Introduction: Navigating the Global Market for nylon cost

Navigating the complexities of nylon cost can be a daunting challenge for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With the rising demand for high-quality nylon products across various applications, from textiles to industrial uses, understanding the nuances of pricing becomes crucial. This guide delves into the various factors influencing nylon costs, including material types, quality grades, and market trends that can affect sourcing decisions.

In this comprehensive resource, we will explore different nylon fabric types, such as ballistic nylon and ripstop, and their respective applications, from outdoor gear to automotive uses. Additionally, we will provide insights into supplier vetting processes, ensuring you partner with reliable manufacturers who meet your quality and pricing expectations. By examining cost structures and market dynamics, this guide empowers B2B buyers to make informed purchasing decisions that align with their operational needs and budget constraints.

As you navigate the global nylon market, our aim is to equip you with actionable insights that streamline your sourcing strategy, ultimately enhancing your competitiveness in a rapidly evolving landscape. Whether you are based in Vietnam, Germany, or anywhere in between, this guide serves as your trusted companion in optimizing your nylon procurement process.

Understanding nylon cost Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ballistic Nylon | High abrasion resistance, thick denier fabric | Military gear, luggage, outdoor gear | Pros: Exceptional durability; Cons: Higher cost compared to standard nylon. |

| Coated Nylon Oxford | Water-resistant, lightweight, and versatile | Bags, tents, outdoor apparel | Pros: Cost-effective; Cons: May not withstand extreme conditions. |

| Cordura | Heavy-duty, tear-resistant, and durable | Backpacks, tactical gear | Pros: Long-lasting performance; Cons: Premium pricing. |

| Ripstop Nylon | Lightweight with reinforced weave to prevent tearing | Outdoor gear, clothing | Pros: Lightweight yet strong; Cons: Less water resistance unless treated. |

| Nylon Blend | Combination of nylon with other fibers for enhanced properties | Apparel, upholstery | Pros: Versatile applications; Cons: May compromise some nylon benefits. |

What Are the Key Characteristics of Ballistic Nylon for B2B Buyers?

Ballistic nylon is a robust, high-denier fabric designed to withstand harsh conditions, making it ideal for military and tactical applications. Its thick weave offers exceptional abrasion and tear resistance, ensuring longevity in demanding environments. B2B buyers should consider the higher price point as an investment in durability, especially for products like luggage and protective gear that require resilience.

How Does Coated Nylon Oxford Stand Out in Various Applications?

Coated nylon Oxford is recognized for its lightweight and water-resistant properties, which make it suitable for a range of applications, including bags and outdoor apparel. Its versatility allows it to be used in both fashion and functional items. While it is generally cost-effective, buyers should evaluate the specific environmental conditions their products will face, as it may not perform well in extreme weather.

What Makes Cordura a Preferred Choice in Heavy-Duty Applications?

Cordura is a trademarked fabric known for its heavy-duty, tear-resistant qualities, making it a top choice for backpacks and tactical gear. Its durability ensures that products can withstand rigorous use, appealing to industries focused on longevity. However, the premium pricing may be a barrier for some buyers, so it’s essential to weigh the long-term benefits against the initial investment.

Why Is Ripstop Nylon Ideal for Lightweight Gear?

Ripstop nylon features a unique reinforced weave that prevents tearing, making it an excellent choice for lightweight outdoor gear and clothing. Its strength-to-weight ratio is beneficial for manufacturers seeking to create portable items without sacrificing durability. Buyers should consider the need for additional treatments for water resistance, as untreated ripstop nylon may not be suitable for wet conditions.

How Do Nylon Blends Offer Versatility for Various Applications?

Nylon blends combine nylon with other fibers to enhance specific properties, such as stretch or breathability, making them suitable for apparel and upholstery. This versatility allows manufacturers to cater to diverse market needs. However, buyers should be aware that blending may reduce some of nylon’s inherent advantages, such as moisture resistance or durability, depending on the blend composition.

Key Industrial Applications of nylon cost

| Industry/Sector | Specific Application of nylon cost | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textile Manufacturing | Production of nylon fabrics for apparel | Durability and lightweight properties enhance product quality | Ensure compliance with international textile standards |

| Automotive | Interior components (seat covers, trims) | Cost-effective, water-resistant materials improve vehicle longevity | Evaluate fire-retardant properties for safety compliance |

| Aerospace | Lightweight structural components | Reduces overall weight, enhancing fuel efficiency | Focus on high-performance nylon grades with certifications |

| Construction | Reinforced nylon for safety nets | Increases safety and reliability on job sites | Consider UV resistance and tensile strength requirements |

| Sports Equipment | Manufacturing of outdoor gear | High abrasion resistance leads to longer-lasting products | Source nylon with moisture-wicking and weather-resistant properties |

How is Nylon Cost-Effective for Textile Manufacturing?

In the textile manufacturing sector, nylon is widely utilized for producing various fabrics, particularly for apparel. The cost-effectiveness of nylon stems from its durability and lightweight nature, which enhances the overall quality of the final product. International buyers, especially from regions like Africa and South America, should ensure that the nylon sourced complies with local and international textile standards to maintain quality and safety. Additionally, the availability of diverse nylon blends allows manufacturers to tailor fabrics for specific uses, optimizing production costs.

What Role Does Nylon Play in the Automotive Industry?

The automotive industry employs nylon in the production of interior components such as seat covers and trims. Its cost-effective nature, combined with water-resistant properties, contributes to the longevity of vehicle interiors. For B2B buyers in the Middle East and Europe, it is crucial to evaluate the fire-retardant properties of the nylon sourced, as this impacts safety compliance. By investing in high-quality nylon, manufacturers can enhance the overall value of their vehicles while minimizing replacement costs.

