Introduction: Navigating the Global Market for order bicycle parts

As the demand for high-quality bicycle parts continues to surge globally, navigating the complexities of sourcing these components can be a daunting task for B2B buyers. Whether you are looking to order bicycle parts for mountain bikes, road bikes, or e-bikes, understanding the nuances of the international market is crucial for making informed purchasing decisions. The challenge lies not only in identifying reliable suppliers but also in ensuring that the components meet stringent quality standards while remaining cost-effective.

This comprehensive guide delves into various aspects of the bicycle parts market, including types of components, applications across different cycling disciplines, and effective strategies for supplier vetting. We will also explore critical factors influencing cost, such as shipping logistics, tariffs, and currency fluctuations, which are particularly relevant for buyers in regions like Africa, South America, the Middle East, and Europe, including Brazil and Nigeria.

By equipping international B2B buyers with actionable insights, this guide aims to empower you to streamline your procurement process, reduce risks, and enhance your supply chain efficiency. With a focus on quality, compatibility, and sustainability, you will gain the knowledge necessary to navigate the global market confidently, ensuring that your business remains competitive in an ever-evolving landscape.

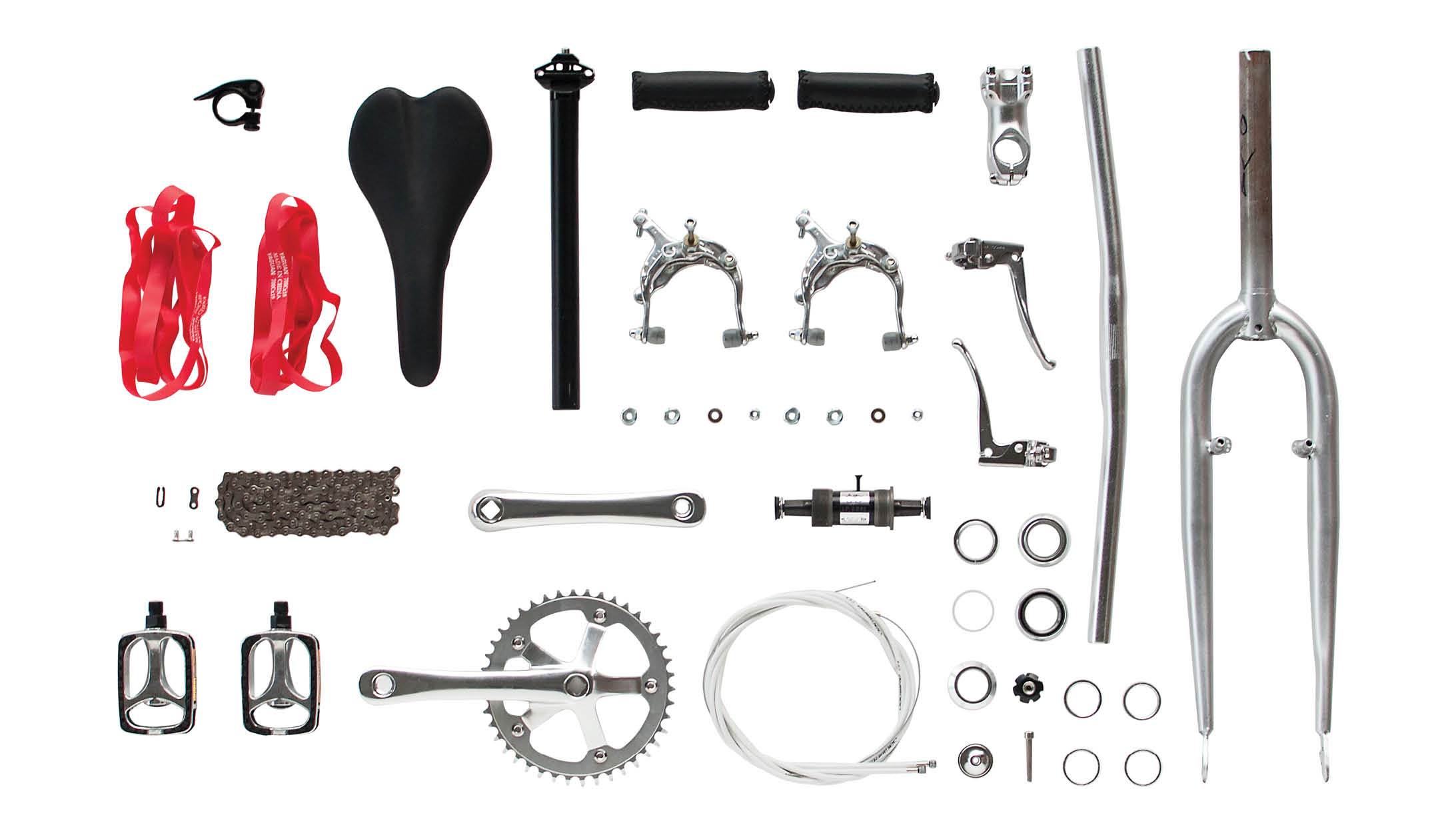

Understanding order bicycle parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Drivetrain Parts | Includes chains, derailleurs, cassettes, cranksets | Replacement and upgrade for performance bikes | Pros: Enhanced performance; Cons: Compatibility issues may arise. |

| Brake Components | Comprises pads, rotors, calipers, and levers | Essential for safety and performance upgrades | Pros: Improved stopping power; Cons: Frequent replacements needed. |

| Suspension Parts | Consists of forks and rear shocks | Vital for mountain and off-road biking | Pros: Increased comfort and control; Cons: Higher cost for premium models. |

| Tires & Wheels | Variety of treads and sizes for different terrains | Essential for all bike types and conditions | Pros: Enhanced grip and ride quality; Cons: Requires regular maintenance and replacement. |

| E-Bike Components | Specialized parts for electric bike systems | Growing market for e-bike retailers | Pros: High demand; Cons: Complexity in compatibility and installation. |

What are the Key Characteristics of Drivetrain Parts?

