Introduction: Navigating the Global Market for ohio machining companies

In the ever-evolving landscape of global manufacturing, sourcing precision components from Ohio machining companies presents a unique opportunity for international B2B buyers. However, navigating this market can be challenging, especially for businesses in Africa, South America, the Middle East, and Europe, such as Nigeria and Brazil. With a diverse range of machining capabilities—from 5-axis CNC milling to custom fabrication—Ohio offers a competitive edge in quality and efficiency. This guide aims to demystify the sourcing process by providing actionable insights into the types of machining services available, their applications across various industries, and effective supplier vetting strategies.

Throughout this guide, you will gain a comprehensive understanding of the factors influencing cost, the importance of quality certifications such as ISO and AS9100, and the critical role of supply chain management in securing timely and compliant deliveries. By empowering you with knowledge about the capabilities and standards of Ohio machining companies, this resource equips international buyers to make informed purchasing decisions. With a focus on quality craftsmanship and a commitment to meeting rigorous specifications, Ohio machining companies stand ready to support your manufacturing needs, ultimately enhancing your competitive advantage in the global marketplace.

Understanding ohio machining companies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Machining Companies | Utilize computer-controlled machines for precision | Aerospace, automotive, medical devices | Pros: High precision, efficiency; Cons: Initial setup costs can be high. |

| Custom Fabrication Shops | Tailor-made solutions for specific client needs | Construction, industrial machinery | Pros: Flexibility in design; Cons: Longer lead times for custom orders. |

| Large Part Machining | Capable of handling heavy and oversized components | Heavy equipment, oil & gas, manufacturing | Pros: Handles large volumes; Cons: Limited to specific industries. |

| Precision Machining Firms | Focus on high-tolerance parts and quality control | Electronics, defense, high-tech industries | Pros: Exceptional quality assurance; Cons: May be more costly due to quality standards. |

| Multi-Process Shops | Offer a range of services from machining to assembly | Diverse industries requiring multiple services | Pros: One-stop-shop convenience; Cons: Potential for diluted specialization. |

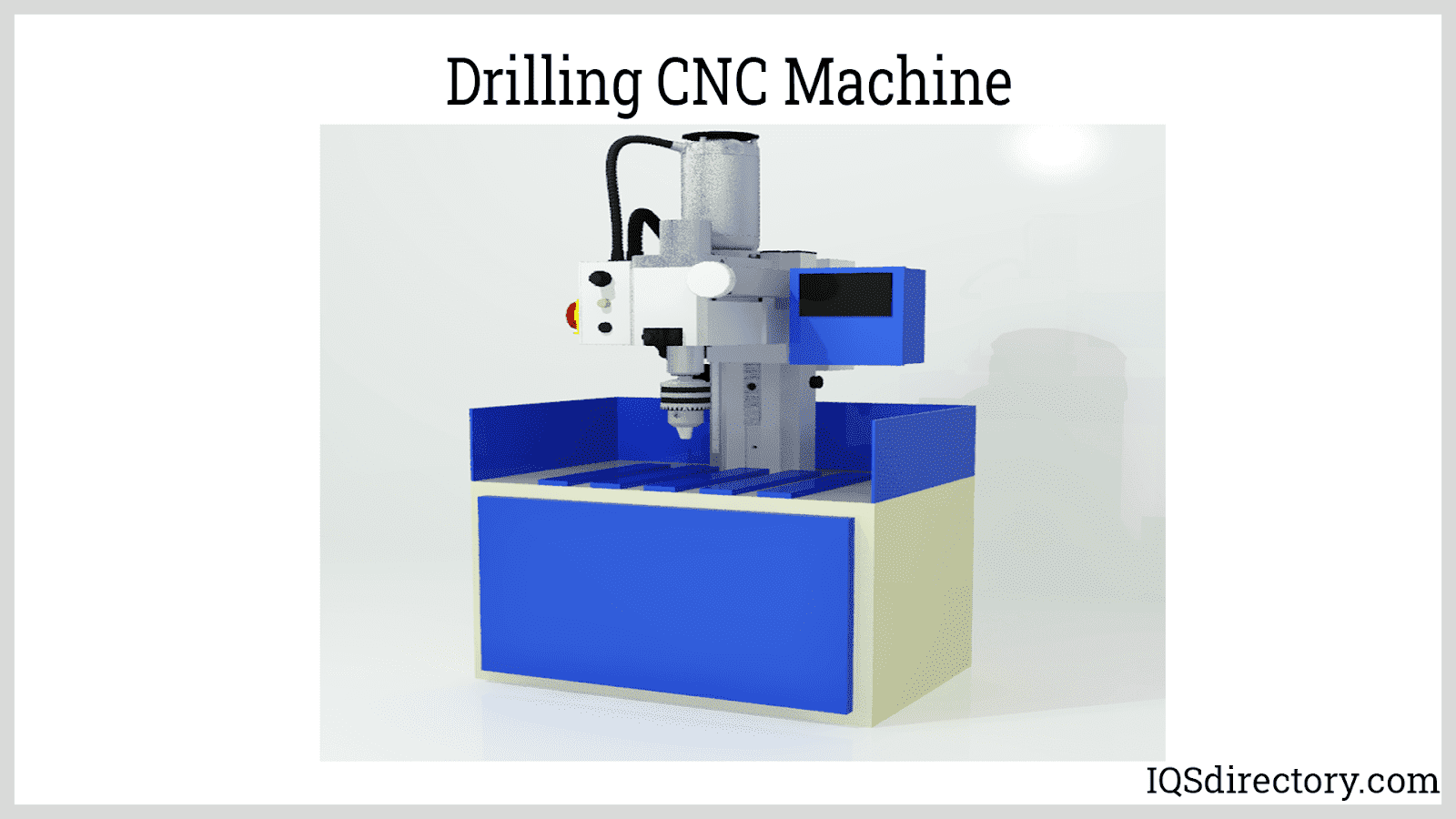

What Are CNC Machining Companies and Their B2B Relevance?

