Contents

Manufacturing Insight: Overmolding Process

Introduction to Precision Overmolding Solutions at Honyo Prototype

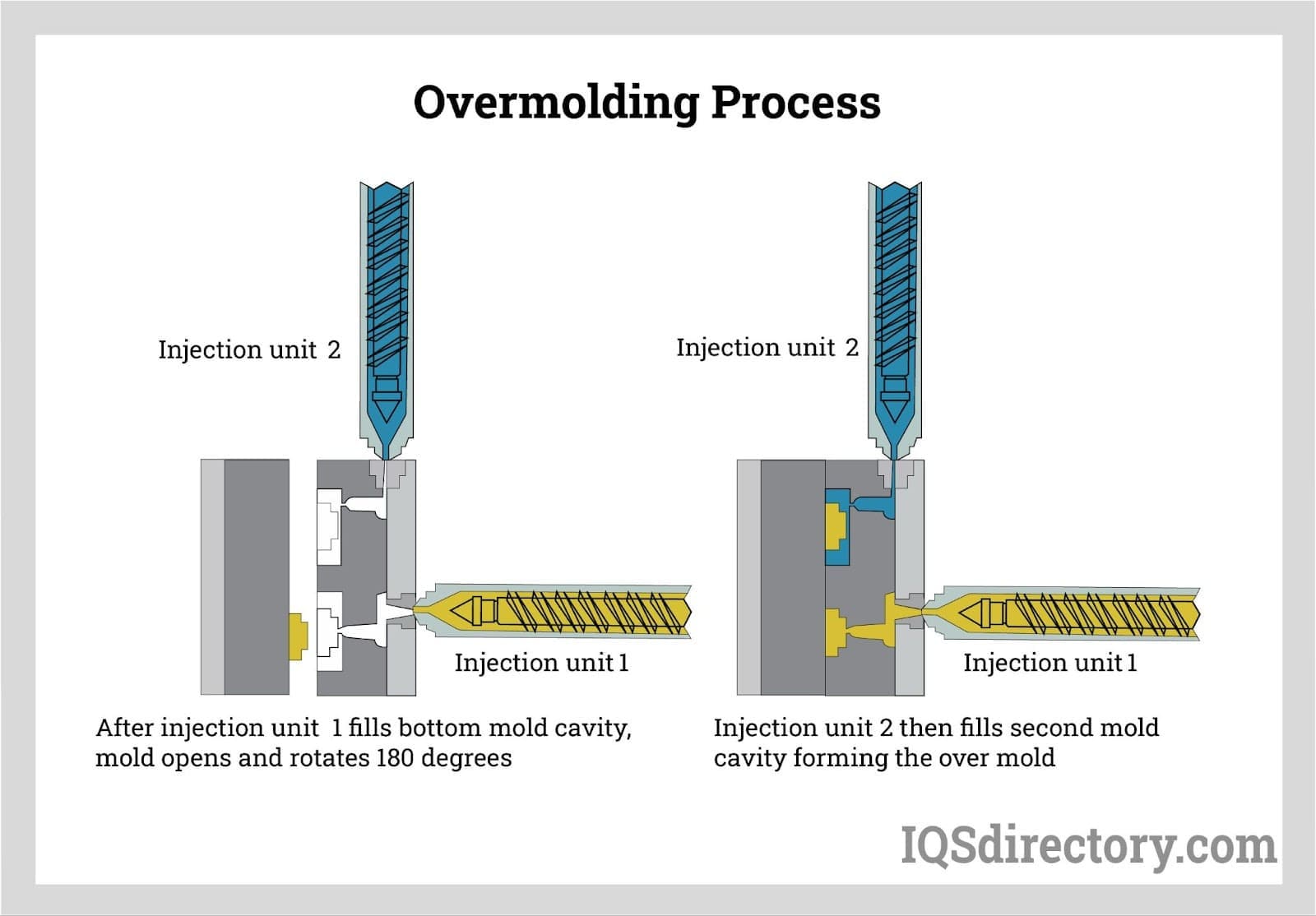

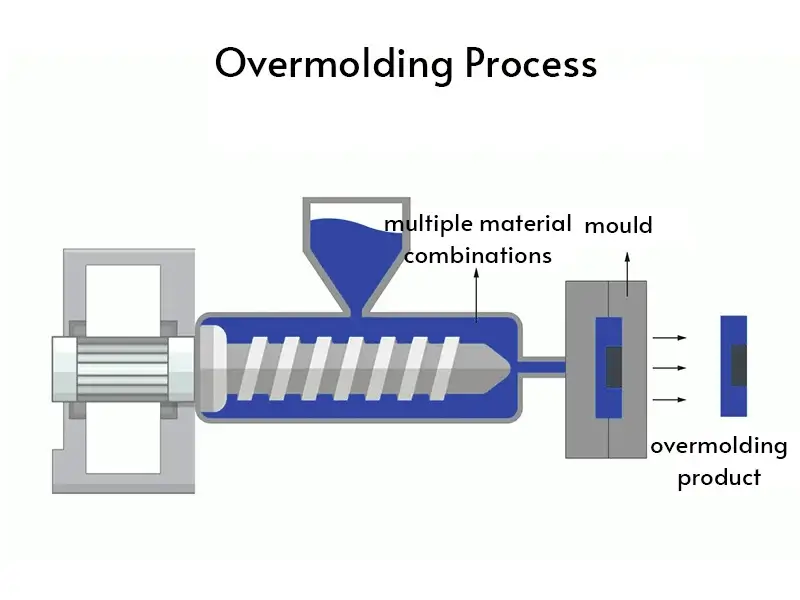

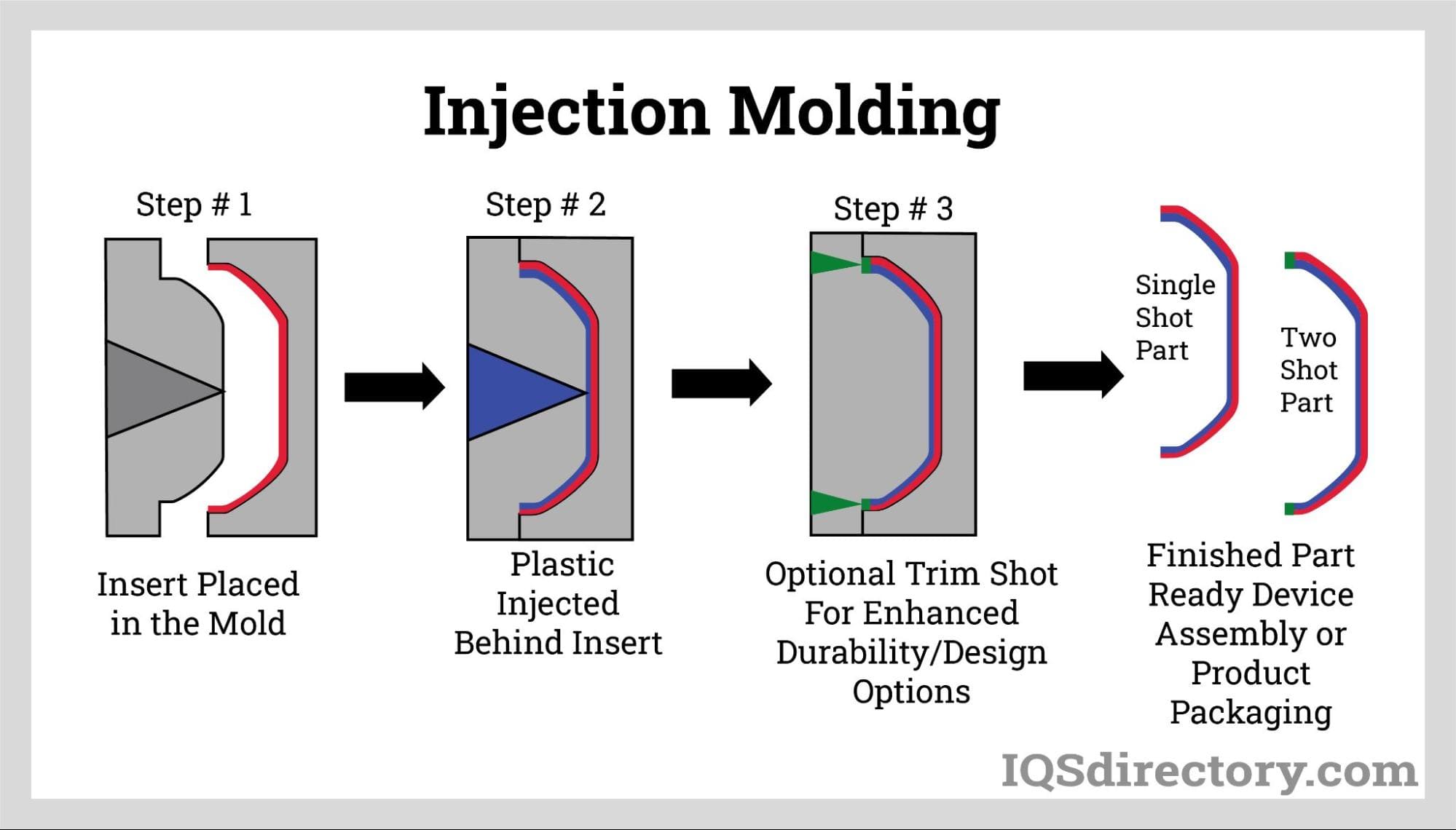

Overmolding is a critical multi-material injection molding process where a secondary thermoplastic elastomer (TPE) or polymer is precisely molded over a primary substrate component, creating integrated parts with enhanced functionality, aesthetics, and durability. Applications range from medical device grips and consumer electronics housings to automotive seals requiring biocompatibility, chemical resistance, or ergonomic soft-touch surfaces. Success hinges on exacting material compatibility, mold design precision, and controlled process parameters to ensure optimal adhesion and eliminate delamination risks.

Honyo Prototype excels in transforming complex overmolding concepts into high-fidelity prototypes and low-to-mid volume production parts through our Rapid Tooling and Injection Molding services. We deploy aluminum or pre-hardened steel molds fabricated via CNC machining and EDM, reducing traditional lead times by 50–70% while maintaining tight tolerances (±0.05mm) and surface finishes critical for overmold integrity. Our engineering team conducts thorough material flow analysis and substrate-adhesion validation, ensuring seamless integration of dissimilar polymers like ABS/TPE or PC/silicone without secondary assembly steps.

