Introduction: Navigating the Global Market for overmold process

In today’s competitive landscape, sourcing innovative manufacturing processes like overmolding can present significant challenges for international B2B buyers, particularly those in rapidly developing markets across Africa, South America, the Middle East, and Europe. As companies seek to enhance product durability, comfort, and functionality, understanding the nuances of the overmold process becomes essential. This guide delves into the intricacies of overmolding, from its fundamental principles to the diverse applications across various industries.

By exploring the advantages of overmolding, such as improved grip and vibration dampening, as well as the critical differences between overmolding and insert molding, this comprehensive resource equips buyers with actionable insights. Additionally, we will cover vital topics such as supplier vetting strategies, cost considerations, and design optimization techniques.

Empowered with this knowledge, B2B buyers—whether in Nigeria or Germany—can make informed purchasing decisions that align with their production needs and market demands. This guide not only aims to demystify the overmold process but also to foster strategic partnerships and enhance product offerings in a global marketplace that increasingly values innovation and efficiency.

Understanding overmold process Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Overmolding | Involves molding a second layer over an existing substrate; often uses thermoplastics. | Grips, seals, ergonomic tools, electronics. | Pros: Reduces assembly time; enhances grip and comfort. Cons: High initial tooling costs. |

| Insert Molding | Utilizes a pre-existing component inserted into the mold; can combine different materials. | Medical devices, automotive parts, electronics. | Pros: Allows for complex designs; strong, durable parts. Cons: Tooling precision is critical; can be costly for low volumes. |

| Two-Shot Molding | A specific type of overmolding where two different materials are injected in sequence. | Consumer products, automotive interiors, electronics. | Pros: Produces parts with varied material properties; efficient for large runs. Cons: Requires precise control over the molding process. |

| Silicone Overmolding | Involves using silicone as the second layer for flexibility and durability. | Medical devices, consumer goods, automotive seals. | Pros: Excellent for soft-touch applications; high resistance to environmental factors. Cons: More expensive than standard thermoplastics. |

| Thermoplastic Elastomer (TPE) Overmolding | Uses TPEs for their rubber-like properties; ideal for soft-touch applications. | Handles, grips, seals, and vibration dampeners. | Pros: Superior grip and comfort; versatile for various applications. Cons: Material selection is crucial to meet specific performance needs. |

What Are the Key Characteristics of Overmolding?

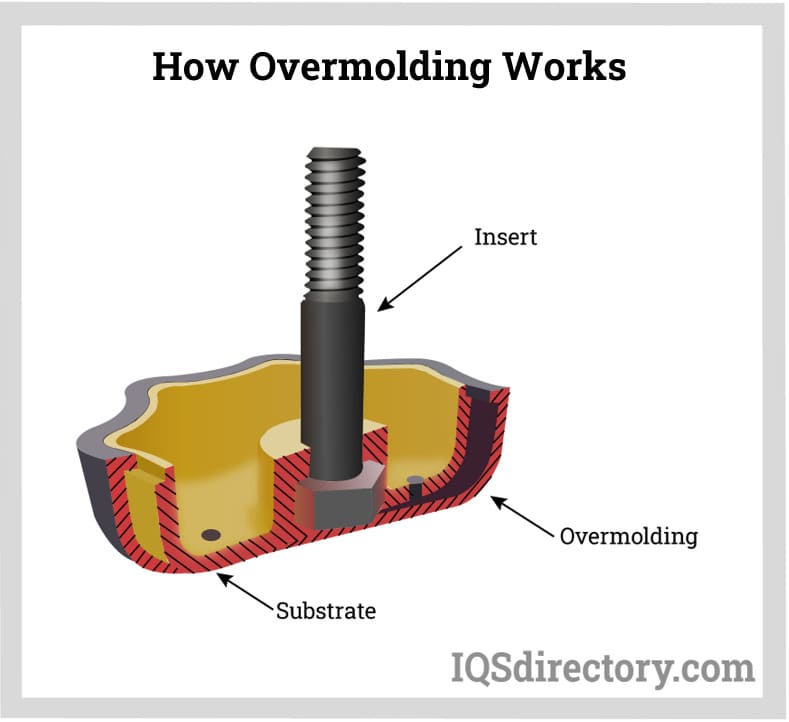

Overmolding is primarily characterized by its ability to apply a second layer of material over a previously molded substrate. This process is particularly advantageous for creating grips, seals, and ergonomic tools. B2B buyers should consider the materials used, as thermoplastics can be customized for various applications. While overmolding can reduce assembly costs and enhance product functionality, it often requires a significant investment in tooling, making it more suitable for larger production runs.

How Does Insert Molding Differ from Other Overmolding Processes?

Insert molding stands out by using a pre-existing component inserted into the mold before the secondary layer is added. This method allows for the integration of different materials, such as plastics and metals, making it ideal for applications like medical devices and automotive parts. Buyers must be aware of the precision required in tooling and the potential for higher costs if production volumes are low. Insert molding is an excellent choice when durability and strength are paramount.

What Benefits Does Two-Shot Molding Offer?

Two-shot molding is a specialized form of overmolding that allows for the injection of two different materials in a single cycle. This process is particularly efficient for producing complex parts with varying material properties, making it a preferred choice for consumer products and automotive interiors. B2B buyers should note that while this method can significantly enhance product design, it requires precise control over the molding parameters to ensure quality and consistency.

When to Choose Silicone Overmolding?

