Contents

Manufacturing Insight: Order Custom Aluminum Parts

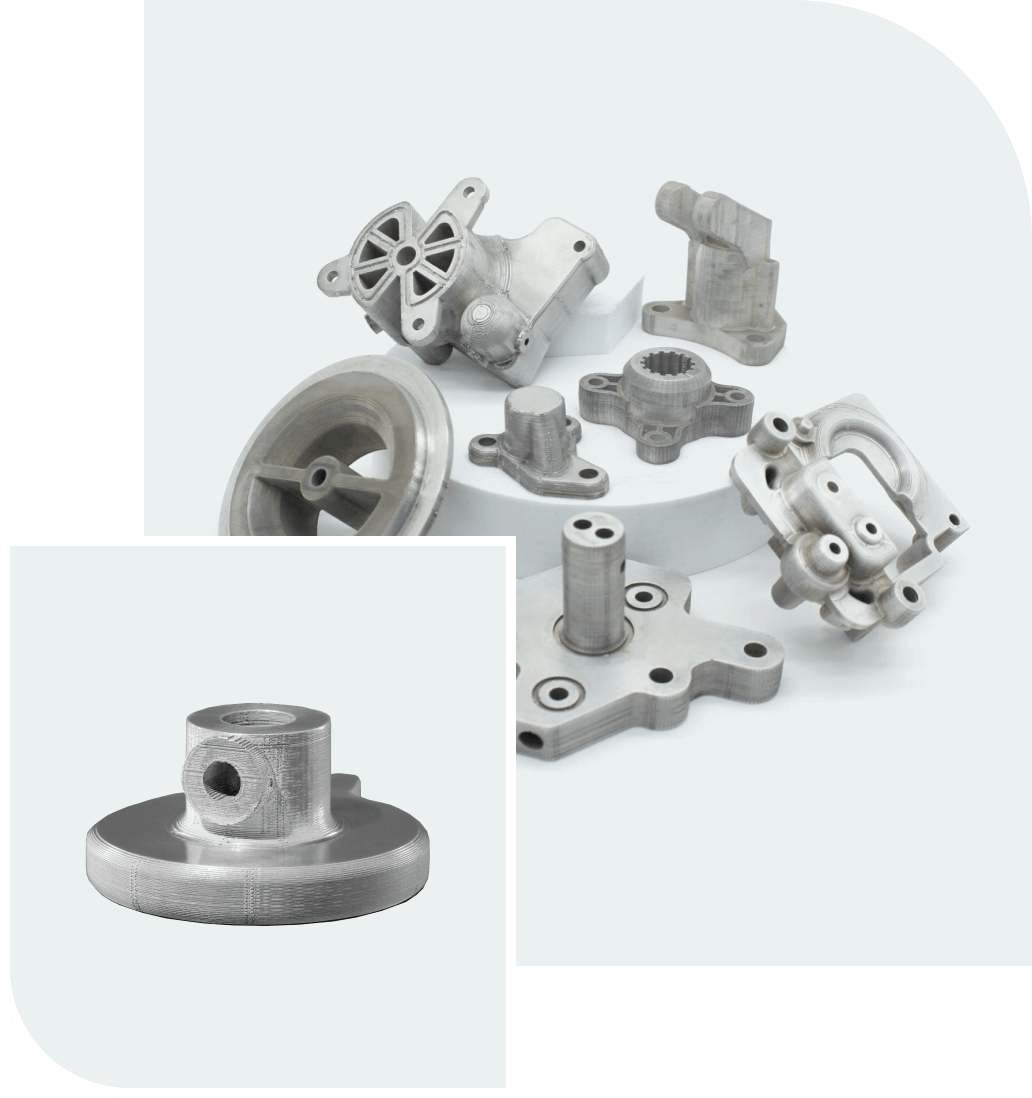

Order Custom Aluminum Parts with Precision CNC Machining from Honyo Prototype

For engineering teams requiring high-integrity aluminum components, Honyo Prototype delivers end-to-end CNC machining services engineered to meet rigorous industrial standards. Our advanced 3-, 4-, and 5-axis milling and turning capabilities consistently achieve tight tolerances down to ±0.005 mm across aerospace-grade alloys like 6061-T6, 7075-T6, and custom material specifications. Every part undergoes in-process metrology and final inspection using calibrated CMMs and optical comparators, ensuring dimensional accuracy and surface finishes as precise as Ra 0.8 µm.

Accelerate your prototyping or low-volume production timeline with our Online Instant Quote platform. Simply upload your STEP or IGES file to receive a detailed, no-obligation cost estimate within seconds—complete with machinability feedback and lead time projections. This seamless integration of engineering-grade manufacturing and digital efficiency eliminates traditional quoting delays, empowering you to move from design validation to functional parts faster. Upload your CAD model today to experience precision aluminum machining built for your project’s technical demands.