CNC (Computer Numerical Control) machining companies are equipped with advanced machinery that operates based on computer-generated commands. This technology allows for high precision and repeatability, making it ideal for industries like aerospace, automotive, and medical devices. When purchasing from CNC machining companies, B2B buyers should consider the machine capabilities, software compatibility, and the company’s experience with similar projects to ensure they meet stringent industry standards.

How Do Custom Fabrication Shops Cater to Unique Client Needs?

Custom fabrication shops specialize in creating tailored solutions that meet specific client requirements. They work closely with clients to understand their project needs, which can range from unique components to complex assemblies. This flexibility makes them suitable for industries such as construction and industrial machinery. Buyers should evaluate the shop’s past projects and material capabilities to ensure they can deliver the desired results within the expected timeframe.

Why Choose Large Part Machining for Heavy Components?

Large part machining companies focus on producing heavy and oversized components, catering primarily to industries like heavy equipment, oil & gas, and manufacturing. Their ability to handle substantial weights and sizes sets them apart. When engaging with these companies, buyers should assess their equipment capacity, turnaround times, and experience with similar large-scale projects to ensure they can meet specific demands.

What Sets Precision Machining Firms Apart in Quality Control?

Precision machining firms are dedicated to producing high-tolerance parts that meet strict quality control standards. They are commonly found in electronics, defense, and high-tech industries where precision is paramount. B2B buyers should prioritize firms that have robust quality assurance processes and certifications, as this can significantly impact the reliability and performance of the finished products.

How Do Multi-Process Shops Provide Comprehensive Solutions?

Multi-process machining shops offer a variety of services, including machining, fabrication, and assembly, making them a convenient option for companies looking for comprehensive solutions. This versatility can benefit industries that require multiple services, but buyers should be cautious of potential dilution in specialization. It’s essential to review the shop’s capabilities and past performance across all services offered to ensure they can meet the specific needs of your project.

Key Industrial Applications of ohio machining companies

| Industry/Sector | Specific Application of Ohio Machining Companies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision components for aircraft manufacturing | Enhanced safety and performance through high-quality parts | Certification standards (AS9100), material traceability |

| Automotive | Custom tooling and parts for vehicle assembly | Improved efficiency and reduced production costs | Supplier reliability, turnaround times |

| Energy | Machined components for oil and gas extraction | Increased operational efficiency and reduced downtime | Compliance with industry regulations, quality assurance |

| Medical Devices | Precision machining for surgical instruments and implants | Ensured reliability and safety of medical products | Regulatory compliance (ISO13485), material specifications |

| Heavy Machinery | Fabrication of large components for construction equipment | Durability and performance in demanding environments | Material selection, lead times, and shipping logistics |

How Are Ohio Machining Companies Beneficial for the Aerospace Industry?

In the aerospace sector, Ohio machining companies provide precision components essential for aircraft manufacturing. These parts must meet stringent safety and performance standards, which is why many firms seek out AS9100-certified suppliers. By partnering with Ohio-based manufacturers, international buyers can ensure that they receive high-quality components that enhance the reliability and performance of their aircraft. This is particularly crucial for companies in regions like Africa and South America, where the aerospace market is rapidly evolving.

What Role Do Ohio Machining Companies Play in the Automotive Sector?

Ohio machining companies are integral to the automotive industry, supplying custom tooling and components for vehicle assembly. This sector demands high efficiency and cost-effectiveness, which Ohio firms deliver through advanced machining capabilities. By sourcing from Ohio, automotive manufacturers can benefit from reduced production costs and improved assembly line efficiency. Buyers from Europe and the Middle East should consider the reliability of suppliers and their ability to meet tight production schedules when making sourcing decisions.

How Do Ohio Machining Companies Support the Energy Sector?

In the energy sector, particularly oil and gas extraction, Ohio machining companies manufacture critical components that ensure operational efficiency. These parts must withstand extreme conditions, making durability a top priority. International buyers can leverage the expertise of Ohio machining firms to secure high-quality components that minimize downtime and enhance productivity. Compliance with industry regulations is a key consideration for sourcing in this sector, especially for companies operating in the Middle East.

Why Are Ohio Machining Companies Important for Medical Devices?

Ohio machining companies specialize in creating precision parts for medical devices, including surgical instruments and implants. The reliability and safety of these products are paramount, necessitating adherence to strict regulatory standards such as ISO13485. International buyers, particularly from Africa and Europe, must prioritize sourcing from certified manufacturers to ensure product safety and compliance. The ability to meet specific material specifications is also crucial in this highly regulated industry.

How Do Ohio Machining Companies Contribute to Heavy Machinery Production?

Heavy machinery production relies heavily on the fabrication of large, robust components, a specialty of Ohio machining companies. These firms deliver parts that are designed to perform in demanding environments, ensuring durability and reliability. Buyers from South America and Africa should focus on material selection and lead times when sourcing from Ohio, as these factors significantly impact the performance and longevity of heavy machinery. Efficient shipping logistics are also essential for timely project execution.

3 Common User Pain Points for ‘ohio machining companies’ & Their Solutions

Scenario 1: Timely Delivery of Precision Parts for Manufacturing Projects

The Problem: One significant pain point for B2B buyers sourcing components from Ohio machining companies is the challenge of timely delivery. Many manufacturers operate on strict production schedules, and delays in receiving critical parts can halt entire projects, leading to increased costs and missed deadlines. For instance, a buyer in the automotive sector may require precision machined components to meet assembly line schedules. If the machining company cannot deliver on time, it disrupts the entire supply chain, causing ripple effects downstream.

