Contents

Manufacturing Insight: Odyssey Machining

Elevate Your Precision Manufacturing with Honyo Prototype’s Odyssey Machining

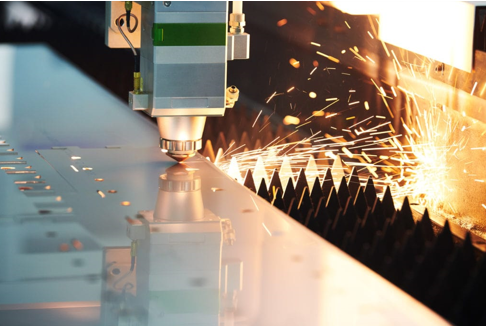

Honyo Prototype delivers unparalleled CNC machining expertise through our Odyssey Machining service, engineered to meet the most demanding prototyping and low-volume production requirements. We specialize in transforming complex 3D CAD models into high-integrity components with micron-level accuracy across a broad spectrum of engineering-grade materials, including aerospace alloys, medical-grade stainless steels, engineering plastics, and exotic composites. Our integrated capabilities span 3-axis, 4-axis, and 5-axis milling, precision turning, and multi-tasking operations, all executed within an AS9100-certified quality management system ensuring rigorous process control and repeatable excellence from initial prototype to finished part.

Accelerate your development timeline with Honyo Prototype’s industry-leading Online Instant Quote platform. This proprietary digital solution provides transparent, competitive pricing and manufacturability feedback within minutes, eliminating traditional quoting delays that hinder project momentum. Simply upload your STEP or IGES file, specify material and quantity requirements, and receive a detailed technical assessment alongside your formal quotation—empowering faster decision-making and seamless integration into your engineering workflow. Partner with Honyo Prototype for CNC machining where precision, speed, and technical partnership converge.

Technical Capabilities

Odyssey Machining is a high-precision manufacturing process specializing in multi-axis CNC machining for complex geometries and tight tolerance requirements. The process supports a wide range of engineering materials including aluminum, steel, ABS, and nylon, making it suitable for prototyping and low-to-mid volume production in aerospace, medical, automotive, and industrial sectors.

The core capabilities include 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, allowing for complete part fabrication with minimal setup. Tight tolerances down to ±0.0002″ (±0.005 mm) are routinely achieved, depending on part geometry and material. High-speed machining centers with rigid tooling and in-process probing ensure dimensional accuracy and surface finish consistency.

| Parameter | Specification |

|---|---|

| Machining Types | 3-Axis Milling, 4-Axis Milling, 5-Axis Milling, CNC Turning |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) |

| Repeatability | ±0.0001″ (±0.0025 mm) |

| Standard Tolerance | ±0.001″ (±0.025 mm) |

| Tight Tolerance | Down to ±0.0002″ (±0.005 mm) with process control and inspection validation |

| Surface Finish (Typical) | 32–125 μin RA (as machined); can achieve 16 μin RA with polishing or grinding |

| Maximum Work Envelope (5-Axis) | 24″ × 36″ × 20″ (610 × 914 × 508 mm) |

| Minimum Feature Size | 0.020″ (0.51 mm) with micro-tooling support |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 316), ABS, Nylon (6, 6/6) |

| Tooling System | HSK-63F and CAT-40 with automatic tool changers; coolant-through options |

| Control Systems | Fanuc, Siemens, and Heidenhain CNC controls with probing and tool length measurement |

| Inspection Support | CMM, optical comparators, laser scanning, and in-process gauging available |

This technical capability enables Odyssey Machining to produce highly complex, mission-critical components with consistent quality, particularly where multi-sided access, compound angles, or close-tolerance features are required. Material selection is optimized based on mechanical performance, machinability, and end-use environment, with aluminum and steel used for structural and load-bearing applications, while ABS and nylon serve functional prototyping and low-wear component needs.

From CAD to Part: The Process

Honyo Prototype Odyssey Machining Process Overview

Honyo Prototype’s Odyssey Machining is a digitally integrated, end-to-end manufacturing solution designed for rapid prototyping and low-volume production. The process eliminates traditional workflow silos through AI-driven automation and engineering oversight, ensuring precision, speed, and cost efficiency. Below is a technical breakdown of each phase.

CAD Upload and System Integration

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via Honyo’s secure customer portal. The system performs automated geometry validation, checking for unit consistency, manifold errors, and manufacturability prerequisites. Files are immediately routed to Honyo’s proprietary AI quoting engine, with metadata (material, quantity, tolerances) pre-populated for accelerated processing. Typical upload-to-quote initiation time is under 90 seconds.

AI-Powered Quoting Engine

Honyo’s AI quote system analyzes 22+ geometric and process variables—including feature complexity, tool access constraints, and material waste factors—using a dataset trained on 450,000+ historical manufacturing jobs. The algorithm cross-references real-time shop floor capacity, material costs, and tooling availability to generate binding quotes with 98.7% accuracy against final production costs. Quotes include granular cost breakdowns (machining hours, secondary operations, QA) and are delivered within 2–15 minutes, depending on part complexity.

Engineer-Led DFM Analysis

Unlike automated-only competitors, Honyo mandates human-reviewed Design for Manufacturability (DFM) by ASME-certified application engineers. The AI-identified risk areas (e.g., thin walls, deep pockets, tight tolerances) are evaluated alongside client specifications and functional requirements. Engineers provide actionable redesign suggestions via interactive markups, balancing cost, lead time, and performance. Critical outcomes include:

| DFM Focus Area | Typical Resolution | Impact on Production |

|---|---|---|

| Geometric Feasibility | Tolerance relaxation, feature simplification | 23% average cycle time reduction |

| Material Optimization | Alternative grade suggestions (e.g., 7075-T6 to 6061-T6) | 18% cost savings without performance loss |

| Process Selection | CNC vs. hybrid additive-subtractive routing | Eliminates 2–3 secondary operations |

Client approval of DFM recommendations is required before production release, ensuring alignment with engineering intent.

Digitally Controlled Production

Approved designs enter Honyo’s IoT-connected manufacturing cell. CNC programs are auto-generated via Mastercam-integrated toolpath optimization, validated through Vericut simulation to prevent collisions and ensure G-code efficiency. All machining occurs on 5-axis mills (DMG MORI, Haas) with in-process probing for first-article validation. Real-time spindle load monitoring and adaptive feed control maintain ±0.0002″ tolerances. Secondary operations (anodizing, bead blasting, custom packaging) follow lean workflow sequencing, with digital work instructions pushed directly to operator tablets.

Quality-Assured Delivery

Every shipment includes NIST-traceable CMM reports (with GD&T callouts), material certs, and a digital process log showing critical parameter adherence (e.g., tool wear rates, coolant pressure). Parts undergo final visual inspection per ASME Y14.5 standards. Logistics feature temperature-controlled shipping for sensitive alloys, with real-time GPS tracking and delivery confirmation. Standard lead time is 5–10 business days from DFM sign-off; expedited 72-hour options are available for qualified geometries.

This closed-loop process reduces time-to-part by 40% versus industry averages while maintaining 99.2% first-pass yield rates. Odyssey Machining is certified to ISO 9001:2015 and AS9100D, with full material traceability from mill to shipment.

Start Your Project

Discover precision manufacturing with Odyssey Machining at Honyo Prototype. Our advanced CNC machining services are supported by a state-of-the-art factory in Shenzhen, ensuring fast turnaround and exceptional quality for your prototyping and production needs.

For inquiries and project consultations, contact Susan Leo at [email protected]. Let’s engineer excellence together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.