Introduction: Navigating the Global Market for nylon 66 sheet

In the dynamic landscape of global manufacturing, sourcing high-quality nylon 66 sheets can present significant challenges for B2B buyers, particularly those navigating diverse markets across Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia. As industries increasingly demand materials that offer durability, low friction, and thermal stability, understanding the nuances of nylon 66 sheets becomes essential for making informed purchasing decisions. This comprehensive guide is designed to empower international buyers by providing an in-depth look into the various types of nylon 66 sheets available, their specific applications across different sectors, and critical factors to consider when vetting suppliers.

Throughout this guide, we will explore the unique properties that make nylon 66 sheets suitable for a wide range of applications, from heavy-duty structural components to intricate mechanical parts. We will also cover essential aspects of the sourcing process, such as evaluating supplier reliability, understanding pricing structures, and identifying the right specifications for your needs. By equipping you with actionable insights and best practices, this guide aims to streamline your procurement process and enhance your strategic purchasing capabilities in the ever-evolving global market. Whether you are looking to reduce operational costs or improve product performance, this resource will serve as your essential companion in navigating the complexities of sourcing nylon 66 sheets.

Understanding nylon 66 sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Extruded Nylon 66 Sheet | High strength, low friction, good abrasion resistance | Heavy-duty machinery parts, structural components | Pros: Durable, versatile, easy to fabricate. Cons: May require careful handling due to sharp edges. |

| Cast Nylon 66 Sheet | Superior impact resistance, better dimensional stability | Gears, bearings, and wear strips | Pros: Excellent mechanical properties, can be machined. Cons: Generally more expensive than extruded options. |

| Filled Nylon 66 Sheet | Enhanced properties with additives (e.g., glass, minerals) | Automotive parts, industrial applications | Pros: Improved strength and stiffness. Cons: Reduced flexibility compared to unfilled variants. |

| Natural vs. Colored Nylon | Color variations for aesthetic or functional purposes | Consumer goods, custom applications | Pros: Customizable appearance. Cons: Color may affect pricing and availability. |

| Thin vs. Thick Nylon Sheets | Range of thicknesses from 0.030 in to over 2 in | Packaging, insulation, and structural parts | Pros: Wide selection for various applications. Cons: Thinner sheets may lack durability for heavy use. |