How Does Nylon Enhance Aerospace Applications?

In the aerospace sector, nylon is used for lightweight structural components that contribute to overall fuel efficiency. The cost of nylon is justified by its high-performance capabilities, which are essential in aviation applications. Buyers from Europe, particularly those in Germany, should focus on sourcing nylon grades with industry-specific certifications to ensure safety and performance standards are met. This not only aids in compliance but also enhances the reliability of aerospace products.

What Benefits Does Nylon Provide in Construction?

Nylon’s application in construction, particularly for safety nets and reinforcement, significantly enhances job site safety and reliability. The cost-benefit of using nylon lies in its ability to withstand harsh environmental conditions, making it a preferred choice for contractors. For international buyers, especially from developing regions, it is essential to consider the UV resistance and tensile strength of the nylon sourced. Ensuring these qualities can prevent costly accidents and improve the durability of construction materials.

Why is Nylon Popular in Sports Equipment Manufacturing?

Nylon is a favored material in the sports equipment industry for manufacturing outdoor gear, thanks to its high abrasion resistance and lightweight characteristics. This cost-effective option allows manufacturers to produce longer-lasting products that withstand rigorous use. When sourcing nylon, businesses should prioritize materials with moisture-wicking and weather-resistant properties to cater to diverse environmental conditions. This is particularly important for buyers looking to enhance the performance and longevity of sports equipment in various markets.

3 Common User Pain Points for ‘nylon cost’ & Their Solutions

Scenario 1: Unexpected Price Fluctuations Impacting Budgeting

The Problem: B2B buyers often face the challenge of fluctuating nylon prices, which can disrupt their budgeting and forecasting processes. A manufacturer in South America may plan a large production run based on current nylon prices, only to find that the cost has surged unexpectedly due to global supply chain disruptions or increased demand. This scenario can lead to unanticipated expenses, affecting profit margins and potentially jeopardizing contracts with clients.

The Solution: To mitigate the impact of price fluctuations, buyers should establish long-term relationships with multiple suppliers to create a competitive pricing environment. Additionally, consider locking in prices with contracts that include a fixed rate for a specified period. This approach not only provides predictability in budgeting but also allows for better negotiation leverage. Implementing a strategic sourcing plan that regularly reviews market trends and forecasts can further empower buyers to make informed purchasing decisions, ultimately ensuring more stable pricing and minimizing financial risk.

Scenario 2: Quality Discrepancies Leading to Increased Costs

The Problem: Another common pain point for B2B buyers is encountering discrepancies in nylon quality, which can lead to increased costs. A textile company in Europe might source nylon fabric that appears suitable for their needs, only to discover that the material does not meet durability standards, leading to higher returns and customer dissatisfaction. This situation not only affects the company’s reputation but also results in unexpected expenses associated with replacement materials and additional labor.

The Solution: To address quality discrepancies, buyers should implement a robust quality assurance process that includes detailed specifications and testing protocols for all nylon materials sourced. Prior to placing large orders, conduct small pilot tests to evaluate the nylon’s performance under real-world conditions. Additionally, establishing clear communication with suppliers about quality expectations and maintaining an ongoing quality audit system can help ensure that the materials received consistently meet the required standards. By prioritizing quality assurance, companies can reduce the risk of costly returns and maintain customer satisfaction.

Scenario 3: Sourcing Challenges in Diverse Markets

The Problem: B2B buyers often struggle with sourcing nylon in diverse markets, particularly in regions with limited access to reliable suppliers. For instance, a buyer in Africa may find it difficult to secure consistent supplies of nylon due to logistical issues or a lack of local manufacturing options. This challenge can lead to production delays, increased shipping costs, and reliance on expensive imports, ultimately affecting the bottom line.

The Solution: To overcome sourcing challenges, buyers should explore local and regional suppliers while leveraging technology for efficient procurement. Utilizing online platforms that connect buyers with manufacturers can uncover potential suppliers who may not be widely known. Additionally, fostering partnerships with local businesses can enhance supply chain resilience and reduce shipping costs. For companies operating in multiple regions, developing a centralized procurement strategy that evaluates suppliers based on reliability, price, and quality across different markets can streamline operations and ensure a consistent supply of nylon. This strategic approach not only mitigates sourcing risks but also enhances overall operational efficiency.

Strategic Material Selection Guide for nylon cost

What Are the Key Properties of Various Nylon Materials?

When selecting nylon materials for B2B applications, understanding the properties of different types is crucial. Common nylon materials include Ballistic Nylon, Coated Nylon Oxford, Cordura, and Ripstop Nylon. Each material offers unique characteristics that impact performance, durability, and cost.

How Does Ballistic Nylon Perform in Various Applications?

Ballistic Nylon is known for its exceptional durability and resistance to abrasions. Typically used in high-stress applications such as military gear, luggage, and protective clothing, it can withstand extreme conditions, including high temperatures and impacts. However, its manufacturing process can be complex and costly, making it a premium option. For international buyers, compliance with military specifications and standards such as ASTM D751 is essential, especially in regions like the Middle East and Europe where such standards are strictly enforced.

What Advantages Does Coated Nylon Oxford Offer?

Coated Nylon Oxford is a versatile material often used in outdoor gear, bags, and tents due to its lightweight and water-resistant properties. Its coating enhances durability and provides resistance to UV light, making it suitable for prolonged outdoor use. While it is generally more affordable than Ballistic Nylon, its performance may not match that of heavier materials in extreme conditions. Buyers from Africa and South America should consider local climate factors and potential exposure to harsh weather when selecting this material.

Why Choose Cordura for High-Performance Needs?