Silicone overmolding is particularly beneficial in applications where flexibility and durability are crucial, such as in medical devices and automotive seals. The unique properties of silicone, including its resistance to extreme temperatures and environmental factors, make it an excellent choice for demanding applications. Buyers should consider the higher costs associated with silicone materials but can benefit from the superior performance and longevity they provide.

Why Is TPE Overmolding Gaining Popularity?

Thermoplastic elastomer (TPE) overmolding is favored for its rubber-like qualities, making it ideal for applications requiring a soft touch, such as grips and seals. TPEs offer excellent grip and comfort, making them suitable for consumer goods and vibration dampeners. Buyers should carefully select the appropriate grade of TPE to meet specific performance requirements, as material choices can significantly affect the final product’s effectiveness and durability.

Key Industrial Applications of overmold process

| Industry/Sector | Specific Application of overmold process | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Protective casings for devices | Enhanced durability and aesthetics | Material compatibility, design for thermal management |

| Medical Devices | Ergonomic grips on surgical instruments | Improved user comfort and safety | Compliance with health regulations, sterilization |

| Automotive | Vibration-dampening components | Increased longevity and performance | Resistance to environmental factors, material strength |

| Industrial Equipment | Seals and gaskets for machinery | Enhanced reliability and efficiency | Customization options, resistance to chemicals |

| Home Appliances | Handles for kitchen tools | Improved ergonomics and user safety | Material selection for cleanliness and durability |

How is Overmolding Used in Consumer Electronics?

In the consumer electronics sector, the overmold process is commonly utilized to create protective casings that enhance the durability of devices such as smartphones, tablets, and wearables. These casings often incorporate softer materials like thermoplastic elastomers (TPE) that provide a better grip and shock absorption. For international buyers, especially in regions like Africa and South America where product longevity is crucial due to varying environmental conditions, sourcing high-quality materials that can withstand temperature fluctuations and moisture is vital.

What are the Applications of Overmolding in Medical Devices?

Overmolding plays a significant role in the medical device industry, particularly for surgical instruments and implants. The process allows manufacturers to create ergonomic grips that improve user comfort and safety during procedures. For buyers in Europe and the Middle East, it’s essential to ensure that the materials used meet stringent health regulations and can be sterilized effectively. This not only guarantees compliance but also enhances the safety and reliability of the medical devices.

How Does Overmolding Benefit the Automotive Industry?

In the automotive sector, overmolding is often employed to produce vibration-dampening components, such as mounts and bushings. These components help reduce noise and enhance the longevity of vehicles by absorbing vibrations from the engine and road. Buyers from regions with extreme weather conditions, like the Middle East, should prioritize sourcing materials that are resistant to heat and wear, ensuring optimal performance and durability in their applications.

What Role Does Overmolding Play in Industrial Equipment?

The overmold process is extensively used to create seals and gaskets for industrial machinery, providing enhanced reliability and efficiency in operations. These components can protect against dust, moisture, and other environmental factors that could compromise machinery performance. For international buyers, especially in Africa and South America, understanding the specific chemical and thermal resistance requirements of their applications is essential when sourcing materials.

How is Overmolding Applied in Home Appliances?

In the home appliances industry, overmolding is frequently used to manufacture handles for kitchen tools and appliances. This process allows for the integration of comfortable, slip-resistant grips that enhance user safety and ergonomics. Buyers in Europe should consider the materials’ cleanliness and durability, as kitchen tools must withstand frequent cleaning and exposure to various substances. Prioritizing high-quality materials ensures that the products not only perform well but also comply with health and safety standards.

3 Common User Pain Points for ‘overmold process’ & Their Solutions

Scenario 1: Complexity in Material Selection for Overmolding

The Problem: B2B buyers often struggle with selecting the right materials for overmolding applications. For instance, a manufacturer in the electronics sector may need to produce a water-resistant casing for a device. Choosing the wrong material can lead to failures in sealing, durability, or even product safety. This challenge is exacerbated by the diverse range of materials available, each with distinct properties such as flexibility, resistance to UV light, and temperature tolerance. Buyers may also face difficulties in sourcing compatible materials that meet regulatory standards in their specific regions, particularly in Africa and South America, where local suppliers may have limited offerings.

The Solution: To navigate this complexity, buyers should start by clearly defining the functional requirements of their overmolded parts. Engage with material suppliers early in the design process to gather insights about the properties of various thermoplastics and elastomers. Consider conducting small-scale tests or prototyping with different materials to evaluate their performance under expected conditions. Furthermore, collaborating with experienced engineers or consultants who specialize in overmolding can provide invaluable guidance in material selection. Utilize sourcing platforms that allow for regional suppliers to showcase their capabilities, ensuring you can find options that meet both your quality and regulatory needs.

Scenario 2: High Initial Tooling Costs Deterring Production

The Problem: One of the most significant barriers for B2B buyers in the overmolding process is the high initial costs associated with tooling. Companies may hesitate to commit to large production runs due to the hefty investment required for creating custom molds. This is particularly challenging for startups or small manufacturers in regions like Nigeria or Brazil, where cash flow may be tighter and risk aversion is high. As a result, they often miss out on the advantages of overmolding, such as reduced assembly time and enhanced product durability.

The Solution: To mitigate tooling costs, buyers can explore the use of 3D-printed molds for prototyping and even low-volume production runs. This approach not only reduces initial expenses but also allows for faster iterations and modifications during the design phase. Additionally, consider partnering with suppliers that offer flexible production options, such as low-volume injection molding services, which can help spread tooling costs over smaller batch sizes. Establishing a solid business case for investing in overmolding by demonstrating potential long-term savings and quality improvements can also persuade stakeholders to allocate necessary funds.

