Introduction: Navigating the Global Market for parts for gas powered rc cars

In the fast-evolving landscape of remote-controlled (RC) vehicles, sourcing high-quality parts for gas-powered RC cars presents a significant challenge for B2B buyers across the globe. As demand increases, particularly in regions like Africa, South America, the Middle East, and Europe, businesses must navigate a complex marketplace filled with various suppliers, pricing structures, and product specifications. This comprehensive guide serves as a vital resource for international buyers, offering insights into the types of parts available, their applications, and strategies for effective supplier vetting.

From engine components and chassis parts to performance upgrades and maintenance essentials, understanding the full spectrum of gas-powered RC car parts is crucial. This guide empowers buyers to make informed purchasing decisions by detailing cost considerations, quality benchmarks, and sourcing strategies. It also emphasizes the importance of establishing reliable partnerships with manufacturers and distributors, ensuring that businesses can maintain a competitive edge in their respective markets.

By leveraging the knowledge provided in this guide, B2B buyers will be equipped to streamline their sourcing processes, mitigate risks, and enhance their product offerings. Whether you are a seasoned distributor or an emerging business in the RC sector, this guide aims to facilitate successful procurement strategies that will drive growth and customer satisfaction.

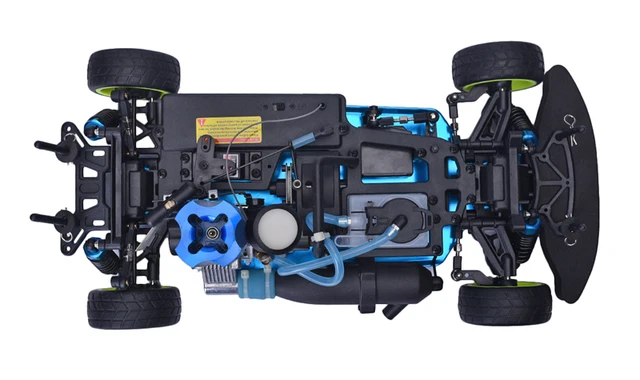

Understanding parts for gas powered rc cars Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Engines | Varying sizes and power outputs, typically nitro or gasoline-powered | Manufacturing, racing events | Pros: High performance, customizable. Cons: Can be complex to maintain. |

| Carburetors | Adjustable fuel-air mixture settings, essential for engine efficiency | Performance tuning, repairs | Pros: Improves engine performance. Cons: Requires tuning expertise. |

| Chassis | Different materials (aluminum, plastic), varying designs for durability and weight | Vehicle assembly, upgrades | Pros: Enhances vehicle stability. Cons: May increase overall weight. |

| Suspension Systems | Types include independent and solid axle, affects handling and comfort | Custom builds, racing applications | Pros: Improves handling and off-road capability. Cons: Can be costly to upgrade. |

| Tires & Wheels | Varying tread patterns and sizes for different terrains and performance needs | Replacement, upgrades, racing | Pros: Enhances traction and control. Cons: Selecting the wrong type can hinder performance. |

What Are the Key Characteristics of Engines for Gas Powered RC Cars?

Engines are the heart of gas-powered RC cars, available in various sizes and power outputs, typically ranging from 2.5cc to 5.0cc. They can be nitro or gasoline-powered, with nitro engines being common for racing due to their high RPM capabilities. B2B buyers should consider the intended application—whether for racing or recreational use—as well as compatibility with existing vehicle components. Maintenance requirements are also crucial, as a more complex engine may necessitate specialized knowledge or tools.

How Do Carburetors Impact the Performance of Gas Powered RC Cars?

Carburetors are vital components that regulate the air-fuel mixture entering the engine. Adjustable settings allow for fine-tuning, which can significantly enhance engine performance and efficiency. B2B buyers should assess the specific needs for their vehicles, including the type of racing or terrain. Understanding the technical aspects of carburetor tuning is essential, as improper adjustments can lead to engine inefficiency or failure.

What Should Buyers Look for When Choosing Chassis for Gas Powered RC Cars?

Chassis types vary greatly, with options in materials like aluminum for lightweight and durability or plastic for cost-effectiveness. The choice of chassis affects the overall performance, stability, and weight of the vehicle. B2B buyers need to consider the specific use case—whether for racing, off-roading, or casual driving—when selecting a chassis. Additionally, compatibility with other vehicle components is crucial for seamless integration.

How Do Suspension Systems Influence the Handling of Gas Powered RC Cars?

Suspension systems play a critical role in a vehicle’s handling and comfort, with options ranging from independent to solid axle systems. The choice impacts how well the car navigates different terrains and absorbs shocks. B2B buyers should evaluate their specific needs—whether for racing or off-road performance—when selecting suspension components. While upgrading can improve performance, it often comes with increased costs and complexity.

Why Are Tires and Wheels Important for Gas Powered RC Cars?

Tires and wheels are essential for traction and control, with various tread patterns designed for specific terrains, such as mud, gravel, or pavement. The right combination can significantly affect performance and handling. B2B buyers should assess the type of terrain their vehicles will encounter and choose tires accordingly. Selecting the wrong type can hinder performance, making it vital to understand the application and environment for effective purchasing decisions.

