Contents

Manufacturing Insight: Oilfield Machining

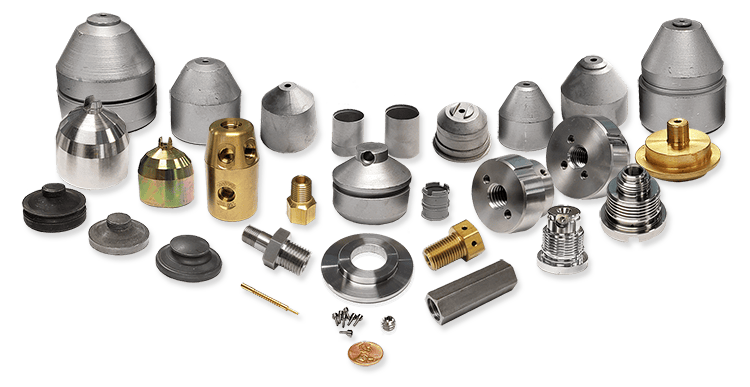

Precision Oilfield Component Manufacturing for Demanding Downhole and Surface Applications

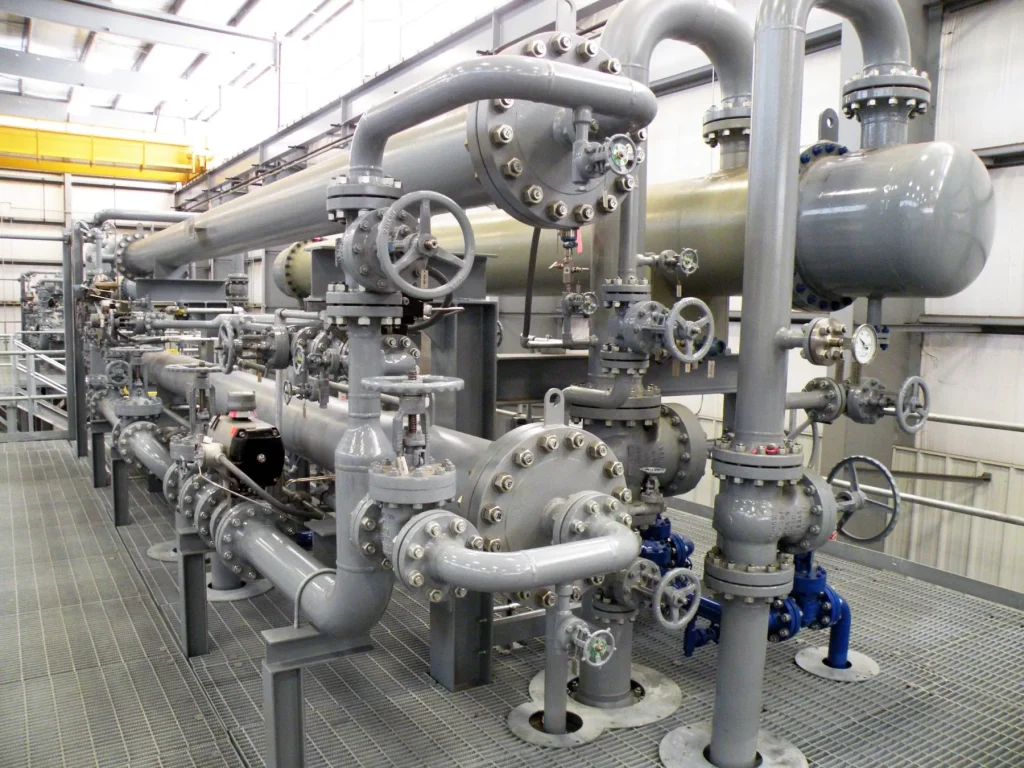

The oil and gas industry operates in environments defined by extreme pressures, corrosive elements, and zero-tolerance safety requirements. Component failure is not an option, making precision machining a non-negotiable element of operational integrity. Honyo Prototype addresses these critical demands through advanced CNC machining services engineered specifically for oilfield applications, from downhole tools and wellhead components to surface drilling equipment and subsea hardware.