For engineering teams prioritizing speed and cost efficiency, our Online Instant Quote platform delivers real-time pricing and manufacturability feedback within hours—not days—enabling rapid iteration from design to functional validation. Partner with Honyo to leverage agile tooling, material science expertise, and streamlined quoting for overmolded components that meet rigorous performance demands.

Key Service Capabilities

| Process Stage | Honyo Prototype Advantage | Typical Lead Time |

|———————|————————————————————|——————-|

| Rapid Tooling | Aluminum molds for prototyping; steel for production runs | 7–15 days |

| Material Expertise | Optimized TPE/substrate pairing with adhesion validation | Included in RFQ |

| Injection Molding | 50–600T presses; cleanroom options; 2K molding support | 3–10 days |

| Quoting | Online Instant Quote with DFM analysis | < 4 hours |

Technical Capabilities

Overmolding is a multi-material injection molding process that bonds two or more substrates together in a single mold. It is commonly used to add a soft-touch thermoplastic elastomer (TPE) layer over a rigid plastic or metal substrate, or to combine different engineering plastics for enhanced functionality. At Honyo Prototype, we specialize in rapid overmolding using high-precision aluminum and steel molds, with a guaranteed T1 sample delivery within 7 days from mold completion.

Our technical capabilities focus on overmolding processes involving rigid substrates such as ABS and Nylon, overmolded with compatible elastomers or secondary plastics. Molds are fabricated from either Aluminum (for rapid prototyping and low-volume production) or Steel (for high-volume, long-life applications).