Key Industrial Applications of parts for gas powered rc cars

| Industry/Sector | Specific Application of parts for gas powered rc cars | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hobby Retail | Retailing of gas-powered RC car parts for enthusiasts | Increased sales through a diverse product range | Supplier reliability, quality assurance, and pricing |

| Event Management | Organizing RC car racing events using customized vehicles | Enhanced customer engagement and brand loyalty | Availability of parts, customization options, and lead times |

| Educational Institutions | Utilizing RC cars in engineering and robotics programs | Hands-on learning experience for students | Durability of parts, ease of assembly, and educational value |

| Automotive Engineering | Research and development of remote-controlled vehicle technologies | Innovation in vehicle design and technology | Access to advanced parts, technical support, and compatibility |

| Film and Media Production | Creating action sequences with gas-powered RC vehicles | Unique visual effects and cost-effective production | Quality of parts, availability of specialized components |

How Are Parts for Gas-Powered RC Cars Used in Hobby Retail?

Hobby retail stores play a significant role in the gas-powered RC car market by offering a variety of parts, including engines, tires, and chassis components. These parts enable enthusiasts to customize and enhance their vehicles, driving customer satisfaction and repeat business. International buyers, especially from regions like Africa and South America, should consider supplier reliability and product quality, as these factors directly impact customer experience and sales performance.

How Do Event Management Companies Benefit from Gas-Powered RC Cars?

Event management companies leverage gas-powered RC cars to host exciting racing events that attract participants and spectators alike. The ability to customize vehicles with high-performance parts enhances the racing experience, fostering community engagement and brand loyalty. Buyers in this sector should prioritize the availability of parts and customization options to ensure timely preparation for events, as well as consider lead times when sourcing from international suppliers.

How Are Educational Institutions Using RC Cars for Learning?

Educational institutions incorporate gas-powered RC cars into engineering and robotics programs to provide students with practical, hands-on learning experiences. This application not only enhances students’ understanding of mechanical engineering concepts but also encourages teamwork and problem-solving skills. For international buyers, the durability of parts and ease of assembly are critical factors to ensure a smooth educational experience and minimize downtime during projects.

What Role Do Gas-Powered RC Cars Play in Automotive Engineering?

In the automotive engineering sector, gas-powered RC cars serve as platforms for research and development of remote-controlled vehicle technologies. Engineers utilize these vehicles to test new designs and innovations in a controlled environment, which can lead to advancements in full-scale automotive technologies. Buyers in this industry should focus on sourcing advanced parts that offer technical support and compatibility with existing systems to facilitate seamless integration into their projects.

How Are Gas-Powered RC Cars Used in Film and Media Production?

Film and media production companies use gas-powered RC cars to create dynamic action sequences and special effects at a fraction of the cost of full-sized vehicles. These cars can be customized with various parts to achieve desired performance characteristics, making them versatile tools for filmmakers. For buyers in this sector, the quality of parts and the availability of specialized components are essential to ensure that production schedules are met and visual effects are executed flawlessly.

3 Common User Pain Points for ‘parts for gas powered rc cars’ & Their Solutions

Scenario 1: Navigating the Complexity of Sourcing Quality Parts

The Problem:

B2B buyers often struggle with sourcing high-quality parts for gas-powered RC cars, particularly when dealing with various suppliers across different regions. The challenge is compounded by the inconsistency in quality, availability, and compatibility of parts. For buyers in regions like Africa or South America, where access to reliable supply chains can be limited, the risk of receiving subpar or incompatible components is significant. This not only leads to delays in production but can also harm customer relationships if the products fail to meet performance expectations.

The Solution:

To overcome this sourcing dilemma, buyers should prioritize establishing relationships with reputable suppliers that specialize in gas-powered RC car parts. Conduct thorough research on potential vendors, focusing on their track record, customer reviews, and the range of parts they offer. It is beneficial to request samples or small orders first to evaluate quality before committing to larger purchases. Additionally, leveraging international trade platforms can provide access to verified suppliers, ensuring that the parts meet industry standards. Establishing a clear communication channel with suppliers about specifications and requirements will also help mitigate risks related to compatibility and quality.

Scenario 2: Managing Inventory and Availability of Parts

The Problem:

A common pain point for B2B buyers is managing inventory levels of gas-powered RC car parts. With fluctuating demand, particularly in seasonal markets or emerging economies, buyers often find themselves either overstocked with parts that don’t sell or facing shortages when demand spikes. This imbalance can lead to increased holding costs or missed sales opportunities, significantly affecting profitability.

The Solution:

Implementing a just-in-time (JIT) inventory system can help manage inventory effectively. This approach minimizes holding costs by aligning orders with production schedules and customer demand. Buyers should analyze sales data to forecast demand accurately, allowing for timely reordering of parts. Collaborating closely with suppliers to establish a reliable supply chain can also facilitate quick turnaround times for restocking. Utilizing inventory management software can streamline this process by providing real-time insights into stock levels and automated alerts for low inventory, ensuring that buyers maintain optimal stock levels without excess.

Scenario 3: Ensuring Compatibility and Performance of Parts

The Problem:

Another challenge faced by B2B buyers involves ensuring that the parts they procure are compatible with the specific models of gas-powered RC cars they are servicing. Incompatibility can lead to performance issues or failures, which can damage a company’s reputation and lead to costly returns. Buyers often struggle to keep up with the rapidly evolving technology in RC cars, making it difficult to know which parts will work best.

The Solution:

To address compatibility concerns, buyers should invest in training and development for their procurement teams, focusing on understanding the specifications and requirements of different RC car models. Maintaining an updated database of compatible parts based on model specifications can also streamline the selection process. Engaging with manufacturers directly can provide valuable insights into the latest parts and their applications. Additionally, creating a feedback loop with end-users can help gather information on performance and compatibility issues, allowing buyers to make informed decisions when sourcing parts in the future.

Strategic Material Selection Guide for parts for gas powered rc cars

What Are the Key Materials Used in Parts for Gas Powered RC Cars?

