Contents

Manufacturing Insight: Oem Parts Cnc Machining

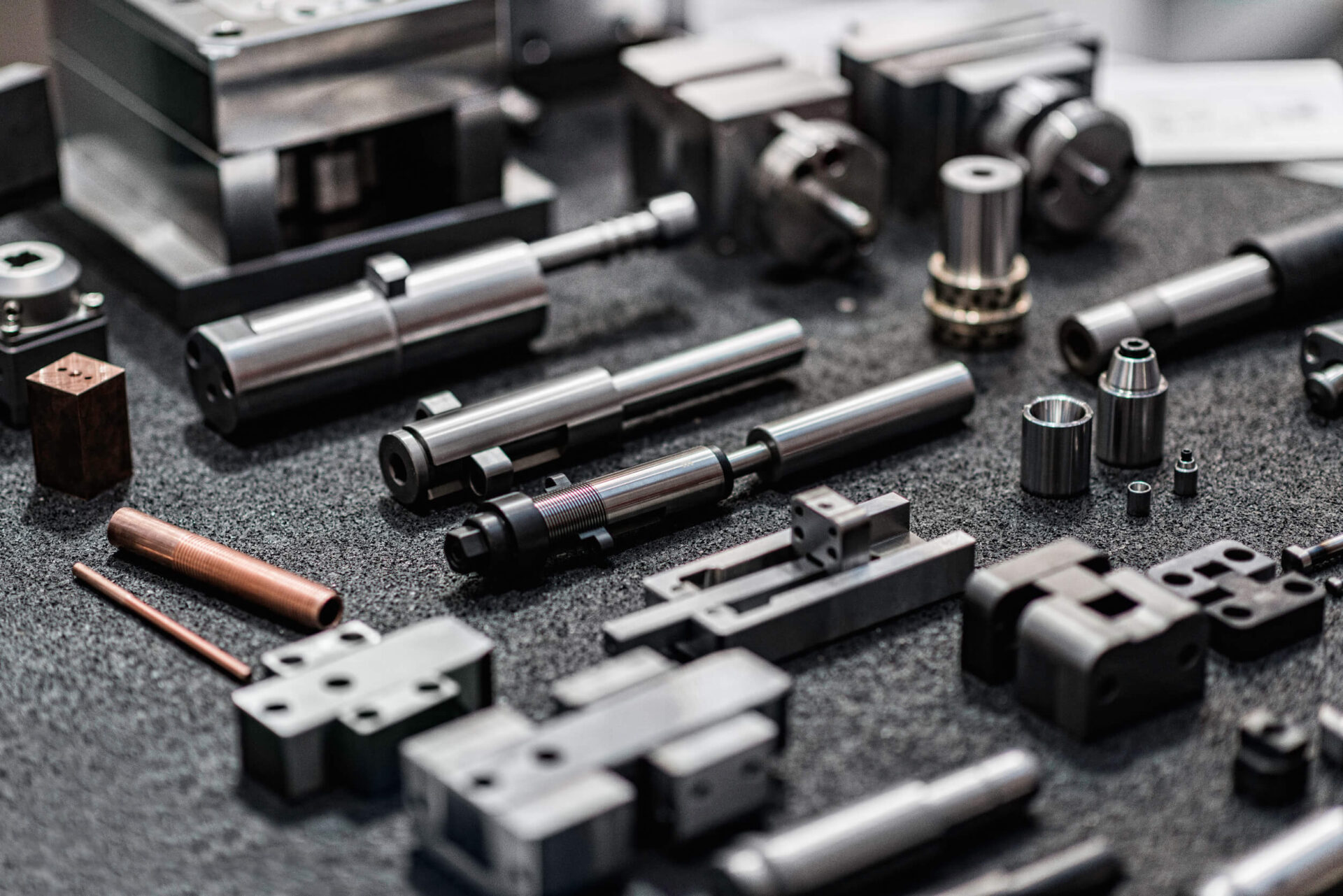

Precision OEM Parts Demand Uncompromising CNC Machining Expertise

For Original Equipment Manufacturers requiring mission-critical components, dimensional accuracy, material integrity, and on-time delivery are non-negotiable. Honyo Prototype delivers end-to-end CNC machining solutions engineered specifically for complex OEM applications across aerospace, medical, industrial automation, and advanced robotics sectors. Our ISO 9001-certified facility leverages state-of-the-art multi-axis machining centers, rigorous in-process metrology, and deep materials science expertise to consistently achieve tolerances down to ±0.0002″ in challenging alloys, composites, and engineered plastics.