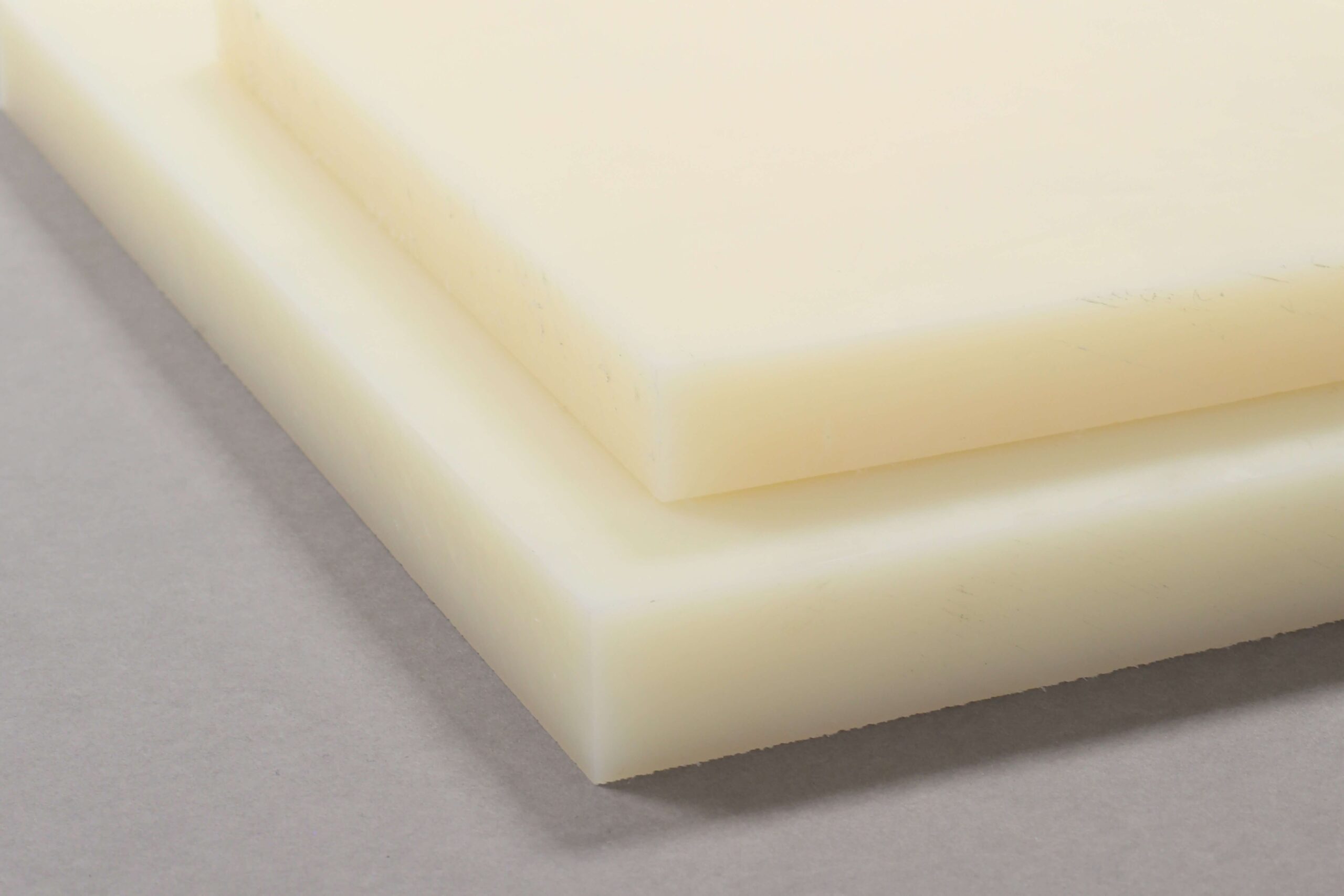

What Are the Key Characteristics of Extruded Nylon 66 Sheets?

Extruded Nylon 66 sheets are recognized for their high strength and low friction properties, making them ideal for demanding applications such as heavy-duty machinery parts and structural components. Their excellent abrasion resistance ensures longevity even in harsh environments. When purchasing, buyers should consider factors such as thickness, size, and any specific machining requirements, as these sheets are easily fabricated using standard equipment.

How Does Cast Nylon 66 Sheet Differ from Other Types?

Cast Nylon 66 sheets offer superior impact resistance and dimensional stability, making them suitable for applications like gears, bearings, and wear strips. This type is typically more robust than extruded nylon, allowing for better performance in high-stress environments. Buyers should weigh the higher cost against the potential for reduced maintenance and longer service life, especially in critical applications.

What Are the Benefits of Using Filled Nylon 66 Sheets?

Filled Nylon 66 sheets incorporate additives that enhance their mechanical properties, providing increased strength and stiffness, which is particularly beneficial in automotive and industrial applications. However, these sheets may sacrifice some flexibility, making them less suitable for applications requiring high ductility. B2B buyers should evaluate their specific application needs to determine if the added strength justifies the potential trade-offs.

Why Choose Natural Over Colored Nylon Sheets?

Natural and colored nylon sheets serve different aesthetic and functional purposes. While natural sheets are often preferred for their versatility, colored sheets can enhance product appearance or signify specific functionalities. Buyers should consider the impact of color on pricing and availability, as well as the intended end-use of the product, when making purchasing decisions.

What Should Buyers Know About Thin vs. Thick Nylon Sheets?

Nylon sheets are available in a wide range of thicknesses, from as thin as 0.030 inches to over 2 inches. Thinner sheets are often used for packaging and insulation, while thicker sheets are favored for structural applications. Buyers should assess the required durability and application-specific demands to choose the appropriate thickness, keeping in mind that thinner options may not withstand heavy use as effectively as their thicker counterparts.

Key Industrial Applications of nylon 66 sheet

| Industry/Sector | Specific Application of nylon 66 sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine components and housings | High strength and thermal stability | Ensure compliance with industry standards and specifications. |

| Aerospace | Structural components | Lightweight yet durable, reducing fuel costs | Certification for aerospace applications is crucial. |

| Food Processing | Conveyor systems and guides | Abrasion resistance and low friction | Food-grade materials must meet health and safety regulations. |

| Industrial Machinery | Wear strips and bushings | Reduces downtime with enhanced wear resistance | Evaluate the thickness and size for specific machinery requirements. |

| Electronics | Insulation and support components | Excellent electrical insulation properties | Confirm compatibility with electrical standards and certifications. |

How is Nylon 66 Sheet Used in the Automotive Industry?

In the automotive sector, nylon 66 sheets are utilized in manufacturing engine components, housings, and other structural elements. Their high strength and thermal stability make them ideal for demanding environments, where they can withstand extreme temperatures and mechanical stress. International buyers, particularly in regions like Europe and the Middle East, should ensure that the nylon sourced meets specific automotive standards and regulations to guarantee performance and safety.