Leveraging state-of-the-art multi-axis CNC milling and turning centers, Honyo consistently achieves tolerances down to ±0.0002 inches while working with challenging materials including API 6A/6D-compliant alloys, corrosion-resistant superalloys (e.g., Inconel 718, 17-4 PH stainless steel), and high-strength tool steels. Our AS9100-certified processes ensure traceability, rigorous in-process inspection, and adherence to NACE MR0175 standards for sour service environments. Every component undergoes comprehensive dimensional validation using coordinate measuring machines (CMMs) and non-destructive testing protocols to guarantee performance under real-world downhole stresses.

For engineering teams requiring rapid validation of complex geometries or urgent replacement parts, Honyo’s Online Instant Quote system accelerates project timelines. Upload CAD files in STEP, IGES, or native formats to receive detailed manufacturability feedback and competitive pricing within hours—not days—enabling faster iteration cycles and reduced downtime for critical assets. This digital workflow integration ensures seamless transition from design to certified production without compromising the metallurgical or dimensional rigor the oilfield demands.

Honyo Prototype delivers more than precision parts; we provide engineered confidence for the most unforgiving operational landscapes. Partner with us to transform technical specifications into field-proven reliability.

Technical Capabilities

Oilfield machining involves the production of high-precision components used in drilling, extraction, and downhole equipment, where reliability under extreme conditions is critical. These parts often require complex geometries, tight tolerances, and compatibility with harsh environments. Advanced CNC machining processes—specifically 3, 4, and 5-axis milling and precision turning—are employed to meet these demands across a range of engineering materials, including aluminum, steel, ABS, and nylon.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Description | Machining on X, Y, Z linear axes | Adds rotational A-axis (around X) | Simultaneous movement across X, Y, Z, A, B | Rotation of workpiece with cutting tool engagement | Consistently holds ±0.0002″ (5 µm) or better |

| Typical Use in Oilfield | Flanges, housings, base plates | Impellers, valve bodies, angled features | Complex manifolds, downhole tools, no re-fixturing | Shafts, pins, connectors, seals | Critical sealing surfaces, mating components |

| Materials Compatible | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS | Aluminum, Steel | Aluminum, Steel, ABS, Nylon | Aluminum, Steel (most common) |

| Surface Finish (Ra) | 32–125 µin | 32–63 µin | 16–32 µin (complex features) | 16–63 µin | <16 µin (with finishing passes) |

| Tolerance Range | ±0.001″ (25 µm) | ±0.0005″ (12.5 µm) | ±0.0002″ (5 µm) or better | ±0.0005″ (12.5 µm) | ±0.0001″ (2.5 µm) achievable |

| Key Advantages | Fast for simple geometries | Indexed angular features, minimal setups | Full 3D contouring, high accuracy | High repeatability, excellent roundness | Ensures fit, function, and sealing in high-pressure environments |

Material Notes:

Aluminum (e.g., 6061-T6, 7075-T6): Lightweight, corrosion-resistant; used for non-critical downhole components, sensors, and housings. Easily machined in multi-axis setups.

Steel (e.g., 4140, 4340, Stainless 17-4 PH): High strength and wear resistance; preferred for high-pressure valves, connectors, and tool joints. Requires robust tooling in milling and turning.

ABS (Acrylonitrile Butadiene Styrene): Thermoplastic used for prototypes, non-structural fixtures, or insulating components. Compatible with 3-axis milling and turning for non-metallic parts.

Nylon (e.g., PA6, PA66): Offers low friction and chemical resistance; used in seals, bushings, and wear components. Requires controlled machining to prevent deformation due to low thermal conductivity.

