficiency. However, the complexity of robotic arm components—including the base, joints, actuators, and end-effectors—can make the procurement process daunting. This guide aims to demystify the various components and applications of robotic arms, providing a comprehensive overview that empowers businesses to make informed purchasing decisions.

Throughout this guide, we will explore the different types of robotic arms and their specific applications across various industries. We will also delve into essential aspects such as supplier vetting, cost considerations, and emerging trends in robotics technology. By understanding the intricacies of robotic arm components, buyers can better assess their needs, evaluate potential suppliers, and ultimately select the right parts to optimize their operations.

With a focus on actionable insights tailored for diverse markets, this resource is designed to help decision-makers navigate the global market for robotic arm components confidently. Whether you are based in Saudi Arabia, Nigeria, or elsewhere, this guide will equip you with the knowledge to enhance your procurement strategies and leverage the full potential of robotic automation in your business.

Understanding parts of a robotic arm Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Articulated Arm | Multi-joint structure mimicking human arm movement | Automotive assembly, welding, packaging | Pros: High flexibility and reach; Cons: Complex programming and maintenance costs. |

| SCARA Arm | Rigid structure with vertical movement, ideal for horizontal tasks | Electronics assembly, material handling | Pros: High speed and precision; Cons: Limited vertical reach. |

| Delta Robot | Parallel arm design for high-speed operations | Food packaging, pharmaceuticals, electronics | Pros: Extremely fast and efficient; Cons: Limited payload capacity. |

| Collaborative Robot (Cobot) | Designed to work alongside humans safely | Assembly lines, small parts handling | Pros: Enhanced safety features; Cons: Lower payload capacity compared to industrial robots. |

| Cartesian Robot | Linear motion along three axes, simple design | CNC machining, 3D printing | Pros: Easy to program and maintain; Cons: Limited flexibility compared to articulated arms. |

What Are the Characteristics of Articulated Arms?

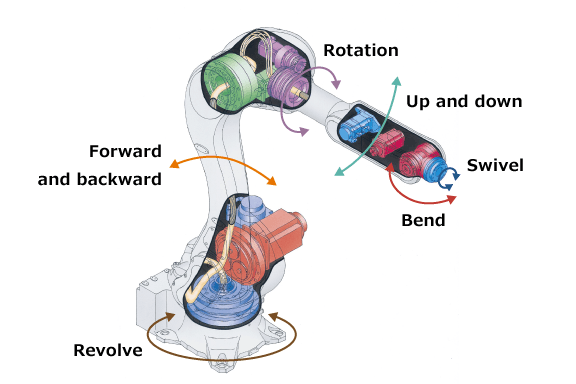

Articulated arms are characterized by their multi-joint design, which allows them to replicate the complex movements of a human arm. They typically feature six or more degrees of freedom, enabling them to perform intricate tasks such as welding and assembly in automotive manufacturing. Buyers should consider the programming complexity and ongoing maintenance costs, as these arms can be expensive to operate. However, their flexibility and extensive reach make them ideal for a variety of applications across different industries.

How Do SCARA Arms Stand Out in Industrial Applications?

SCARA (Selective Compliance Assembly Robot Arm) robots are known for their rigid structure and vertical motion capabilities. They excel in tasks that require horizontal movement, making them a popular choice for electronics assembly and material handling. Their high speed and precision can significantly boost productivity. However, potential buyers should be aware of their limited vertical reach, which may restrict their use in certain applications. The investment in SCARA arms often pays off in environments where speed is critical.

Why Choose Delta Robots for High-Speed Operations?

Delta robots are designed with a parallel arm structure, allowing for rapid and precise movements. This design is particularly advantageous in high-speed applications like food packaging and electronics assembly. While they can handle lightweight items efficiently, their limited payload capacity may not suit all manufacturing needs. Companies looking to optimize speed and efficiency in their operations should consider delta robots, balancing their fast performance against the types of products being handled.

What Makes Collaborative Robots (Cobots) Unique?

Collaborative robots, or cobots, are engineered to work safely alongside human operators. They feature advanced safety mechanisms that allow them to operate without traditional safety cages, making them suitable for small parts handling and assembly tasks. While they offer enhanced safety and ease of use, buyers should note that cobots typically have lower payload capacities compared to traditional industrial robots. Their adaptability in smaller workspaces and user-friendly interfaces make them an appealing choice for businesses aiming to integrate automation without extensive retraining.

How Do Cartesian Robots Simplify Motion Control?

Cartesian robots utilize a straightforward design that allows movement along three linear axes. This simplicity makes them easy to program and maintain, making them ideal for applications such as CNC machining and 3D printing. While they provide reliable performance, their flexibility is limited compared to more complex robotic arms. Buyers should evaluate their specific needs, as Cartesian robots can offer a cost-effective solution for straightforward tasks, particularly in environments where precision is paramount.

Key Industrial Applications of parts of a robotic arm

| Industry/Sector | Specific Application of parts of a robotic arm | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Robotic arms for welding and assembly processes | Increased precision and speed in manufacturing, reducing labor costs | Compatibility with existing systems and ease of integration |

| Food and Beverage | Robotic arms for packaging and palletizing | Enhanced efficiency and hygiene in packaging processes | Compliance with food safety regulations and material certifications |

| Electronics Assembly | Robotic arms for circuit board assembly | Higher accuracy and reduced error rates in electronic components | Precision requirements and the ability to handle small components |

| Healthcare | Robotic arms for surgical assistance and rehabilitation | Improved patient outcomes and reduced recovery times | Compliance with medical standards and adaptability to various procedures |

| Logistics and Warehousing | Robotic arms for sorting and inventory management | Streamlined operations and reduced labor costs | Scalability and adaptability to different warehouse layouts |

How Are Robotic Arm Parts Utilized in the Automotive Manufacturing Sector?