Drivetrain parts are essential for the bike’s overall performance, affecting speed and efficiency. This category includes components like chains, derailleurs, and cranksets, which facilitate the transfer of power from the pedals to the wheels. B2B buyers must consider compatibility with existing bike models and the specific requirements for different riding styles. Upgrading to high-performance drivetrain parts can significantly enhance a bike’s efficiency, making this a crucial area for retailers focusing on performance-oriented bicycles.

How Do Brake Components Impact Bike Safety?

Brake components are critical for ensuring rider safety and performance. This category includes brake pads, rotors, calipers, and levers. B2B buyers should prioritize quality and compatibility, as these parts must withstand varying weather conditions and riding styles. While higher-quality brake components can provide better stopping power and durability, they may also require more frequent replacements. Retailers need to stock a diverse range to cater to different customer needs, from casual riders to competitive athletes.

What Role Do Suspension Parts Play in Riding Comfort?

Suspension parts, such as forks and rear shocks, are vital for enhancing comfort and control, especially in rugged terrains. These components absorb shocks and vibrations, allowing for a smoother ride. B2B purchasers should focus on the type of biking their customers engage in—mountain biking often requires more sophisticated suspension systems. While investing in quality suspension can improve riding experience, it often comes at a higher price point, necessitating a careful evaluation of cost versus benefit.

Why Are Tires & Wheels Crucial for Performance?

Tires and wheels play a significant role in a bike’s performance and handling. Different tread patterns and sizes cater to various terrains, affecting grip and rolling efficiency. B2B buyers must consider the specific requirements of their target market, whether for road, mountain, or hybrid bikes. While quality tires can enhance ride quality, they also require regular maintenance and timely replacements. Retailers should offer a comprehensive selection to meet diverse customer demands, ensuring they can cater to all riding preferences.

How is the Market for E-Bike Components Evolving?

E-bike components represent a rapidly growing segment in the cycling industry. These specialized parts, including batteries, motors, and electronic controls, are essential for the functionality of electric bicycles. B2B buyers must keep abreast of technological advancements and compatibility issues, as the e-bike market is still evolving. The increasing popularity of e-bikes presents a lucrative opportunity for retailers, but they must navigate the complexities of stocking and selling these advanced components effectively.

Key Industrial Applications of order bicycle parts

| Industry/Sector | Specific Application of Order Bicycle Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce Retail | Stocking bicycle parts for online sales | Increased product range and customer satisfaction | Reliable suppliers with competitive pricing and quality |

| Public Transport | Integration of bicycles into public transport systems | Enhanced mobility options and reduced congestion | Compliance with local regulations and quality standards |

| Tourism and Recreation | Supplying bike rental companies with parts | Improved service reliability and customer retention | Availability of diverse parts for various bike models |

| Logistics and Delivery | Equipping delivery services with durable bicycles | Cost-effective and sustainable delivery solutions | Parts compatibility with electric and traditional bikes |

| Sports and Events | Providing components for competitive cycling events | Enhanced performance and competitive edge | Timely delivery and high-performance product availability |

How E-commerce Retailers Utilize Bicycle Parts for Success

E-commerce retailers specializing in bicycles and accessories often order bicycle parts in bulk to maintain a diverse inventory. This enables them to cater to various customer needs, from casual riders to professional cyclists. The ability to offer a wide range of components, such as drivetrain parts or suspension systems, can significantly enhance customer satisfaction and drive sales. For international buyers, ensuring reliable suppliers who can provide quality parts at competitive prices is crucial, especially in regions like Africa and South America, where logistics may pose challenges.

Public Transport Systems and Bicycle Integration

Public transport systems in urban areas are increasingly integrating bicycles to promote eco-friendly transportation. By ordering bicycle parts, these systems can maintain and upgrade their bike-sharing programs, enhancing mobility options for users. This integration helps reduce congestion and promotes healthier lifestyles. Buyers in this sector must consider compliance with local regulations regarding safety and quality standards, ensuring that all bicycle components meet the necessary requirements for public use.

Supporting Tourism and Recreation with Bicycle Rentals

In the tourism and recreation sector, bike rental companies require a steady supply of bicycle parts to keep their fleets in top condition. By ordering high-quality components, these businesses can ensure reliability and enhance customer experiences. This is particularly important in regions with high tourist traffic, where maintaining operational efficiency is essential. International buyers should focus on sourcing parts that are compatible with a variety of bike models to accommodate diverse customer preferences.

Enhancing Logistics and Delivery Services with Bicycles

Logistics and delivery services are increasingly adopting bicycles as a sustainable delivery option. Ordering durable bicycle parts is essential for maintaining these vehicles, which must withstand the demands of urban environments. This approach not only reduces operational costs but also supports green initiatives. Buyers should ensure that the parts ordered are compatible with both electric and traditional bicycles, considering the specific needs of their delivery operations.

Elevating Sports and Events through Quality Components

In the sports sector, particularly during competitive cycling events, the demand for high-performance bicycle parts is paramount. Organizers and teams often order specialized components to enhance their competitive edge. The right parts can significantly affect performance outcomes, making timely delivery and product availability critical for success. International buyers must prioritize sourcing from suppliers who can provide high-quality, durable components suited for various racing conditions, ensuring that athletes have the best equipment available.

3 Common User Pain Points for ‘order bicycle parts’ & Their Solutions

Scenario 1: Navigating Compatibility Issues with Bicycle Parts

The Problem: One of the most significant challenges B2B buyers face when ordering bicycle parts is ensuring compatibility with existing inventory or specific models. This issue is particularly pronounced in regions with a diverse range of bicycle types, from mountain bikes to electric models. Buyers may find themselves with parts that do not fit, leading to wasted resources and delayed sales. The frustration compounds when suppliers do not provide adequate specifications or guidance, leaving buyers uncertain about their choices.