When selecting materials for parts in gas-powered RC cars, several factors come into play, including performance, durability, cost, and regulatory compliance. Here, we analyze four common materials used in these applications: aluminum, carbon fiber, nylon, and steel.

How Does Aluminum Benefit Gas Powered RC Car Parts?

Aluminum is a popular choice for various components such as chassis, suspension arms, and engine mounts. It offers a favorable strength-to-weight ratio, making it ideal for performance-oriented applications. Key properties include excellent corrosion resistance and good thermal conductivity, which helps dissipate heat from engine components.

Pros: Aluminum is lightweight and relatively easy to machine, which simplifies manufacturing processes. It also has a lower cost compared to other high-performance materials, making it accessible for both manufacturers and end-users.

Cons: While aluminum is durable, it can be prone to fatigue over time, particularly in high-stress applications. Additionally, it may not withstand extreme temperatures as well as some other materials.

International Considerations: Buyers in regions like the Middle East and South America should ensure that the aluminum used complies with local standards, such as ASTM or JIS, to guarantee quality and performance.

What Advantages Does Carbon Fiber Offer for RC Car Parts?

Carbon fiber is renowned for its exceptional strength and lightweight properties. It is commonly used in high-end components such as chassis and body panels, where performance is critical. The material’s rigidity and resistance to deformation enhance the vehicle’s handling characteristics.

Pros: Carbon fiber components can significantly reduce the overall weight of the vehicle, improving speed and agility. Its high tensile strength also ensures durability under demanding conditions.

Cons: The primary drawback of carbon fiber is its high cost, which can be prohibitive for budget-conscious buyers. Additionally, manufacturing carbon fiber parts can be complex, requiring specialized processes.

International Considerations: Compliance with international standards is crucial, especially in markets like Europe, where regulations may dictate the use of specific materials for safety and performance.

How Does Nylon Contribute to the Performance of RC Car Parts?

Nylon is frequently used for gears, bushings, and other components that require resilience and flexibility. Its excellent wear resistance and low friction properties make it suitable for moving parts in gas-powered RC cars.

Pros: Nylon is lightweight and cost-effective, making it an attractive option for manufacturers. It also offers good chemical resistance, which is beneficial for parts exposed to fuel and lubricants.

Cons: One limitation of nylon is its susceptibility to UV degradation, which can affect its longevity in outdoor applications. Additionally, it may not perform well under high-temperature conditions.

International Considerations: Buyers should verify that nylon components meet relevant standards, particularly in regions like Africa and South America, where material quality can vary significantly.

What Role Does Steel Play in Gas Powered RC Car Parts?

Steel is often used for critical components such as drive shafts, axles, and engine parts due to its high strength and durability. It can withstand significant stress and is less likely to deform under load.

Pros: The primary advantage of steel is its robustness, making it suitable for high-performance applications. It is also relatively inexpensive compared to advanced materials like carbon fiber.

Cons: Steel is heavier than other materials, which can negatively impact the vehicle’s performance. It is also prone to rust and corrosion if not properly treated.

International Considerations: Compliance with standards such as DIN in Europe or ASTM in the U.S. is essential for ensuring that steel components are of high quality and suitable for use in various environmental conditions.

Summary of Material Selection

| Material | Typical Use Case for parts for gas powered rc cars | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Chassis, suspension arms, engine mounts | Lightweight and corrosion-resistant | Prone to fatigue over time | Medium |

| Carbon Fiber | Chassis, body panels | Exceptional strength-to-weight ratio | High cost and complex manufacturing | High |

| Nylon | Gears, bushings | Cost-effective and low friction | Susceptible to UV degradation | Low |

| Steel | Drive shafts, axles, engine parts | High strength and durability | Heavier and prone to corrosion | Medium |

Selecting the right material for gas-powered RC car parts involves balancing performance, cost, and compliance with international standards. Understanding the properties and implications of each material will help B2B buyers make informed decisions that meet their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for parts for gas powered rc cars

What Are the Key Stages in the Manufacturing Process for Parts of Gas-Powered RC Cars?

The manufacturing of parts for gas-powered RC cars involves several critical stages, each designed to ensure high-quality output. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step is sourcing high-quality raw materials, such as aluminum, steel, or composite materials, which are essential for durability and performance. Manufacturers often conduct material inspections to ensure compliance with specifications and standards, such as ASTM or ISO norms.

-

Forming: During this stage, raw materials undergo various forming techniques, including machining, casting, or forging. CNC (Computer Numerical Control) machining is a common method employed to achieve precision in the production of intricate components, such as engine parts and chassis. This method allows for high repeatability and accuracy, which is crucial for performance-critical applications.

-

Assembly: After forming, parts are assembled into sub-assemblies or final products. This process may involve manual labor or automated assembly lines, depending on the complexity and volume of production. It is essential that assembly procedures are well-documented and followed to minimize errors and ensure consistency.

-

Finishing: The final stage involves surface treatments such as anodizing, powder coating, or painting to enhance aesthetic appeal and corrosion resistance. Finishing processes also include quality checks to ensure that the parts meet visual and functional standards.

How Is Quality Assurance Integrated into Manufacturing for RC Car Parts?

Quality assurance (QA) is a critical aspect of the manufacturing process that ensures each part meets stringent quality standards. Various international and industry-specific standards guide the QA processes.

-

International Standards: Compliance with standards like ISO 9001 is vital, as it outlines the requirements for a quality management system. This certification helps ensure that manufacturers consistently provide products that meet customer and regulatory requirements.

