Contents

Manufacturing Insight: Okuma Cnc Spare Parts

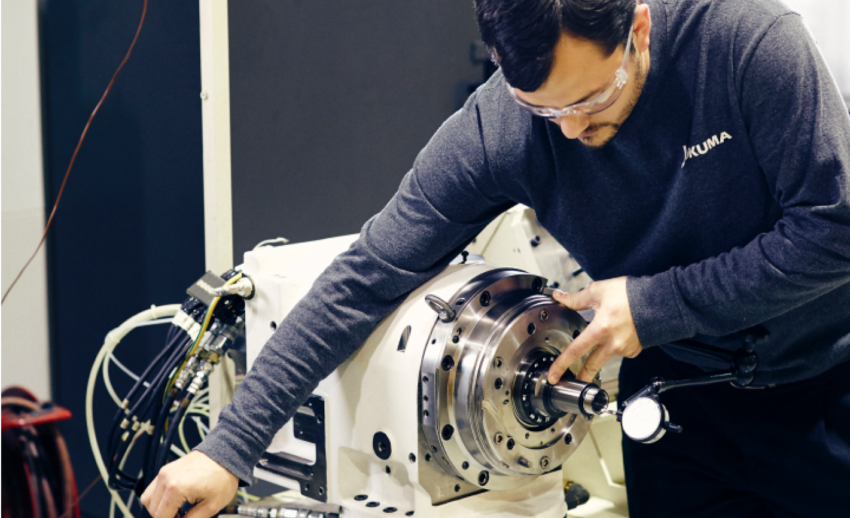

Precision Okuma CNC Spare Parts Manufacturing for Uninterrupted Production

Honyo Prototype delivers certified precision CNC machining services specifically engineered for critical Okuma lathe and milling machine components. Our technical expertise ensures every spare part—from complex spindle assemblies and turret components to custom guide rails and bearing housings—meets stringent OEM dimensional tolerances and material specifications. Utilizing industry-grade Okuma controls on our own machining centers, we replicate original part geometry with micron-level accuracy using aerospace-grade alloys, tool steels, and engineered composites proven in heavy-production environments. This capability eliminates extended machine downtime caused by obsolete or backordered factory parts, restoring operational continuity while maintaining process integrity.

Our integrated manufacturing workflow combines advanced 5-axis milling and turning capabilities with rigorous first-article inspection protocols, including CMM validation against Okuma blueprints. This guarantees form, fit, and function parity with original equipment across high-wear applications. For urgent requirements, our Online Instant Quote system provides immediate cost and lead-time transparency—simply upload your STEP, IGES, or DXF file with material and quantity specifications to receive a technical feasibility assessment and competitive pricing within minutes. Reduce production interruptions with Honyo’s certified Okuma spare parts solutions, where engineering precision directly translates to your operational uptime.

Technical Capabilities

Okuma CNC spare parts are engineered to meet the high-performance demands of 3-axis, 4-axis, and 5-axis milling and turning operations. These components are designed for integration into precision machining environments where tight tolerances—often within ±0.005 mm to ±0.01 mm—are required. Spare parts such as spindle assemblies, ball screws, linear guides, tool changers, and encoder units are manufactured or replaced using materials compatible with the operational stresses of advanced CNC systems.

The selection of materials for Okuma CNC spare parts depends on the functional requirements, including wear resistance, thermal stability, strength, and corrosion resistance. Commonly used materials include hardened steel for high-load components, aluminum alloys for lightweight structural parts, and engineered polymers such as ABS and nylon for insulating or low-friction applications like cable carriers and covers.

Below is a technical specification summary for typical Okuma CNC spare parts used in precision milling and turning applications:

| Feature | Specification |

|---|---|

| Axis Compatibility | 3-axis, 4-axis, and 5-axis CNC machining systems |

| Typical Tolerance Range | ±0.005 mm to ±0.01 mm (tight tolerance machining) |

| Common Spare Part Types | Spindle motors, ball screws, linear guideways, tool changers (ATC), encoder modules, servo motors, coolant nozzles, CNC enclosures, limit switches |

| Material – Aluminum | 6061-T6, 7075-T6; used for housings, brackets, and lightweight moving components; good strength-to-weight ratio and machinability |