The Solution: To mitigate compatibility issues, B2B buyers should implement a systematic approach to sourcing parts. Start by maintaining a comprehensive inventory list that includes the specifications of all bicycle models offered. Utilize online resources, such as manufacturer websites or dedicated bike parts databases, to cross-reference compatibility before placing orders. When engaging with suppliers, request detailed product specifications, including dimensions, weight limits, and compatibility charts. Additionally, establish a relationship with a reliable supplier who offers technical support, as they can assist in identifying the right parts for your needs. By proactively addressing compatibility concerns, buyers can streamline their ordering process and enhance customer satisfaction.

Scenario 2: Managing Lead Times and Supply Chain Delays

The Problem: International B2B buyers often encounter challenges with lead times and supply chain disruptions, particularly when sourcing bicycle parts from overseas suppliers. Factors such as customs delays, transportation issues, and fluctuating demand can lead to extended wait times. This unpredictability can severely impact a business’s ability to fulfill orders on time, jeopardizing customer relationships and potential sales.

The Solution: To effectively manage lead times, buyers should develop a robust supply chain strategy that includes diversifying their supplier base. Establish relationships with multiple suppliers across different regions to mitigate risks associated with any single source. Additionally, invest in inventory management software that provides real-time tracking and alerts for low stock levels. This proactive approach enables businesses to anticipate demand and reorder parts well in advance. Communication with suppliers is also crucial; regular check-ins can provide insights into production schedules and potential delays. By adopting these strategies, B2B buyers can enhance their resilience against supply chain disruptions and maintain a steady flow of bicycle parts.

Scenario 3: Understanding Pricing Structures and Hidden Costs

The Problem: Another common pain point for B2B buyers is navigating complex pricing structures and hidden costs associated with ordering bicycle parts. International shipping fees, import taxes, and currency fluctuations can significantly increase the total cost of an order, leading to budget overruns. Moreover, some suppliers may not disclose additional fees upfront, resulting in unpleasant surprises that can strain financial planning.

The Solution: To tackle pricing transparency, B2B buyers should conduct thorough market research before placing orders. Compare prices from various suppliers, and request detailed quotes that outline all potential costs, including shipping, taxes, and handling fees. Engaging with suppliers who provide clear pricing models and comprehensive terms can help avoid unexpected expenses. Additionally, consider negotiating long-term contracts with suppliers to lock in prices and reduce costs over time. Understanding the total cost of ownership, including maintenance and replacement cycles for parts, will also aid in making more informed purchasing decisions. By being vigilant about pricing and actively seeking transparent suppliers, B2B buyers can better manage their budgets and maximize profitability.

Strategic Material Selection Guide for order bicycle parts

What Are the Key Properties of Aluminum for Bicycle Parts?

Aluminum is a widely used material in the manufacturing of bicycle parts due to its lightweight nature and excellent strength-to-weight ratio. It typically has a temperature rating that allows it to perform well in various climates, making it suitable for international markets. Aluminum also exhibits good corrosion resistance, particularly when treated with anodization, which enhances its durability against environmental factors.

Pros and Cons of Aluminum in Bicycle Parts

The primary advantages of aluminum include its lightweight properties, which improve the overall performance of bicycles by enhancing speed and maneuverability. Additionally, aluminum is relatively cost-effective compared to other materials like carbon fiber. However, it can be less durable than steel, especially under high-stress conditions, and may require more complex manufacturing processes, such as welding and machining, which can increase production costs.

Impact on Application and Considerations for International Buyers

For international B2B buyers, particularly in regions like Africa and South America, it is crucial to consider local environmental conditions that may affect aluminum’s performance. Compliance with international standards such as ASTM can ensure the quality and reliability of aluminum parts. Buyers should also be aware of the availability of aluminum alloys that may be preferred for specific applications, such as 6061 or 7075, which offer different balances of strength and weight.

How Does Steel Compare as a Material for Bicycle Parts?

Steel is another common material used in bicycle parts, particularly for frames and components that require high strength and durability. It has excellent temperature and pressure ratings, making it suitable for heavy-duty applications. Steel also has a natural resistance to wear and tear, which is beneficial for parts subjected to constant friction and stress.

Pros and Cons of Steel in Bicycle Parts

The key advantages of steel include its unmatched durability and strength, making it ideal for rugged terrains and heavy loads. Steel parts are generally easier to manufacture and repair, which can be a significant advantage for buyers in regions with limited access to specialized services. However, steel is heavier than aluminum, which can negatively impact performance, especially in competitive cycling. Additionally, it is more prone to corrosion unless properly treated or coated.

Impact on Application and Considerations for International Buyers

International buyers must consider the specific applications for which steel parts are intended. For example, in humid or coastal regions, corrosion resistance becomes paramount, necessitating the use of stainless steel or galvanized coatings. Compliance with local standards like DIN or JIS can also ensure that the steel used meets the necessary quality benchmarks for safety and performance.

What Role Does Carbon Fiber Play in Bicycle Parts Manufacturing?

Carbon fiber is a high-performance material that has gained popularity in the cycling industry, particularly for high-end bicycles. It offers exceptional strength while being significantly lighter than both aluminum and steel. Carbon fiber parts can withstand high pressures and temperatures, making them suitable for competitive environments.

Pros and Cons of Carbon Fiber in Bicycle Parts

The main advantage of carbon fiber is its superior weight-to-strength ratio, which allows for the creation of lightweight, aerodynamic designs. This material also provides excellent vibration dampening, enhancing rider comfort. However, carbon fiber is considerably more expensive than aluminum and steel, and its manufacturing process can be complex, requiring specialized equipment and expertise. Additionally, carbon fiber components can be more susceptible to damage from impacts.