-

Industry-Specific Standards: In addition to general ISO standards, manufacturers may adhere to specific standards such as CE marking in Europe or API standards for components in the oil and gas sector. These certifications assure buyers that products comply with safety and performance benchmarks.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early and ensure compliance with quality standards.

-

Incoming Quality Control (IQC): This step involves inspecting raw materials before they enter the production process. IQC ensures that only materials meeting the required specifications are used, minimizing defects in the final product.

-

In-Process Quality Control (IPQC): During production, manufacturers conduct IPQC to monitor processes and identify any deviations from standards. This includes regular inspections and tests at various stages of manufacturing.

-

Final Quality Control (FQC): After assembly, FQC involves comprehensive testing of the finished products. This may include functional testing, stress testing, and aesthetic inspections to ensure that parts perform well under operational conditions.

What Testing Methods Are Commonly Used for Gas-Powered RC Car Parts?

Testing is a fundamental part of the QC process, and several methods are employed to evaluate the performance and durability of RC car components.

-

Functional Testing: This method assesses whether the parts operate correctly under simulated conditions. For instance, engine components may be tested for performance metrics such as power output and fuel efficiency.

-

Durability Testing: Parts are subjected to stress tests that mimic real-world usage. This can include vibration testing, thermal cycling, and fatigue testing to ensure long-term reliability.

-

Dimensional Inspection: Utilizing tools such as calipers and coordinate measuring machines (CMM), manufacturers verify that the dimensions of parts adhere to design specifications. This is crucial for ensuring compatibility and performance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is essential to mitigate risks associated with subpar products.

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate a supplier’s manufacturing processes, quality control measures, and compliance with international standards. This hands-on approach provides insights into the supplier’s operational capabilities.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers assess compliance with standards such as ISO 9001. These reports typically include information on past performance, defect rates, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspectors can perform random sampling and testing to verify that products meet specified standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the complexities of international quality control can present challenges for B2B buyers. Understanding regional regulations and expectations is crucial.

-

Cultural Considerations: Different regions may have varying expectations regarding quality standards and practices. Buyers should familiarize themselves with local regulations and industry norms to ensure effective communication with suppliers.

-

Documentation: Ensure that all quality control documentation is available in a language and format that is understandable. This includes certifications, test results, and compliance records.

-

Flexibility in Standards: Recognize that while international standards provide a baseline, local market conditions may necessitate additional requirements. Buyers should discuss these nuances with suppliers to establish clear expectations.

By understanding the manufacturing processes and quality assurance practices for parts of gas-powered RC cars, international B2B buyers can make informed decisions and build long-term partnerships with reliable suppliers. This comprehensive approach not only enhances product quality but also strengthens the supply chain, ensuring that businesses can meet the demands of their customers effectively.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts for gas powered rc cars’

Introduction

This guide provides a practical checklist for B2B buyers seeking to procure parts for gas-powered RC cars. Whether you’re a distributor, retailer, or hobby shop owner, understanding the sourcing process is critical to ensure quality, reliability, and cost-effectiveness in your inventory. Follow these steps to streamline your procurement process and make informed decisions.

1. Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the parts you need. This includes identifying the type of gas-powered RC cars you cater to, such as models from Traxxas or other brands. Knowing the dimensions, materials, and performance requirements will help you communicate effectively with suppliers and avoid compatibility issues.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in gas-powered RC car parts. Look for companies with a proven track record and positive reviews from other B2B buyers. Consider factors such as:

– Product Range: Ensure they offer a comprehensive selection of parts, including engines, carburetors, and performance upgrades.

– Industry Experience: Suppliers with extensive experience in the RC market are more likely to understand your needs.

3. Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications and comply with international quality standards. Certifications such as ISO 9001 can indicate a commitment to quality management. Request documentation to ensure that the products meet safety and performance standards, which is crucial for maintaining customer satisfaction.

4. Request Samples or Prototypes

Before finalizing a supplier, request samples or prototypes of the parts you intend to purchase. This step allows you to assess the quality, durability, and overall performance of the products firsthand. Pay attention to:

– Material Quality: Ensure that the parts are made from high-quality materials that can withstand rigorous use.

– Compatibility: Test the parts with your existing RC car models to confirm fit and functionality.

5. Analyze Pricing and Payment Terms

Compare pricing structures among different suppliers to ensure you receive competitive rates. Be aware of the total cost, including shipping, duties, and potential tariffs, particularly if sourcing from international suppliers. Additionally, clarify payment terms to avoid any surprises, such as:

– Payment Methods: Ensure they accept secure payment options that suit your business.

– Discounts for Bulk Orders: Inquire about discounts for large orders, which can significantly affect your bottom line.

6. Assess Customer Support and After-Sales Service

Evaluate the level of customer support and after-sales service offered by the suppliers. Reliable suppliers should provide assistance with product inquiries, troubleshooting, and warranty claims. Consider:

– Response Time: Quick and efficient communication is vital in addressing any concerns that may arise post-purchase.

– Return Policy: Understand the return policy in case the parts do not meet your expectations or are defective.

7. Establish a Long-Term Relationship

Once you have selected a supplier, aim to build a long-term relationship. Consistent communication and feedback will foster collaboration and may lead to better pricing, priority service, and exclusive access to new products. Consider:

– Regular Orders: Establish a routine for placing orders based on your inventory needs.

– Feedback Loop: Provide constructive feedback to help suppliers improve their offerings and services.

By following these steps, you can effectively navigate the sourcing process for parts for gas-powered RC cars, ensuring a reliable supply chain that meets your business needs.