In automotive manufacturing, robotic arms play a critical role in welding and assembly processes. These arms, equipped with precise end-effectors like welding torches, ensure consistent quality and speed in joining metal components. By automating these tasks, manufacturers can significantly reduce labor costs and improve production efficiency. For international buyers, sourcing robotic arms requires a focus on compatibility with existing manufacturing systems and the ability to integrate seamlessly into their production lines.

What Are the Benefits of Robotic Arms in the Food and Beverage Industry?

In the food and beverage sector, robotic arms are increasingly used for packaging and palletizing tasks. They enhance operational efficiency by automating repetitive processes, which also ensures higher hygiene standards during food handling. This is particularly important in regions with strict food safety regulations. Buyers should consider sourcing options that comply with food safety standards and ensure that materials used in robotic arms are certified for contact with food products.

How Do Robotic Arms Improve Electronics Assembly Processes?

Robotic arms are essential in the electronics assembly industry, particularly for tasks such as circuit board assembly. With high precision and speed, these robots minimize error rates and enhance the overall quality of electronic components. International buyers in this sector must prioritize precision requirements, ensuring that the robotic arms can handle the small, delicate components typical in electronics manufacturing while also being adaptable to various assembly processes.

What Role Do Robotic Arms Play in Healthcare Applications?

In healthcare, robotic arms are revolutionizing surgical assistance and rehabilitation. These sophisticated systems enable surgeons to perform procedures with enhanced accuracy, leading to better patient outcomes and quicker recovery times. For buyers in the healthcare sector, it is crucial to source robotic arms that comply with medical standards and can be adapted for various surgical procedures, ensuring they meet the specific needs of different medical environments.

How Are Robotic Arms Transforming Logistics and Warehousing?

In logistics and warehousing, robotic arms are utilized for sorting and inventory management, streamlining operations and reducing labor costs. They can efficiently handle repetitive tasks, allowing human workers to focus on more complex activities. When sourcing robotic arms for this application, businesses should consider scalability and the adaptability of the robots to different warehouse layouts, ensuring they can grow alongside the business needs.

3 Common User Pain Points for ‘parts of a robotic arm’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Actuators

The Problem: Many B2B buyers face significant challenges when it comes to sourcing high-quality actuators for robotic arms. The actuator is crucial as it powers the arm’s movements, and using subpar components can lead to mechanical failures or inefficient operations. Buyers often struggle with a lack of reliable suppliers, inconsistent product quality, and the daunting task of ensuring that the actuators meet their specific operational requirements, such as load capacity and speed. This not only affects production timelines but can also lead to increased costs due to maintenance and replacement.

The Solution: To overcome these challenges, B2B buyers should develop a robust supplier evaluation process. This involves identifying manufacturers with a proven track record in producing high-quality actuators and conducting thorough due diligence, including reviewing certifications, customer testimonials, and case studies. Additionally, buyers should specify their requirements clearly, including the type of actuator (electric, pneumatic, or hydraulic), load specifications, and environmental conditions in which the actuator will operate. Engaging in direct communication with suppliers can also facilitate customization options tailored to specific applications, ensuring that the actuators sourced will seamlessly integrate with the robotic arm systems.

Scenario 2: Integration Challenges with Controllers

The Problem: Integrating the controller with the robotic arm components poses a significant headache for many B2B buyers. The controller acts as the brain of the robotic arm, but issues often arise when it comes to compatibility with different parts, leading to suboptimal performance or even operational failures. Buyers may find themselves confused by the myriad of programming languages, software interfaces, and communication protocols, which can hinder the setup process and lead to costly downtime.

The Solution: To address these integration challenges, buyers should prioritize purchasing components from the same manufacturer or ensure compatibility through thorough research. When selecting a controller, it’s essential to consider one that offers an intuitive user interface and extensive documentation for ease of programming. Additionally, buyers should invest in training for their technical teams on the specific software and programming languages used by the controller. This will not only enhance the integration process but also empower the team to troubleshoot issues efficiently. Establishing a direct line of communication with the supplier for technical support during the integration phase can also prove invaluable.

Scenario 3: Maintenance and Upkeep of Robotic Arm Components

The Problem: Maintenance of robotic arm components, particularly joints and end-effectors, is a persistent concern for B2B buyers. Over time, wear and tear can lead to decreased performance, misalignment, and even complete failure of the robotic arm. Buyers often lack a structured maintenance plan, which can result in unexpected breakdowns and production halts, ultimately affecting their bottom line. The challenge lies in finding the right balance between regular maintenance and operational efficiency.

The Solution: Implementing a proactive maintenance strategy is crucial. Buyers should create a detailed maintenance schedule that includes regular inspections, lubrication of joints, and replacement of worn-out parts. Utilizing condition monitoring technologies, such as sensors that detect wear and fatigue, can help predict potential failures before they occur. Additionally, establishing a partnership with suppliers for ongoing support and spare parts can streamline the maintenance process. Training staff on basic troubleshooting and maintenance procedures will also empower them to address minor issues before they escalate, ensuring the robotic arms operate smoothly and efficiently.