The Solution: To mitigate this risk, buyers should prioritize machining companies that have a proven track record of on-time delivery. Request detailed lead time estimates and explore companies that offer robust supply chain management practices. Establishing a clear communication channel with your chosen machining partner is essential; regular updates on production progress can provide peace of mind. Additionally, consider utilizing companies that provide comprehensive services, including inventory management and stocking programs. This approach ensures that your supplier can respond quickly to your needs without compromising quality or timelines.

Scenario 2: Navigating Quality Assurance Standards in Machining

The Problem: In industries such as aerospace and medical devices, adhering to stringent quality assurance standards is non-negotiable. B2B buyers often face difficulties ensuring that their machining suppliers comply with necessary certifications like AS9100 or ISO 9001. A lack of clarity regarding quality control processes can result in receiving subpar parts, which not only affects product reliability but can also lead to regulatory penalties and loss of reputation.

The Solution: To overcome this issue, buyers should conduct thorough due diligence when selecting Ohio machining companies. Inquire about their quality management systems and request documentation of their certifications. Engaging with suppliers who emphasize quality control and have certified staff can provide additional assurance. Establishing a collaborative relationship where you can share specifications and expectations is crucial. Additionally, consider incorporating regular quality audits into your contract terms to ensure ongoing compliance. This proactive approach helps maintain high standards and fosters a culture of quality throughout the production process.

Scenario 3: Customization Challenges in Machining Parts

The Problem: Many B2B buyers require customized parts tailored to specific applications. However, finding machining companies that can efficiently handle custom orders without compromising on precision can be challenging. For example, a manufacturer in the renewable energy sector may need specialized components that are not standard in the industry. Misalignment in expectations regarding design and functionality can lead to costly iterations and project delays.

The Solution: To effectively address customization needs, buyers should engage with Ohio machining companies that have demonstrated expertise in bespoke manufacturing. Clearly communicate your design specifications and functional requirements upfront. It is advisable to request samples or prototypes before committing to large production runs. Many machining companies offer prototyping services, allowing for adjustments based on real-world testing. Leverage the knowledge and experience of your machining partner to explore material options and design modifications that could enhance performance and reduce costs. Establishing a clear feedback loop during the design and production phases can help align expectations and streamline the process, ultimately leading to successful outcomes.

Strategic Material Selection Guide for ohio machining companies

What Are the Key Properties of Common Materials Used by Ohio Machining Companies?

In the realm of precision machining, the selection of materials is critical to the performance and reliability of the final products. Ohio machining companies often work with a variety of materials, each with distinct properties that influence their suitability for different applications. Below, we explore four common materials used in this sector, analyzing their key properties, advantages, disadvantages, and considerations for international B2B buyers.

How Do Ductile and Grey Iron Perform in Machining Applications?

Key Properties: Ductile and grey iron are known for their excellent castability and machinability. They exhibit good wear resistance and can withstand high temperatures. Ductile iron, in particular, has a higher tensile strength compared to grey iron, making it suitable for more demanding applications.

Pros & Cons: The primary advantages of these materials include their durability and cost-effectiveness. However, they can be prone to corrosion if not treated properly, and the machining process can be complex due to the need for specialized tools.

Impact on Application: Ductile and grey iron are often used in automotive and heavy machinery components. Their ability to absorb vibrations makes them suitable for parts that require noise reduction.

Considerations for International Buyers: Buyers should ensure compliance with ASTM standards for iron castings. In regions like Africa and South America, where environmental conditions can be harsh, additional coatings or treatments may be necessary to enhance corrosion resistance.

What Are the Benefits of Using Carbon and Alloy Steels?

Key Properties: Carbon steels are known for their high strength and hardness, while alloy steels can be engineered to enhance specific properties like toughness and wear resistance. These materials can handle high-pressure applications and are often heat-treated for improved performance.

Pros & Cons: The versatility of carbon and alloy steels is a significant advantage, allowing for a wide range of applications. However, they can be more expensive than other materials, and the machining process can require more time and specialized equipment.

Impact on Application: These steels are commonly used in manufacturing gears, shafts, and other critical components in machinery. Their strength makes them suitable for high-stress environments.

Considerations for International Buyers: Compliance with international standards such as DIN and JIS is crucial. Buyers from the Middle East and Europe may prefer specific grades of alloy steel that meet stringent quality requirements.

How Do Aluminum Alloys Compare in Machining?

Key Properties: Aluminum alloys are lightweight, corrosion-resistant, and have good thermal conductivity. They are easy to machine and can be anodized for additional surface protection.

Pros & Cons: The primary advantage of aluminum alloys is their lightweight nature, making them ideal for applications where weight is a concern. However, they may not be suitable for high-stress applications due to lower tensile strength compared to steel.

Impact on Application: Aluminum alloys are widely used in the aerospace and automotive industries, where reducing weight without compromising performance is essential.

Considerations for International Buyers: Buyers should be aware of the specific alloy grades and their corresponding properties. Compliance with ASTM standards is also important for ensuring quality and performance.

What Makes Plastics a Viable Option for Machining?

Key Properties: Plastics are lightweight, resistant to corrosion, and can be molded into complex shapes. They also have good electrical insulating properties.

Pros & Cons: The advantages of plastics include their versatility and lower cost compared to metals. However, they may not withstand high temperatures or heavy loads, limiting their use in certain applications.

Impact on Application: Plastics are often used in the production of components for electronics, automotive interiors, and consumer goods, where weight and corrosion resistance are critical.