Scenario 3: Challenges with Design Optimization for Overmolding

The Problem: Many B2B buyers encounter difficulties in optimizing designs for overmolding, which can result in production delays or quality issues. For example, a manufacturer may design a grip for a handheld tool without considering wall thickness or gate locations, leading to inconsistent plastic flow and potential defects. Such oversights can be costly, particularly when they result in wasted materials or the need for rework, impacting both timelines and budgets.

The Solution: To address design optimization challenges, buyers should invest time in understanding the principles of overmolding design. This includes consulting with mold designers and utilizing software that simulates the injection molding process. Conducting thorough design reviews that take into account factors such as wall thickness, gate placement, and mechanical interlocks can significantly enhance the manufacturability of the part. Moreover, implementing a feedback loop with production teams during the design phase can ensure that practical insights are integrated into the final design, resulting in a smoother transition from concept to production.

Strategic Material Selection Guide for overmold process

What Are the Key Properties of Common Materials Used in the Overmold Process?

When selecting materials for the overmolding process, understanding the unique properties of each material is crucial for ensuring optimal product performance. Here, we analyze four common materials used in overmolding: Thermoplastic Elastomers (TPE), Polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS), and Silicone (SI). Each material offers distinct advantages and limitations that can significantly impact the final product.

How Do Thermoplastic Elastomers (TPE) Perform in Overmolding Applications?

TPEs are rubber-like materials that combine the properties of elastomers and thermoplastics. They exhibit excellent flexibility, resilience, and grip, making them ideal for applications requiring comfort and ergonomics, such as tool handles and grips.

Pros: TPEs are durable and resistant to wear and tear, which enhances the longevity of overmolded products. They are also easy to process and can be molded in various colors, allowing for aesthetic customization.

Cons: While TPEs are versatile, they can be more expensive than traditional plastics and may require specific processing conditions that complicate manufacturing.

Impact on Application: TPEs are compatible with a variety of media, including water and oils, making them suitable for outdoor and industrial applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential, especially in regulated industries. Buyers in regions like Europe may prefer TPEs that meet stringent environmental regulations.

What Makes Polycarbonate (PC) a Suitable Choice for Overmolding?

Polycarbonate is a robust thermoplastic known for its high impact resistance and optical clarity. It is often used in applications where strength and transparency are critical, such as in electronic housings and safety equipment.

Pros: PC offers excellent dimensional stability and can withstand high temperatures, making it suitable for demanding environments. Its ability to be overmolded with softer materials enhances grip and comfort.

Cons: The cost of polycarbonate can be higher than other plastics, and its processing can be complex due to its sensitivity to moisture.

Impact on Application: PC is compatible with various chemicals, but prolonged exposure to harsh solvents can degrade its properties.

Considerations for International Buyers: Buyers should ensure that the polycarbonate used complies with safety standards relevant to their specific industries, such as those in the automotive or medical sectors.

Why Choose Acrylonitrile Butadiene Styrene (ABS) for Overmolding?

ABS is a popular thermoplastic known for its excellent mechanical properties and ease of processing. It is commonly used in consumer products, automotive components, and electronic housings.

Pros: ABS is relatively inexpensive and offers good impact resistance, making it a cost-effective choice for many applications. It also has good chemical resistance and can be easily painted or finished.

Cons: ABS has lower heat resistance compared to other materials, which can limit its use in high-temperature applications.

Impact on Application: ABS is suitable for a variety of environments, but it may not perform well in outdoor applications due to UV sensitivity unless treated.

Considerations for International Buyers: Compliance with material safety data sheets (MSDS) and international standards is crucial for buyers in regulated markets, particularly in Europe and North America.

How Does Silicone (SI) Enhance Overmolding Applications?

Silicone is a highly flexible and durable material known for its excellent thermal stability and resistance to extreme temperatures. It is often used in applications requiring sealing, insulation, or food-grade materials.

Pros: Silicone is biocompatible and can withstand a wide range of temperatures, making it ideal for medical and food-related applications. Its flexibility allows for complex shapes and designs.

Cons: Silicone can be more expensive than other materials and may require specialized processing techniques, which can complicate manufacturing.

Impact on Application: Silicone is resistant to many chemicals and is suitable for applications involving exposure to harsh environments.

Considerations for International Buyers: Buyers must ensure that the silicone used meets relevant food safety and medical device regulations, particularly in Europe and North America.

Summary of Material Selection for Overmolding

| Material | Typical Use Case for overmold process | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| TPE | Tool handles, grips | Excellent flexibility and grip | Higher cost, specific processing needs | Medium |

| PC | Electronic housings, safety equipment | High impact resistance | Sensitive to moisture, higher cost | High |

| ABS | Consumer products, automotive components | Cost-effective, good impact resistance | Lower heat resistance | Low |

| SI | Medical devices, food-grade applications | Biocompatible, wide temperature range | Higher cost, specialized processing | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions that align with their specific application requirements and compliance needs.

In-depth Look: Manufacturing Processes and Quality Assurance for overmold process

What Are the Main Stages of the Overmold Manufacturing Process?

The overmolding process consists of several key stages that ensure the final product meets quality standards and customer specifications. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers and assessing their capabilities.