Strategic Material Selection Guide for parts of a robotic arm

What Are the Key Materials for Parts of a Robotic Arm?

When selecting materials for the various components of a robotic arm, it is crucial to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance, durability, and cost-effectiveness of the robotic arm, especially in diverse international markets such as Africa, South America, the Middle East, and Europe.

Which Metals Are Commonly Used in Robotic Arms?

Aluminum

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for various applications.

Pros & Cons: The primary advantage of aluminum is its low weight, which enhances the speed and efficiency of robotic arms. However, it may not be as durable as heavier metals like steel and can be more susceptible to deformation under high stress.

Impact on Application: Aluminum is well-suited for applications requiring agility and speed, such as assembly lines. However, it may not be ideal for environments with extreme temperatures or heavy loads.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN when sourcing aluminum components. Additionally, the availability of aluminum alloys may vary by region, affecting lead times and costs.

Steel

Key Properties: Steel is known for its high tensile strength and durability, with excellent resistance to wear and fatigue. It can handle high temperatures and pressures, making it suitable for heavy-duty applications.

Pros & Cons: The key advantage of steel is its robustness, which allows for the construction of reliable and long-lasting robotic arms. However, it is heavier than aluminum, which can affect the arm’s speed and energy efficiency. Steel also tends to be more expensive due to its manufacturing complexity.

Impact on Application: Steel is ideal for applications involving heavy lifting or harsh environments, such as automotive manufacturing. Its durability ensures longevity, reducing maintenance costs.

Considerations for International Buyers: Buyers should be aware of regional standards and certifications for steel, such as JIS in Japan or EN in Europe. The sourcing of high-quality steel may also depend on local suppliers’ capabilities.

Composite Materials

Key Properties: Composites, such as carbon fiber and fiberglass, offer a unique combination of lightweight characteristics and high strength. They also exhibit excellent resistance to corrosion and thermal expansion.

Pros & Cons: The primary advantage of composites is their high strength-to-weight ratio, allowing for agile robotic arms that can perform complex tasks. However, they can be more expensive and challenging to manufacture, requiring specialized processes.

Impact on Application: Composites are particularly beneficial in applications where weight savings are critical, such as in aerospace or high-speed manufacturing. However, their performance can be compromised in extremely high-temperature environments.

Considerations for International Buyers: Buyers should verify that composite materials meet international standards for safety and performance. Additionally, the availability of specialized manufacturing facilities may vary by region, impacting lead times.

Plastics

Key Properties: Engineering plastics, such as nylon and polycarbonate, are lightweight and resistant to corrosion and chemicals. They can operate effectively in a range of temperatures, though they may have lower mechanical strength compared to metals.

Pros & Cons: The main advantage of plastics is their low cost and ease of manufacturing, making them suitable for prototyping and low-load applications. However, their lower strength limits their use in heavy-duty robotic arms.

Impact on Application: Plastics are ideal for applications that require non-conductive materials or where weight is a concern, such as in consumer product assembly. However, they may not withstand heavy loads or extreme environmental conditions.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with relevant safety and environmental regulations, such as REACH in Europe. Material availability may vary, influencing production schedules.

Summary Table of Material Selection for Robotic Arms

| Material | Typical Use Case for parts of a robotic arm | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight robotic arms for assembly tasks | Low weight enhances speed | Less durable under high stress | Medium |

| Steel | Heavy-duty robotic arms in manufacturing | High strength and durability | Heavier, affecting speed | High |

| Composite Materials | Aerospace and high-speed applications | High strength-to-weight ratio | More expensive and complex to manufacture | High |

| Plastics | Prototyping and low-load applications | Low cost and easy to manufacture | Lower mechanical strength | Low |

This strategic material selection guide provides insights into the various materials used in robotic arms, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for parts of a robotic arm

What Are the Main Stages in the Manufacturing Process of Robotic Arm Parts?

The manufacturing of robotic arm components involves several critical stages, each designed to ensure precision and reliability. Understanding these stages can help B2B buyers identify quality suppliers capable of meeting their specific needs.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage in manufacturing robotic arm parts is material preparation. Manufacturers typically choose high-strength materials such as steel, aluminum, or composite materials based on the application requirements. For instance, the base and links may require robust materials to handle heavy loads, while the end effector might benefit from lighter materials for improved speed and efficiency.

During material preparation, suppliers often conduct material testing to verify properties such as tensile strength, ductility, and fatigue resistance. Buyers should inquire about the sources of raw materials and the testing protocols in place to ensure they meet the necessary specifications.

Forming: What Techniques Are Used to Shape Robotic Arm Components?

Once materials are prepared, the next stage is forming, where raw materials are shaped into the required components. Common techniques include:

-

Machining: This involves cutting, drilling, and milling processes to achieve precise dimensions and surface finishes. CNC (Computer Numerical Control) machines are frequently used for high accuracy.

-

Casting: For complex shapes, casting can be an effective technique. It allows for the creation of intricate designs that would be difficult to achieve through machining alone.

-

Forging: This process enhances the strength of components through deformation under high pressure, which aligns the material’s grain structure. It is particularly useful for parts that require high strength, like joints.

