Contents

Manufacturing Insight: Nylon Filling

Precision Nylon Milling Solutions from Honyo Prototype

Nylon milling presents distinct manufacturing challenges due to the material’s inherent hygroscopic nature, thermal sensitivity, and tendency toward dimensional drift. Achieving tight tolerances and consistent surface finishes requires specialized CNC machining expertise, optimized toolpaths, and controlled environmental conditions. At Honyo Prototype, our advanced CNC machining services are engineered specifically for high-performance polymers like PA6, PA66, and reinforced nylons. We combine multi-axis milling capabilities with rigorous material preconditioning protocols to mitigate moisture-related variability, ensuring parts meet exacting specifications for strength, fit, and function in demanding applications.

Our end-to-end process—from material selection to final inspection—delivers repeatability down to ±0.025 mm while maintaining critical geometric integrity. Whether prototyping or low-volume production, Honyo guarantees nylon components that perform reliably under mechanical stress, chemical exposure, or elevated temperatures.

Accelerate your project timeline with Honyo’s Online Instant Quote system. Upload your CAD file to receive a detailed, transparent cost and lead time estimate within minutes—no manual review delays. Experience how our technical precision and digital efficiency solve nylon’s unique manufacturing complexities.

| Key Nylon Milling Capabilities | Specification Range |

|---|---|

| Tolerance Control | ±0.025 mm (0.001″) |

| Material Grades | PA6, PA66, Glass-Filled, Carbon-Filled |

| Max Work Envelope | 1000 x 600 x 500 mm |

| Surface Finish | Ra 0.8 µm to 3.2 µm |

Technical Capabilities

Technical specifications for “nylon filling” in the context of CNC machining—specifically 3/4/5-axis milling and turning—typically refer to the use of nylon or nylon-based materials as a functional or structural component within an assembly, or sometimes as a filler material in overmolding or insert applications. However, in precision CNC operations, “filling” is not a standard machining term. It is likely interpreted here as the machining of nylon components alongside metals (e.g., aluminum, steel) and other thermoplastics (e.g., ABS) in high-precision environments where tight tolerances are required.

Below is a comparative technical specification table outlining key parameters for machining aluminum, steel, ABS, and nylon under tight tolerance conditions in 3/4/5-axis milling and turning operations.

| Parameter | Aluminum (6061-T6) | Steel (1018/4140) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (PA6/PA66) |

|---|---|---|---|---|

| Typical Machining Process | 3/4/5-axis milling, turning | 3/4/5-axis milling, turning | 3/4-axis milling | 3/4-axis milling, turning |

| Tolerance Capability | ±0.005 mm (±0.0002″) | ±0.01 mm (±0.0004″) | ±0.025 mm (±0.001″) | ±0.025 mm (±0.001″) to ±0.05 mm (hygroscopic) |

| Surface Finish (Typical) | 0.8–1.6 µm Ra | 1.6–3.2 µm Ra | 3.2–6.3 µm Ra | 3.2–6.3 µm Ra (can achieve smoother with sharp tools) |

| Material Hardness | 95 HB | 120–200 HB | Shore D 70–80 | Shore D 70–85 |

| Thermal Sensitivity | Low | Low | Moderate (softens at ~100°C) | High (absorbs moisture, expands) |

| Tooling Recommendations | Carbide end mills, sharp cutting edges | Carbide or HSS, high feed rates | Sharp carbide, low rake angles | Sharp carbide, high rake angles, polished flutes |

| Coolant Requirement | Recommended (flood or mist) | Required (flood cooling) | Not required (air blast preferred) | Not required (air blast recommended) |

| Chip Formation | Continuous, stringy | Continuous, segmented | Fine chips, powdery | Tough, stringy chips |

| Moisture Absorption (Nylon) | N/A | N/A | <0.5% | 2–3% (PA6), 1–1.5% (PA66) – dimensional instability risk |

| Key Challenges in Tight Tolerance | Thermal expansion, chatter | Work hardening, tool wear | Poor dimensional stability, burring | Moisture absorption, creep, elastic recovery |

| Post-Machining Considerations | Deburring, anodizing | Heat treatment, plating | Solvent smoothing, painting | Conditioning (stabilize moisture), stress relieving |

Notes on Nylon in Precision Machining:

Nylon exhibits high toughness and wear resistance but is hygroscopic—absorbing moisture from the environment—which can lead to dimensional changes post-machining. For tight tolerance components, it is critical to machine nylon close to final dimensions and allow for moisture stabilization before final inspection.

In multi-axis milling, nylon requires rigid setups and sharp tooling to prevent melting or deformation due to heat buildup.

Turning operations on nylon benefit from high-speed spindles with minimal vibration to avoid chatter and achieve consistent diametrical tolerances.

When used in assemblies with metals (e.g., aluminum or steel), differential thermal expansion and long-term environmental exposure must be considered in design.

This technical data supports Honyo Prototype’s capability in hybrid material fabrication, ensuring precision across diverse substrates including metals and engineering thermoplastics.