Engineered for Scalability from Prototyping Through Production

We eliminate the traditional friction between design intent and manufactured reality through integrated DFM analysis, dedicated project engineering, and seamless transition from rapid prototyping to high-mix, low-volume production runs. Every component undergoes stringent first-article inspection and batch traceability protocols to ensure compliance with AS9100, ISO 13485, and customer-specific quality frameworks. This commitment to process control directly translates to reduced scrap rates, minimized assembly rework, and accelerated time-to-market for your finished products.

Accelerate Your Sourcing Workflow with Online Instant Quoting

Initiate your project within minutes using Honyo Prototype’s proprietary Online Instant Quote system. Upload CAD files (STEP, IGES, Parasolid), specify materials, quantities, and critical tolerances to receive a detailed, geometry-aware manufacturing assessment and competitive pricing within hours—not days. This transparent digital workflow provides immediate cost visibility while our engineering team proactively identifies potential manufacturability optimizations before formal order placement.

| Key Capability | Technical Implementation | OEM Impact |

|---|---|---|

| Tight Tolerance Machining | 5-axis milling, Swiss turning, ±0.0002″ capability | Ensures seamless integration into final assemblies |

| Advanced Material Expertise | Titanium, Inconel, PEEK, 17-4PH, custom alloys | Supports performance-critical applications |

| Quality Assurance | CMM, optical comparators, SPC-controlled processes | Guarantees compliance with sector-specific regulations |

| Digital Integration | Cloud-based project tracking, real-time updates | Reduces communication delays and supply chain risk |

Partner with Honyo Prototype to transform your OEM part specifications into precision-engineered realities with the speed and reliability your production schedule demands. Start your project today with our Online Instant Quote platform.

Technical Capabilities

OEM parts CNC machining involves high-precision manufacturing processes used to produce custom components to exact specifications. At Honyo Prototype, we specialize in multi-axis CNC milling and turning operations, ensuring tight tolerances and superior surface finishes across a range of engineering materials. Our capabilities support complex geometries and critical features required in aerospace, medical, automotive, and industrial applications.

Key Capabilities Overview:

| Parameter | Specification Details |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including mill-turn with live tooling) |

| Tolerance Capability | Standard: ±0.005 mm (±0.0002″) Tight Tolerance: ±0.001 mm (±0.00004″) achievable with process control and inspection |

| Surface Finish | As-machined: 3.2 µm (125 µin) Custom finishes available down to 0.8 µm (32 µin) via polishing or grinding |

| Materials Supported | Aluminum: 6061, 7075, 2024, 5052 (excellent machinability, lightweight, corrosion-resistant) Steel: 1018, 4140, 4340, Stainless Steel 303, 304, 316 (high strength, wear and corrosion resistance) Engineering Plastics: ABS (good impact strength, easy to machine), Nylon 6/66 (low friction, high toughness, chemical resistance) |

| Max Work Envelope | Milling: 1000 mm × 600 mm × 500 mm (X×Y×Z) Turning: Ø300 mm × 500 mm length |

| Tooling & Control | High-speed spindles up to 24,000 RPM; Solid carbide and PCD tooling; Fanuc, Siemens, and Heidenhain controls |

| Inspection & QA | In-process and final inspection using CMM, optical comparators, and micrometers; First Article Inspection (FAI) and PPAP available |

| Secondary Operations | Deburring, anodizing (Type II & III), plating, passivation, laser marking, heat treatment coordination |

Our 5-axis simultaneous machining enables single-setup production of highly complex parts, reducing lead time and improving accuracy. Turning centers support full contouring and precision diameter control, ideal for shafts, fittings, and threaded components. Material-specific cutting strategies and fixturing ensure optimal results across both metals and plastics.