Each of these techniques has its advantages and drawbacks, and the choice often depends on the specific part being manufactured. Buyers should seek suppliers who can demonstrate expertise in the relevant forming techniques.

Assembly: How Are Robotic Arm Parts Brought Together?

The assembly stage is crucial for ensuring that all components function cohesively. This process often involves:

-

Sub-Assembly: Individual components, such as joints, actuators, and sensors, are first assembled separately before being integrated into the complete robotic arm.

-

Quality Checks: Assembly lines typically include checkpoints where critical dimensions and alignments are verified. This can involve the use of jigs and fixtures to ensure consistency.

-

Integration of Electronics: For robotic arms that require sophisticated control systems, the integration of electronic components, such as controllers and sensors, must be performed with precision.

Buyers should inquire about the assembly processes employed by suppliers, as well as any automated systems that enhance accuracy and efficiency.

Finishing: What Finishing Processes Ensure Durability and Aesthetic Quality?

The finishing stage enhances both the durability and appearance of robotic arm parts. Common finishing processes include:

-

Surface Treatment: Techniques such as anodizing, painting, or powder coating can improve corrosion resistance and wear properties.

-

Quality Inspections: Final inspections are crucial to ensure that all parts meet specified tolerances and surface finish requirements. This may involve visual inspections as well as measurements with precision instruments.

Buyers should ask suppliers about their finishing processes and the standards they adhere to, as these can significantly impact the long-term performance of robotic arms.

How Is Quality Assurance Implemented in Robotic Arm Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that every component meets industry standards and customer expectations.

What International Standards Are Relevant to Robotic Arm Manufacturing?

Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates that a supplier has processes in place for consistent quality output.

In addition to ISO standards, industry-specific certifications, such as CE marking for compliance with European safety standards or API certifications for components used in energy applications, are essential. B2B buyers should verify that suppliers hold relevant certifications, especially when sourcing from international markets.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure adherence to quality standards. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production line to ensure they meet specified requirements.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, QC measures are taken at various stages to catch defects early. This includes monitoring tolerances and performing tests on components.

-

Final Quality Control (FQC): Before products are shipped, a comprehensive inspection is conducted to verify that all components meet the required specifications and standards.

What Common Testing Methods Are Used for Robotic Arm Parts?

Common testing methods employed in the QC process include:

-

Dimensional Inspection: Using gauges and calipers to ensure that parts meet specified measurements.

-

Functional Testing: Verifying the operational effectiveness of the robotic arm, including stress tests and load tests to assess performance under expected conditions.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic or X-ray testing can identify internal defects without damaging the parts.

These testing methods are essential for ensuring that robotic arms can perform reliably in demanding industrial applications.

How Can B2B Buyers Verify Supplier Quality Control Measures?

To ensure quality assurance in their supply chain, B2B buyers should take proactive steps to verify supplier QC processes:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing practices and quality control measures. This can include reviewing documentation related to their quality management systems.

-

Requesting Quality Reports: Buyers should request comprehensive quality reports that detail the results of inspections and testing. These reports can help assess a supplier’s commitment to quality.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of a supplier’s QC processes and product quality. This is particularly valuable for international transactions where buyers may not have direct oversight.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of international quality control is crucial. Buyers should be aware of:

-

Regional Standards: Familiarity with local regulations and standards is important, as these can vary significantly by region. For example, products sold in Europe may require CE marking, while products in North America may need to comply with different standards.

-

Cultural Considerations: Building strong relationships with suppliers can facilitate better communication regarding quality expectations. Understanding cultural differences can enhance negotiations and collaboration.

-

Logistical Challenges: International shipping can introduce risks to product quality, such as damage during transit. Buyers should discuss packaging and shipping methods with suppliers to mitigate these risks.

By thoroughly understanding the manufacturing processes and quality assurance protocols for robotic arm parts, B2B buyers can make informed decisions, ensuring they select suppliers who meet their quality and performance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of a robotic arm’

This guide provides a structured approach for B2B buyers looking to procure parts for robotic arms. As robotic technology continues to transform industries, sourcing the right components is crucial for ensuring efficiency, reliability, and optimal performance in automated systems. Here’s a step-by-step checklist to facilitate your procurement process.

Step 1: Define Your Technical Specifications

Understanding your requirements is the first critical step in sourcing robotic arm parts. Clearly outline the specifications such as payload capacity, reach, degrees of freedom, and operational environment.

– Consider application-specific needs: For instance, if the robotic arm will be used in a manufacturing facility, ensure it can withstand the operational demands and environmental conditions.

– Document all necessary details: This will help in communicating effectively with suppliers and ensuring that you receive appropriate options.

Step 2: Research and Identify Potential Suppliers

Begin your search for suppliers by leveraging industry networks, trade shows, and online platforms. A well-researched list of potential suppliers will set the foundation for a successful procurement process.

– Look for suppliers with industry experience: Those with a proven track record in robotic components can offer insights and solutions tailored to your needs.

– Assess their product range: Ensure they provide a comprehensive selection of parts, from actuators to end-effectors, to avoid the hassle of dealing with multiple vendors.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Check for certifications and compliance: Ensure that the suppliers adhere to international standards relevant to robotic components, which is vital for quality assurance.

– Review customer feedback: Look for testimonials or reviews that can provide insight into their reliability and customer service.