Cordura is renowned for its strength and resistance to tears and abrasions, making it ideal for rugged applications such as backpacks, workwear, and military gear. It offers a balance between durability and weight, often coming at a higher price point. The complexity of its manufacturing process can also contribute to increased costs. For European buyers, adherence to environmental regulations and sustainability practices is becoming increasingly important, making Cordura a suitable option for eco-conscious brands.

What Makes Ripstop Nylon a Popular Choice?

Ripstop Nylon features a unique grid pattern that enhances its strength while remaining lightweight, making it a popular choice for applications like outdoor gear, parachutes, and sports equipment. Its resistance to tearing and ripping is a significant advantage, although it may not offer the same level of abrasion resistance as Ballistic Nylon. B2B buyers should be aware of the varying grades of Ripstop Nylon available, as this can affect performance and cost. Compliance with international standards such as JIS for Japan and DIN for Germany can also influence purchasing decisions.

Summary of Material Selection for Nylon Cost

| Material | Typical Use Case for nylon cost | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ballistic Nylon | Military gear, protective clothing | Exceptional durability and abrasion resistance | High manufacturing complexity and cost | High |

| Coated Nylon Oxford | Outdoor gear, bags, tents | Lightweight and water-resistant | Less durable in extreme conditions | Medium |

| Cordura | Backpacks, workwear, military gear | Strong and tear-resistant | Higher cost due to complex manufacturing | High |

| Ripstop Nylon | Outdoor gear, parachutes, sports equipment | Lightweight with tear resistance | Lower abrasion resistance than Ballistic Nylon | Medium |

This strategic material selection guide aims to provide international B2B buyers with actionable insights into nylon cost considerations, ensuring informed purchasing decisions that align with their specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for nylon cost

What Are the Main Stages of Nylon Manufacturing Processes?

The manufacturing of nylon involves several critical stages, each contributing to the final product’s quality and cost. Understanding these stages is essential for B2B buyers to gauge the effectiveness and efficiency of their suppliers.

Material Preparation

The first stage in nylon manufacturing is the preparation of raw materials. Nylon is a synthetic polymer derived from petrochemicals, primarily hexamethylenediamine and adipic acid. These materials undergo a polymerization process, which transforms them into nylon chips. The quality of these raw materials significantly impacts the final product, influencing its durability, strength, and overall performance. Buyers should inquire about the source and specifications of raw materials to ensure they meet their requirements.

Forming Techniques

Once the nylon chips are prepared, they are subjected to various forming techniques to create the desired fabric or product. The most common methods include:

-

Extrusion: This process involves melting the nylon chips and forcing them through a die to create continuous filament. The filaments are cooled and then wound onto spools.

-

Weaving and Knitting: For fabric applications, the extruded filaments are either woven or knitted. Woven nylon fabrics provide strength and durability, while knitted fabrics offer flexibility and stretch.

-

Coating: Some nylon products undergo coating processes to enhance properties such as water resistance, UV protection, or flame retardancy. Coating can be done using techniques like dip coating or spray coating, depending on the end-use requirements.

Understanding the forming techniques employed by suppliers can help B2B buyers assess the suitability of the nylon products for their applications.

Assembly and Finishing Processes

In the assembly phase, different nylon components may be joined together through sewing, welding, or adhesive bonding, depending on the product’s design. Finishing processes, such as dyeing, printing, and applying additional coatings, are also crucial in this stage. These processes not only enhance the aesthetic appeal but also improve functional properties like abrasion resistance and moisture wicking.

What Quality Assurance Standards Are Relevant in Nylon Manufacturing?

Quality assurance is vital in ensuring that nylon products meet the required specifications and standards. B2B buyers should be aware of international and industry-specific quality standards that govern nylon manufacturing.

International Quality Standards

One of the most recognized quality management systems is ISO 9001, which sets out the criteria for a quality management system (QMS). Compliance with ISO 9001 indicates that the manufacturer has established a robust QMS that focuses on customer satisfaction and continuous improvement.

Industry-Specific Standards

In addition to ISO standards, industry-specific certifications may apply, such as:

-

CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: For nylon used in the oil and gas industry, adherence to American Petroleum Institute (API) standards ensures that products meet stringent performance and safety requirements.

B2B buyers should verify that their suppliers are compliant with these standards, as it reflects their commitment to quality and safety.

How Are Quality Control Checkpoints Structured in Nylon Manufacturing?

Quality control (QC) checkpoints are integral to the manufacturing process, ensuring that each stage meets predetermined quality standards.

Incoming Quality Control (IQC)

The first checkpoint, Incoming Quality Control (IQC), involves inspecting raw materials upon arrival at the manufacturing facility. This includes verifying the specifications of nylon chips and other components to ensure they meet the required standards. Any discrepancies at this stage can lead to defects in the final product, making this checkpoint crucial.

In-Process Quality Control (IPQC)

In-Process Quality Control (IPQC) occurs during the manufacturing process. It involves regular inspections of the production line to monitor parameters such as temperature, pressure, and material consistency. Statistical process control (SPC) techniques may be employed to analyze data and detect variations that could affect product quality.

Final Quality Control (FQC)

The final checkpoint, Final Quality Control (FQC), occurs before products are shipped to customers. This involves comprehensive testing, including tensile strength tests, abrasion resistance tests, and colorfastness tests. FQC ensures that the finished products conform to the specified standards and are ready for market.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should implement several verification strategies:

Conducting Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Audits can be performed by the buyer’s quality assurance team or by third-party organizations specializing in supplier audits.

Reviewing Quality Reports

Buyers should request quality assurance reports from suppliers, detailing the results of IQC, IPQC, and FQC processes. These reports should outline any discrepancies found during production and the corrective actions taken.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These services can conduct inspections at various stages of the manufacturing process, ensuring compliance with international standards and industry-specific requirements.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, should be aware of certain nuances in quality control when sourcing nylon products internationally.