Impact on Application and Considerations for International Buyers

For B2B buyers in markets such as Europe and the Middle East, the high cost of carbon fiber may limit its use to premium products. Buyers should ensure that their suppliers comply with relevant international standards for carbon fiber products to guarantee quality and safety. Understanding the specific applications and performance requirements is essential to justify the investment in carbon fiber components.

What Are the Benefits of Plastic Composites in Bicycle Parts?

Plastic composites, including materials like nylon and polycarbonate, are increasingly used in bicycle components due to their lightweight and corrosion-resistant properties. These materials can withstand a range of temperatures and pressures, making them versatile for various applications.

Pros and Cons of Plastic Composites in Bicycle Parts

The primary advantage of plastic composites is their low weight and resistance to corrosion, which can extend the lifespan of components. They are also generally less expensive than metals, making them an attractive option for cost-sensitive buyers. However, plastic composites may lack the strength and durability of metals, especially in high-stress applications. They can also be more susceptible to UV degradation over time.

Impact on Application and Considerations for International Buyers

International buyers should consider the specific environmental conditions where the bicycles will be used. For example, in regions with high UV exposure, selecting UV-stabilized plastics can enhance durability. Compliance with international standards can also help ensure that the plastic components meet the necessary safety and performance criteria.

| Material | Typical Use Case for order bicycle parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frames, handlebars, wheels | Lightweight and corrosion-resistant | Less durable under high stress | Medium |

| Steel | Frames, components for heavy-duty bikes | High strength and durability | Heavier and prone to corrosion | Low |

| Carbon Fiber | High-end frames, forks, wheels | Superior strength-to-weight ratio | Expensive and complex to manufacture | High |

| Plastic Composites | Accessories, grips, fenders | Lightweight and corrosion-resistant | Weaker than metals and UV sensitive | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for order bicycle parts

What Are the Key Stages in the Manufacturing Process of Bicycle Parts?

The manufacturing of bicycle parts involves several critical stages that ensure the final product meets quality standards and performance expectations. Understanding these stages can help B2B buyers make informed decisions when sourcing bicycle components.

-

Material Preparation: The first step in the manufacturing process involves selecting and preparing raw materials. Common materials include aluminum, carbon fiber, steel, and plastics. Manufacturers often use advanced technologies like CNC machining to ensure precision in cutting and shaping materials before they enter the forming stage. The quality of the raw materials is crucial, as it directly impacts the durability and performance of the finished parts.

-

Forming: This stage involves shaping the prepared materials into specific components. Techniques such as forging, extrusion, and injection molding are commonly employed. For instance, forging is often used for components requiring high strength, like cranksets and brake levers, while injection molding is suitable for plastic parts such as grips and housings. Precision is essential here, as any deviation can lead to compatibility issues and affect the overall performance of the bicycle.

-

Assembly: After forming, the components are assembled into final products. This can involve manual labor or automated processes, depending on the complexity of the parts. For example, wheelsets require precise assembly of spokes, rims, and hubs, while drivetrain components must be aligned perfectly to ensure smooth operation. Quality control checks during assembly help identify any issues early, reducing the risk of faulty products reaching the market.

-

Finishing: The final stage in manufacturing includes finishing processes such as anodizing, painting, or powder coating. These not only enhance the aesthetics of the bicycle parts but also provide protective layers against corrosion and wear. Proper finishing is vital for ensuring the longevity of components, especially those exposed to harsh environmental conditions.

How Is Quality Assurance Ensured in Bicycle Parts Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that all components meet international standards and customer expectations. B2B buyers should be aware of various QA practices that can impact their purchasing decisions.

-

What International Standards Should B2B Buyers Look For?

– ISO 9001: This standard ensures a quality management system is in place, which can lead to improved efficiency and customer satisfaction. Manufacturers adhering to ISO 9001 demonstrate a commitment to continuous improvement.

– CE Marking: For companies selling in the European market, CE marking indicates compliance with safety, health, and environmental protection standards. This is particularly important for bicycle parts that are critical for rider safety.

– API Standards: For specialized components, especially in e-bikes, adherence to API standards may be relevant, ensuring components meet industry-specific safety and performance criteria. -

What Are the Key Quality Control Checkpoints?

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components before they enter production. It ensures that only materials meeting specified criteria are used.

– In-Process Quality Control (IPQC): This continuous monitoring occurs during the manufacturing process, allowing for real-time adjustments and immediate rectification of issues.

– Final Quality Control (FQC): Before products are shipped, final inspections are conducted to ensure they meet all specifications and standards. This step often involves rigorous testing and validation. -

What Testing Methods Are Commonly Used?

– Destructive Testing: Components may undergo stress tests to determine their durability and performance under extreme conditions. This is crucial for safety-critical parts like frames and brakes.

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection are employed to detect internal flaws without damaging the component.

– Functional Testing: This ensures that components perform as intended, such as testing the responsiveness of brakes or the smoothness of gear shifts.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, it is essential to ensure that suppliers adhere to rigorous quality control practices. Here are actionable steps to verify supplier quality:

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards. This can be done independently or through third-party auditing firms.

-

Request Quality Assurance Reports: Suppliers should be able to provide documentation detailing their quality assurance processes, test results, and certifications. Reviewing these documents can help buyers assess the reliability of the supplier.

-

Engage Third-Party Inspection Services: Utilizing independent inspection services can add an additional layer of assurance. These services can verify compliance with quality standards before shipping, ensuring that only products meeting specifications are delivered.

-

Understand Regional Quality Nuances: Buyers should be aware of any regional certifications or standards that may apply to bicycle parts in their specific markets. For instance, certain countries may have additional requirements for e-bike components that differ from traditional bicycles.

Conclusion: How Can Buyers Leverage Manufacturing and Quality Insights?