All oilfield machined components undergo rigorous inspection using CMMs (Coordinate Measuring Machines), optical comparators, and surface profilers to ensure compliance with API and ISO standards. Multi-axis machining reduces lead time and improves accuracy by minimizing workpiece repositioning, which is essential for maintaining tight tolerances across complex features.

From CAD to Part: The Process

Honyo Prototype Oilfield Machining Process Overview

Honyo Prototype executes oilfield machining projects through a rigorously controlled five-stage workflow designed for high-integrity components operating in extreme downhole, subsea, and surface environments. This process ensures compliance with API, NACE, and ISO 15156 standards while minimizing lead time risk.

Upload CAD

Clients submit 3D CAD models (STEP, Parasolid, or native formats) via our secure portal, specifying critical oilfield requirements: material grade (e.g., 13Cr, Super Duplex, Inconel 718 per NACE MR0175), pressure ratings, sour service conditions, and applicable API specifications (e.g., 6A, 17D). Our system validates geometric completeness and flags missing critical features like API thread profiles or pressure-tested sealing surfaces before proceeding.

AI Quote

Our proprietary AI engine analyzes the CAD geometry against real-time machine capacity data, material availability from certified mills, and oilfield-specific process constraints. It generates a detailed quote within 4 business hours, including:

Material certification costs (MTRs with traceability to heat number)

NDT requirements (PMI, MPI, UT per API 5L)

Lead time impact of sour service passivation or H2S testing

Cost drivers for complex geometries (e.g., tapered threads, internal hardfacing)

The AI cross-references historical oilfield project data to predict manufacturability risks, such as distortion in long-string tool joints during heat treatment.

DFM Analysis

Honyo engineers conduct oilfield-specific Design for Manufacturability review within 24 hours of quote acceptance. This phase focuses on operational reliability in harsh environments:

| DFM Check Category | Oilfield-Specific Focus Areas |

|---|---|

| Material & Corrosion | Sour service compatibility, galvanic corrosion mitigation, hardness verification per NACE |

| Geometry & Tolerancing | API thread gauging compliance, pressure boundary integrity, thermal expansion allowances |

| Process Feasibility | Deep-hole drilling stability for mandrels, stress-relief sequencing for high-pressure housings |

| Testing & Documentation | Mandatory NDT coverage maps, hydrostatic test protocols, as-built dimensional reports |

Non-conformances (e.g., inadequate fillet radii causing stress concentration) trigger immediate client collaboration for design refinement. All DFM decisions are documented per API Q1 requirements.

Production

Machining occurs in climate-controlled cells with dedicated oilfield tooling:

CNC turning/milling centers equipped with live tooling for API thread cutting (8-round, buttress)

In-process CMM verification of critical sealing diameters at 25°C to offset thermal growth

Dedicated cleaning stations using filtered solvents meeting API 16B standards

Real-time SPC monitoring of thread parameters (pitch diameter, taper) with automated gauge R&R

Materials undergo full traceability from certified mill certs through heat treatment logs. Every component receives NDT per the approved ITP, with MPI/UT reports linked to the part serial number.

Delivery

Final documentation package includes:

Material Test Reports (MTRs) with full chemical and mechanical properties

NDT reports signed by ASNT Level II technicians

Dimensional inspection report showing API thread gauge results

Hydrostatic test certificate at 1.5x rated working pressure

Packing list with serialized traceability to the delivery manifest

Parts ship in VCI-treated containers with humidity indicators, accompanied by a chain-of-custody log. All deliveries include a digital twin of the as-built part for client validation against original CAD. Honyo maintains 99.2% on-time delivery for oilfield projects through our buffer stock of common alloys and dedicated logistics partners serving global energy hubs.

Start Your Project

Looking for precision machining solutions tailored to the oilfield industry? Honyo Prototype delivers high-quality, reliable components manufactured in our Shenzhen facility. With expertise in complex part production and strict adherence to industry standards, we support demanding oil and gas applications with on-time delivery and exceptional service.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Factory Location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.