1. Material Preparation: What Materials Are Used in Overmolding?

Material selection is critical in the overmolding process. Common materials include various thermoplastics such as ABS, Nylon, and TPE. The first step involves sourcing high-quality materials that meet the required specifications for the product’s intended use. Suppliers must ensure that materials are free from contaminants and meet industry standards.

- Material Testing: Before production begins, materials are often subjected to rigorous testing to verify their physical and chemical properties. This may involve assessing tensile strength, flexibility, and thermal resistance.

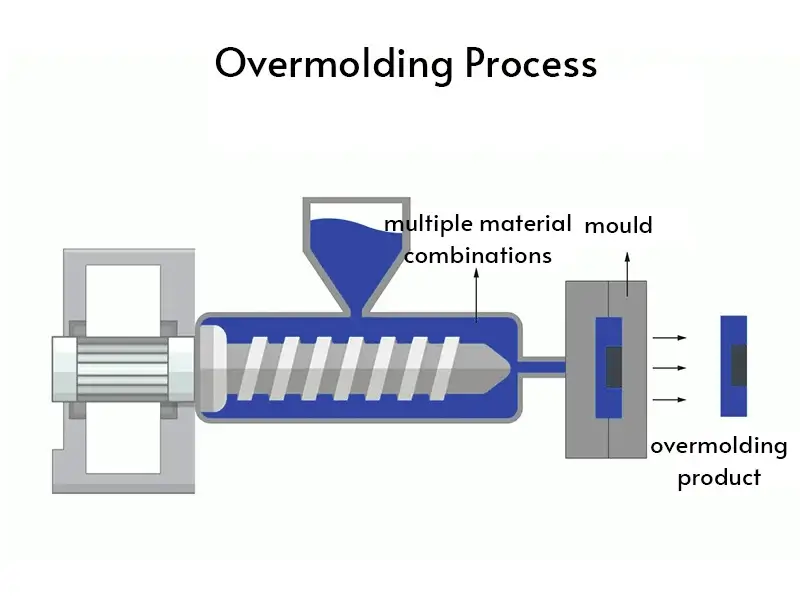

2. Forming: How Is the Overmolding Process Executed?

The forming stage is where the actual overmolding takes place. This multi-step injection molding process typically involves two key phases:

-

First Injection: The base component, usually a substrate, is injected into the mold and allowed to cure. This initial layer forms the foundation for the overmolded part.

-

Second Injection: After the first layer has cured, the second material is injected over the substrate to form a cohesive unit. This step is crucial for achieving the desired mechanical properties, such as grip or vibration dampening.

Key techniques in this stage may include:

- Two-Shot Molding: A specialized technique where two different materials are injected in a single cycle, allowing for seamless integration.

- Sequential Molding: Involves injecting one material, waiting for it to partially cure, and then injecting the second material.

3. Assembly: What Assembly Techniques Are Used?

In most overmolding processes, assembly is minimal because the components are formed together. However, if the design includes multiple parts, the assembly stage may involve:

- Mechanical Fastening: Using screws, clips, or adhesives to join components that cannot be overmolded together.

- Quality Checks: Assembly areas must incorporate checkpoints to ensure that components are correctly positioned and securely fastened.

4. Finishing: How Are Overmolded Products Finished?

The finishing stage enhances the aesthetic and functional attributes of the overmolded part. Techniques may include:

- Trimming: Removing excess material or flash from the part.

- Surface Treatment: Processes like painting, coating, or polishing to improve appearance or performance.

- Quality Assurance: Final inspections to ensure that products meet specified tolerances and performance criteria.

What Quality Assurance Standards Are Relevant for Overmolding?

Quality assurance is paramount in the overmolding process to ensure the reliability and safety of the final product. International and industry-specific standards guide this process.

International Standards: How Do ISO Standards Apply?

ISO 9001 is the most recognized quality management standard globally and provides a framework for consistent quality practices. B2B buyers should look for suppliers who are ISO 9001 certified, as this indicates a commitment to quality management and continuous improvement.

Industry-Specific Standards: What Are the Key Certifications?

Depending on the application, additional certifications may be required:

- CE Marking: Essential for products sold in the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

- API Standards: Important for components used in the oil and gas industry, ensuring they meet specific safety and performance criteria.

What Are the Quality Control Checkpoints in Overmolding?

Effective quality control is achieved through a series of checkpoints throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): Inspecting raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to detect any deviations from standards.

- Final Quality Control (FQC): Comprehensive testing of finished products to verify their performance, durability, and compliance with specifications.

What Common Testing Methods Are Used in Overmolding Quality Control?

To ensure product quality, various testing methods are employed:

- Mechanical Testing: Assessing tensile strength, impact resistance, and elongation.

- Environmental Testing: Evaluating the product’s performance under conditions such as UV exposure, temperature variations, and chemical resistance.

- Dimensional Inspection: Using tools like calipers and gauges to ensure that the parts meet specified dimensions and tolerances.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

- Audits: Conducting on-site audits to assess the manufacturing process, quality control systems, and adherence to standards.

- Quality Reports: Requesting documentation that outlines the quality control measures taken, including test results and compliance with certifications.

- Third-Party Inspections: Engaging independent inspectors to evaluate the supplier’s capabilities and quality assurance processes.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of several nuances:

- Cultural Differences: Understanding the local business practices and quality expectations can facilitate better communication and collaboration.

- Regulatory Compliance: Different regions may have varying regulations regarding materials, safety, and environmental impact. Buyers must ensure that suppliers comply with local laws.