Regional Compliance Requirements

Different regions may have varying compliance requirements, impacting the quality standards suppliers must adhere to. For instance, products sold in Europe must comply with CE marking, while those destined for the Middle East may need to meet Gulf Cooperation Council (GCC) standards.

Cultural and Communication Considerations

Cultural differences can influence quality assurance practices. Effective communication with suppliers about quality expectations is essential. Buyers should consider hiring local representatives or consultants who understand the regional landscape to facilitate this process.

Logistics and Supply Chain Challenges

International shipping can pose challenges related to product integrity. B2B buyers should work closely with suppliers to ensure proper packaging and handling during transit to minimize the risk of damage and maintain quality.

In summary, understanding the manufacturing processes and quality assurance practices associated with nylon products is vital for B2B buyers. By paying close attention to the stages of production, relevant quality standards, and effective verification strategies, buyers can ensure they source high-quality nylon that meets their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nylon cost’

Introduction

Navigating the complexities of nylon procurement can be challenging, especially for international B2B buyers. This guide provides a practical checklist to help you understand the costs associated with nylon, ensuring you make informed purchasing decisions. By following these steps, you can streamline your sourcing process and optimize your budget.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to outline your specific needs for nylon. Determine the type of nylon fabric required—whether it’s ballistic, ripstop, or coated—along with the desired denier (thickness) and any special characteristics (e.g., flame retardant, waterproof). A clear specification will help suppliers provide accurate quotes and ensure the material meets your project requirements.

Step 2: Research Market Prices

Conduct thorough market research to understand the current price range for nylon materials. Prices can vary significantly based on the type, quality, and supplier location. Utilize online fabric stores, trade publications, and industry reports to gather data, allowing you to identify competitive pricing and budget accordingly.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Consider their reputation, customer service, and responsiveness, as these factors can significantly impact your purchasing experience and the quality of the product you receive.

Step 4: Request Samples

Always ask for samples before placing a bulk order. Evaluating samples allows you to assess the fabric’s quality, durability, and appearance firsthand. Ensure that the samples reflect the specific characteristics you require, such as color and finish, to avoid discrepancies in your order.

Step 5: Verify Supplier Certifications

Ensure that your selected suppliers comply with industry standards and certifications. Look for certifications such as ISO for quality management or Oeko-Tex for environmental safety. This verification helps mitigate risks associated with quality and compliance, especially when sourcing from international suppliers.

Step 6: Negotiate Terms and Conditions

Engage in open discussions about pricing, payment terms, and delivery schedules. Negotiating favorable terms can lead to cost savings and better cash flow management. Be clear about your expectations regarding lead times and minimum order quantities to avoid future misunderstandings.

Step 7: Plan for Logistics and Shipping

Consider the logistics involved in transporting nylon from the supplier to your location. Analyze shipping costs, timelines, and potential customs duties, especially if you are sourcing internationally. A well-planned logistics strategy can help you avoid unexpected expenses and delays, ensuring a smooth procurement process.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing nylon, making informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for nylon cost Sourcing