Technical Capabilities

Custom Aluminum Parts Manufacturing – Technical Capabilities

Honyo Prototype offers precision CNC machining services for custom aluminum and other material parts, utilizing advanced 3-axis, 4-axis, and 5-axis milling alongside CNC turning operations. Our processes are optimized for tight tolerance requirements and complex geometries, serving industries including aerospace, medical, robotics, and industrial automation.

| Capability | Specification |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including mill-turn and live tooling) |

| Materials Supported | Aluminum (6061, 6061-T6, 7075, 7075-T6, 2024, 5052), Steel (1018, 4140, 4340, stainless steels 303, 304, 316), ABS (thermoplastic), Nylon (PA6, PA66) |

| Tolerance Range | Standard: ±0.005 mm (±0.0002″) |

| Feature Accuracy | Positional tolerance: ±0.010 mm |

| Max Work Envelope (Milling) | 5-Axis: 800 x 500 x 400 mm |

| Max Turning Diameter | 300 mm |

| CNC Control Systems | Fanuc, Siemens, and Heidenhain for high-precision motion control |

| Inspection & Metrology | CMM (Coordinate Measuring Machine), optical comparators, micrometers, and calipers; full First Article Inspection (FAI) reports available |

| Lead Time | Prototype: 5–7 days |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, bead blasting, powder coating, heat treatment (material-dependent) |

All parts are machined using optimized toolpaths and rigid fixturing to maintain repeatability and geometric accuracy. Multi-axis capabilities enable single-setup machining of complex features, reducing cumulative error and improving overall part integrity. Material selection guidance is provided based on functional requirements including strength-to-weight ratio, corrosion resistance, and thermal performance.

From CAD to Part: The Process

Honyo Prototype Custom Aluminum Parts Order Process

Our streamlined workflow for custom aluminum part production begins with digital integration and concludes with certified delivery, ensuring technical precision and timeline adherence for B2B clients. The process eliminates traditional quoting bottlenecks while embedding engineering rigor at each phase.

Upload CAD

Clients initiate orders by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. The system validates geometric integrity and confirms aluminum alloy compatibility (e.g., 6061-T6, 7075-T6). File acceptance triggers automated metadata extraction for dimensional analysis and material requirements, with immediate feedback on unsupported formats or critical geometry errors.

AI-Powered Quoting Engine

Within 90 seconds, our proprietary AI engine generates a formal quotation based on real-time production parameters. Unlike static algorithms, the system cross-references live data from CNC machining centers, material stock levels, and labor capacity. Key cost drivers include:

| Factor | Traditional Quoting | Honyo AI Quoting |

|---|---|---|

| Pricing Basis | Manual labor hours | Machine cycle time + material waste optimization |

| Material Cost | Fixed vendor rates | Dynamic scrap rate adjustment per part geometry |

| Lead Time Estimate | Fixed buffer days | Machine queue depth + setup optimization |

| Tolerance Impact | Not quantified upfront | Cost delta per IT grade deviation |

The quote includes explicit cost breakdowns for secondary operations (e.g., anodizing, deburring) and flags non-value-added features.

Engineered DFM Analysis

All orders undergo mandatory Design for Manufacturability review by our aluminum machining specialists. This phase focuses on mitigating aluminum-specific risks:

Wall thickness validation against minimum bend radii for milled features

Chip evacuation analysis for deep pockets in 6061 aluminum

Thermal distortion compensation for thin-walled geometries

Anodizing clearance verification (minimum 0.2mm gaps)

Tool access assessment for internal radii below 0.5mm

Clients receive an actionable DFM report with annotated CAD markups and tolerance rationalization. Critical deviations trigger collaborative engineering sessions before production release.

Precision Production

Approved designs enter our dedicated aluminum production cell featuring:

Haas VF-2SS vertical mills with high-pressure coolant for aluminum swarf management

Automated tool presetters ensuring ±0.005mm tool length accuracy

In-process probing for first-article validation per AS9102 standards

Dedicated aluminum workholding to prevent cross-contamination from steel machining

All parts undergo mandatory post-process validation: CMM inspection for critical features (report available upon request), surface roughness verification (Ra ≤ 1.6µm standard), and visual inspection for burrs per ISO 1302.

Certified Delivery

Shipments include:

Traceable material certificates (mill test reports for alloy composition)

Dimensional conformance documentation (GD&T callouts per ASME Y14.5)

Packaging engineered for aluminum part protection (VCI paper for corrosion prevention)

Real-time logistics tracking with temperature/humidity monitoring for sensitive finishes

Standard lead time is 7–12 business days from DFM sign-off, with expedited 72-hour options for prototypes. Every shipment meets ISO 9001:2015 controls, with full process audit trails available through the client portal. This integrated approach reduces time-to-part by 40% versus conventional prototyping while ensuring manufacturing feasibility is validated before metal cutting begins.

Start Your Project

Need custom aluminum parts manufactured to your exact specifications? Contact Susan Leo today at [email protected] to discuss your project requirements.

Honyo Prototype operates a dedicated manufacturing facility in Shenzhen, China, specializing in rapid prototyping and low-to-mid volume production of precision aluminum components. Our in-house capabilities include CNC machining, sheet metal fabrication, and finishing services, ensuring fast turnaround and consistent quality.

Whether you require prototypes or production-ready parts, we deliver high-accuracy aluminum components with tight tolerances and quick lead times.

Reach out to Susan Leo via email to request a quote or technical consultation. Let Honyo Prototype be your trusted partner for custom aluminum part manufacturing.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.