- Logistics and Supply Chain: Consider the impact of shipping times, customs regulations, and potential delays on the quality assurance process. Establishing clear communication channels with suppliers can help mitigate these risks.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make more informed decisions and select suppliers that align with their quality expectations and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘overmold process’

To effectively navigate the procurement of the overmold process, this practical sourcing guide serves as a comprehensive checklist for B2B buyers. By following these structured steps, you can ensure that your sourcing strategy is thorough and aligns with your project needs.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for your overmolding project. Consider the function of the final product, the materials to be used, and the desired properties such as grip, vibration dampening, or water resistance. This clarity will help you communicate your needs effectively to potential suppliers.

- Material Selection: Identify which materials (e.g., TPE, silicone) will be most suitable for your application.

- Performance Criteria: Define what performance metrics are critical, such as durability or flexibility.

Step 2: Research Potential Suppliers

Conduct thorough research to identify manufacturers that specialize in overmolding. Look for companies with a proven track record in your industry and those that can demonstrate expertise in handling complex projects.

- Industry Experience: Prioritize suppliers with experience relevant to your specific application.

- Portfolio Review: Examine their previous work and case studies to assess quality and innovation.

Step 3: Evaluate Supplier Capabilities

Assess the manufacturing capabilities of potential suppliers to ensure they can meet your production needs. This includes their equipment, technology, and production capacity.

- Technology Use: Look for suppliers utilizing advanced technologies such as 3D printing for prototyping.

- Production Scale: Confirm that they can handle your required volume, whether it’s low or high production runs.

Step 4: Request Samples and Prototypes

Before finalizing a supplier, request samples or prototypes of their previous work. This step allows you to evaluate their quality and performance firsthand.

- Quality Assessment: Analyze the samples for durability, finish, and functionality.

- Prototype Testing: Conduct tests to ensure the product meets your specifications and functional requirements.

Step 5: Verify Certifications and Compliance

Ensure that the suppliers you are considering adhere to industry standards and regulations. This verification helps mitigate risks associated with quality and safety.

- Quality Certifications: Check for ISO certifications or other relevant quality management systems.

- Compliance Standards: Ensure they comply with regional regulations, especially if you’re targeting markets in Africa, South America, or Europe.

Step 6: Negotiate Terms and Pricing

Once you’ve shortlisted suppliers, begin negotiations regarding pricing, lead times, and payment terms. This step is crucial to ensure you receive a competitive offer while maintaining quality.

- Cost Transparency: Request a detailed breakdown of costs to understand what you’re paying for.

- Lead Time Agreements: Confirm lead times to ensure they align with your project timeline.

Step 7: Establish Communication Channels

Set up clear communication channels with your chosen supplier. Open lines of communication are vital for addressing concerns and ensuring project milestones are met.

- Regular Updates: Schedule consistent check-ins to monitor progress and address any issues.

- Feedback Mechanism: Implement a system for providing feedback during the production process to ensure alignment with your expectations.

By following this checklist, you can streamline the procurement process for the overmold process, ensuring that you partner with the right suppliers and achieve the desired outcomes for your projects.

Comprehensive Cost and Pricing Analysis for overmold process Sourcing

What Are the Key Cost Components in Overmold Process Sourcing?

Understanding the cost structure of the overmold process is essential for B2B buyers looking to optimize their sourcing strategies. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts overall costs. Commonly used materials such as thermoplastics (e.g., TPE, TPU) and engineering plastics (e.g., ABS, Nylon) vary in price based on market conditions, availability, and specific performance characteristics. Buyers should consider sourcing from local suppliers to mitigate transportation costs.

-

Labor: Labor costs encompass both direct labor involved in the manufacturing process and indirect labor for administrative functions. Regions with higher labor costs might influence the overall pricing structure. For buyers in Africa or South America, understanding local wage standards can provide a competitive edge.

-

Manufacturing Overhead: This includes expenses related to factory operation, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing practices can help minimize overhead, thereby reducing the final cost of the product.

-

Tooling: Tooling represents a significant upfront investment in the overmold process. The complexity of the mold design and the materials used for tooling can greatly influence pricing. Custom tooling for unique specifications may lead to increased costs but can also provide long-term savings through enhanced production efficiency.

-

Quality Control (QC): Implementing robust QC measures ensures product reliability and compliance with industry standards. While this adds to upfront costs, it can save money in the long run by reducing defects and minimizing returns.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping method, and customs duties can add significant costs. Utilizing Incoterms effectively can help clarify responsibilities and reduce logistical expenses.

-

Margin: Supplier margins vary based on market conditions, competition, and the perceived value of the product. Building long-term relationships with suppliers can lead to better pricing structures and favorable terms.

How Do Price Influencers Affect Overmold Process Sourcing?

Several price influencers can affect the overall cost structure of sourcing overmolded products:

-

Volume/MOQ (Minimum Order Quantity): Larger order quantities often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their production needs to avoid excess inventory.

-

Specifications and Customization: Custom designs or specific material requirements can significantly impact pricing. Buyers should clearly communicate their specifications to obtain accurate quotes from suppliers.

-

Material Selection: High-performance materials may incur higher costs but can deliver superior product performance. Buyers should weigh the benefits against the additional expenses when selecting materials.

-

Quality Certifications: Products that meet specific quality standards (e.g., ISO certifications) often carry a premium price. However, these certifications can enhance product reliability and customer satisfaction.