Below are the key technical specifications for our overmolding process:

| Parameter | Specification |

|---|---|

| Mold Material Options | Aluminum (7075-T6, 6061-T6), Steel (P20, H13, S136, 420 Stainless) |

| Mold Fabrication Lead Time | 5–7 days (Aluminum), 10–14 days (Steel) |

| T1 Sample Delivery | Within 7 days after mold completion |

| Standard Part Tolerances | ±0.1 mm (Aluminum), ±0.05 mm (Steel) |

| Max Mold Size | 600 mm × 600 mm × 400 mm (L×W×H) |

| Clamping Force Range | 90–400 tons (suitable for parts up to 300g per shot) |

| Primary Substrate Materials | ABS (Acrylonitrile Butadiene Styrene), Nylon (PA6, PA66, glass-filled options) |

| Overmold Materials | TPE, TPU, Silicone (Shore A 40–90), compatible with substrate adhesion |

| Surface Finishes | As-machined, EDM texture, polished (SPI finishes up to A1), custom textures |

| Secondary Operations | Ultrasonic welding, pad printing, assembly, packaging |

| Process Control | Real-time monitoring of pressure, temperature, and cycle time |

| Tooling Life Expectancy | 10,000–50,000 cycles (Aluminum), 100,000+ cycles (Steel) |

We ensure precise core-cavity alignment and optimized gating to prevent delamination and ensure strong interfacial adhesion between substrates. Our in-house material testing includes bond strength evaluation and environmental aging to validate overmold integrity.