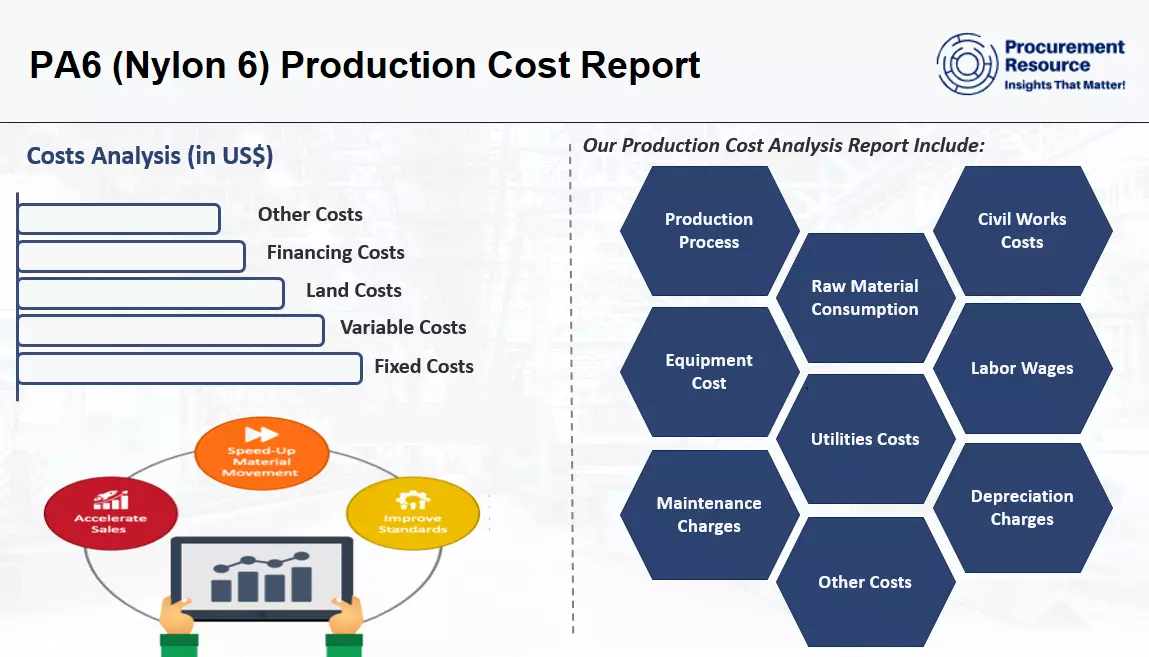

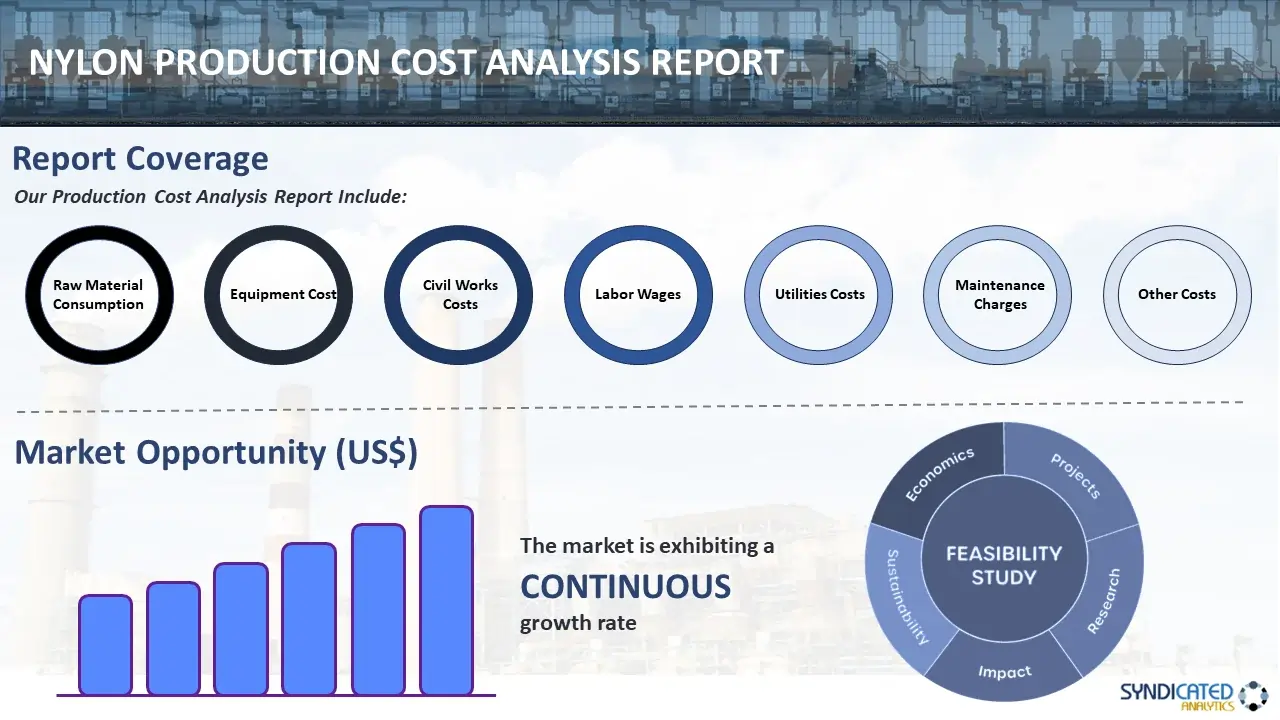

What Are the Key Cost Components in Nylon Sourcing?

When analyzing the costs associated with nylon sourcing, several components come into play. Materials form the largest part of the cost structure, with prices varying based on the type of nylon fabric (e.g., ballistic, coated, or ripstop). As of recent market data, nylon fabrics can range from approximately $5 to over $30 per yard, depending on specifications and quality.

Labor costs also contribute significantly, especially when sourcing from regions with varying wage levels. In countries with lower labor costs, you may find more competitive pricing, but it’s essential to balance this with the quality of workmanship. Manufacturing overhead includes expenses related to equipment maintenance, facility costs, and utilities, which can fluctuate based on the production scale.

Tooling costs are particularly relevant for customized nylon products, where specific molds or setups are required. Quality control (QC) measures are critical, especially for international buyers who may require certifications (like ISO) to ensure compliance with their quality standards. Finally, logistics costs can be substantial, especially when transporting materials across borders, influenced by the choice of shipping methods and Incoterms.

How Do Pricing Influencers Affect Nylon Costs?

Several factors influence the pricing of nylon fabrics in a B2B context. Volume and minimum order quantities (MOQ) play a crucial role; larger orders often lead to better pricing due to economies of scale. Customization requests, such as specific colors or performance features (e.g., waterproofing), can also increase costs, as they may require additional manufacturing processes.

Material quality and certifications are vital considerations. Higher-quality nylons or those with special features (like flame retardant properties) will command higher prices. Additionally, supplier factors such as reputation, reliability, and production capacity can impact pricing. Buyers should also be aware of Incoterms, as they dictate shipping responsibilities, which can significantly affect the total landed cost of the nylon.

What Buyer Tips Can Enhance Cost-Efficiency in Nylon Sourcing?

International B2B buyers should adopt several strategies to optimize their sourcing costs. Negotiation is a critical skill; understanding the supplier’s pricing structure can provide leverage during discussions. Buyers should aim for transparency regarding costs, which can lead to mutually beneficial agreements.

Understanding the Total Cost of Ownership (TCO) is essential. This includes not just the purchase price but also logistics, storage, and potential wastage costs. Buyers should carefully evaluate all these aspects when assessing suppliers.

For buyers in regions like Africa, South America, the Middle East, and Europe, it is crucial to consider pricing nuances. Factors such as currency fluctuations, local tariffs, and import duties can affect overall costs. Conducting a thorough market analysis can also reveal opportunities for cost savings, such as identifying suppliers who offer favorable payment terms or discounts for bulk purchases.

Disclaimer on Indicative Prices

While this analysis provides a comprehensive overview of the cost structure and pricing factors associated with nylon sourcing, it is important to note that prices can fluctuate based on market conditions, supplier negotiations, and regional economic factors. Always conduct due diligence and obtain multiple quotes before finalizing any purchase agreements.