Step 4: Request Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request detailed quotes for the parts you need. Comparing pricing is essential to ensure you receive value for your investment.

– Examine the cost breakdown: Look beyond just the price; analyze shipping, handling, and potential hidden costs that could affect your budget.

– Consider long-term relationships: Sometimes, suppliers may offer discounts for bulk purchases or long-term contracts, which can lead to significant savings.

Step 5: Assess Quality Control Measures

Quality assurance is paramount when sourcing robotic arm components. Inquire about the quality control processes that suppliers implement.

– Request information on testing protocols: Suppliers should be able to demonstrate how they test their components for durability and performance.

– Verify warranty and support: Understand the warranty terms and post-purchase support offered, as this can impact the longevity of your robotic systems.

Step 6: Finalize the Order and Establish Clear Terms

Once you select a supplier, finalize your order with clear terms regarding delivery schedules, payment conditions, and after-sales support.

– Draft a comprehensive contract: Ensure that all specifications, timelines, and responsibilities are explicitly stated to avoid misunderstandings later.

– Maintain open communication: Establish a point of contact to facilitate smooth interaction throughout the procurement process.

Step 7: Plan for Installation and Integration

Consider how the new parts will be integrated into your existing systems. Planning for installation is critical to minimize downtime and ensure seamless operation.

– Engage with the supplier for support: Many suppliers offer installation services or can recommend qualified technicians.

– Train your staff: Ensure that your team is adequately trained to operate and maintain the new robotic components effectively.

By following this checklist, B2B buyers can streamline their sourcing process for robotic arm parts, ensuring they make informed decisions that enhance their operational capabilities.

Comprehensive Cost and Pricing Analysis for parts of a robotic arm Sourcing

What Are the Key Cost Components for Sourcing Robotic Arm Parts?

When sourcing parts for robotic arms, understanding the cost structure is essential for effective budgeting and procurement strategies. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials include aluminum, steel, and composite materials, each offering different properties at varying price points. High-quality materials ensure durability and performance but may increase initial costs.

-

Labor: Labor costs encompass the wages paid to skilled workers involved in manufacturing and assembly. Labor costs can vary based on geographic location, with regions offering lower wages potentially providing a cost advantage.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and indirect labor. Efficient manufacturing processes can reduce overhead costs, directly impacting pricing.

-

Tooling: Specialized tools and molds are often required for production. The initial investment in tooling can be substantial, but amortizing these costs over large production runs can lead to lower per-unit costs.

-

Quality Control (QC): Ensuring the quality of parts is crucial, particularly in industries where precision is paramount. Implementing rigorous QC processes may incur additional costs but can prevent costly defects and recalls.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and the destination. International shipments may incur additional tariffs and customs fees, impacting overall expenses.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Impact the Sourcing of Robotic Arm Parts?

Several factors influence the pricing of robotic arm components, and understanding these can help buyers negotiate better deals:

-

Volume/MOQ: Suppliers often provide discounts for larger orders. Understanding minimum order quantities (MOQ) can help buyers optimize their purchasing strategy.

-

Specifications and Customization: Custom parts typically come at a premium. Buyers should clearly define their specifications to avoid unnecessary modifications that can inflate costs.

-

Materials: The quality and type of materials selected can greatly influence the price. High-performance materials may be necessary for certain applications but will increase overall costs.

-

Quality and Certifications: Components that meet specific industry standards or certifications may be more expensive. Buyers should assess whether these certifications are essential for their operations.

-

Supplier Factors: Supplier reputation, reliability, and service quality can influence pricing. Established suppliers with a track record of quality may charge higher prices but offer greater assurance of performance.

-

Incoterms: The chosen Incoterms (International Commercial Terms) affect shipping costs and responsibilities. Understanding these terms can help buyers manage logistics more effectively and avoid unexpected expenses.

What Buyer Tips Can Enhance Cost-Efficiency in Robotic Arm Parts Sourcing?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency:

-

Negotiate Effectively: Leverage volume and long-term relationships to negotiate better pricing. Building rapport with suppliers can lead to favorable terms and conditions.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate maintenance, operational efficiency, and potential downtime costs associated with the parts to make informed decisions.

-

Stay Informed on Pricing Nuances: Be aware of market trends and fluctuations in material costs, which can impact pricing. Building relationships with multiple suppliers can provide insights into the best times to purchase.

-

Explore Local Suppliers: For buyers in regions like Nigeria or Saudi Arabia, sourcing from local suppliers may reduce logistics costs and lead times, despite potentially higher material costs.

-

Focus on Long-term Partnerships: Establishing long-term partnerships with suppliers can lead to better pricing, priority service, and access to new technologies.

Disclaimer on Indicative Prices

Prices for robotic arm components can vary widely based on numerous factors, including market conditions, supplier pricing strategies, and specific project requirements. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to their needs.

Alternatives Analysis: Comparing parts of a robotic arm With Other Solutions

Understanding Alternatives in Robotic Arm Technology

In the landscape of industrial automation, robotic arms are pivotal for enhancing efficiency and precision in various applications. However, businesses often seek alternatives to robotic arms that may better suit their operational needs, budget constraints, or specific task requirements. This analysis compares the components of a robotic arm against two viable alternatives: Automated Guided Vehicles (AGVs) and Cartesian Robots. Understanding these options can help international B2B buyers make informed decisions tailored to their unique operational environments.