Comprehensive Cost and Pricing Analysis for parts for gas powered rc cars Sourcing

When sourcing parts for gas-powered RC cars, understanding the comprehensive cost structure and pricing analysis is crucial for international B2B buyers. This involves a thorough examination of cost components, price influencers, and strategic buyer tips tailored to regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Sourcing RC Car Parts?

The cost structure for parts of gas-powered RC cars typically consists of several critical components:

-

Materials: The primary cost driver, materials used in manufacturing such as metals, plastics, and composites significantly impact pricing. High-quality materials can enhance performance but may also increase costs.

-

Labor: Labor costs are influenced by the region of production. Countries with lower wage standards may offer cheaper labor, but this could compromise quality.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory management. Overhead can vary greatly depending on the efficiency of the manufacturing process.

-

Tooling: Initial investment in molds and tools can be substantial, particularly for custom parts. This cost is often amortized over the production volume.

-

Quality Control (QC): Ensuring that parts meet specified standards requires investment in QC processes, which can add to overall costs. Certifications may also be necessary, particularly for international markets.

-

Logistics: Shipping and handling costs are pivotal, especially when sourcing parts internationally. Factors such as distance, shipping method, and customs duties can significantly affect the final price.

-

Margin: Suppliers will typically add a markup to cover their costs and profit. Understanding standard margin rates in the industry can help buyers gauge fair pricing.

How Do Various Price Influencers Affect the Sourcing of RC Car Parts?

Several factors influence the pricing of gas-powered RC car parts, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Negotiating MOQs can lead to significant cost savings.

-

Specifications and Customization: Custom parts may come at a premium. Buyers should clearly define specifications to avoid unexpected costs.

-

Materials: The choice of materials directly impacts both the cost and performance of the parts. Higher-grade materials may be necessary for performance but will also elevate costs.

-

Quality and Certifications: Parts that meet international quality standards or have specific certifications may command higher prices but ensure reliability and compliance with regulations.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may offer higher prices due to their quality assurance processes.

-

Incoterms: Understanding shipping terms is critical for managing costs. Different Incoterms can shift the responsibility for shipping costs and risks, impacting the total cost of ownership.

What Strategic Tips Can Buyers Utilize to Optimize Costs?

International B2B buyers should adopt several strategies to enhance cost efficiency:

-

Negotiation: Leverage volume purchases and long-term relationships to negotiate better pricing. Transparent discussions about budget constraints can lead to favorable terms.

-

Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, durability, and replacement costs. Investing in higher-quality parts may reduce long-term expenses.

-

Be Aware of Pricing Nuances: Different regions may have varying standards and expectations that influence pricing. Buyers in Africa, South America, the Middle East, and Europe should be cognizant of local market conditions and cultural factors that may affect negotiations.

-

Conduct Market Research: Understanding competitor pricing and market trends can provide leverage in negotiations. Use online resources and industry reports to inform your sourcing decisions.

-

Plan for Logistics: Consider the logistics involved in sourcing parts, including potential delays and additional costs. A well-planned supply chain can mitigate unexpected expenses.

Disclaimer

Prices for gas-powered RC car parts can vary widely based on the aforementioned factors. The information provided is indicative and should be verified with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing parts for gas powered rc cars With Other Solutions

Understanding the Alternatives to Parts for Gas Powered RC Cars

When considering the procurement of parts for gas-powered RC cars, it is crucial for B2B buyers to evaluate alternative solutions that may provide similar performance or fulfill the same needs. This analysis will compare traditional gas-powered RC car parts with electric RC car components and DIY kits, highlighting key performance metrics, costs, ease of implementation, maintenance requirements, and best use cases.

Comparison Table

| Comparison Aspect | Parts For Gas Powered RC Cars | Electric RC Car Parts | DIY RC Car Kits |

|---|---|---|---|

| Performance | High torque and speed | Moderate torque; high acceleration | Customizable performance based on components |

| Cost | Generally higher | Moderate initial cost; lower long-term costs | Variable; can be low or high based on components |

| Ease of Implementation | Requires technical knowledge | Easier to set up; plug-and-play options available | Requires assembly and knowledge of components |

| Maintenance | High; frequent tuning needed | Low; minimal maintenance required | Variable; depends on complexity of build |

| Best Use Case | Competitive racing, rugged terrain | Casual driving, indoor use | Custom builds for specific needs or preferences |

Exploring the Alternatives in Detail

Electric RC Car Parts

Electric RC car parts present a viable alternative to gas-powered components, especially for users who prioritize ease of use and lower maintenance. These systems typically feature plug-and-play components, making them accessible for beginners and those with limited technical expertise. However, while they offer high acceleration and are often quieter and cleaner, electric models may not match the torque and overall performance of gas-powered systems in competitive environments. The initial costs can be moderate, but the long-term savings in maintenance make them attractive for casual users.

DIY RC Car Kits

DIY RC car kits cater to enthusiasts who enjoy the assembly and customization process. These kits allow buyers to tailor their vehicles to specific performance needs and preferences, creating a unique product that can outperform standard models. However, they require a good understanding of the components and assembly process, which can be a barrier for some users. Costs can vary widely depending on the quality and type of components chosen, but the potential for high-performance outcomes makes DIY kits appealing for serious hobbyists and competitive racers.

Making the Right Choice for Your B2B Needs

In conclusion, the choice between parts for gas-powered RC cars and their alternatives hinges on specific business needs and user preferences. Buyers should consider factors such as performance requirements, budget constraints, and the level of technical expertise available. For competitive racing or rugged terrains, gas-powered parts might be the best fit. Conversely, for casual use or those looking for an engaging project, electric parts or DIY kits could provide a more suitable and cost-effective solution. Careful evaluation of these alternatives will ensure that B2B buyers invest in the right products that align with their operational goals.