Considerations for International Buyers: Understanding the specific type of plastic and its properties is essential. Compliance with international standards for safety and performance is also necessary, especially for products used in regulated industries.

Summary Table of Material Selection for Ohio Machining Companies

| Material | Typical Use Case for Ohio Machining Companies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ductile and Grey Iron | Automotive components, heavy machinery | Excellent durability and castability | Prone to corrosion if untreated | Low |

| Carbon and Alloy Steels | Gears, shafts, critical machinery parts | High strength and versatility | Higher cost and machining complexity | Medium |

| Aluminum Alloys | Aerospace, automotive lightweight components | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Plastics | Electronics, automotive interiors, consumer goods | Versatile and cost-effective | Limited high-temperature performance | Low |

This strategic material selection guide serves as a vital resource for international B2B buyers, providing insights into the properties and applications of materials commonly used by Ohio machining companies. Understanding these factors can aid in making informed purchasing decisions that align with specific project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for ohio machining companies

What Are the Main Stages of Manufacturing in Ohio Machining Companies?

The manufacturing process in Ohio machining companies typically involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is essential for B2B buyers looking to partner with reliable machining suppliers.

Material Preparation: How Do Machining Companies Start?

Material preparation is the foundation of the manufacturing process. It involves selecting the right raw materials based on the specifications of the final product. Ohio machining companies often work with a variety of materials, including aluminum, stainless steel, carbon and alloy steels, and even exotic materials.

The materials are usually sourced through trusted suppliers to ensure quality. Once selected, the materials undergo processes such as cutting, grinding, or milling to achieve the desired dimensions before moving on to the forming stage.

How Do Machining Companies Form Parts?

Forming is the stage where the prepared materials are shaped into the required components. In Ohio, companies leverage advanced techniques such as CNC (Computer Numerical Control) machining, which allows for high precision and efficiency.

For example, 5-axis CNC milling is commonly used to create complex geometries, while CNC turning is employed for cylindrical parts. These technologies enable manufacturers to produce components with tight tolerances, which is critical for industries such as aerospace and automotive.

What Is Involved in the Assembly Process?

After forming, the next step is assembly. This stage may involve integrating various machined parts into larger systems or sub-assemblies. Companies in Ohio often provide light assembly services, where they ensure that all components fit and function correctly.

Quality assurance is crucial during assembly, as even minor discrepancies can lead to significant issues in the final product. This is where close attention to detail and skilled craftsmanship come into play.

How Do Machining Companies Finish Their Products?

Finishing is the final stage in the manufacturing process, which enhances both the aesthetics and functionality of the parts. Techniques such as anodizing, plating, and heat treating are common in Ohio machining companies.

These processes not only improve the appearance of the components but also enhance their resistance to wear and corrosion. Finishing processes are critical for ensuring that the final product meets the required specifications and industry standards.

What Are the Quality Assurance Practices in Ohio Machining Companies?

Quality assurance (QA) is integral to the manufacturing processes of Ohio machining companies. Buyers from international markets need to understand the QA practices in place to ensure that they receive high-quality products.

Which International Standards Do Ohio Machining Companies Follow?

Many Ohio machining companies adhere to international quality management standards, such as ISO 9001. This certification indicates that a company has established a quality management system that meets international benchmarks.

Additionally, industry-specific certifications like AS9100 for aerospace or API for oil and gas further validate the quality of the machining processes. Buyers can look for these certifications as indicators of a company’s commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control in machining typically involves several checkpoints, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC: This stage involves inspecting raw materials upon receipt to ensure they meet specified requirements.

- IPQC: During the manufacturing process, regular inspections are conducted to monitor quality and identify any deviations.

- FQC: The final inspection ensures that the finished products conform to all specifications before shipping.

These checkpoints help maintain high standards throughout the manufacturing process, ensuring that any issues are addressed promptly.

What Common Testing Methods Do Machining Companies Use?

Ohio machining companies utilize various testing methods to verify the quality of their products. Common techniques include:

- CNC Coordinate Measuring Machines: These machines provide accurate measurements of parts to ensure they meet design specifications.

- Electronic Surface-Finish Testing: This method assesses the texture of the surface, which can be critical for components that interact with other parts.

- Magnetic Particle and Die Penetrant Testing: These non-destructive testing methods are used to detect surface and subsurface defects in metal parts.

Understanding these testing methods can help B2B buyers assess the reliability of potential suppliers.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control measures of Ohio machining companies is crucial for ensuring reliable partnerships.

What Steps Can Buyers Take to Audit Suppliers?

Buyers can conduct audits of potential suppliers to assess their quality control processes. This can include reviewing the company’s quality management system documentation, observing production processes, and examining records of previous inspections and tests.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection agencies can provide an additional layer of assurance. These independent entities can evaluate the machining processes, materials, and finished products to ensure compliance with international standards.

What Are the QC Nuances for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific quality control nuances. Different markets may have varying standards and expectations regarding quality certifications.

It is essential to communicate clearly with suppliers about the required certifications and quality expectations to avoid misunderstandings. Additionally, familiarity with local regulations can aid in ensuring compliance with both international and domestic standards.

Conclusion

In summary, understanding the manufacturing processes and quality assurance practices of Ohio machining companies is vital for international B2B buyers. By familiarizing themselves with the stages of manufacturing, quality control standards, and verification methods, buyers can make informed decisions when selecting suppliers. This knowledge not only facilitates smoother transactions but also contributes to successful long-term partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ohio machining companies’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in effectively procuring services from Ohio machining companies. By following this step-by-step checklist, you will ensure that your sourcing process is efficient, thorough, and aligned with your specific manufacturing needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of successful sourcing. Detail the dimensions, tolerances, materials, and production volumes required for your project. This clarity will not only help suppliers provide accurate quotes but also ensure that the end products meet your quality standards.