What Role Does Nylon 66 Sheet Play in Aerospace Applications?

Nylon 66 sheets serve critical functions in aerospace applications, including the production of lightweight structural components. These sheets offer durability while significantly reducing weight, contributing to lower fuel consumption and enhanced aircraft efficiency. Buyers in the aerospace industry must prioritize sourcing materials that are certified for aerospace use, ensuring compliance with stringent safety and performance standards.

Why is Nylon 66 Sheet Preferred in Food Processing?

In food processing, nylon 66 sheets are commonly used in conveyor systems and guides due to their abrasion resistance and low friction properties. These characteristics help maintain operational efficiency and minimize wear over time. B2B buyers in this sector, especially from Africa and South America, need to ensure that the nylon sheets are food-grade certified, adhering to health regulations to prevent contamination.

How Does Nylon 66 Sheet Enhance Industrial Machinery Operations?

Nylon 66 sheets are extensively applied in industrial machinery as wear strips and bushings. Their exceptional wear resistance helps reduce downtime by prolonging the life of components, which is crucial in high-demand manufacturing environments. Buyers should assess the specific thickness and size of nylon sheets required for their machinery to ensure optimal performance and compatibility with existing systems.

What Benefits Does Nylon 66 Sheet Offer for Electronics?

In the electronics sector, nylon 66 sheets are valued for their excellent electrical insulation properties, making them suitable for insulation and support components. This application is critical for maintaining safety and performance in electrical assemblies. International buyers must confirm that the nylon sheets meet relevant electrical standards and certifications to ensure reliable performance in their applications.

3 Common User Pain Points for ‘nylon 66 sheet’ & Their Solutions

Scenario 1: Sourcing High-Quality Nylon 66 Sheets for Critical Applications

The Problem:

B2B buyers often face significant challenges when sourcing nylon 66 sheets that meet specific quality and performance standards. Many suppliers may offer products that do not adhere to the necessary industrial specifications, leading to potential failures in critical applications such as machinery components or structural parts. This can result in costly downtimes, increased maintenance, and even safety hazards. Buyers in regions like Africa and South America might struggle with limited access to reputable suppliers, compounding the risk of procuring substandard materials.

The Solution:

To overcome this challenge, buyers should conduct thorough research on suppliers before making any purchasing decisions. Look for suppliers with a strong reputation in the market, particularly those that provide detailed technical data sheets and compliance certifications for their nylon 66 sheets. It’s advisable to request samples for testing prior to bulk purchasing. Furthermore, utilizing a standardized grading system, such as ASTM or ISO certifications, can help in identifying high-quality materials. Engaging directly with manufacturers who can provide customization options based on specific project requirements also ensures that the material sourced will perform effectively in intended applications.

Scenario 2: Addressing the Challenges of Nylon 66 Sheet Machining

The Problem:

Machining nylon 66 sheets can present a variety of issues, including tool wear, poor surface finishes, and difficulties in achieving precise tolerances. For manufacturers in the Middle East and Europe, the costs associated with rework and scrap due to machining errors can be significant. Additionally, without proper machining techniques, the sheets may warp or melt, resulting in wasted materials and production delays.

The Solution:

To mitigate these machining challenges, it is essential to adopt best practices specific to nylon 66. This includes using the right tools—preferably those made from carbide or high-speed steel—and ensuring they are kept sharp to reduce friction and heat. Implementing optimal feed rates and cutting speeds tailored for nylon can also minimize tool wear and enhance surface quality. Additionally, incorporating coolant systems can help maintain a lower temperature during machining, preventing melting and warping. For companies unfamiliar with these techniques, investing in training for their machining staff can yield long-term benefits in efficiency and product quality.

Scenario 3: Managing Nylon 66 Sheets’ Environmental Sensitivity

The Problem:

Nylon 66 sheets are known for their excellent mechanical properties, but they can also be sensitive to moisture and environmental conditions. For buyers operating in humid climates or regions with temperature fluctuations—such as parts of South America and Africa—this sensitivity can lead to dimensional changes and reduced performance of the final products. Such environmental factors can complicate inventory management and project timelines, leading to potential financial losses.

The Solution:

To address these environmental challenges, it’s crucial to implement proper storage and handling practices for nylon 66 sheets. Buyers should store sheets in a climate-controlled environment to minimize exposure to moisture and temperature extremes. Using desiccants in storage areas can further help control humidity levels. Moreover, it’s beneficial to educate teams about the importance of acclimatization prior to machining or fabrication. Allowing sheets to reach ambient temperature and moisture content can significantly improve performance and dimensional stability. When possible, consider sourcing nylon 66 sheets with moisture-resistant additives for applications where humidity is a concern, ensuring enhanced durability and reliability.