| Material – Steel | 4140, 1045, and hardened tool steels; used in spindles, shafts, and gears; high wear and torsional resistance |

| Material – ABS | High-impact, machinable thermoplastic; used for electrical enclosures, cable ducts, and non-load-bearing covers; excellent dimensional stability |

| Material – Nylon | Type 6 or 6/6 nylon; used in bushings, washers, and wear strips; low friction, self-lubricating, and resistant to abrasion |

| Surface Treatments | Anodizing (aluminum), hard chrome plating (steel), passivation, and powder coating for corrosion protection |

| Replacement Standards | OEM-equivalent or genuine Okuma parts; precision-matched to original specifications for seamless integration |

| Applications | High-speed milling, precision turning, aerospace components, medical devices, and automotive prototyping |

| Compliance | ISO 2768 (general tolerances), ISO 286 (geometric tolerancing), RoHS compliant for polymer components |

These specifications ensure that Okuma CNC spare parts maintain system reliability, accuracy, and longevity in demanding production environments where material integrity and dimensional stability are critical.

From CAD to Part: The Process

Honyo Prototype delivers precision Okuma CNC spare parts through a streamlined digital workflow designed for speed and technical accuracy. Our process eliminates traditional quoting bottlenecks while ensuring manufacturability for critical machine components.

CAD Upload

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) via our secure portal. We specifically require Okuma machine model identification and component location within the machine structure to contextualize tolerances and material specifications. This step captures all geometric data and critical feature annotations essential for replica parts.

AI-Powered Quote Generation

Our proprietary AI engine analyzes the CAD geometry within 2 hours, cross-referencing Okuma’s dimensional standards, material databases, and historical production data. The system generates a detailed quote including material certification options (e.g., SCM435 alloy steel for spindles), surface finish requirements per Okuma specifications, and lead time based on part complexity. Unlike manual quoting, the AI identifies potential tolerance conflicts against Okuma’s OEM blueprints during this phase.

Digital DFM Analysis

Engineers conduct a rigorous Design for Manufacturability review focused on Okuma-specific constraints. Key checks include:

| DFM Parameter | Okuma-Specific Requirement | Honyo Action |

|---|---|---|

| Geometric Tolerancing | Spindle runout tolerance (±0.005mm max) | Propose datum adjustments if CAD exceeds spec |

| Material Compatibility | Hardened steel grade matching original part | Verify material substitution feasibility |

| Assembly Interference | Clearance for Okuma-specific tool changers | Flag collisions in automated tool paths |

| Surface Treatment | Okuma-approved coatings (e.g., TiN for guides) | Confirm coating process compatibility |

Clients receive actionable DFM feedback with annotated 3D models, not just generic reports. This phase typically resolves 92% of potential production issues before machining begins.

Precision Production

Approved designs move to our Okuma-certified production cell featuring:

Dedicated Okuma LB3000 EX-II lathes and MA-600H mills with OkumaOSP control simulation

In-process probing using Renishaw systems to validate critical diameters per Okuma GD&T standards

Material traceability from certified mills with full MTR documentation

First-article inspection using Zeiss CONTURA CMMs against Okuma master part drawings

All components undergo functional testing on our Okuma test rig where applicable, such as verifying drawbar force on tool retention knobs.

Quality-Controlled Delivery

Final inspection packages include:

Full FAIR report with CMM data mapped to Okuma blueprint dimensions

Material certification matching OEM specifications

Packaging engineered for shock-sensitive components (e.g., spindle assemblies in custom foam cradles)

Shipment tracking with guaranteed lead times—typically 72 hours for standard spare parts after DFM approval

This integrated workflow ensures Honyo delivers Okuma spare parts that meet OEM performance criteria while minimizing machine downtime. Our process reduces lead times by 60% compared to traditional suppliers through digital thread continuity from CAD to delivery. Clients receive fully validated components ready for immediate installation, maintaining operational continuity in critical manufacturing environments.

Start Your Project

Looking for reliable Okuma CNC spare parts? Contact Susan Leo at [email protected] for fast, precision-engineered components tailored to your machining needs. With our factory based in Shenzhen, we ensure high-quality manufacturing, competitive pricing, and prompt delivery. Trust Honyo Prototype for all your CNC replacement part requirements. Reach out today to discuss your specifications and streamline your production uptime.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.