Alternatives Analysis: Comparing nylon cost With Other Solutions

Exploring Alternative Solutions to Nylon Cost

In the competitive landscape of industrial materials, understanding the cost-effectiveness and performance of various solutions is crucial for B2B buyers. While nylon is widely recognized for its durability and versatility, alternative materials can offer distinct advantages depending on specific application needs. This analysis compares nylon against two viable alternatives: polyester and polypropylene, providing insights to assist buyers in making informed purchasing decisions.

| Comparison Aspect | Nylon Cost | Polyester Cost | Polypropylene Cost |

|---|---|---|---|

| Performance | High durability, abrasion resistance; excellent for outdoor applications. | Good durability; less abrasion-resistant than nylon but better UV stability. | Moderate durability; resistant to moisture but not as strong as nylon. |

| Cost | Ranges from $5 to $30 per yard, depending on type and coating. | Generally cheaper, ranging from $3 to $20 per yard. | Typically the least expensive, around $2 to $10 per yard. |

| Ease of Implementation | Requires specific handling due to its properties; can be more complex to sew. | Easier to handle and sew; compatible with various applications. | Very easy to work with; often used in simple applications. |

| Maintenance | Requires special care to maintain properties; may be less resistant to certain chemicals. | Generally low maintenance; resistant to most chemicals. | Low maintenance; easy to clean and resistant to staining. |

| Best Use Case | Ideal for high-performance applications like outdoor gear, military, and sports equipment. | Suitable for everyday wear, home textiles, and outdoor applications. | Best for packaging, non-woven fabrics, and disposable products. |

What Are the Pros and Cons of Polyester as an Alternative to Nylon?

Polyester is a popular alternative to nylon, particularly in applications requiring lower costs and moderate durability. Its cost-effectiveness, ranging from $3 to $20 per yard, makes it an attractive option for businesses looking to manage budgets while still providing quality products. Polyester exhibits good UV stability, making it suitable for outdoor applications. However, it is not as strong or abrasion-resistant as nylon, which could be a drawback in high-performance environments.

How Does Polypropylene Compare to Nylon in Terms of Cost and Performance?

Polypropylene stands out as the most economical choice among the alternatives, with prices ranging from $2 to $10 per yard. Its properties make it ideal for lightweight and moisture-resistant applications, such as packaging and disposable products. However, polypropylene’s overall durability and strength are inferior to nylon, making it less suitable for demanding applications. While it offers ease of handling and low maintenance requirements, buyers should carefully consider whether its performance aligns with their specific needs.

How Should B2B Buyers Choose the Right Material for Their Needs?

Selecting the appropriate material hinges on a thorough understanding of application requirements, budget constraints, and performance expectations. For high-performance needs where durability is paramount, nylon remains the preferred choice despite its higher cost. Conversely, for applications where cost is a critical factor and performance demands are moderate, polyester or polypropylene may serve as viable alternatives. Buyers should evaluate the specific attributes of each material against their project specifications to ensure they make the most informed purchasing decision.

Essential Technical Properties and Trade Terminology for nylon cost

What Are the Key Technical Properties of Nylon Relevant to Cost?

Understanding the technical properties of nylon is crucial for B2B buyers to make informed purchasing decisions. Here are some critical specifications to consider:

-

Denier (D)

Denier measures the thickness of the nylon fibers. A higher denier indicates a thicker, more durable fabric, which is essential for applications requiring strength, such as outdoor gear and industrial uses. For example, 1000 denier ballistic nylon is often used for military and tactical applications due to its high tensile strength. -

Coating

Nylon fabrics can be coated with various materials (e.g., polyurethane or silicone) to enhance their properties, such as water resistance or UV protection. This coating can significantly impact the cost, as treated fabrics typically command higher prices due to their enhanced performance. -

Tensile Strength

This property indicates how much force a nylon fabric can withstand before breaking. It is measured in pounds per square inch (PSI) and is vital for applications where durability is non-negotiable, such as in automotive or aerospace sectors. A higher tensile strength generally correlates with increased material costs but ensures better performance and longevity. -

Weight

The weight of nylon fabric is often expressed in ounces per square yard. Lightweight fabrics are preferred for applications like apparel and travel gear, while heavier fabrics are suitable for industrial or outdoor applications. Understanding weight helps buyers assess shipping costs and end-use suitability. -

Flame Retardancy

Some nylon fabrics are treated to be flame retardant, which is crucial for specific applications in industries such as aviation, construction, and automotive. Fabrics with this property usually have a higher cost due to the additional processing required. -

Color Fastness

This property measures a fabric’s resistance to fading when exposed to light or washing. For B2B buyers, color fastness is essential for products meant for long-term use, such as uniforms or outdoor equipment. Fabrics with excellent color fastness may have a higher price point due to the dyes and treatments used.

What Are Common Trade Terms Related to Nylon Cost?

Familiarity with industry jargon can enhance negotiations and decision-making processes. Here are essential terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. When sourcing nylon, understanding OEM relationships can help buyers gauge quality and reliability, as OEMs often adhere to strict manufacturing standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it directly impacts inventory costs and cash flow. Understanding MOQs can also help negotiate better pricing based on larger orders. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific goods or services. This is particularly important in the nylon industry, where prices can fluctuate based on material specifications and market conditions. A well-crafted RFQ can lead to better pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with these terms helps in understanding shipping costs, insurance, and liability. For example, “FOB” (Free On Board) indicates that the seller covers costs until the goods are loaded onto the shipping vessel. -

Lead Time

This refers to the time taken from placing an order to delivery. In the nylon industry, lead times can vary significantly based on the complexity of the order and the supplier’s capabilities. Understanding lead times is crucial for project planning and inventory management. -

Sustainability Certifications

Many nylon suppliers now offer fabrics that are produced with environmentally friendly processes. Certifications like OEKO-TEX or GOTS (Global Organic Textile Standard) can add value to products and influence purchasing decisions, especially in markets that prioritize sustainability.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of nylon sourcing more effectively, ensuring they make strategic purchasing decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the nylon cost Sector

What Are the Current Market Dynamics and Key Trends in the Nylon Cost Sector?