From CAD to Part: The Process

Honyo Prototype OEM Parts CNC Machining Process Overview

Honyo Prototype delivers precision OEM parts through a streamlined, technology-driven CNC machining workflow designed for efficiency, quality, and client collaboration. Our process begins with seamless digital integration and concludes with certified delivery, ensuring strict adherence to OEM specifications and timelines.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or native formats like SolidWorks) via our secure client portal. All data undergoes immediate encryption and IP protection protocols compliant with ISO 27001 standards. Our system automatically validates file integrity and geometry, flagging common issues like non-manifold edges or unit inconsistencies before proceeding. This step eliminates manual file handling delays and establishes a digital thread for traceability.

AI-Powered Quote Generation

Uploaded designs are processed through Honyo’s proprietary AI quoting engine, which analyzes geometric complexity, material requirements, tolerances, and surface finishes against real-time machine capacity and material costs. The AI cross-references historical production data from 50,000+ machined parts to predict manufacturability risks and generate accurate labor/machine-time estimates. Within 2 hours, clients receive a detailed quote including cost breakdown, lead time projection, and initial material recommendations—accelerating traditional quoting cycles by 70%. Human engineers review all AI outputs for complex geometries or tight-tolerance features before finalization.

Engineer-Validated DFM Analysis

Every project undergoes a dual-phase Design for Manufacturability review. First, automated DFM software checks wall thicknesses, hole depth-to-diameter ratios, and tool accessibility against CNC capabilities (3-axis to 5-axis milling/turning). Critical findings trigger immediate notifications to the client portal. Second, a senior manufacturing engineer conducts a manual review focusing on OEM-specific requirements: secondary operations, fixture strategy, and first-article inspection (FAI) planning per AS9102 standards. Clients receive a collaborative DFM report with actionable suggestions—such as tolerance relaxation opportunities—reducing production iterations by up to 40%.

Precision Production Execution

Approved designs move to our climate-controlled machining floor featuring 42 CNC centers (DMG MORI, Haas, Makino) with sub-micron repeatability. Each job includes:

Material certification verification against client specs (e.g., 6061-T6 aluminum with mill test reports)

In-process CMM checks at critical stages using Zeiss CONTURA systems

Real-time machine monitoring via MTConnect for spindle load, vibration, and thermal drift

Dedicated work cells for high-mix OEM batches to prevent cross-contamination

All processes follow documented work instructions traceable to the original CAD model, with non-conformances managed through our corrective action system (CAPA).

Certified Delivery and Documentation

Final parts undergo 100% dimensional validation against client drawings using calibrated optical comparators and surface roughness testers. Each shipment includes:

FAI report with ballooned drawing callouts

Material and process compliance certificates

Batch-specific traceability logs (heat numbers, machine IDs, operator stamps)

Custom packaging meeting OEM shipping requirements (ESD-safe, serialized labeling)

Parts are shipped via monitored logistics partners with GPS tracking, typically achieving 98.5% on-time delivery for volumes under 5,000 units. Post-delivery, clients access lifetime digital records through our client portal for audit readiness.

This integrated approach reduces time-to-part by 35% compared to industry averages while maintaining <0.5% defect rates for OEM programs. For complex projects, we recommend initiating with a pre-DFM consultation to optimize design manufacturability upfront. Contact Honyo’s engineering team to request a DFM report template or schedule a process walkthrough.

Start Your Project

Looking for precision OEM parts through CNC machining? Partner with Honyo Prototype for high-quality, custom-manufactured components tailored to your specifications. Our state-of-the-art CNC machining capabilities in our Shenzhen factory ensure tight tolerances, fast turnaround, and consistent quality for low to medium volume production runs.

Contact Susan Leo today to discuss your project requirements and receive a competitive quote.

Email: [email protected]

Factory Location: Shenzhen, China

Let us be your trusted manufacturing partner for reliable, scalable, and precision-engineered OEM components.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.