- Considerations: Be specific about machining processes (e.g., CNC milling, turning) and any secondary operations (e.g., heat treating, coatings) that may be necessary.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify suitable Ohio machining companies. Look for firms that specialize in the specific machining processes you require and have experience in your industry.

- Tip: Utilize online directories, industry associations, and trade shows to compile a list of potential suppliers. Pay attention to their capabilities and past projects.

Step 3: Evaluate Supplier Certifications

Verify the certifications and quality management standards of your shortlisted suppliers. Look for ISO certifications, AS9100 approval, or ITAR registration, as these indicate a commitment to quality and compliance.

- Importance: Certifications assure you that the supplier adheres to industry standards, which is crucial for maintaining the integrity of your products.

Step 4: Request and Review Quotes

Once you have narrowed down your options, request detailed quotes from the selected machining companies. Ensure that the quotes include pricing, lead times, and any additional services.

- What to Look For: Compare not just the costs but also the value offered, such as quality assurance processes, delivery timelines, and customer service.

Step 5: Conduct Supplier Visits or Virtual Tours

If possible, visit the machining facilities or request virtual tours to assess their capabilities firsthand. This step allows you to evaluate the equipment, workforce, and overall operational environment.

- Key Observations: Check for cleanliness, organization, and the technology used, which can reflect the quality of work you can expect.

Step 6: Check References and Customer Feedback

Ask for references from previous clients and seek feedback on their experiences with the supplier. This can provide insight into the supplier’s reliability, communication, and quality of work.

- Action Point: Look for reviews or testimonials from companies in similar industries or regions to gauge compatibility and performance.

Step 7: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, delivery schedules, and warranties. Clear agreements can prevent misunderstandings and ensure a smooth collaboration.

- Negotiation Tips: Be open about your expectations and listen to the supplier’s capabilities. A mutually beneficial agreement can foster a long-term partnership.

By following these steps, you will be well-equipped to make informed decisions when sourcing from Ohio machining companies, ensuring that you find the right partner for your manufacturing needs.

Comprehensive Cost and Pricing Analysis for ohio machining companies Sourcing

What Are the Key Cost Components for Ohio Machining Companies?

When sourcing from Ohio machining companies, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

-

Materials: The type of materials selected significantly influences costs. Ohio machining companies offer diverse materials, including metals (aluminum, stainless steel, carbon, and alloy steels) and plastics. Prices fluctuate based on market demand and material specifications.

-

Labor: Skilled labor is a substantial part of the cost. Ohio boasts a workforce experienced in advanced machining techniques, which can lead to higher labor costs. However, the expertise often results in superior quality and efficiency.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and equipment maintenance. Companies with advanced machinery, such as 5-axis CNC milling machines, may incur higher overheads but can deliver more complex parts efficiently.

-

Tooling: Tooling costs vary based on the complexity of the machining process. Custom tooling may be necessary for unique projects, which can increase initial costs but reduce per-unit costs in high-volume runs.

-

Quality Control (QC): Adherence to certifications like ISO 9000 or AS9100 requires investment in quality assurance processes. Buyers should consider these costs as they ensure product reliability and compliance with international standards.

-

Logistics: Transportation and shipping costs are vital, especially for international buyers. Incoterms will dictate responsibility for shipping costs, insurance, and duties, influencing the overall pricing strategy.

-

Margin: The profit margin varies by company and can be affected by the volume of orders. Larger orders typically see reduced per-unit costs due to economies of scale.

How Do Price Influencers Impact Sourcing Decisions?

Several factors influence pricing in Ohio machining, essential for international buyers to consider:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounts. Establishing a long-term relationship with a supplier can also yield better pricing over time.

-

Specifications and Customization: Custom parts with specific tolerances and features generally incur higher costs. Clear communication of specifications can help in obtaining accurate quotes.

-

Material Choice: The choice of material can dramatically affect pricing. Exotic materials or those with special properties (e.g., heat resistance) may lead to increased costs.

-

Quality and Certifications: Products requiring stringent quality controls or certifications will be priced higher. Buyers should weigh the benefits of quality assurance against costs.

-

Supplier Factors: Reputation and capability of the machining company can impact costs. Established suppliers may charge more for their reliability and service quality.

-

Incoterms: Understanding the shipping terms is crucial, especially for international transactions. Incoterms clarify who bears the costs and responsibilities at various stages of the shipping process, which can affect the total landed cost.

What Are the Best Negotiation Tips for International B2B Buyers?

When negotiating with Ohio machining companies, international buyers should consider the following strategies:

-

Conduct Market Research: Understanding the prevailing market rates for similar parts can empower buyers during negotiations.

-

Emphasize Long-term Relationships: Companies are often willing to offer better pricing to clients who commit to ongoing business. Highlighting potential future orders can be advantageous.

-

Explore Total Cost of Ownership (TCO): Evaluate not just the upfront costs but the entire lifecycle costs, including shipping, maintenance, and potential downtime. This holistic view can justify a higher initial price for better quality.

-

Leverage Payment Terms: Flexible payment terms can sometimes be negotiated. Suppliers may be willing to reduce prices in exchange for quicker payments.

-

Be Aware of Pricing Nuances: International buyers must understand that currency fluctuations and import duties can affect overall costs. Pricing should be agreed upon in a stable currency to mitigate risks.

Disclaimer on Pricing

It is important to note that prices in machining can vary widely based on the factors mentioned above. This analysis provides a general overview; specific quotes should be obtained from suppliers to ensure accuracy. International buyers are encouraged to conduct due diligence and obtain multiple quotes to find the best value for their needs.