-

Supplier Factors: The reputation and experience of suppliers can influence pricing. Established suppliers may offer higher prices but provide assurance in terms of quality and delivery reliability.

-

Incoterms: Familiarity with Incoterms can help buyers understand shipping responsibilities and costs, allowing for more informed financial planning.

What Tips Can Help B2B Buyers Optimize Costs in Overmold Process Sourcing?

-

Negotiate Effectively: Engage in open discussions with suppliers about pricing, lead times, and payment terms. Leverage your order volume as a negotiation tool to secure better pricing.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, handling, and potential costs related to quality issues. This holistic view can help identify the most cost-effective sourcing options.

-

Understand Pricing Nuances for International Buyers: Buyers from different regions, like Nigeria or Germany, may face unique challenges such as currency fluctuations, import duties, and varying supplier standards. Researching local market conditions can provide insights into potential cost savings.

-

Request Multiple Quotes: Obtaining quotes from several suppliers can help you benchmark prices and identify competitive rates. This practice also allows you to assess different suppliers’ capabilities and service levels.

-

Plan for Future Needs: Consider long-term production needs and potential scaling when negotiating pricing and terms. Building flexibility into contracts can help accommodate future changes without incurring additional costs.

Disclaimer

Pricing for the overmold process can vary widely based on numerous factors, including market conditions, material availability, and regional economic factors. This analysis serves as a guideline and should not be interpreted as definitive pricing. Always seek specific quotes from suppliers to obtain accurate pricing tailored to your project needs.

Alternatives Analysis: Comparing overmold process With Other Solutions

Understanding Alternatives to the Overmold Process

In the landscape of manufacturing and product design, the overmold process stands out for its ability to create durable, multi-material parts. However, it’s crucial for B2B buyers to explore alternative methods that may suit their specific needs better. This section compares the overmold process with two viable alternatives: insert molding and traditional assembly methods. Each method has its own strengths and weaknesses, and understanding these differences can help buyers make informed decisions.

| Comparison Aspect | Overmold Process | Insert Molding | Traditional Assembly |

|---|---|---|---|

| Performance | High durability, multi-material parts | Strong integration of different materials | Flexibility in design, but may require more parts |

| Cost | Higher upfront costs, efficient for large runs | Moderate costs, effective for varied materials | Lower initial costs, but higher per-unit costs |

| Ease of Implementation | Requires specialized equipment and tooling | Also needs specialized equipment, but simpler than overmolding | Easier to implement with standard tools |

| Maintenance | Minimal maintenance once set up | Similar to overmolding, with added complexity for inserts | Higher maintenance due to multiple components |

| Best Use Case | Ideal for ergonomic, multi-functional products | Best for embedding components like electronics | Suitable for complex assemblies where customization is key |

Detailed Breakdown of Alternatives

What are the Benefits and Drawbacks of Insert Molding?

Insert molding offers a distinct advantage by allowing manufacturers to encase pre-existing components within a molded plastic shell. This method is particularly beneficial for products requiring a combination of plastic and metal, such as tools or medical devices. The primary advantage lies in its ability to create strong, cohesive parts without requiring additional assembly. However, the need for precise tooling and the challenges associated with inserting components into molds can make this process more complex than overmolding. Additionally, while it can cater to a wide variety of materials, the initial setup costs can still be significant.

How Does Traditional Assembly Compare to Overmolding?

Traditional assembly methods involve joining separate components to create a final product, providing flexibility in design and material selection. This approach is beneficial for low-volume production runs or highly customized products where individual parts can be tailored to specific needs. However, the drawbacks include increased assembly time and potential quality control issues, as each part must be fitted and assembled correctly. Furthermore, the final product may not achieve the same level of durability or aesthetic appeal as those produced through overmolding or insert molding, which can integrate materials more seamlessly.

Choosing the Right Solution for Your Needs

When selecting between the overmold process and its alternatives, B2B buyers should consider several factors, including production volume, design complexity, and budget constraints. For high-volume production of durable, ergonomic products, overmolding remains a top choice. Conversely, if embedding components or working with mixed materials is a priority, insert molding may be more advantageous. For projects that demand flexibility and customization with lower initial costs, traditional assembly might be the best fit. Ultimately, understanding the specific requirements of your project will guide you toward the most suitable manufacturing method.

Essential Technical Properties and Trade Terminology for overmold process

What Are the Critical Technical Properties of the Overmold Process?

Understanding the essential technical properties of the overmold process is crucial for B2B buyers looking to optimize production and ensure product quality. Here are some key specifications:

1. Material Grade

The choice of material grade directly influences the performance and durability of the final product. Common materials include thermoplastic elastomers (TPE), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC). Each material has specific properties such as flexibility, strength, and resistance to environmental factors. For B2B buyers, selecting the appropriate material grade can lead to enhanced product functionality and longevity, reducing replacement costs and improving customer satisfaction.

2. Tolerance

Tolerance refers to the allowable deviation from a specified dimension in the manufacturing process. In overmolding, maintaining tight tolerances is essential for ensuring that the overmolded layers adhere properly and function as intended. For international buyers, understanding tolerances can help prevent costly reworks and delays, ensuring that products meet specific regulatory and quality standards across different markets.

3. Wall Thickness

Consistent wall thickness is vital in the overmolding process to ensure even material flow and minimize defects such as voids or shrink marks. Varying wall thickness can lead to uneven cooling and distortion of the final product. Buyers should consider wall thickness during the design phase to optimize production efficiency and maintain product integrity, particularly in high-volume runs.