The global nylon market is witnessing significant transformations, driven by factors such as technological advancements, rising demand for high-performance materials, and increasing applications across various industries. B2B buyers, particularly in Africa, South America, the Middle East, and Europe, should be aware of the ongoing shifts in sourcing strategies and market dynamics. The expansion of e-commerce platforms has made it easier for buyers to access a wider range of nylon products, while innovations in production technologies are enhancing the quality and performance of nylon fabrics.

Emerging trends include the growing popularity of specialty nylon fabrics, such as flame-retardant and water-repellent options, which cater to specific industry needs. Additionally, the demand for durable and lightweight materials in sectors like automotive, aerospace, and outdoor gear is escalating, prompting suppliers to develop more advanced nylon compositions. As international trade continues to evolve, buyers must also be vigilant about geopolitical factors that can impact sourcing costs and availability.

Furthermore, the integration of digital tools in supply chain management is reshaping procurement processes, enabling buyers to make data-driven decisions. This trend is particularly relevant for businesses looking to optimize their sourcing strategies and minimize costs while ensuring product quality.

How Can Sustainability and Ethical Sourcing Impact the Nylon Cost Sector?

Sustainability has become a pivotal concern for B2B buyers in the nylon sector, with increasing pressure to adopt ethical sourcing practices. The environmental impact of nylon production, including its reliance on fossil fuels and the generation of waste, has led to a demand for more sustainable alternatives. Buyers are now prioritizing suppliers that adhere to environmentally responsible practices, which can influence their purchasing decisions.

Ethical supply chains are essential not only for reducing environmental footprints but also for enhancing brand reputation. Buyers should seek out suppliers that offer certifications for sustainable materials, such as recycled nylon or those produced with reduced carbon emissions. Emphasizing the importance of ‘green’ certifications can help buyers align their sourcing strategies with global sustainability goals and consumer expectations.

Incorporating sustainable practices can also lead to cost savings in the long term. For example, investing in recycled nylon can reduce raw material costs and minimize waste. By focusing on ethical sourcing, businesses can contribute to a circular economy, improving their market position while addressing the growing consumer demand for environmentally friendly products.

What Is the Evolution of the Nylon Cost Sector and Its Significance for B2B Buyers?

The nylon industry has evolved significantly since its introduction in the 1930s as the first synthetic fiber. Initially popularized in textiles, nylon has expanded its applications into various sectors, including automotive, aerospace, and consumer goods. The versatility of nylon, combined with advancements in technology, has allowed for the development of specialized products that meet the demands of a dynamic market.

In the B2B context, understanding the historical evolution of nylon can provide insights into current market trends and sourcing strategies. The shift from traditional nylon production methods to more sustainable practices reflects broader industry changes, emphasizing the importance of innovation and environmental responsibility. As B2B buyers navigate the complexities of the nylon cost sector, recognizing these historical developments can aid in making informed sourcing decisions that align with both business goals and ethical standards.

Conclusion

Navigating the nylon cost sector requires a keen understanding of market dynamics, sustainability considerations, and historical context. By staying informed about current trends and prioritizing ethical sourcing practices, B2B buyers can enhance their procurement strategies and contribute to a more sustainable future.

Frequently Asked Questions (FAQs) for B2B Buyers of nylon cost

-

How do I determine the cost of nylon fabric for my business needs?

To accurately assess the cost of nylon fabric, consider factors such as the type of nylon (e.g., ballistic, ripstop, or coated), the denier (thickness), and the specific application (e.g., apparel, outdoor gear, or industrial use). Additionally, request quotes from multiple suppliers, as prices can vary based on volume, shipping costs, and regional market conditions. Consider engaging with suppliers who offer samples to evaluate quality before committing to larger orders. -

What is the best type of nylon fabric for outdoor applications?

For outdoor applications, coated nylon fabrics such as nylon oxford or pack cloth are ideal due to their water-resistant and durable properties. Fabrics with higher denier ratings (e.g., 420D or 1050D) provide added strength and tear resistance, making them suitable for tents, backpacks, and outdoor gear. When selecting nylon, also consider factors like UV resistance and flame retardancy, depending on the specific outdoor environment. -

What are the typical minimum order quantities (MOQs) for nylon fabric?

Minimum order quantities for nylon fabric can vary significantly by supplier and fabric type. Generally, MOQs can range from as low as 50 yards for standard fabrics to several hundred yards for specialty or custom materials. It’s advisable to communicate directly with suppliers to negotiate MOQs that suit your purchasing needs, especially if you’re testing new products or entering new markets. -

How can I vet potential nylon suppliers for quality and reliability?

To vet potential suppliers, start by checking their industry reputation through online reviews and testimonials. Request samples to assess fabric quality, and inquire about their production processes and quality assurance measures. Additionally, evaluate their certifications, such as ISO standards, and ensure they comply with international trade regulations. Establishing clear communication and requesting references from other B2B clients can further assure you of their reliability. -

What payment terms should I expect when sourcing nylon fabric internationally?

Payment terms for international nylon fabric transactions can vary, but common practices include upfront deposits (usually 30-50%) with the balance due upon shipment or delivery. Letters of credit (LC) are often used to secure transactions, providing protection for both parties. Be sure to negotiate terms that align with your cash flow needs and consider any potential currency exchange risks. -

What should I know about logistics and shipping for nylon fabric orders?