Understanding the manufacturing processes and quality assurance practices involved in bicycle parts production equips B2B buyers with the knowledge needed to make informed purchasing decisions. By focusing on reliable suppliers who adhere to international standards and implementing rigorous quality checks, buyers can ensure they receive high-quality components that meet their specific requirements. This diligence not only enhances product reliability but also fosters long-term business relationships built on trust and quality assurance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘order bicycle parts’

In today’s competitive marketplace, sourcing bicycle parts effectively is essential for B2B buyers looking to optimize their supply chains. This guide provides a structured approach to streamline the procurement process, ensuring you get the right components at the best prices while maintaining quality and reliability.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of the bicycle parts you need is crucial. Clearly outline the type, dimensions, and materials of the components to avoid compatibility issues. This step ensures that all stakeholders are aligned on the expectations and minimizes the chances of costly returns or exchanges.

Step 2: Research Potential Suppliers

Take the time to identify and research suppliers who specialize in bicycle parts. Look for companies with a strong online presence, positive reviews, and a comprehensive product range. Utilize industry forums and trade shows to gather insights and recommendations, which will help you create a shortlist of potential partners.

Step 3: Evaluate Supplier Certifications

Before entering into any agreements, verify that suppliers meet industry standards and certifications. Look for certifications such as ISO 9001 for quality management and any relevant safety standards. These certifications are indicators of a supplier’s commitment to quality and reliability, which is essential for maintaining your own business’s reputation.

Step 4: Request Samples and Product Specifications

Obtaining samples of critical components is a key step in the sourcing process. This allows you to assess the quality and compatibility of the parts with your existing products. Additionally, request detailed product specifications and datasheets to understand performance metrics and installation requirements better.

Step 5: Negotiate Terms and Pricing

Once you’ve identified a reliable supplier, initiate discussions on pricing and terms. Be clear about your budget and expected order volumes to negotiate better rates. Consider discussing payment terms, lead times, and shipping costs, as these factors can significantly impact your overall procurement strategy.

Step 6: Establish a Communication Plan

Effective communication is vital for a successful sourcing relationship. Set up a regular schedule for updates and feedback with your supplier. This can help address any potential issues early on and ensure that both parties are on the same page regarding timelines and expectations.

Step 7: Monitor Supplier Performance

After placing your order, continuously evaluate the supplier’s performance based on quality, delivery times, and responsiveness. Establish key performance indicators (KPIs) that align with your business goals. Regular assessments will help you identify areas for improvement and foster a stronger partnership.

By following this structured checklist, B2B buyers can enhance their sourcing strategies for bicycle parts, ensuring that they procure the right components efficiently and effectively.

Comprehensive Cost and Pricing Analysis for order bicycle parts Sourcing

What Are the Key Cost Components in Bicycle Parts Sourcing?

When sourcing bicycle parts, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of materials used significantly impacts cost. High-performance materials like carbon fiber or specialized alloys tend to be more expensive than standard steel or aluminum. Buyers should consider the longevity and performance benefits of premium materials against their upfront costs.

-

Labor: Labor costs vary by region and the complexity of manufacturing processes. Countries with lower labor costs may offer competitive pricing, but it’s essential to consider the potential trade-offs in quality.

-

Manufacturing Overhead: This includes costs associated with the facilities, utilities, and equipment necessary for production. Efficient manufacturing processes can help minimize overhead, allowing suppliers to offer more competitive pricing.

-

Tooling: Initial setup costs for tooling can be significant, especially for customized parts. These costs are often amortized over larger production runs, making bulk orders more cost-effective.

-

Quality Control (QC): Ensuring product quality incurs costs, particularly if strict testing and certification are required. Buyers should inquire about QC processes to ensure they align with their quality expectations.

-

Logistics: Transportation and warehousing costs can add significantly to the overall price. Understanding the logistics of the supply chain, including shipping methods and routes, can help buyers optimize their total cost.

-

Margin: Suppliers typically mark up prices to achieve a profit margin. Understanding the industry standards for margins can aid in negotiations.

How Do Price Influencers Affect Bicycle Parts Sourcing?

Several factors influence pricing in the bicycle parts market, which international B2B buyers should consider:

-

Volume/MOQ: Minimum order quantities (MOQs) often dictate pricing. Larger orders typically result in lower per-unit costs due to economies of scale. Negotiating MOQs can lead to significant cost savings.

-

Specifications and Customization: Customized parts often come with higher costs. Buyers should balance the need for specific features with budget constraints and assess whether off-the-shelf solutions might meet their needs.

-

Materials and Quality Certifications: Parts made from high-grade materials or those that have specific certifications (like ISO or CE) may command higher prices but can justify the cost with enhanced performance and reliability.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers may offer higher prices due to their brand value but can provide better service and quality assurance.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) is essential for international shipping. They dictate who bears the cost and risk at various points in the shipping process, which can significantly affect overall costs.

What Are Essential Buyer Tips for Cost-Efficiency in Bicycle Parts Sourcing?

B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should employ several strategies for cost-efficient sourcing:

-

Negotiate Effectively: Leverage volume and long-term partnerships to negotiate better pricing. Suppliers may be willing to offer discounts for consistent orders or larger quantities.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the TCO, which includes maintenance, operational costs, and expected lifespan of the parts. Investing in quality can lead to lower overall costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and taxes that can impact pricing. Understanding local regulations can also prevent unforeseen costs.

-

Research and Compare: Utilize multiple suppliers to compare prices and terms. This research can reveal market trends and allow buyers to make informed decisions.

Disclaimer on Pricing

The prices referenced in various sources are indicative and may fluctuate based on market conditions, supplier negotiations, and specific order requirements. Buyers should conduct thorough research and obtain quotes tailored to their unique needs to ensure accurate budgeting.