4. Cycle Time

Cycle time is the duration it takes to complete one cycle of the manufacturing process, from mold filling to ejection. A shorter cycle time can significantly increase production efficiency, thereby reducing costs. For B2B buyers, understanding cycle times helps in planning production schedules and managing inventory effectively, leading to better cash flow and responsiveness to market demands.

5. Mechanical Interlock Features

These features enhance the bond between the substrate and the overmolded layer, improving the overall strength and durability of the product. Mechanical interlocks can include grooves or ridges designed into the substrate. For businesses, incorporating these features can lead to reduced assembly time and increased product reliability, which are critical in competitive markets.

What Are Common Trade Terms in the Overmold Process?

Familiarity with industry jargon is essential for effective communication and negotiation in the overmold process. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of overmolding, OEMs often provide the substrate components that are overmolded. Understanding this term helps buyers identify potential suppliers and clarify their role in the production chain.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as understanding MOQ can influence purchasing decisions and inventory management. It is especially relevant in overmolding, where setup costs can make small runs economically unfeasible.

3. RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process, allowing for better comparison of costs and services among different manufacturers, particularly in the complex overmolding landscape.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping, insurance, and tariffs. For international B2B buyers, understanding Incoterms is crucial for effective negotiation and risk management in the supply chain.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. In the context of overmolding, lead time can be affected by tooling, material availability, and production capacity. B2B buyers must consider lead times when planning product launches or managing inventory to ensure timely delivery to their customers.

By grasping these critical properties and trade terms, B2B buyers can make informed decisions that enhance their manufacturing processes and optimize their supply chain management in the overmolding industry.

Navigating Market Dynamics and Sourcing Trends in the overmold process Sector

What Are the Current Market Dynamics and Key Trends in the Overmold Process Sector?

The overmold process sector is experiencing significant growth, driven by an increasing demand for lightweight, durable components across various industries, including consumer electronics, automotive, and healthcare. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek cost-effective and efficient manufacturing solutions, they are increasingly turning to overmolding for its ability to create complex, multi-material products in a single process. This trend is particularly relevant in countries like Nigeria and Germany, where innovation in product design is paramount.

Emerging technologies, such as advanced 3D printing and automation, are revolutionizing the prototyping and production phases of overmolding. These technologies enable manufacturers to reduce lead times and costs while enhancing design flexibility. Additionally, the integration of Industry 4.0 practices—such as IoT-enabled machinery and data analytics—provides manufacturers with real-time insights into production processes, further driving efficiency and reducing waste.

Another key trend is the increasing customization of products. B2B buyers are looking for manufacturers who can provide tailored solutions to meet specific market needs, whether that involves unique material combinations or specialized designs. This shift is prompting suppliers to adopt more agile manufacturing processes that can quickly adapt to changes in demand.

How Is Sustainability and Ethical Sourcing Shaping the Overmold Process?

Sustainability has become a critical concern for B2B buyers in the overmold process sector. The environmental impact of manufacturing practices is under scrutiny, leading to a demand for more sustainable materials and processes. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint through eco-friendly practices, such as using recyclable or biodegradable materials for overmolding.

Ethical sourcing is equally important, as international buyers seek to ensure that their supply chains adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and the Global Recycle Standard (GRS) for recycled materials are becoming essential criteria for selecting suppliers. These certifications not only enhance a company’s reputation but also align with the growing consumer demand for responsible sourcing practices.

The use of green materials, such as thermoplastic elastomers (TPE) that are both durable and recyclable, is gaining traction. These materials offer the dual benefit of performance and sustainability, making them an attractive choice for B2B buyers looking to innovate while maintaining corporate responsibility.

What Is the Brief Evolution and History of the Overmold Process?

The overmold process has evolved significantly since its inception in the mid-20th century. Initially developed to enhance product durability and functionality, it has transformed into a sophisticated manufacturing technique that allows for the combination of multiple materials in a single component.

The introduction of advanced materials, such as thermoplastics and elastomers, has expanded the applications of overmolding, enabling manufacturers to create products that are not only functional but also aesthetically pleasing. Over the years, improvements in injection molding technology and design software have further refined the process, making it more accessible and efficient for B2B buyers.

As global competition increases, the ability to produce complex, high-quality components through overmolding has positioned it as a vital technique in modern manufacturing, appealing to a diverse range of industries and applications.

Frequently Asked Questions (FAQs) for B2B Buyers of overmold process

-

How do I solve challenges related to overmolding material selection?

To address material selection challenges in overmolding, start by identifying the specific requirements of your application, such as flexibility, durability, and environmental resistance. Consider materials like TPE for rubber-like properties or PC for strength. Collaborate with suppliers who can provide insights on material compatibility and performance under various conditions. Additionally, request samples for testing to ensure the chosen materials meet your functional and aesthetic needs before committing to large-scale production. -

What is the best process for prototyping overmolded parts?

The most effective method for prototyping overmolded parts involves utilizing 3D printing technologies to create molds or even the parts themselves. This approach significantly reduces lead times and costs, allowing for rapid iterations based on testing feedback. Engage with suppliers who specialize in rapid prototyping and can guide you through the design optimization process, ensuring that your prototypes accurately represent the final product in terms of both functionality and aesthetics. -

What factors should I consider when vetting suppliers for the overmold process?