Essential Technical Properties and Trade Terminology for parts for gas powered rc cars

What Are the Key Technical Properties Important for Gas-Powered RC Car Parts?

When sourcing parts for gas-powered remote control (RC) cars, understanding specific technical properties is crucial for ensuring product quality, performance, and compatibility. Here are some essential specifications to consider:

-

Material Grade

The material grade indicates the quality and durability of components, such as chassis, gears, and engine parts. Common materials include aluminum, carbon fiber, and high-density plastics. B2B buyers should prioritize high-grade materials to enhance longevity and performance, particularly in high-stress applications like racing. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. Precise tolerances are critical in mechanical parts to ensure proper fit and function, especially in engine components like pistons and sleeves. Understanding tolerance levels helps buyers avoid costly operational issues and maintain optimal performance. -

Weight

The weight of parts influences the overall performance of the RC car, affecting speed and handling. Lighter materials can improve acceleration and maneuverability, while heavier components may enhance stability. Buyers should consider the weight specifications when selecting parts to align with their performance goals. -

Fuel Compatibility

Different gas-powered RC engines are designed for specific fuel types, such as nitro or gasoline. Ensuring that parts are compatible with the intended fuel type is essential for performance and engine longevity. Buyers should verify fuel compatibility to avoid operational failures and potential damage to the vehicle. -

Heat Resistance

Heat resistance is vital for components exposed to high temperatures during operation, particularly engine parts. Materials with high heat resistance can prevent warping and failure, ensuring reliability in high-performance settings. Buyers should check heat resistance specifications to maintain optimal functionality. -

Corrosion Resistance

Parts exposed to moisture or harsh environments should have corrosion-resistant properties to prolong service life. Materials such as stainless steel or specially coated components can help mitigate rust and degradation. B2B buyers must consider corrosion resistance, especially in regions with high humidity or varying temperatures.

What Are the Common Trade Terms Used in the Gas-Powered RC Car Parts Industry?

Familiarity with industry-specific jargon can facilitate smoother transactions and negotiations. Here are several common trade terms relevant to B2B buyers:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the RC car. These parts are designed for compatibility and performance, making them a reliable choice for buyers seeking quality replacements. Understanding OEM specifications can aid in selecting appropriate parts. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budgeting and inventory management. Buyers should clarify MOQ requirements to ensure they can meet supplier conditions without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is an essential step in the procurement process, enabling buyers to compare offers and negotiate terms effectively. Buyers should prepare detailed RFQs to receive accurate and competitive quotations. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping transactions. Understanding Incoterms helps buyers anticipate costs and liabilities related to shipping, insurance, and customs clearance, facilitating smoother international trade. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. This term is vital for project planning and inventory management. Buyers should inquire about lead times to ensure timely delivery of parts, especially for urgent projects. -

Aftermarket Parts

Aftermarket parts are components made by manufacturers other than the original producer. These parts can offer cost savings or enhanced performance options. Buyers should evaluate the quality and compatibility of aftermarket parts to ensure they meet their specific needs.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance the performance and reliability of gas-powered RC cars while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the parts for gas powered rc cars Sector

What Are the Current Market Dynamics and Key Trends in the Parts for Gas-Powered RC Cars Sector?

The global market for gas-powered remote control (RC) cars is witnessing significant growth, driven by increasing consumer interest in hobbies that combine technology and outdoor activity. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where urbanization and improved disposable incomes are fostering a vibrant hobbyist community. Furthermore, the rise of online marketplaces has simplified access to a diverse range of products, making it easier for B2B buyers to source high-quality parts efficiently.

Emerging technologies are reshaping the sourcing landscape within this sector. For instance, 3D printing is gaining traction for manufacturing custom parts, allowing for rapid prototyping and reduced lead times. Additionally, the integration of e-commerce platforms with advanced analytics and artificial intelligence is facilitating better inventory management and tailored marketing strategies, helping B2B buyers make informed purchasing decisions.

Sustainability is becoming increasingly relevant, with consumers and businesses alike seeking eco-friendly alternatives. This includes a growing demand for parts made from recyclable materials and those produced through sustainable practices. As a result, suppliers that prioritize transparency in their sourcing and manufacturing processes are likely to gain a competitive edge in the market.

How Does Sustainability and Ethical Sourcing Impact B2B in the Gas-Powered RC Car Parts Market?

The environmental impact of manufacturing and sourcing parts for gas-powered RC cars is a critical consideration for B2B buyers. The production processes often involve materials that can be harmful to the environment if not managed responsibly. As such, ethical sourcing has become an imperative for businesses looking to align with global sustainability goals and consumer expectations.

B2B buyers should prioritize suppliers that are committed to sustainable practices, such as using eco-friendly materials and minimizing waste throughout the production cycle. Certifications like ISO 14001 (Environmental Management) and participation in sustainability initiatives can serve as indicators of a supplier’s commitment to ethical sourcing. Furthermore, sourcing parts that utilize biodegradable materials or are manufactured using renewable energy sources can enhance brand reputation and appeal to environmentally conscious consumers.

In regions like Europe and South America, where regulatory frameworks around sustainability are tightening, businesses that adopt green practices may not only meet compliance requirements but also differentiate themselves in a competitive market. Emphasizing sustainability in procurement strategies can lead to long-term cost savings and improved customer loyalty.

What Is the Brief Evolution of the Gas-Powered RC Car Parts Market?