Strategic Material Selection Guide for nylon 66 sheet

What Are the Key Properties of Nylon 66 Sheets for B2B Applications?

Nylon 66, known for its exceptional mechanical properties, is a popular choice in various industrial applications. Key properties include high tensile strength, excellent abrasion resistance, and thermal stability. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for environments with fluctuating temperatures. Additionally, it exhibits low friction characteristics, which is beneficial for applications requiring smooth operation. This combination of properties makes Nylon 66 an ideal material for heavy-duty applications, such as gears, bearings, and structural components.

What Are the Pros and Cons of Using Nylon 66 Sheets?

Pros:

Nylon 66 sheets offer significant durability, which translates to longer service life in demanding environments. Their resistance to wear and tear reduces maintenance costs over time. Furthermore, Nylon 66 is relatively easy to fabricate using standard machining techniques, allowing for precise component manufacturing.

Cons:

However, Nylon 66 can be more expensive than alternative materials like PVC or polypropylene. Its susceptibility to moisture absorption can lead to dimensional changes, which may affect the performance of precision components. Additionally, while it is resistant to many chemicals, it is not suitable for use with strong acids or bases, limiting its applicability in certain industries.

How Do Nylon 66 Sheets Impact Specific Applications?

The performance of Nylon 66 sheets can significantly affect application outcomes. For instance, in the automotive industry, components made from Nylon 66 can withstand high stress and friction, leading to improved efficiency and reduced wear. In the food processing sector, its low friction properties can enhance operational efficiency in conveyor systems. However, international buyers must consider media compatibility; for example, Nylon 66 is not recommended for applications involving strong acids or bases.

What Should International B2B Buyers Consider When Selecting Nylon 66 Sheets?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of compliance with local regulations and standards. For example, ASTM standards are commonly referenced in North America, while DIN standards are prevalent in Germany. Buyers should also consider the availability of materials in their region and the potential for supply chain disruptions. Understanding local preferences for material specifications can enhance procurement strategies and ensure successful project outcomes.

| Material | Typical Use Case for nylon 66 sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon 66 | Gears and bearings | High tensile strength and durability | Moisture absorption affects dimensions | Medium |

| Nylon 66 | Structural components | Excellent abrasion resistance | Not suitable for strong acids/bases | Medium |

| Nylon 66 | Food processing equipment | Low friction properties | Higher cost compared to alternatives | High |

| Nylon 66 | Electrical insulation parts | Thermal stability | Limited chemical resistance | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for nylon 66 sheet

What Are the Key Stages in the Manufacturing Process of Nylon 66 Sheets?

The manufacturing process of Nylon 66 sheets involves several critical stages that ensure the final product meets both quality and performance standards. Understanding these stages is crucial for B2B buyers who seek reliability and consistency in their supply chains.

Material Preparation

The first step in the manufacturing process is the preparation of the raw materials. Nylon 66 is produced through the polymerization of hexamethylenediamine and adipic acid, resulting in a high-performance polymer. The raw materials are sourced from reputable suppliers to ensure they meet the necessary quality standards. This stage may also include the drying of the nylon granules to reduce moisture content, which is essential for optimal processing.

Forming Techniques: How Is Nylon 66 Sheet Formed?

Once the materials are prepared, the next stage involves forming the nylon sheets. The most common techniques include:

-

Extrusion: This is the primary method used for producing Nylon 66 sheets. The nylon granules are heated and melted, then forced through a die to form sheets of various thicknesses. The extrusion process allows for continuous production and results in uniform thickness and properties across the sheet.

-

Casting: In some cases, casting methods are employed, where the molten nylon is poured into molds. This technique can produce thicker sheets but is less common than extrusion due to higher costs and longer production times.

-

Calendering: This method involves passing the nylon material through a series of rollers to achieve the desired thickness and smoothness. Calendering can enhance surface characteristics, making the sheets suitable for specific applications.

Finishing Processes: What Are the Final Steps?

After the forming stage, the sheets undergo finishing processes to enhance their properties. This may include cutting the sheets to specified dimensions, surface treatments to improve chemical resistance, and surface polishing to achieve a smooth finish. Additionally, sheets can be colored or coated based on customer requirements, which is particularly relevant for applications in industries like automotive and consumer goods.

What Quality Assurance Measures Are Implemented During Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for Nylon 66 sheets. It ensures that the final products meet the required specifications and industry standards.