When vetting suppliers for overmolding, evaluate their experience in the industry, particularly with similar projects. Assess their production capabilities, including equipment quality and material sourcing. Request references and case studies to understand their track record in delivering quality products on time. Additionally, inquire about their quality assurance processes and certifications to ensure compliance with international standards relevant to your market. -

What are the typical minimum order quantities (MOQs) for overmolded products?

Minimum order quantities for overmolded products can vary significantly based on the supplier, the complexity of the design, and the materials used. Generally, MOQs range from a few hundred to several thousand units. Discuss your specific needs with potential suppliers to negotiate MOQs that fit your project scale and budget. Some suppliers may offer lower MOQs for initial runs or prototypes, making it easier for you to test market demand before committing to larger orders. -

What payment terms are commonly offered in overmolding contracts?

Payment terms for overmolding contracts can differ based on supplier policies and your negotiation outcomes. Common arrangements include a deposit upfront (20-50%) with the balance due upon delivery or after successful inspection of goods. Some suppliers may offer credit terms for established businesses. Ensure you clearly outline payment terms in your contract to avoid misunderstandings and maintain a healthy cash flow throughout the production process. -

How can I ensure quality assurance in the overmolding process?

To ensure quality assurance in overmolding, establish clear quality criteria and communicate them to your supplier before production begins. Implement regular inspections and testing phases throughout the manufacturing process. Consider utilizing third-party quality assurance services for unbiased evaluations. Additionally, ask suppliers about their quality management systems, such as ISO certifications, which can indicate their commitment to maintaining high standards. -

What logistics considerations should I keep in mind when sourcing overmolded products internationally?

When sourcing overmolded products internationally, consider logistics factors such as shipping costs, lead times, and customs regulations. Collaborate with suppliers who have experience in international shipping to ensure smooth transportation. Evaluate the impact of potential tariffs and trade agreements on your costs. It may also be beneficial to establish relationships with local logistics providers in your target market to facilitate timely deliveries and reduce overall shipping risks. -

How can I customize overmolded products to meet specific market needs?

Customization of overmolded products can be achieved through collaborative design processes with your supplier. Start by defining your target market’s specific needs, such as ergonomic features or aesthetic preferences. Leverage advanced design software to create prototypes that incorporate these elements. Suppliers experienced in overmolding can offer insights into material options and design modifications that enhance functionality while meeting your customization goals effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Overmold Process Manufacturers & Suppliers List

1. Basilius – Overmolding Solutions

Domain: basilius.com

Registered: 1999 (26 years)

Introduction: Overmolding is an injection molding process that involves molding one plastic (commonly TPE) over another component (substrate). Applications include: 1. Grip enhancement for handles, improving safety in wet conditions. 2. Vibration dampening for electronics protection. 3. Ergonomic comfort through customizable grip shapes. 4. Creation of water-resistant seals for electronics. 5. Sound absorption …

2. Protolabs – Overmolding Solutions

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: Overmolding is an injection molding process that adds an additional layer of resin to an existing molded part, providing a combination of characteristics that no single material can offer. Common applications include adding a soft, rubber-like layer (typically TPE) over a hard substrate, enhancing appearance, and improving functionality. Insert molding integrates threaded metal inserts into compon…

3. Sybridge – Two-Shot Molding

Domain: sybridge.com

Registered: 2003 (22 years)

Introduction: Two-Shot Molding: A subcategory of injection molding that creates multi-material or multi-colored parts without extra assembly steps. It involves injecting the first material to create a substrate, which is then transferred to another chamber for the second material injection. Advantages include efficiency, cost-effectiveness, durability, and design flexibility. Common applications: power tool gri…

4. Prototool – Overmolding Solutions

Domain: prototool.com

Registered: 2004 (21 years)

Introduction: Overmolding is a specific injection molding process used to create components from different materials. It involves injecting molten material over an existing substrate (such as metal, plastic, or glass) to form a solid product. Common materials for overmolding include rubber or thermoplastic, which are typically softer and more malleable than the substrate. The process allows for the combination …

5. VEM Tooling – Overmolding Solutions

Domain: vem-tooling.com

Registered: 2005 (20 years)

Introduction: Overmolding is a type of injection molding process where two or more components are molded over one another. It involves covering a substrate (the first material) with subsequent materials. Common examples include power tools with ergonomic grips and car tail-lights with multiple color parts. The process can use either single-shot (insert molding) or two-shot (multiple-shot molding) techniques. Th…

Strategic Sourcing Conclusion and Outlook for overmold process

How Can Strategic Sourcing Enhance Your Overmolding Projects?

In the evolving landscape of manufacturing, strategic sourcing for the overmold process is essential for international B2B buyers aiming to optimize cost, quality, and efficiency. By understanding the unique advantages of overmolding, such as reduced assembly time and enhanced product durability, companies can make informed decisions that align with their production goals. Leveraging diverse materials and advanced technologies like 3D printing can further streamline prototyping, resulting in significant time and cost savings.

As buyers from regions like Africa, South America, the Middle East, and Europe navigate the complexities of sourcing, it is crucial to evaluate suppliers based on their capabilities and experience in overmolding. Establishing strong partnerships with manufacturers who understand local market dynamics can lead to more resilient supply chains and innovative product solutions.

Looking ahead, the demand for customizable, high-performance products will continue to rise. International B2B buyers are encouraged to embrace strategic sourcing as a means to stay competitive and responsive to market changes. Engage with suppliers who can provide tailored solutions that meet your specific needs, and position your business for future success in the dynamic overmolding landscape.