Alternatives Analysis: Comparing order bicycle parts With Other Solutions

Exploring Alternatives to Ordering Bicycle Parts

In the competitive landscape of bicycle parts procurement, B2B buyers must consider various solutions that can meet their operational needs. While ordering bicycle parts online is a popular choice, alternative methods exist that can offer distinct advantages depending on the specific requirements of the buyer. This section explores and compares the traditional ordering of bicycle parts with two viable alternatives: local sourcing and manufacturing bicycle parts in-house.

Comparison Table

| Comparison Aspect | Order Bicycle Parts | Local Sourcing | In-house Manufacturing |

|---|---|---|---|

| Performance | High-quality parts from reputable suppliers | Variable quality; dependent on local suppliers | High control over quality, but requires expertise |

| Cost | Moderate to high, including shipping fees | Potentially lower costs, no shipping fees | High initial investment; lower long-term costs |

| Ease of Implementation | Simple online process, quick delivery | May require relationship building and negotiation | Complex setup; requires skilled labor and equipment |

| Maintenance | Supplier handles quality issues | Buyer must manage quality and returns | Ongoing maintenance of machinery and skills required |

| Best Use Case | Fast, reliable orders for standard parts | Cost-effective for bulk purchases, localized needs | Custom parts or specific designs, long-term projects |

Detailed Breakdown of Alternatives

Local Sourcing

Local sourcing involves procuring bicycle parts from nearby suppliers or manufacturers. This method can significantly reduce shipping costs and time, making it ideal for businesses that require quick access to parts for repairs or custom builds. However, the quality of parts can vary widely among local suppliers, and buyers may need to invest time in establishing reliable relationships. Additionally, local sourcing may limit the variety of parts available compared to online ordering, where larger inventories can be accessed.

In-house Manufacturing

Manufacturing bicycle parts in-house offers businesses complete control over the quality and specifications of the components produced. This approach is particularly beneficial for companies that need custom parts tailored to their unique specifications. However, the initial investment in equipment and skilled labor can be substantial, and ongoing maintenance of machinery and training for staff is necessary to ensure consistent quality. In-house manufacturing may be the best choice for businesses focused on innovation or those that frequently require specialized components.

Conclusion: Choosing the Right Solution for Your Bicycle Parts Needs

When selecting a solution for obtaining bicycle parts, B2B buyers must consider factors such as performance, cost, ease of implementation, and maintenance. Ordering bicycle parts online offers a convenient and efficient method for obtaining quality components quickly. In contrast, local sourcing may provide cost advantages and faster access for businesses with established relationships. Meanwhile, in-house manufacturing can be the optimal choice for those needing specialized parts and willing to invest in the necessary infrastructure. Ultimately, the decision should align with the company’s operational goals, budget constraints, and long-term strategic vision.

Essential Technical Properties and Trade Terminology for order bicycle parts

Understanding the technical properties and trade terminology associated with ordering bicycle parts is crucial for B2B buyers. This knowledge not only facilitates smoother transactions but also ensures that the components meet specific operational needs.

What are the Essential Technical Specifications for Bicycle Parts?

-

Material Grade

Material grade refers to the quality and composition of the materials used in bicycle parts, such as aluminum, carbon fiber, or steel. Each material has unique properties affecting weight, strength, and durability. For instance, carbon fiber is lightweight and strong, making it ideal for high-performance racing bikes, while aluminum is often used for its balance of weight and cost-effectiveness. Understanding material grades helps buyers choose parts that align with their performance expectations and budget. -

Tolerance

Tolerance is the allowable deviation from a specified dimension of a part. It is critical in ensuring parts fit together correctly, especially in precision components like brake calipers and gear systems. Tight tolerances can lead to better performance and safety. For B2B buyers, knowing the required tolerances can prevent compatibility issues and reduce the risk of costly returns or repairs. -

Weight

Weight is a vital property that influences the overall performance of a bicycle. Lighter components enhance speed and maneuverability, making them preferable for competitive cyclists. However, buyers must balance weight with durability, particularly for parts that experience significant stress, such as frames and wheels. Understanding the weight specifications can assist in selecting parts that meet the intended use of the bicycle. -

Compatibility

Compatibility refers to the ability of a part to fit and function correctly with other components of a bicycle. This is particularly important for drivetrain parts, brakes, and wheels. B2B buyers must ensure that the parts they order are compatible with the bicycle models they support to avoid installation issues and customer dissatisfaction. -

Finish

The finish of a bicycle part affects both aesthetics and performance. Common finishes include anodizing, powder coating, and chrome plating. These finishes can enhance resistance to corrosion and wear, impacting the longevity of the parts. Buyers should consider the environmental conditions where the bicycles will be used, as this will influence the choice of finish.

What are the Common Trade Terms in the Bicycle Parts Industry?

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the bicycle or its components. These parts are typically designed to meet specific performance standards and compatibility requirements. B2B buyers often prefer OEM parts for their reliability and warranty coverage. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for buyers as it can affect inventory management and cash flow. If a buyer’s needs are below the MOQ, they may face higher costs or have to find alternative suppliers. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific parts. It is a critical step in the procurement process, enabling buyers to compare options and negotiate better deals. A well-structured RFQ can streamline purchasing and ensure clarity on requirements. -

Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping costs, insurance, and risks during transport. Familiarity with Incoterms is vital for B2B buyers engaged in cross-border transactions to avoid misunderstandings and disputes. -

Lead Time

Lead time is the time it takes from placing an order to receiving the parts. It can vary significantly based on supplier capabilities, stock availability, and shipping methods. Understanding lead times is crucial for inventory planning and meeting customer demand, particularly in regions with longer shipping durations.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions when ordering bicycle parts, ensuring they meet performance standards and operational needs.

Navigating Market Dynamics and Sourcing Trends in the order bicycle parts Sector

What are the Key Market Dynamics and Sourcing Trends in the Bicycle Parts Sector?