International Standards for Quality Control

International standards such as ISO 9001 play a significant role in the quality assurance processes of manufacturers. Compliance with ISO 9001 indicates that a company has established a robust quality management system (QMS) that focuses on continuous improvement, customer satisfaction, and adherence to regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE marking for European markets or API standards for the oil and gas industry may apply. These certifications ensure that the products meet specific safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

To maintain quality throughout the manufacturing process, several checkpoints are implemented:

-

Incoming Quality Control (IQC): This initial stage involves inspecting the raw materials upon arrival. Suppliers must provide certificates of analysis (CoA) that detail the material specifications, and these are verified against industry standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to ensure that the production parameters are within the specified limits. This can include monitoring temperature, pressure, and thickness of the extruded sheets.

-

Final Quality Control (FQC): After manufacturing, the final product undergoes comprehensive testing. Common methods include mechanical property testing, dimensional checks, and visual inspections to identify any surface defects.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating in international markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for ensuring product reliability.

Conducting Supplier Audits

One effective way to verify a supplier’s quality control processes is through supplier audits. These audits can be conducted by the buying company or through third-party organizations. During an audit, buyers can assess the supplier’s manufacturing processes, quality management systems, and compliance with international standards.

Reviewing Quality Reports and Certifications

Buyers should request and review quality reports, including test results and compliance certifications. These documents provide insights into the supplier’s adherence to quality standards and their manufacturing capabilities.

Engaging Third-Party Inspection Services

Third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. These services typically involve on-site inspections and testing of the products before shipment, providing an additional layer of assurance for B2B buyers.

What Are the Unique Quality Control Considerations for International Buyers?

International B2B buyers must navigate various quality control nuances based on their region. For instance, regulatory requirements may differ significantly between Europe and the Middle East. Buyers must ensure that their suppliers comply with local regulations and international standards relevant to their industry.

Additionally, cultural differences can impact quality expectations and communication. Establishing clear specifications and maintaining open lines of communication with suppliers can help mitigate misunderstandings and ensure that quality standards are consistently met.

In conclusion, understanding the manufacturing processes and quality assurance measures for Nylon 66 sheets is vital for B2B buyers. By familiarizing themselves with these processes and implementing thorough verification methods, buyers can ensure they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nylon 66 sheet’

To facilitate an efficient and effective procurement process for nylon 66 sheets, this guide outlines essential steps that B2B buyers should follow. Each step is designed to ensure that you make informed decisions that align with your business needs and compliance requirements.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the nylon 66 sheets you need. Consider factors such as thickness, dimensions, color, and any specific properties like abrasion resistance or thermal stability. This step is crucial as it helps narrow down potential suppliers and ensures that the materials meet your operational needs.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to compile a list of suppliers that specialize in nylon 66 sheets. Focus on suppliers with a proven track record in your industry. Key aspects to consider include:

– Industry Experience: Look for suppliers with extensive experience in supplying nylon sheets to businesses similar to yours.

– Client Reviews and Testimonials: Check online reviews or request references to gauge customer satisfaction and reliability.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; instead:

– Ask for Samples: Request material samples to assess quality firsthand.

– Inquire About Certifications: Verify if the suppliers hold relevant certifications that affirm product quality and compliance with safety standards.

Step 4: Assess Pricing and Payment Terms

Gather quotes from multiple suppliers to understand the market pricing for nylon 66 sheets. When evaluating pricing, consider the following:

– Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

– Payment Terms: Review payment options and terms, including any upfront payments or credit terms that could impact your cash flow.

Step 5: Verify Compliance and Safety Standards

Ensure that the suppliers comply with international safety and environmental regulations. This is particularly important for materials that may involve hazardous substances. Key actions include:

– Request Material Safety Data Sheets (MSDS): These documents provide critical information on the safety and handling of the materials.

– Check for Compliance Certifications: Verify that the supplier meets local and international standards relevant to your industry.

Step 6: Finalize the Contract and Delivery Terms

Once you’ve selected a supplier, negotiate and finalize the contract. Pay attention to:

– Delivery Schedules: Clearly outline delivery timelines to avoid operational delays.

– Return and Warranty Policies: Understand the terms related to returns or defective products to mitigate risks.

Step 7: Plan for Quality Control and Follow-Up

Establish a quality control process to monitor the nylon 66 sheets upon arrival. Consider:

– Inspection Procedures: Develop a checklist for inspecting the sheets to ensure they meet your specifications.

– Supplier Communication: Maintain open lines of communication with your supplier for any future orders or issues that may arise.