Alternatives Analysis: Comparing ohio machining companies With Other Solutions

Exploring Alternatives to Ohio Machining Companies for Precision Manufacturing

In the competitive landscape of precision manufacturing, B2B buyers often seek various solutions to meet their specific machining needs. While Ohio machining companies offer robust capabilities, exploring alternative methods can provide valuable insights into achieving efficiency, cost-effectiveness, and quality. This section compares Ohio machining companies with two viable alternatives: offshore machining services and additive manufacturing (3D printing).

| Comparison Aspect | Ohio Machining Companies | Offshore Machining Services | Additive Manufacturing (3D Printing) |

|---|---|---|---|

| Performance | High precision, often ISO certified; specialized in large parts | Varies widely; some companies may lack stringent quality controls | Excellent for complex geometries; rapid prototyping |

| Cost | Higher due to quality and local labor rates | Generally lower due to reduced labor costs | Costs vary; initial setup can be high, but low per-part cost for large runs |

| Ease of Implementation | Straightforward with local communication and support | Language barriers and time zone differences can complicate processes | Requires skilled operators and software; may need design adjustments |

| Maintenance | Regular service and quality checks are standard | Limited oversight can lead to quality issues; maintenance depends on vendor | Minimal maintenance; however, technology requires updates |

| Best Use Case | Large, precise components; industries like aerospace and automotive | High-volume production of simple parts; cost-sensitive projects | Rapid prototyping, complex shapes, and low-volume production |

What Are the Advantages and Disadvantages of Offshore Machining Services?

Offshore machining services often attract buyers with their lower labor costs and ability to produce high volumes of simple parts. These services can be particularly appealing for large-scale projects where budget constraints are critical. However, quality control can be inconsistent, and communication challenges due to time zone differences and language barriers may arise. Additionally, the logistics of shipping components internationally can lead to longer lead times, which may not suit all projects.

How Does Additive Manufacturing (3D Printing) Compare to Traditional Machining?

Additive manufacturing, or 3D printing, offers unique advantages, especially for creating complex geometries that would be difficult or impossible with traditional machining methods. It allows for rapid prototyping and can significantly reduce waste since materials are added layer by layer. However, the initial setup costs for 3D printing can be high, and while the per-part cost decreases with larger runs, it may not be the best option for high-volume production. Furthermore, specialized knowledge is required for operating 3D printers and adjusting designs for optimal production.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right machining solution, B2B buyers should assess their specific requirements, including project complexity, budget constraints, and desired lead times. Ohio machining companies are ideal for projects requiring high precision and quality assurance, especially for critical industries such as aerospace and automotive. Conversely, offshore machining may be suitable for cost-sensitive, high-volume production, while additive manufacturing excels in rapid prototyping and custom designs. Ultimately, the choice will depend on balancing factors such as performance, cost, and the specific needs of the project at hand. By carefully evaluating these alternatives, buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for ohio machining companies

What Are the Key Technical Properties Critical for Ohio Machining Companies?

When engaging with Ohio machining companies, understanding certain technical properties is essential for ensuring that the manufactured parts meet the required specifications and performance criteria. Here are several critical specifications to consider:

-

Material Grade

Material grade refers to the classification of the materials used in machining processes, which can include metals, plastics, and composites. Common material grades include ASTM (American Society for Testing and Materials) standards, which define the mechanical properties, chemical compositions, and performance criteria. B2B buyers must ensure that the material grades specified meet the requirements of their applications, as this impacts durability, strength, and overall performance of the final product. -

Tolerance

Tolerance is the permissible limit or limits of variation in a physical dimension. It is crucial in machining because it dictates how closely a part can be manufactured to its intended design. Tight tolerances may be necessary for precision components, while looser tolerances might suffice for less critical applications. Understanding tolerance specifications helps buyers ensure that parts fit correctly within their assembly processes, thereby reducing the risk of costly rework or failure. -

Surface Finish

Surface finish refers to the texture and smoothness of a part’s surface, which can affect its performance, aesthetics, and resistance to wear and corrosion. Different machining processes yield varying surface finishes, and specific applications may require particular finishes (e.g., polished, anodized). Buyers should communicate their surface finish requirements to machining companies to ensure that the parts perform effectively in their intended environments. -

Heat Treatment

Heat treatment involves processes like annealing, quenching, and tempering, which alter the physical and sometimes chemical properties of a material. This process is often used to enhance strength, hardness, and durability. Understanding the heat treatment options available from Ohio machining companies allows buyers to select parts that meet their operational demands, especially in high-stress applications. -

Dimensional Accuracy

Dimensional accuracy indicates how closely a manufactured part conforms to its specified dimensions. It is critical in applications where parts must fit together precisely, such as in assemblies or systems requiring high reliability. Buyers should assess the dimensional accuracy capabilities of machining companies to ensure that the components will meet their engineering requirements.

What Are Common Trade Terms Used in the Machining Industry?

Familiarizing oneself with industry jargon can significantly enhance communication between buyers and Ohio machining companies. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers seeking components that meet specific quality and compatibility standards for their products. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to consider, especially when sourcing custom parts. Knowing the MOQ helps in planning inventory and budgeting for large-scale production runs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. It typically includes detailed specifications, quantities, and delivery timelines. B2B buyers should prepare comprehensive RFQs to ensure they receive accurate and competitive pricing. -

Incoterms

Incoterms (International Commercial Terms) are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. They define who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is vital for buyers to avoid misunderstandings and ensure smooth transactions across borders. -

CNC (Computer Numerical Control)

CNC refers to the automated control of machining tools by means of a computer. CNC technology enables precision and repeatability in machining processes, which is essential for high-quality production. Buyers should inquire about CNC capabilities when sourcing parts to ensure they meet technical requirements. -

Lead Time

Lead time is the amount of time it takes from placing an order until the product is delivered. Understanding lead times is crucial for buyers to manage production schedules and ensure timely delivery of components for their projects.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions when collaborating with Ohio machining companies, ultimately leading to successful partnerships and high-quality outcomes.