The global bicycle parts market is witnessing robust growth, driven by increasing urbanization, a surge in cycling as a sustainable transportation mode, and the growing popularity of e-bikes. In regions like Africa, South America, the Middle East, and Europe, this trend is reflected in rising demand for high-quality bicycle components that cater to diverse riding conditions and preferences. Key trends include the integration of advanced technologies such as e-commerce platforms, which facilitate direct access to suppliers and streamline the procurement process for B2B buyers. Additionally, the rise of data analytics is enabling companies to forecast demand more accurately, optimize inventory levels, and enhance customer experiences.

Emerging technologies such as IoT (Internet of Things) are also influencing sourcing strategies. Smart components that monitor performance and provide real-time data are becoming increasingly sought after, particularly in markets that prioritize performance and safety. Furthermore, international buyers are increasingly looking for suppliers that offer customizable solutions, ensuring that they can meet local market needs effectively. The emphasis on quick turnaround times and efficient logistics further underscores the dynamic nature of this sector, making it essential for businesses to stay agile and responsive to market shifts.

How is Sustainability and Ethical Sourcing Affecting the Bicycle Parts Industry?

Sustainability is becoming a critical factor in sourcing bicycle parts, as environmental concerns gain prominence among consumers and businesses alike. The bicycle industry’s environmental impact primarily stems from manufacturing processes, packaging, and end-of-life disposal of components. Consequently, international B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials, energy-efficient manufacturing processes, and responsible waste management strategies.

Ethical sourcing is equally important, as it ensures that suppliers adhere to fair labor practices and human rights standards. Certifications such as Fair Trade, ISO 14001 (Environmental Management), and others signal a supplier’s commitment to responsible practices, making them more attractive to conscientious buyers. Moreover, the demand for ‘green’ materials—such as recycled metals and biodegradable composites—is on the rise, providing B2B buyers with a broader range of options that align with their sustainability goals. This shift not only benefits the environment but also enhances brand reputation and customer loyalty.

How Has the Bicycle Parts Sector Evolved Over Time?

The bicycle parts sector has evolved significantly over the past few decades, transitioning from local craftsmanship to a globalized industry characterized by mass production and advanced manufacturing techniques. Initially, bicycle parts were manufactured using rudimentary methods, often resulting in limited availability and high costs. However, the advent of technology has revolutionized production processes, enabling manufacturers to produce high-quality, durable components at scale.

The rise of online marketplaces has further transformed the landscape, allowing international B2B buyers to access a wider range of products and suppliers. This evolution has also been marked by the increasing specialization of components, catering to diverse cycling disciplines, including mountain biking, road racing, and commuting. As consumer preferences shift towards customized and high-performance products, the bicycle parts sector continues to adapt, embracing innovation and sustainability as key drivers of growth.

Frequently Asked Questions (FAQs) for B2B Buyers of order bicycle parts

-

How do I ensure the bicycle parts I order are compatible with my specifications?

To ensure compatibility, first identify the specific requirements for your bicycle models, including frame size, type of riding, and existing components. Consult technical specifications from the manufacturer or supplier websites for precise measurements and compatibility guidelines. If uncertain, leverage the expertise of your supplier’s customer service team to confirm that the parts will fit your needs before placing a bulk order. -

What are the most common bicycle parts that require replacement?

Commonly replaced bicycle parts include brake pads, chains, tires, inner tubes, and drivetrain components. Depending on the bike’s usage, components such as cables, handlebars, and pedals may also need regular updates. Understanding which parts are most frequently replaced will help you maintain inventory and provide better service to your customers. -

How can I verify the reliability of a bicycle parts supplier?

Start by researching the supplier’s reputation through reviews, testimonials, and industry ratings. Request references from other B2B buyers, particularly those in your region. Additionally, verify their certifications and compliance with international standards. Engaging in small initial orders can also help gauge their reliability and service before committing to larger quantities. -

What are the typical minimum order quantities (MOQs) for bicycle parts?

Minimum order quantities can vary significantly among suppliers, often ranging from 50 to 500 units per part. However, some suppliers may offer flexible MOQs for first-time buyers or smaller businesses. It’s advisable to discuss your specific needs with suppliers to negotiate favorable terms that align with your purchasing strategy. -

What payment terms should I expect when ordering bicycle parts internationally?

Payment terms can vary, but typical options include upfront payment, partial payment with the balance due on delivery, or letters of credit for larger orders. Be sure to clarify terms such as payment methods (e.g., bank transfers, credit cards) and any potential currency exchange fees. Establishing clear payment terms upfront can help avoid misunderstandings and facilitate smoother transactions. -

How do I manage logistics for international shipping of bicycle parts?

Managing logistics involves choosing a reliable shipping partner that understands the complexities of international trade, including customs regulations and import/export duties. Confirm shipping timelines and costs upfront, and consider options for tracking shipments. Collaborating with a logistics provider can streamline the process and help ensure timely delivery to your location. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should provide quality assurance through inspections and certifications for their products. Ask about their quality control processes, such as testing for durability and performance. Request samples before placing large orders to assess the quality firsthand, and consider establishing a quality agreement that outlines expectations for product specifications. -

Can I customize bicycle parts to meet my specific needs?