By following this checklist, B2B buyers can streamline their sourcing process for nylon 66 sheets, ensuring that they select the right materials from reputable suppliers that meet their business requirements.

Comprehensive Cost and Pricing Analysis for nylon 66 sheet Sourcing

What Are the Key Cost Components in Sourcing Nylon 66 Sheets?

When sourcing nylon 66 sheets, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include:

-

Materials: The raw material cost for nylon 66 is a significant portion of the total expense. Prices can fluctuate based on the global market for petrochemicals, which directly influences nylon production.

-

Labor: Labor costs vary depending on the region of manufacturing. Countries with lower labor costs may offer more competitive pricing, but it’s essential to consider the skill level and expertise of the workforce, which can impact the quality of the final product.

-

Manufacturing Overhead: This includes utilities, maintenance, and general operational costs associated with the production facility. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: If customization is required, tooling costs can add up quickly. Investing in high-quality tooling can lead to better precision and reduced waste, ultimately affecting the overall price.

-

Quality Control (QC): Ensuring that the nylon sheets meet specific standards involves additional costs related to testing and inspection. This is particularly important for industries that require certifications, such as aerospace or food processing.

-

Logistics: Shipping and handling costs vary greatly depending on the distance, method of transport, and size of the order. Understanding Incoterms can help clarify who bears the costs and risks during transit.

-

Margin: Suppliers will typically include a profit margin that reflects the market demand and competition. This can vary widely between suppliers and regions.

What Influences the Pricing of Nylon 66 Sheets?

Several factors influence the pricing of nylon 66 sheets, which international B2B buyers must consider:

-

Volume/MOQ: Purchasing in bulk often leads to discounts. Suppliers may have a minimum order quantity (MOQ) that affects pricing strategies. Negotiating favorable terms based on anticipated demand can yield cost savings.

-

Specifications and Customization: Custom dimensions, colors, or grades can significantly affect pricing. Standard sizes are generally less expensive than custom orders, which require additional processing.

-

Material Quality and Certifications: Higher quality materials or those with specific certifications (e.g., FDA compliance) often come at a premium. Buyers should evaluate whether the added cost aligns with their application needs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer better warranties and customer service but might charge higher prices.

-

Incoterms: Understanding Incoterms is vital for calculating total landed costs. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping costs and risks, which can influence the overall price.

How Can Buyers Optimize Costs When Sourcing Nylon 66 Sheets?

To achieve cost-efficiency when sourcing nylon 66 sheets, consider the following tips:

-

Negotiate Wisely: Establishing long-term relationships with suppliers can lead to better pricing and terms. Don’t hesitate to negotiate based on volume, payment terms, or future orders.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as durability, maintenance, and performance in your specific applications. A slightly higher upfront cost may result in lower lifetime costs.

-

Evaluate Regional Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing from local suppliers may reduce shipping costs and lead times. Additionally, consider regional economic conditions that may affect pricing.

-

Be Aware of Pricing Nuances: Different regions may have varying price structures due to local market conditions, tariffs, or trade agreements. Understanding these nuances can help in making informed sourcing decisions.

Disclaimer on Indicative Prices

Prices for nylon 66 sheets can vary significantly based on the aforementioned factors. The information provided here is for indicative purposes only and should be verified with suppliers for accurate and current pricing.

Alternatives Analysis: Comparing nylon 66 sheet With Other Solutions

Understanding the Importance of Alternative Solutions

In the dynamic landscape of industrial materials, businesses often face the challenge of selecting the most suitable solution for their operational needs. Nylon 66 sheets are renowned for their strength, durability, and versatility, making them a popular choice in various applications. However, understanding viable alternatives can provide valuable insights for B2B buyers, enabling them to make informed decisions that best align with their specific requirements.

Comparison Table of Nylon 66 Sheet and Alternatives

| Comparison Aspect | Nylon 66 Sheet | Polycarbonate Sheet | Acetal Sheet |

|---|---|---|---|

| Performance | High strength, excellent wear resistance, low friction | High impact resistance, good clarity | Excellent dimensional stability, low friction |

| Cost | Moderate to high | Moderate | Moderate to high |

| Ease of Implementation | Easy to machine and fabricate | Requires specialized tools for cutting | Easily machined with standard tools |

| Maintenance | Low maintenance, resistant to wear | Moderate, can scratch easily | Low maintenance, excellent durability |

| Best Use Case | Heavy-duty applications, gears, bearings | Safety shields, light covers | Precision parts, fittings, valves |

Detailed Breakdown of Alternatives

Polycarbonate Sheet

Polycarbonate sheets are an excellent alternative to nylon 66, particularly in applications requiring high impact resistance and transparency. Their robustness makes them suitable for safety shields and protective covers. However, while they offer good strength, they can be prone to scratching, which may require additional maintenance or protective measures. Additionally, their cost is comparable to nylon 66, making them a viable option for businesses that prioritize impact resistance over wear resistance.