Navigating Market Dynamics and Sourcing Trends in the ohio machining companies Sector

What Are the Current Market Dynamics in the Ohio Machining Companies Sector?

The Ohio machining sector is experiencing a robust transformation driven by several global factors. Key trends include the increased demand for precision manufacturing and customization, propelled by advancements in technology such as 5-axis CNC machining and automation. Companies in Ohio, like Ansco Machine and Wagner Machine, are well-positioned to cater to this demand, offering capabilities that range from small batch production to large-scale manufacturing.

Additionally, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking reliable suppliers that can provide high-quality components with quick turnaround times. This demand is further fueled by the global push for supply chain resilience, leading buyers to diversify their sourcing strategies. The trend towards digital integration, including the use of AI and IoT for better inventory management and predictive maintenance, is also gaining momentum. Companies that leverage these technologies can not only enhance efficiency but also improve their competitive edge in the global market.

How Are Sustainability and Ethical Sourcing Impacting B2B Relationships?

Sustainability is becoming a critical factor in the decision-making process for international B2B buyers. Companies are increasingly aware of their environmental impact and the importance of ethical sourcing practices. In Ohio, machining firms are adopting sustainable practices by utilizing green materials and minimizing waste through advanced manufacturing techniques.

Moreover, certifications such as ISO 14001 for environmental management and AS9100 for quality control are becoming essential for companies looking to establish credibility in the global marketplace. Buyers from regions like Nigeria and Brazil are particularly focused on sourcing from companies that demonstrate a commitment to sustainable practices. This shift not only enhances brand reputation but also aligns with regulatory pressures and consumer expectations for ethical supply chains.

What Is the Historical Context of Ohio Machining Companies?

The Ohio machining industry has a rich history that dates back to the industrial revolution, evolving from basic metalworking to advanced manufacturing solutions. Initially focused on local needs, the sector has expanded significantly, incorporating cutting-edge technologies and practices. Over the decades, Ohio machining companies have built a reputation for quality and precision, making them key players in various sectors, including automotive, aerospace, and energy.

As global competition intensified, Ohio firms began to adopt more sophisticated techniques and quality standards, such as ISO certifications, to meet international demands. This evolution has allowed Ohio machining companies to not only survive but thrive, establishing long-term partnerships with international buyers and reinforcing their status as reliable suppliers in the global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of ohio machining companies

-

How do I ensure quality when sourcing from Ohio machining companies?

To ensure quality when sourcing from Ohio machining companies, request certifications such as ISO 9001 or AS9100, which indicate adherence to international quality management standards. Additionally, ask about their quality assurance processes, including inspection methods and testing capabilities. Engage in direct communication with the suppliers to discuss your specific quality requirements, and consider visiting their facilities if possible to assess their capabilities and commitment to quality firsthand. -

What factors should I consider when evaluating machining capabilities?

When evaluating machining capabilities, consider the company’s equipment and technology, such as CNC capabilities and specialized machinery for specific tasks. Assess their experience in your industry and their ability to handle custom projects. Additionally, inquire about their production capacity, turnaround times, and flexibility in accommodating changes in order volume. A supplier with a diverse range of services, such as fabrication and assembly, can provide added value by streamlining your supply chain. -

What is the typical minimum order quantity (MOQ) for Ohio machining companies?

Minimum order quantities (MOQs) can vary significantly among Ohio machining companies based on their capabilities and your specific requirements. Many companies are willing to accommodate small batch orders, especially for custom machining projects. However, larger orders may yield better pricing and shorter lead times. It’s advisable to directly discuss your needs with potential suppliers to understand their MOQ policies and negotiate terms that work for both parties. -

How do I manage shipping and logistics when sourcing from Ohio?

Managing shipping and logistics when sourcing from Ohio involves understanding the costs and timelines associated with international shipping. Coordinate with your machining supplier to determine the best shipping method, whether air freight for speed or ocean freight for cost-effectiveness. Ensure that the supplier can handle the necessary export documentation and customs requirements. Collaborating with a freight forwarder experienced in international shipping can help streamline the process and mitigate potential delays. -

What payment terms are common in B2B machining transactions?

Common payment terms in B2B machining transactions include net 30 or net 60 days, where payment is due within 30 or 60 days after delivery. Some suppliers may require a deposit upfront, especially for larger orders or custom projects. It’s crucial to clarify payment terms before finalizing the contract to avoid misunderstandings. Consider using letters of credit or escrow services for larger transactions to protect your investment and ensure compliance with agreed terms. -

How can I customize my machining orders for specific applications?

To customize your machining orders for specific applications, provide detailed specifications, including dimensions, tolerances, and material requirements. Collaborate with the machining company during the design phase to leverage their expertise in optimizing part functionality and manufacturability. Many Ohio machining firms offer engineering support and prototyping services, which can help refine your designs before full-scale production, ensuring that the final product meets your exact needs. -

What should I know about supplier vetting in Ohio?

When vetting suppliers in Ohio, research their industry reputation, experience, and customer testimonials. Request references from previous clients and inquire about their performance on similar projects. Conduct site visits if possible to assess their facilities, equipment, and quality control processes. Additionally, verify certifications and compliance with international standards to ensure they can meet your quality and operational requirements. -

How do I handle issues with defective parts from my Ohio machining supplier?