Comparison Table

| Comparison Aspect | Parts of a Robotic Arm | Automated Guided Vehicles (AGVs) | Cartesian Robots |

|---|---|---|---|

| Performance | High precision and flexibility for varied tasks | Efficient for material transport but limited in task versatility | High precision in linear movements, less flexible |

| Cost | Higher initial investment, varying operational costs | Moderate initial cost, lower operational costs | Generally lower initial investment, maintenance costs can vary |

| Ease of Implementation | Requires programming and integration | Easy to implement with existing systems | Simple setup and programming, less integration needed |

| Maintenance | Regular maintenance required for joints and actuators | Minimal maintenance, mainly battery care | Regular checks needed for linear guides and motors |

| Best Use Case | Complex assembly, welding, and painting tasks | Material handling in warehouses and factories | Simple pick-and-place tasks in controlled environments |

Pros and Cons of Each Alternative

Automated Guided Vehicles (AGVs)

AGVs are mobile robots designed primarily for transporting materials within a facility. They excel in efficiency and safety, navigating through predefined paths without human intervention. The key advantage of AGVs is their ability to streamline logistics, significantly reducing labor costs associated with manual transport. However, their functionality is limited to movement and they lack the versatility of robotic arms for complex tasks like assembly or welding. For companies focused on optimizing material handling, AGVs present a robust alternative.

Cartesian Robots

Cartesian robots, or linear robots, operate on three linear axes (X, Y, Z) and are ideal for tasks requiring precise linear movements. Their simple structure allows for cost-effective implementation and ease of use. These robots are particularly effective for repetitive tasks such as pick-and-place operations in environments where movement is predictable. However, their lack of flexibility compared to robotic arms makes them less suitable for intricate operations that require a range of motion and adaptability. Businesses looking for straightforward automation solutions may find Cartesian robots to be a compelling choice.

Making the Right Choice for Your Business Needs

When choosing between robotic arms and their alternatives, it is essential for B2B buyers to assess their specific operational requirements. Factors such as the complexity of tasks, budget constraints, and integration capabilities should guide the decision-making process. While robotic arms provide unparalleled versatility for intricate applications, AGVs and Cartesian robots offer significant advantages in specialized scenarios. By evaluating the pros and cons of each option, businesses can select the most effective automation solution that aligns with their strategic objectives and operational context.

Essential Technical Properties and Trade Terminology for parts of a robotic arm

What Are the Key Technical Properties of Robotic Arm Components?

In the realm of robotic arms, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some of the most critical specifications that B2B buyers should consider:

1. Material Grade

The material used in constructing robotic arm components significantly impacts their performance and longevity. Common materials include aluminum for lightweight applications, steel for high strength, and composites for specific applications requiring reduced weight and increased durability. Selecting the right material grade is essential for ensuring the robotic arm can withstand operational demands, especially in high-stress environments.

2. Tolerance

Tolerance refers to the allowable deviation from a specified dimension. In robotic arms, precise tolerances are vital for ensuring accurate movements and interactions with other components. Tight tolerances reduce the risk of malfunction and enhance the arm’s ability to perform tasks requiring precision, such as assembly or welding. For B2B buyers, understanding tolerances can influence the choice of parts, impacting overall system performance.

3. Payload Capacity

Payload capacity indicates the maximum weight a robotic arm can safely handle. This specification is critical for applications where heavy items are manipulated. Buyers should evaluate their operational needs to select a robotic arm that can accommodate the expected loads without compromising performance or safety. Overloading a robotic arm can lead to mechanical failure, increased wear, and safety hazards.

4. Degrees of Freedom (DoF)

Degrees of freedom refer to the number of independent movements a robotic arm can perform. A higher number of DoF allows for more complex and versatile operations, enabling the arm to reach various angles and positions. Buyers should assess the required DoF based on the intended applications, as this will determine the arm’s flexibility and usability in diverse environments.

5. Speed and Acceleration

These specifications dictate how quickly a robotic arm can move and change direction. Speed is particularly crucial in high-throughput manufacturing environments, where efficiency is paramount. Buyers should consider the speed and acceleration capabilities to ensure the robotic arm can meet production demands without sacrificing precision.

6. Power Supply Requirements

Understanding the power supply needs of a robotic arm is essential for seamless integration into existing systems. Robotic arms can operate on different power sources, such as electric, pneumatic, or hydraulic systems. Evaluating these requirements helps buyers ensure compatibility with their infrastructure and prevents operational disruptions.

What Are Common Trade Terms in the Robotic Arm Industry?

Navigating the robotic arm market involves understanding various trade terms. Here are some essential terms that B2B buyers should familiarize themselves with:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or systems that are used in another company’s products. In the context of robotic arms, partnering with reputable OEMs can ensure quality and reliability in the components sourced, ultimately affecting the performance of the robotic systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding the MOQ is vital for budgeting and inventory planning. Buyers should negotiate MOQs that align with their operational needs while ensuring they do not overstock components that may not be needed immediately.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. Utilizing RFQs allows buyers to compare offers from multiple suppliers, facilitating better decision-making and cost management.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand the logistics and risks associated with international transactions, ensuring smoother procurement processes.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. For B2B buyers, understanding lead times is crucial for project planning and inventory management. Long lead times can affect production schedules and operational efficiency, making it essential to factor this into procurement decisions.