Acetal Sheet

Acetal, also known as polyoxymethylene (POM), is another strong contender in the industrial materials market. It boasts excellent dimensional stability and low friction properties, making it ideal for precision components such as fittings and valves. The ease of machining acetal with standard tools allows for efficient production processes. On the downside, acetal may not perform as well in high-temperature environments compared to nylon 66, which may limit its applicability in certain industries. Its cost is typically on par with nylon 66, providing a balanced option for precision engineering needs.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right material for your business applications, it is crucial to assess the specific requirements of your projects. Nylon 66 sheets excel in heavy-duty applications where wear resistance and strength are paramount. However, if your needs lean towards high impact resistance, polycarbonate may be the better choice. Alternatively, for precision engineering applications, acetal sheets offer excellent stability and machining properties. By carefully evaluating performance, cost, ease of implementation, and maintenance needs, B2B buyers can ensure they make the most informed decision tailored to their operational goals.

Essential Technical Properties and Trade Terminology for nylon 66 sheet

What Are the Key Technical Properties of Nylon 66 Sheet?

When considering Nylon 66 sheets for industrial applications, several critical technical properties are essential for B2B buyers to understand. These properties not only influence the performance of the material but also its suitability for specific applications.

-

Material Grade: Nylon 66, also known as PA66, is a high-performance engineering plastic. The grade of the nylon can affect its strength, durability, and thermal stability. For businesses, selecting the appropriate grade is crucial for ensuring that the material can withstand the specific stresses of its intended application, whether in automotive, aerospace, or manufacturing sectors.

-

Thickness and Tolerance: The thickness of Nylon 66 sheets can vary, typically ranging from 0.030 inches to over 4 inches. Tolerance refers to the allowable deviation from specified dimensions. Precise tolerances are essential for applications requiring exact fit and functionality, such as in precision machining. A reliable supplier will provide sheets with consistent thickness and tight tolerances, which can minimize waste and rework costs.

-

Mechanical Properties: Key mechanical properties include tensile strength, impact resistance, and elongation at break. Nylon 66 exhibits high tensile strength and excellent abrasion resistance, making it suitable for heavy-duty applications. Understanding these properties helps B2B buyers assess whether the material will meet the demands of their specific use cases.

-

Thermal Stability: Nylon 66 has a high melting point, typically around 250°C (482°F). This property is crucial for applications involving heat exposure, as it ensures the material maintains its integrity under high temperatures. For industries such as automotive and electronics, thermal stability is a non-negotiable requirement.

-

Chemical Resistance: Nylon 66 is generally resistant to a variety of chemicals, which is vital for applications in environments where exposure to oils, greases, and solvents is common. Understanding the chemical resistance properties can assist buyers in selecting the right material for specific operational conditions, thus reducing the risk of premature failure.

-

Low Friction Coefficient: The low coefficient of friction of Nylon 66 makes it an ideal choice for applications requiring smooth operation, such as gears, bearings, and other moving components. This property can lead to improved performance and reduced wear in mechanical systems, which is particularly important for OEMs looking to enhance product longevity.

What Are Common Trade Terms in the Nylon 66 Sheet Market?

Navigating the purchasing process for Nylon 66 sheets involves understanding several key industry terms that facilitate communication and transactions between buyers and suppliers.

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for B2B buyers looking to source Nylon 66 sheets that meet specific design requirements for their products.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest number of units a supplier is willing to sell. For international buyers, particularly those in Africa and South America, knowing the MOQ helps in budgeting and inventory planning, ensuring that they do not overcommit financially.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Issuing an RFQ for Nylon 66 sheets allows buyers to compare offers from different suppliers, ensuring they secure the best price and terms available.

-

Incoterms (International Commercial Terms): Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, risk, and insurance. Familiarity with Incoterms is essential for B2B buyers to ensure they understand who is responsible for costs at various stages of the shipping process.

-

Lead Time: This term refers to the time it takes from placing an order to receiving the product. For businesses operating on tight schedules, understanding lead times for Nylon 66 sheets is critical to maintaining production timelines and avoiding delays.