If you encounter defective parts from your Ohio machining supplier, promptly communicate the issue to them and provide detailed documentation, including photographs and descriptions of the defects. Most reputable suppliers will have a quality assurance process in place to address such concerns. Discuss potential remedies, such as replacements, refunds, or adjustments to future orders. Maintaining a constructive relationship with your supplier can facilitate quicker resolutions and prevent similar issues in future transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Ohio Machining Companies Manufacturers & Suppliers List

1. Ansco Machine – 5-Axis CNC Milling & Large Part Turning

Domain: anscomachine.com

Registered: 2002 (23 years)

Introduction: Ansco Machine is a full-service Ohio machine shop specializing in 5-axis CNC milling and large part turning from 1″ to 100″ (2500mm) diameters. Key capabilities include: 5-axis machining, flexible machining centers (FMC), bar feed lathes, and live tooling on lathes. The company offers a complete component service from raw stock to finished parts, including coatings, heat treating, anodizing, certi…

2. Rable Machine Inc. – Precision Machining Solutions

Domain: rablemachineinc.com

Registered: 1998 (27 years)

Introduction: Rable Machine Inc. is a 100% employee-owned precision machining company located in Mansfield, OH. They have over 90 machining professionals and more than 200 pieces of equipment with 82,000 square feet of production capacity. Their capabilities include: CNC Turning, CNC Milling, Grinding, Honing, Drilling, Tapping, CNC Swiss Turning, CNC Enhanced Screw Machining, Assembly Operations, Broaching, An…

3. Wagner Machine – Custom Machining & Fabrication Services

Domain: wagnermachine.com

Registered: 1998 (27 years)

Introduction: Wagner Machine, Inc. is a full service custom machining and fabrication shop located in Norton, Ohio, with over 65 years of experience. They offer custom machining and fabrication services for metal parts and products, capable of handling weights up to 30,000 lbs. The company is AS9100 approved for quality management standards and employs certified quality assurance staff from The American Society…

4. Proficient Machining – CNC Milled Parts

Domain: proficientmachining.com

Registered: 2000 (25 years)

Introduction: CNC Milled Parts, Ohio, Proficient Machining Co.

5. Mach3 Machining – Large Diameter Precision Machining

Domain: mach3machining.com

Registered: 2023 (2 years)

Introduction: Large Diameter Machining, Turning and Fabrication in Ohio. Specializes in large diameter turning and precision machining of large parts for industrial applications. Capabilities include: CNC Milling for large components, CNC Turning up to 80″ in diameter and 14 feet in length, Heavy Boring & Threading, Manual Turning with swing sizes up to 84″ in diameter and 37 feet in length, Vertical Turning wi…

6. SemOhio – CNC Machining & Fabrication Services

Domain: semohio.com

Registered: 2003 (22 years)

Introduction: Southeastern Machining and Field Service, Inc. offers a range of services including CNC Machining, Fabrication, Engineering, and Quality Control. Key products and services include: 1. CNC Machining: Capable of handling single parts to long-term contracts with a wide range of equipment. 2. Fabrication: Services range from weld repair to complete machine rebuilds. 3. Engineering: Services include So…

7. Bardons & Oliver – Contract Machining Services

Domain: bardonsoliver.com

Registered: 1997 (28 years)

Introduction: Bardons & Oliver offers contract machining services specializing in medium to large part machining with weights up to 20,000 lbs and sizes up to 120″/78″/60″ in X,Y and Z. Key services include horizontal and vertical CNC milling, horizontal and vertical CNC turning, precision metrology, grinding (I.D., O.D., and surface), painting, assembly, and sourcing of raw materials. They work with various co…

8. Columbus Machine Works – Custom Machining Services

Domain: columbusmachine.com

Registered: 2000 (25 years)

Introduction: Columbus Machine Works offers a wide range of machining services including custom machining, CNC machining, conventional machining, repairs and retrofits, and fabrication & welding. Key product details include:

1. **Custom Machining**:

– CNC mill capacity: up to 84″ x 32″ x 30″

– Full 4-axis milling capabilities

– High speed machining

– CAD/CAM programming of 3-D contours

– W…

9. FM Machine – Precision Machined Parts

Domain: fmmachine.com

Registered: 1998 (27 years)

Introduction: FM Machine, established in 1963, is a manufacturer located in Akron, Ohio, specializing in precision machined parts, prototypes, assemblies, and custom special machinery. Key capabilities include:

– Precision CNC Machining with tolerances as close as .000050″

– Machined Parts Inspection certified to ISO 9001:2008 with a 100% inspection process

– Fabrication services that emphasize precision and ve…

Strategic Sourcing Conclusion and Outlook for ohio machining companies

In today’s competitive landscape, strategic sourcing is paramount for international B2B buyers seeking reliable machining partners in Ohio. The state’s machining companies, like Ansco Machine, Wagner Machine, and Rable Machine, offer a diverse array of services, including precision machining, custom fabrication, and comprehensive supply chain management. These firms excel in quality assurance, adhering to stringent certifications such as ISO and AS9100, ensuring that products meet international standards.

By leveraging Ohio’s machining capabilities, buyers can optimize their supply chains, reduce lead times, and enhance the quality of their end products. The emphasis on full-service offerings—from raw materials to finished components—means that companies can simplify their procurement processes, consolidating orders and reducing complexity.

As global markets continue to evolve, Ohio machining companies are well-positioned to support international buyers with innovative solutions and exceptional craftsmanship. For businesses in Africa, South America, the Middle East, and Europe, engaging with these suppliers can unlock new opportunities and drive growth. Consider partnering with Ohio’s machining experts to elevate your operations and achieve strategic advantages in your market.