Many suppliers offer customization options for bicycle parts, such as branding, color variations, or specific component configurations. Discuss your requirements directly with the supplier to explore available options. Keep in mind that customization may affect lead times and MOQs, so plan accordingly to meet your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Order Bicycle Parts Manufacturers & Suppliers List

1. Specialized – S120800009 Bar My12 Shiv Alloy Base Bar 41cm

Domain: bikeparts.com

Registered: 1998 (27 years)

Introduction: {“products”:[{“name”:”Specialized S120800009 Bar My12 Shiv Alloy Base Bar 41cm”,”price”:”$120.00″},{“name”:”Specialized FRK MY21 FUTURE SHOCK (G2.1), 700C, TA, CARBON, 12X100MM, DISC, 55MM OFFSET, 200MM ST – SATIN CARBON”,”price”:”$275.00″},{“name”:”Specialized MSC KICKSTAND, GLOBE, HAUL LT KICKSTAND, CENTER MOUNT, DUAL LEG (WIDE STANCE)”,”price”:”$87.00″},{“name”:”DT Swiss F 1900 Classic Front Wh…

2. Jenson USA – Bike Parts & Accessories

Domain: jensonusa.com

Registered: 1996 (29 years)

Introduction: Online mountain & road bike parts, clothing and accessories shop. Free shipping on most items over $50. Same day shipping on orders placed by 3pm PST. Bike build process takes 2-3 days. In-stock items ship same day if ordered by 3PM PST. Customer service available at 888-880-3811. Categories include Bikes, Components, Apparel, Accessories, and more. Featured brands and recommended products availab…

3. Nashbar – Bikes, Parts & Accessories

Domain: nashbar.com

Registered: 1995 (30 years)

Introduction: Nashbar offers a wide range of bikes, parts, and accessories including: Mountain Bikes (Hardtail, Rigid, Fat Bikes, Dirt Jump Bikes), Road Bikes (Performance, Endurance, Gravel, Cyclocross), City & Fitness Bikes (Urban, Fixed Gear, Single Speed, BMX, Kids), Bike Frames (Mountain, Road, Gravel), Bike Forks (Suspension, Rigid), Components (Brakes, Cables, Cassettes, Chains, Cranks, Derailleurs), Gro…

4. Bicycle Warehouse – Best Selling Bike Parts

Domain: bicyclewarehouse.com

Registered: 1998 (27 years)

Introduction: Best Selling Bike Parts:

1. Shimano PD-EH500 Multi-Purpose Bike Pedals – $79.99

2. Giant FlatGuard Mountain Bike Tire – 26 x 2.1″ – $34.99

3. Shimano PD-M520 Mountain Bike Pedals – $49.99

4. Continental Contact Plus E-Bike Tire – 700 x 32c – TR9069 – $54.95

5. Shimano PD-RS500 SPD-SL Road Bike Pedals – $64.99

6. Giant Adjustable Angle 31.8mm Stem – 95mm / 31.8mm / Adjustable – $40.99

7. Giant Adju…

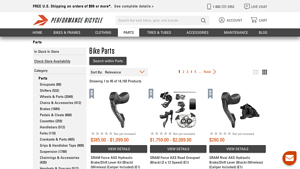

5. Performance Bicycle – Bike Parts & Accessories

Domain: performancebike.com

Registered: 1996 (29 years)

Introduction: Bike Parts – Performance Bicycle includes a wide range of categories such as Bikes & Frames, Clothing, Parts & Accessories, and more. Key categories include:

– Bikes: Specialized, Giant, Mountain, Road, Gravel, E-Bikes, Kids Bikes.

– Clothing: Jerseys, Shorts, Helmets, Footwear, Casual Clothing, High Vis & Reflective.

– Parts: Groupsets, Wheels, Chains, Brakes, Pedals, Handlebars, Forks, Crankset…

6. QBP – Wholesale Bike Distribution

Domain: qbp.com

Registered: 1996 (29 years)

Introduction: This company, QBP – Wholesale Bike Distribution, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. JBI – Fast Same-Day Shipping

Domain: jbi.bike

Registered: 2014 (11 years)

Introduction: This company, JBI – Fast Same-Day Shipping, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. SRAM – Force AXS Power-Meter Groupset

Domain: outlet.wheelandsprocket.com

Registered: 2000 (25 years)

Introduction: Featured Products:

1. SRAM AXS eTap: Redefining Wireless Precision and Performance

– SRAM Force AXS 2×12 Power-Meter Groupset, Disc

– Price: $1,099.95 (Regular Price: $2,499.99)

– Rating: 5.0 / 5.0 (2 reviews)

– SRAM Force AXS XLPR Power-Meter Groupset, 1×12-Speed, 40T, 10-44T, Disc, D1, XDR

– Price: $899.95 (Regular Price: $2,199.99)

– Rating: 5.0 / 5.0 (5 reviews)

– …

Strategic Sourcing Conclusion and Outlook for order bicycle parts

Why Is Strategic Sourcing Essential for Ordering Bicycle Parts?

In the competitive landscape of bicycle parts procurement, strategic sourcing emerges as a vital component for B2B success. By establishing strong supplier relationships, buyers can secure high-quality components at competitive prices, ultimately enhancing their operational efficiency. The ability to leverage global suppliers not only broadens the product selection but also mitigates risks associated with supply chain disruptions, particularly relevant in regions like Africa and South America, where market volatility can be pronounced.

What Are the Key Takeaways for International B2B Buyers?

- Diversification of Suppliers: Engage with multiple suppliers to ensure a steady flow of parts and reduce dependency on single sources.

- Quality Assurance: Prioritize suppliers who offer high-quality components to maintain customer satisfaction and brand reputation.

- Cost Management: Utilize strategic sourcing to negotiate favorable terms and optimize procurement costs, enabling competitive pricing in local markets.

How Can B2B Buyers Prepare for Future Trends?

As the bicycle market evolves, staying ahead of trends such as e-bike components and sustainability in manufacturing will be crucial. International buyers should actively seek partnerships with suppliers who are innovating in these areas. By embracing strategic sourcing practices today, businesses can position themselves for growth and adaptability in the dynamic cycling industry.

In conclusion, the pathway to successful procurement of bicycle parts lies in strategic sourcing. By implementing these practices, international B2B buyers from regions like Europe, the Middle East, and Africa can ensure they meet the demands of an ever-changing market. Now is the time to explore new sourcing strategies and partnerships that will propel your business forward.