The gas-powered RC car market has evolved significantly since its inception in the late 20th century. Initially dominated by simple designs and limited availability, technological advancements have transformed both the cars and their parts into sophisticated machines capable of high performance. The introduction of nitro engines, for instance, revolutionized speed and power, attracting a dedicated fan base.

As the market matured, manufacturers began to focus on customization and performance enhancement, leading to a wide array of aftermarket parts. This evolution has been further accelerated by the rise of online platforms, enabling hobbyists and businesses to connect more effectively. Today, the market is characterized by a blend of traditional craftsmanship and cutting-edge technology, positioning gas-powered RC cars as not just toys, but as serious hobbyist vehicles appealing to a diverse audience globally.

In conclusion, understanding the current market dynamics, prioritizing sustainability, and acknowledging the historical context are crucial for B2B buyers in the gas-powered RC car parts sector. These insights can inform more strategic sourcing decisions that not only meet current demands but also anticipate future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of parts for gas powered rc cars

-

How do I identify high-quality suppliers for gas-powered RC car parts?

To identify high-quality suppliers, research their reputation through online reviews, industry forums, and testimonials from other B2B buyers. It’s beneficial to request samples to assess product quality firsthand. Furthermore, ensure that the supplier has a solid track record in international trade, including compliance with local regulations in your region. Look for suppliers who provide certifications for their products, such as ISO or CE, as these can indicate adherence to quality standards. -

What are the most essential parts to stock for gas-powered RC cars?

Key parts to stock include engine components (pistons, carburetors), chassis parts, tires, and fuel systems. Additionally, consider carrying high-demand accessories such as performance upgrades, batteries, and replacement bodies. Keeping an inventory of both OEM and aftermarket parts can cater to a wider range of customer preferences and price points, enhancing your ability to meet diverse market needs. -

What is the typical minimum order quantity (MOQ) for gas-powered RC car parts?

MOQs can vary widely based on the supplier and the type of parts ordered. Generally, for gas-powered RC car parts, you might expect MOQs ranging from 50 to 500 units. Always clarify MOQs with your supplier to avoid unexpected costs. Some suppliers may offer flexibility on MOQs for first-time orders or for bulk purchases, so negotiate terms that align with your business strategy. -

What payment terms should I expect when sourcing RC car parts internationally?

Payment terms can vary significantly by supplier. Common options include upfront payment, partial payment upon order confirmation, and balance upon delivery. For larger orders, consider using letters of credit or escrow services to protect your investment. Be sure to discuss payment methods acceptable to both parties, such as wire transfers, PayPal, or other online payment platforms, and ensure they are secure. -

How can I ensure the quality of parts sourced from international suppliers?

To ensure quality, implement a thorough supplier vetting process, which includes checking references and certifications. Request product samples before placing large orders to evaluate quality firsthand. Additionally, consider establishing quality assurance protocols, such as third-party inspections or audits, especially for critical components. Maintaining open communication with suppliers throughout the production process can also help address any quality concerns proactively. -

What logistics considerations should I keep in mind when importing RC car parts?

When importing RC car parts, factor in shipping costs, delivery times, and customs duties. Understand the logistics of your supply chain, including the reliability of shipping carriers and their transit times. It’s advisable to work with freight forwarders who can navigate customs and provide insights into the best shipping routes. Ensure that your suppliers provide accurate documentation to facilitate a smooth customs clearance process. -

What customization options are available for gas-powered RC car parts?

Many suppliers offer customization options for gas-powered RC car parts, including branding, color variations, and performance modifications. Discuss specific needs with your supplier to determine what can be tailored to fit your market demands. Customization can enhance your product offering and differentiate your brand in competitive markets, particularly in regions with unique consumer preferences. -

How can I stay updated on trends and innovations in the gas-powered RC car market?

To stay informed about industry trends, subscribe to trade publications, join relevant online forums, and participate in industry trade shows. Networking with other businesses and attending webinars can provide insights into emerging technologies and consumer preferences. Additionally, follow leading manufacturers and suppliers on social media to receive updates on new products and innovations that may impact your sourcing strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Parts For Gas Powered Rc Cars Manufacturers & Suppliers List

1. RC Planet – Nitro Gas Engines & Parts

Domain: rcplanet.com

Registered: 1998 (27 years)

Introduction: RC Nitro Gas Engines Carburetor Parts for RC Cars & Trucks. Free Shipping on Orders over $99. Various categories available including Airplanes, Boats, Drones, and more. Engine accessories such as air filters, glow plugs, and tuned pipes are included. Comprehensive parts finder and customer support via phone and text.

2. Traxxas – RC Cars & Trucks

Domain: rcsuperstore.com

Registered: 2002 (23 years)

Introduction: RC Cars, RC Trucks, RC Parts & Kits for Adults & Kids. Free Shipping on Orders Over $99. Ready-to-Run & Kit Vehicles available. Brands include Traxxas and LaTrax. Categories include Wheels & Tires, Bodies & Paint, Scale Crawler Accessories, Electric Motors & ESCs, Nitro/Gas Engines, Shock & Diff Oils, Batteries & Chargers. Various models listed such as 1/16 E-Revo, 1/16 Rally, 1/16 Slash, 1/10 Sum…

3. 1UP Racing – Nitro Gas RC Engine Piston

Domain: amainhobbies.com

Registered: 2004 (21 years)