This rapid turnaround with high-quality tooling makes our overmolding service ideal for functional prototyping, pilot runs, and bridge-to-production applications in automotive, medical, and consumer electronics industries.

From CAD to Part: The Process

Honyo Prototype Overmolding Process Workflow

Honyo Prototype executes a rigorously controlled overmolding process designed to mitigate risk, ensure manufacturability, and deliver precision-engineered components. Our integrated workflow begins with client CAD data and concludes with validated delivery, leveraging proprietary systems at each stage. Below is a technical breakdown of the sequence.

CAD Upload and Initial Processing

Clients upload native or neutral-format CAD files (STEP, IGES, Parasolid) via our secure customer portal. This triggers automated geometric validation to confirm file integrity, unit consistency, and topology completeness. Critical parameters such as substrate geometry, intended overmold coverage zones, and material interface surfaces are isolated for downstream analysis. All data undergoes AES-256 encryption during transfer and storage, adhering to ISO 27001 protocols for intellectual property protection.

AI-Powered Quoting Engine

Uploaded geometry feeds directly into our AI quoting platform, which performs multi-factor cost analysis. The system evaluates material compatibility matrices (e.g., TPE adhesion to PBT substrates), calculates shot volume differentials between substrate and overmold layers, and assesses gate location feasibility based on wall thickness gradients. Real-time machine-hour costing integrates regional energy tariffs, press tonnage requirements, and secondary operation estimates. Quotes include granular cost drivers such as melt temperature differentials between materials and cycle time impacts from sequential curing stages.

Engineering-Driven DFM Analysis

Upon quote acceptance, our DFM team conducts a dual-phase review. Phase one uses Moldflow simulation to model polymer flow front progression, predicting knit line formation at material interfaces and optimizing venting for trapped air elimination. Phase two focuses on mechanical interlock validation: we verify undercuts, mechanical anchors, and surface textures meet minimum 0.2mm depth thresholds to prevent delamination under ASTM D638 tensile testing. Critical findings are documented in an actionable report with annotated CAD markups, addressing risks like insufficient draft angles in overmold cavities or thermal mismatch-induced warpage.

Precision Production Execution

Approved DFM packages move to dedicated overmolding cells featuring multi-shot hydraulic presses (550–1200 tons) with temperature-controlled platens. Substrates are injection molded in the first station using specified engineering resins, then transferred via robotic arm to the overmold station within 8–12 seconds to maintain thermal bonding integrity. In-process verification includes cavity pressure monitoring at 1,000 Hz sampling rates and automated vision inspection of bond-line continuity. All tools incorporate conformal cooling channels validated through thermal imaging to ensure uniform solidification across complex geometries.

Validation and Delivery

Final components undergo first-article inspection per AS9102 standards, with critical characteristics like bond strength (tested via peel force per ISO 813) and dimensional tolerance stack-ups documented in the Certificate of Conformance. Parts ship in ESD-safe packaging with serialized traceability tags linking to lot-specific process data. Typical lead time from CAD upload to delivery is 18–22 business days for tooling and 5–7 days for production runs, with expedited paths available for medical-grade projects requiring ISO 13485 documentation.

Process Risk Mitigation Table

| Process Stage | Common Industry Risk | Honyo’s Mitigation Protocol |

|—————|———————-|—————————-|

| CAD to Quote | Inaccurate material adhesion prediction | AI cross-references 12,000+ material pair test datasets from our in-house lab |

| DFM | Undetected thermal stress at interface | Moldflow thermal analysis with coefficient of linear expansion (CLTE) differentials |

| Production | Substrate cooling before overmolding | Robotic transfer with <10-second thermal decay window enforced via PLC timers |

| Delivery | Bond strength variance in production lots | 100% automated peel force testing for medical/automotive projects |

This closed-loop methodology ensures overmolded assemblies achieve target bond strengths exceeding 90% of the overmold material’s cohesive strength while maintaining geometric fidelity to ±0.05mm. We prioritize eliminating iterative tool corrections through upfront digital validation, directly reducing time-to-market for client applications.

Start Your Project

Learn more about our precision overmolding process for high-performance prototypes and production parts. Contact Susan Leo at [email protected] to discuss your project requirements. Our advanced manufacturing facility in Shenzhen ensures tight tolerances, rapid turnaround, and consistent quality for complex overmolded components.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.