When importing nylon fabric, consider shipping options, lead times, and customs regulations. Air freight is faster but more expensive, while sea freight is cost-effective for larger orders but takes longer. Ensure you understand the import duties and taxes applicable in your country and verify that your supplier can handle the necessary export documentation. Collaborating with a freight forwarder can streamline the logistics process. -

Can I customize nylon fabric for my specific business needs?

Yes, many suppliers offer customization options for nylon fabric, including color, weight, and treatments (e.g., water repellency or flame retardancy). Custom designs may require minimum order quantities and longer lead times, so it’s essential to discuss your specific requirements upfront. Collaborating closely with your supplier can help ensure the final product meets your specifications. -

What quality assurance measures should I implement when sourcing nylon fabric?

Implementing quality assurance measures involves setting clear specifications and standards with your supplier before production begins. Request pre-production samples to evaluate quality and conduct inspections at various stages of production. Consider using third-party quality control services to perform inspections before shipment, ensuring that the fabric meets your standards and reducing the risk of defects in your final products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Nylon Cost Manufacturers & Suppliers List

1. Online Fabric Store – Coated Nylon Oxford Fabric

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: This company, Online Fabric Store – Coated Nylon Oxford Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Fabric Wholesale Direct – Nylon Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Nylon Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Tarps Now – Nylon Fabric Solutions

Domain: tarpsnow.com

Registered: 2010 (15 years)

Introduction: Nylon Fabric available by the yard and roll, with deniers ranging from 200 to 1680. Features include: strong and adaptable material, water resistant, UV resistant, mildew resistant, abrasion resistant, insect resistant, and chemical resistant. Applications include coverings, seat belts, tire cords, bags, totes, and military uses. Available in various colors. Specific products include: 1000 Denier …

4. Walmart – Nylon Fabric

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – Nylon Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Big Duck Canvas – 12 oz. Waterproof Nylon Duck Cloth – Sage Grey

Domain: bigduckcanvas.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “12 oz. Waterproof Nylon Duck Cloth – Sage Grey”, “Weight”: “12 oz. per sq yd”, “Width”: “43 inches”, “Color”: “Sage Grey”, “Material”: “Nylon”, “Specifications”: {“Weave Construction”: “Duck Cloth”, “Federal Specifications”: “PIA-C-43375 Class 2”, “Shrinkage”: “>1%”, “Origin”: “Made in the USA”}, “Care Instructions”: “To remove dust buildup, gently brush the surface with a soft b…

6. Seattle Fabrics – 1.9 oz. Ripstop Nylon Fabric

Domain: seattlefabrics.com

Registered: 1998 (27 years)

Introduction: 1.9 oz. Ripstop Nylon Fabric by the Yard

– Weight: 1.9 oz. per square yard

– Denier: 70 Denier

– Features: Water repellent, breathable, downproof, tear-resistant squares due to reinforcing threads woven in each direction.

– Price: $9.50 per linear yard

– Available Options: Uncoated, Polyurethane Coated, Fire Retardant, Silicone Coated, Black-Out, Imported.

– Applications: Suitable for outdoor recr…

7. Ripstop by the Roll – Ultralight Nylon Fabric Collection

Domain: ripstopbytheroll.com

Registered: 2013 (12 years)

Introduction: Ultralight Nylon Fabric collection with 13 different fabrics, all under 1.5 oz per square yard. Fabrics known for higher strength than polyester, with finishes like C6 DWR or Calendering. Popular options include: 1.5 oz MONOLITE™ Ripstop Nylon Mesh, 1.0 oz HyperD, 0.56 oz MEMBRANE 7 Ripstop Nylon. Applications include quilts, jackets, sleeping bags, garments, ultralight hammocks, bug netting, tent…

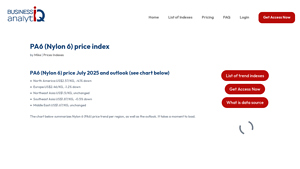

8. Business Analytiq – PA6 Nylon Price Index

Domain: businessanalytiq.com

Registered: 2020 (5 years)

Introduction: PA6 (Nylon 6) price index: North America: US$2.57/KG, -4.1% down; Europe: US$2.46/KG, -1.2% down; Northeast Asia: US$1.5/KG, unchanged; Southeast Asia: US$1.87/KG, -0.5% down; Middle East: US$1.67/KG, unchanged. Nylon PA6 is a synthetic polymer known for its strength, durability, and resistance to wear and chemicals. It is produced by polymerizing caprolactam and is used in automotive parts, beari…

9. ePlastics – Nylon Sheets Cut-to-Size

Domain: eplastics.com

Registered: 1998 (27 years)

Introduction: Huge Selection of Black & Natural Nylon Sheets Cut-to-Size from ePlastics

Strategic Sourcing Conclusion and Outlook for nylon cost

How Can Strategic Sourcing Impact Your Nylon Procurement Costs?

In the evolving landscape of nylon procurement, international B2B buyers must prioritize strategic sourcing to navigate fluctuating costs effectively. By understanding market dynamics, such as raw material pricing and regional supply chain challenges, companies can make informed purchasing decisions that optimize their budgets. Leveraging relationships with trusted suppliers ensures access to diverse nylon products—from ballistic to coated options—while maintaining quality standards.

Furthermore, proactive engagement in market analysis and supplier negotiations can lead to significant cost savings. As buyers in Africa, South America, the Middle East, and Europe face unique challenges, tailored sourcing strategies that account for local conditions and logistics will enhance competitiveness.

Looking ahead, it is crucial for businesses to adopt agile sourcing practices that can adapt to future market shifts and consumer demands. By investing in strategic sourcing now, companies position themselves to not only mitigate risks associated with price volatility but also capitalize on emerging opportunities in the nylon market.

Engage with your suppliers today to explore innovative solutions that align with your procurement goals and drive sustainable growth in the competitive fabric industry.