Introduction: Radio Control Engine Parts, Nitro Gas RC Engine Piston Carb, Free Shipping on Orders over $99, Contact: 1-800-705-2215, Top Brands: 1UP Racing, Arrma, Castle Creations, Cayote, Cow RC, EcoPower, Flysky, Futaba, Gens Ace, Hitec, Hobbywing, Hudy, J&T Bearing Co., JConcepts, Junsi, Koswork, Kyosho, Losi, MIP, MYLAPS, No Superior Designs, RC Pro-Line, ProTek RC, Racebox, RadioMaster, RC4WD, Reedy, Ree…

4. Dollar Hobbyz – Traxxas LaTrax PreRunner 1/18 4X4 Desert Truck RTR

Domain: dollarhobbyz.com

Registered: 2011 (14 years)

Introduction: Dollar Hobbyz offers a variety of RC vehicles and accessories, including: 1. Traxxas LaTrax PreRunner 1/18 4X4 Desert Truck RTR – Blue, Price: $129.95 2. Traxxas LaTrax PreRunner 1/18 4X4 Desert Truck RTR – Red, Price: $129.95 3. ARRMA Granite GROM Mega 1/18 4X4 Monster Truck RTR – Green, Price: $149.99 (was $172.49) 4. ARRMA Granite GROM Mega 1/18 4X4 Monster Truck RTR – Blue, Price: $149.99 (was…

5. Eugene Toy & Hobby – RC Car Replacement Parts

Domain: eugenetoyandhobby.com

Registered: 1999 (26 years)

Introduction: RC Car Replacement Parts available at Eugene Toy & Hobby include a wide selection of parts and repair kits. Categories of parts include Accessories (15), Adapters & Connectors (20), Axle Parts (131), Battery Chargers (2), Battery Connectors (9), Battery Packs (4), Bearings & Bushings (58), Bellcranks (5), Bodies (58), Brakes (1), Bumpers (22), Chassis Parts (106), Clips (2), Clutches & Flywheels (…

6. Tower Hobbies – RC Parts & Accessories

Domain: towerhobbies.com

Registered: 1995 (30 years)

Introduction: RC Parts, Electronics & Accessories include a variety of components for cars, trucks, airplanes, boats, helicopters, trains, plastic models, and more. Key categories include: Batteries (2S, 3S, 4S LiPo, NiMH), Chargers (1 Port, 2 Port, 4 Port), Motors, Electronic Speed Controls, Engines, Bodies, Tires & Wheels, Radio Systems (Transmitters, Receivers, Servos), Tools, Paints, Lubricants, and Adhesiv…

7. RCA – Crankcase with Bearings + Carburetor Retainer

Domain: rcamerica.com

Registered: 1997 (28 years)

Introduction: [{‘name’: ‘CRANKCASE WITH BEARINGS + CARBURETOR RETAINER’, ‘code’: ‘611001’, ‘price’: ‘$50.35’, ‘availability’: ‘In stock’}, {‘name’: ‘REAR COVER & GASKET’, ‘code’: ‘611201’, ‘price’: ‘$17.40’, ‘availability’: ‘Out of stock’}, {‘name’: ‘CRANKSHAFT’, ‘code’: ‘611401’, ‘price’: ‘$62.80’, ‘availability’: ‘In stock’}, {‘name’: ‘BLUE HEATSINK HEAD – CNC MACHINED + HEAD SHIM’, ‘code’: ‘611601’, ‘price’:…

8. EngineDIY – TWOLF TW-715 V8 Engine Powered RC Truck

Domain: enginediy.com

Registered: 2018 (7 years)

Introduction: {“products”:[{“name”:”TWOLF TW-715 V8 Engine Powered 1:10 Scale RC Off-road 4WD 4-Door Pickup Truck Vehicle Crawler Kit”,”original_price”:”$1,999.99″,”current_price”:”$1,999.99″,”features”:”4WD, V8 Engine, KIT Version, No Electronic Equipment”,”rating”:”5.0/5.0″,”reviews”:3},{“name”:”VRX RH1006 RC Car 1/10 2.4G 4WD 75km/h High Speed Force 18 Gas Engine RTR Truck”,”original_price”:”$249.99″,”curren…

9. Atlanta Hobby – RC Cars & Trucks Replacement Parts

Domain: atlantahobby.com

Registered: 2002 (23 years)

Introduction: RC Cars & Trucks Replacement Parts available at Atlanta Hobby. Categories include Drive parts for various scales (1/10, 1/5, 1/6, 1/8, 1/12, 1/14, 1/16, 1/18, 1/24, 1/36), Motors and ESC’s, Tires & Wheels, Vehicle Bodies, Shock Fluid, Differential fluid, and more. Brands include ARRMA, Associated, Axial, Traxxas, and others. The store has been operational since 1978 and offers a wide range of prod…

Strategic Sourcing Conclusion and Outlook for parts for gas powered rc cars

In today’s competitive landscape for gas-powered RC car parts, strategic sourcing has never been more crucial. International B2B buyers must prioritize quality, reliability, and innovation when selecting suppliers. By leveraging a diverse network of manufacturers, especially those from regions like Africa, South America, the Middle East, and Europe, buyers can ensure they have access to high-performance components that meet the evolving demands of the market.

Investing in strong relationships with reputable suppliers not only enhances product offerings but also fosters resilience against market fluctuations. As the popularity of gas-powered RC vehicles continues to grow, so does the opportunity for businesses to capture market share by offering superior products and services.

Looking ahead, it is vital for B2B buyers to stay informed about emerging trends and technologies in the RC industry. Engage with suppliers who are committed to innovation and customer satisfaction, and consider participating in industry events to broaden your network. Now is the time to act—secure your competitive advantage by optimizing your sourcing strategies and positioning your business for success in the dynamic world of gas-powered RC cars.