6. Warranty and Support

This term refers to the guarantees provided by manufacturers regarding the performance and durability of their products. Understanding warranty terms and the availability of technical support can significantly influence purchasing decisions, ensuring buyers are protected against defects and have access to assistance if needed.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and reduce risks associated with robotic arm procurement.

Navigating Market Dynamics and Sourcing Trends in the parts of a robotic arm Sector

What Are the Current Trends Influencing the Robotic Arm Parts Market?

The global market for robotic arm components is witnessing significant transformation driven by advancements in automation technology and the growing demand for efficiency across various industries. Key trends include the rising adoption of collaborative robots (cobots) in manufacturing, particularly in regions such as Africa, South America, and the Middle East. These robots are designed to work alongside human operators, enhancing productivity while minimizing labor costs. In Europe, the focus is shifting towards more complex robotic systems that incorporate artificial intelligence and machine learning, allowing for greater adaptability and precision in operations.

Another notable trend is the increasing interest in modular robotic arms, which allow businesses to customize their systems according to specific operational needs. This flexibility is particularly appealing to international B2B buyers, as it facilitates easier upgrades and scalability. Moreover, as companies strive to improve their supply chain resilience, there is a growing emphasis on sourcing from local suppliers, reducing lead times, and enhancing responsiveness to market changes.

Emerging technologies such as IoT integration in robotic arms are also transforming the landscape, enabling real-time monitoring and predictive maintenance. This evolution not only improves operational efficiency but also supports data-driven decision-making. For international buyers, understanding these dynamics is crucial for making informed purchasing decisions and ensuring long-term competitiveness in the market.

How Can Sustainability and Ethical Sourcing Impact Your B2B Strategy?

The importance of sustainability and ethical sourcing in the robotic arm components sector cannot be overstated. As global environmental concerns rise, buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes the use of environmentally friendly materials and processes in the manufacturing of robotic arm parts. Certifications such as ISO 14001 for environmental management systems or the use of recycled materials are becoming essential criteria for supplier evaluation.

Furthermore, ethical supply chains are vital for maintaining brand reputation and compliance with international regulations. Buyers must ensure that their suppliers adhere to fair labor practices and environmental standards. This not only mitigates risk but also aligns with the growing consumer demand for corporate social responsibility. Companies that prioritize sustainability can differentiate themselves in the market, fostering loyalty among environmentally-conscious customers.

Incorporating ‘green’ certifications and materials into sourcing strategies not only enhances corporate image but also contributes to cost savings in the long run. For instance, energy-efficient manufacturing processes can reduce operational costs while also minimizing carbon footprints. B2B buyers should actively seek partnerships with suppliers that embrace sustainable practices, as this alignment can lead to a more resilient and responsible supply chain.

What Is the Historical Context of Robotic Arm Development for B2B Buyers?

The development of robotic arms has evolved significantly since their inception in the early 1960s. Initially designed for simple tasks in manufacturing, these machines have undergone a remarkable transformation. The introduction of programmable logic controllers (PLCs) in the 1970s revolutionized the industry, allowing for more complex operations and greater precision.

In the 1980s and 1990s, advancements in computer technology and software development further propelled the capabilities of robotic arms, enabling them to perform a wider range of tasks with improved accuracy. The recent surge in artificial intelligence and machine learning technologies has paved the way for even more sophisticated robotic systems capable of adapting to dynamic environments.

For international B2B buyers, understanding this historical context is essential. It highlights the rapid pace of innovation and the importance of selecting suppliers who are at the forefront of technological advancements. By aligning with manufacturers that leverage the latest technologies, buyers can ensure they are investing in components that will remain relevant and efficient in a fast-evolving market.

Frequently Asked Questions (FAQs) for B2B Buyers of parts of a robotic arm

-

How do I solve compatibility issues with robotic arm parts?

To address compatibility issues, begin by assessing the specifications of your existing robotic arm components. Ensure that any new parts, such as actuators or end-effectors, are compatible with the current controller and joints. Collaborate closely with your suppliers to obtain detailed technical documentation and compatibility information. If necessary, consider custom solutions from manufacturers that can tailor parts to meet specific requirements. Always test components in a controlled environment before full-scale implementation to avoid costly downtime. -

What is the best actuator type for a robotic arm application?

The best actuator type for your robotic arm depends on the specific application requirements. Electric actuators are preferred for precision tasks due to their accuracy and responsiveness. Hydraulic actuators are ideal for heavy-duty applications needing high force, while pneumatic actuators offer cleanliness and speed for lighter tasks. Evaluate factors such as load capacity, speed, and environmental conditions before making a decision. Consulting with manufacturers can provide insights tailored to your operational needs. -

How can I ensure the quality of robotic arm parts from suppliers?

To ensure quality, conduct thorough due diligence on potential suppliers. Request certifications such as ISO 9001, which indicates adherence to quality management standards. Review customer testimonials and case studies to gauge their reliability. Implement a quality assurance program that includes incoming inspections and testing of parts upon delivery. Establishing a robust communication channel with suppliers can also facilitate ongoing quality improvements and issue resolution. -

What are the minimum order quantities (MOQs) for robotic arm components?

Minimum order quantities vary widely among suppliers and are influenced by factors such as component type and customization. Typically, standard parts may have lower MOQs, while specialized or custom components may require larger orders. Engage with multiple suppliers to compare MOQs and negotiate terms that fit your procurement strategy. Be mindful that larger orders may offer cost savings, but assess your inventory management capacity before committing. -

What payment terms should I expect when sourcing robotic arm parts internationally?