From CAD to Part: The Process

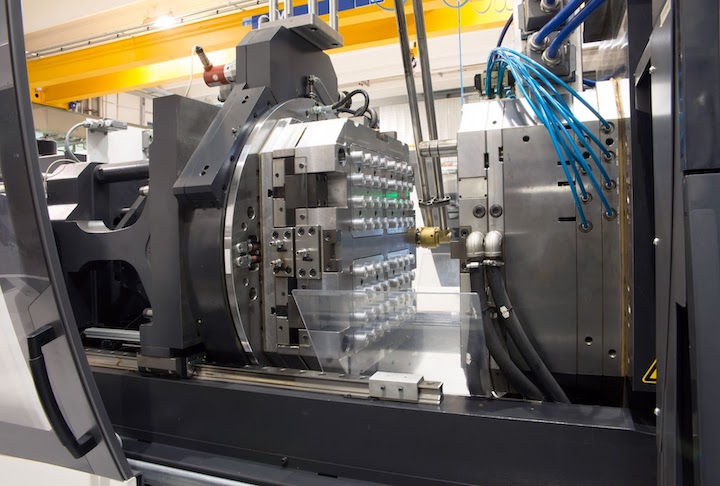

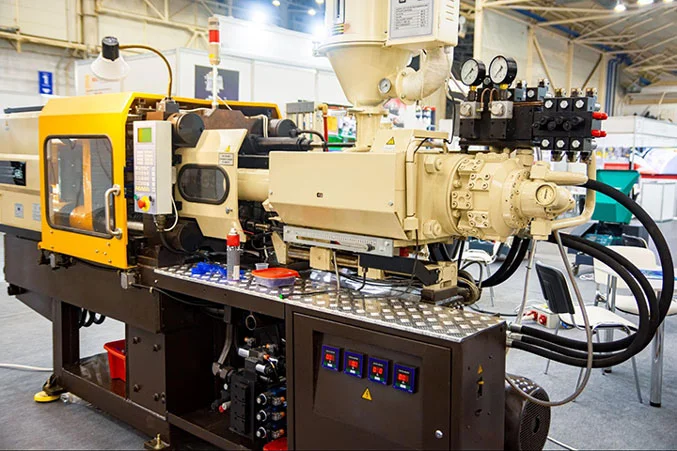

Honyo Prototype employs a rigorously defined process for nylon overmolding and insert molding operations—commonly referenced as “nylon filling” in client communications—which integrates advanced digital workflows with precision manufacturing. This process ensures optimal material performance, dimensional accuracy, and structural integrity for nylon-based components. Below is the technical workflow, emphasizing nylon-specific controls:

CAD Upload and Material Specification

Clients initiate the process by uploading native CAD files (STEP, IGES, or native MCAD formats) via our secure portal. Critical nylon-specific parameters must be declared at this stage: nylon grade (e.g., PA6, PA66, glass-filled variants), color requirements, and critical tolerances per ISO 2768-mK. Our system validates file integrity and flags unsupported geometries (e.g., undercuts exceeding 3° draft for nylon) before proceeding. Material selection directly influences downstream process settings due to nylon’s hygroscopic nature and thermal sensitivity.

AI-Powered Quoting with Material Intelligence

Our proprietary AI engine processes the CAD data alongside declared nylon specifications to generate a comprehensive quote within 2 hours. The algorithm factors in:

Nylon-specific cycle time adjustments (e.g., +15–25% for glass-filled grades due to higher viscosity)

Moisture preconditioning requirements (nylon must be dried to <0.2% RH pre-processing)

Tool steel compatibility (e.g., corrosion-resistant steels for hydrolysis-prone nylons)

Warpage risk scoring based on wall thickness transitions and fiber orientation

The quote includes material cost breakdowns, showing price deltas between unfilled and reinforced nylons, and highlights potential DFM conflicts requiring resolution.

DFM Analysis with Nylon-Specific Validation

All nylon projects undergo mandatory DFM review by our engineering team, focusing on material-critical factors. Key checkpoints include:

| DFM Parameter | Nylon-Specific Requirement | Risk Mitigation Action |

|---|---|---|

| Wall Thickness | Uniformity within 15% variance; min. 0.6mm for thin walls | Recommends core shifts or rib redesign |

| Gate Location | Avoids weld lines on high-stress zones | Proposes hot runner relocation |

| Ejection Design | 1–2° draft minimum; avoids sharp corners | Adds texture or modifies parting line |

| Moisture Management | Specifies drying protocol (80°C/4hrs for PA66-GF30) | Includes drying step in work order |

| Fiber Orientation | Simulates flow to prevent weak knit lines | Adjusts injection speed profile |

Clients receive a detailed DFM report with annotated CAD views and actionable recommendations. Approval requires sign-off on nylon processing parameters.

Nylon-Optimized Production

Approved orders move to production with nylon-specific protocols:

Material handling: Nylon pellets are dried in dehumidifying hoppers at 80–90°C for 4+ hours immediately pre-processing

Machine setup: Barrel temperatures staged 260–290°C (grade-dependent); mold temps maintained at 80–120°C to minimize crystallization defects

Process validation: First articles undergo CT scanning to verify internal voids and fiber distribution; moisture content tested per ASTM D789

In-process controls: Real-time cavity pressure monitoring ensures consistent packing for nylon’s high shrinkage rates (1.2–1.8% for unfilled grades)

Delivery and Documentation

Completed nylon parts undergo final inspection against ASME Y14.5 geometric tolerances, with material certification (including moisture content at time of molding) and process validation reports. All shipments include desiccant packs and moisture-barrier packaging. Typical lead time for nylon overmolding is 8–12 business days post-DFM approval, with expedited options maintaining full material validation steps.

This integrated approach minimizes scrap rates for nylon components by 35% compared to industry averages, addressing inherent challenges like moisture sensitivity and anisotropic shrinkage through data-driven process control. Clients receive full traceability from material lot to machine parameters via our digital twin platform.

Start Your Project

Looking for reliable nylon filling services? Partner with Honyo Prototype for precision results and fast turnaround.

Our manufacturing facility in Shenzhen is equipped to handle high-quality nylon filling with strict process control and material consistency.

Contact Susan Leo today at [email protected] to discuss your project requirements and request a quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.