Payment terms can vary based on supplier policies and the nature of the transaction. Common terms include upfront payment, 30-60 days net, or payment upon delivery. For international transactions, consider using letters of credit or escrow services to mitigate risks. Always clarify terms before placing an order, and ensure they align with your cash flow requirements. Establishing a good relationship with your supplier may also lead to more favorable terms over time. -

How do I evaluate and select suppliers for robotic arm components?

When evaluating suppliers, consider their industry reputation, experience, and technical expertise in robotic components. Request samples or prototypes to assess quality firsthand. Look for suppliers that offer comprehensive support, including after-sales service and technical assistance. Additionally, assess their production capabilities, lead times, and flexibility in meeting your specific needs. A supplier’s ability to provide customization can be a significant advantage, especially for specialized applications. -

What logistics considerations should I keep in mind when importing robotic arm parts?

Logistics play a crucial role in the timely delivery of robotic arm parts. Assess shipping options and lead times based on your location and the supplier’s location. Consider customs regulations and duties that may apply when importing components, which can affect overall costs and timelines. Work with freight forwarders who have experience in handling industrial equipment to streamline the process. Additionally, ensure that the supplier provides adequate packaging to prevent damage during transit. -

How can I customize robotic arm components to fit my specific needs?

Customization of robotic arm components typically involves collaboration with manufacturers who specialize in tailored solutions. Clearly define your requirements, including dimensions, materials, and functionality. Many suppliers offer design services and can create prototypes based on your specifications. Be prepared for potential lead time increases and cost adjustments associated with custom parts. Regular communication with the manufacturer throughout the design and production process can help ensure that the final product meets your expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Parts Of A Robotic Arm Manufacturers & Suppliers List

1. Robots.com – Key Components of Industrial Robot Arms

Domain: robots.com

Registered: 1993 (32 years)

Introduction: Main parts of an industrial robot arm include: 1. Controller: The “brain” of the robot that runs programs and connects to other systems. 2. Arm: The structure that positions the end effector, consisting of joints like shoulder, elbow, and wrist. 3. End Effector: Functions as the robot’s hand, interacting directly with materials; variations include grippers, vacuum pumps, magnets, and welding torch…

2. LinkedIn – Manipulator Arm

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: 1. Manipulator Arm: A programmable mechanical arm that mimics human arm movement, consisting of segments called cross-slides that can move over one another. It has a fixed base and a free end for the end-effector. Designed with a specific coordinate system, available in two or three-axis designs. Types of joints include: Revolute (R), Prismatic (P), Helical (H), Cylindrical (C), Universal (S), and…

3. igus® – Industrial Robot Components

Domain: igus.com

Registered: 1995 (30 years)

Introduction: Industrial Robot Components from igus® are designed for building custom automated solutions. Key features include:

– Low-cost options for creating robotic solutions.

– Fully integrated strain wave gear boxes suitable for ReBeL cobot.

– Modular robotic joints and gearbox joints available in various sizes.

– Utilization of dry-running plastics for lightweight and maintenance-free performance.

– Redu…

4. RobotShop – Premium Robot Parts

Domain: robotshop.com

Registered: 2004 (21 years)

Introduction: This company, RobotShop – Premium Robot Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Servodynamics – Industrial Robotic Arms

Domain: servodynamics.com.vn

Introduction: Industrial robotic arms are programmable extensions of the human arm, engineered for manufacturing environments. Key components include:

1. Base: Provides stability and enables rotational movement.

2. Arm: The primary structure with interconnected joints for motion.

3. Wrist: Allows multi-axis rotation for flexibility.

4. End-effector: Customizable tool for specific tasks (e.g., welding, paint…

6. Awe Robotics – Robotic Arm Components

Domain: awerobotics.com

Registered: 2022 (3 years)

Introduction: The five components of a robotic arm are: 1. The Base – Provides stability and support, typically made from aluminum or steel, containing a motor and gears for movement. 2. The Shoulder – Allows the arm to extend and retract, mimicking human shoulder flexibility. 3. The Elbow – Enables bending, adding versatility to movement. 4. The Wrist – Responsible for rotation and orientation, allowing the ar…

Strategic Sourcing Conclusion and Outlook for parts of a robotic arm

In the rapidly evolving landscape of robotics, strategic sourcing of robotic arm components is essential for businesses aiming to enhance operational efficiency and maintain a competitive edge. Understanding the integral parts of robotic arms—including the base, joints, links, end-effectors, actuators, sensors, controllers, and power supply—enables buyers to make informed decisions that align with their specific applications and operational needs.

A strategic approach to sourcing not only optimizes costs but also ensures the procurement of high-quality components that can withstand the demands of diverse industrial environments. As markets in Africa, South America, the Middle East, and Europe grow increasingly interconnected, buyers are encouraged to leverage global supplier networks to access innovative technologies and best practices.

Looking ahead, the integration of AI and advanced materials in robotic arm components promises to revolutionize manufacturing processes. International B2B buyers are urged to stay abreast of these developments, fostering partnerships that facilitate the adoption of cutting-edge solutions. By investing in strategic sourcing today, companies can position themselves for success in tomorrow’s automation-driven economy.