-

Custom Fabrication: This term refers to the process of modifying standard Nylon 66 sheets to meet specific dimensions or features required by the buyer. Knowledge of custom fabrication capabilities is beneficial for buyers seeking tailored solutions for unique applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Nylon 66 sheets, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the nylon 66 sheet Sector

What Are the Key Market Dynamics and Trends Influencing the Nylon 66 Sheet Sector?

The nylon 66 sheet market is witnessing transformative dynamics driven by technological advancements, evolving industrial applications, and global supply chain shifts. A significant driver is the increasing demand for lightweight, high-strength materials across industries such as automotive, aerospace, and manufacturing. International B2B buyers are particularly focused on sourcing nylon 66 sheets that offer superior mechanical properties, such as high abrasion resistance and thermal stability, which are essential for applications in harsh environments.

Emerging B2B technology trends, including online procurement platforms and digital supply chain management tools, are reshaping sourcing strategies. Buyers from regions like Africa, South America, the Middle East, and Europe (notably Germany and Saudi Arabia) are leveraging these technologies to streamline their purchasing processes, enabling them to access a wider array of suppliers and products. Additionally, the rise of just-in-time (JIT) inventory systems is encouraging buyers to procure nylon 66 sheets in smaller, more frequent batches, enhancing flexibility and reducing storage costs.

Market dynamics are also influenced by geopolitical factors and trade agreements, which can impact the availability and pricing of raw materials. For instance, fluctuations in oil prices affect the production costs of nylon, a petrochemical product. Buyers must remain vigilant regarding these external factors, as they can significantly influence procurement strategies and cost structures.

How Can Sustainability and Ethical Sourcing Impact B2B Purchasing Decisions?

Sustainability and ethical sourcing are becoming paramount in the nylon 66 sheet sector. Environmental concerns are driving B2B buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes sourcing materials from manufacturers that have adopted eco-friendly production techniques, which reduce waste and energy consumption. Buyers are increasingly seeking products that not only meet their performance needs but also align with their corporate social responsibility goals.

The importance of ethical supply chains cannot be overstated. Companies are now more accountable for the environmental and social impacts of their sourcing decisions. Certifications such as ISO 14001 for environmental management and other green certifications are becoming essential criteria for evaluating suppliers. Buyers from Europe, particularly Germany, are leading the charge in demanding transparency and sustainability in their supply chains, pushing suppliers to innovate in material sourcing and production methods.

In addition, the adoption of recycled or bio-based nylon options is gaining traction. These materials help mitigate the environmental impact associated with conventional nylon production. By choosing suppliers who offer sustainable alternatives, international B2B buyers can enhance their market reputation while contributing to a circular economy.

What Is the Evolution of the Nylon 66 Sheet Market and Its Relevance for Today’s B2B Buyers?

The nylon 66 sheet market has evolved significantly since its introduction in the mid-20th century. Originally utilized in the textile industry, nylon 66 has expanded into various applications due to its remarkable strength, durability, and resistance to wear and chemicals. Over the decades, advancements in manufacturing techniques have improved the material’s properties and broadened its applications, making it a preferred choice in sectors such as automotive, aerospace, and electronics.

Today, the evolution of nylon 66 sheets is closely tied to advancements in material science and technology. Innovations in extrusion techniques have allowed for the production of high-performance sheets with tailored specifications, catering to specific industry requirements. This evolution is particularly relevant for B2B buyers, as it provides them with a diverse range of options to meet their unique application needs, from heavy-duty structural components to precision-engineered parts.

As the market continues to grow, international buyers must stay informed about ongoing developments and trends within the nylon 66 sector. Understanding the historical context and technological advancements can provide valuable insights into sourcing strategies and supplier partnerships, ultimately driving business success in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of nylon 66 sheet

-

How do I solve issues related to the durability of nylon 66 sheets?

To ensure the durability of nylon 66 sheets, choose high-quality materials from reputable suppliers who provide comprehensive product specifications and certifications. Regularly assess the operating conditions, such as temperature and load, to avoid exceeding the material’s limits. Implement routine maintenance and inspection protocols to identify wear and tear early. Additionally, consider using nylon 66 in applications that align with its properties, such as resistance to abrasion and impact, to maximize longevity. -

What is the best thickness of nylon 66 sheet for heavy-duty applications?

For heavy-duty applications, a thickness of at least 0.375 inches (9.525 mm) is often recommended. Thicker sheets provide enhanced strength and durability, making them suitable for applications requiring high wear resistance and structural integrity. It’s also advisable to evaluate specific project requirements, such as load-bearing capacity and environmental conditions, to select the most appropriate thickness. Consulting with suppliers for tailored solutions can also yield optimal results. -

How can I vet suppliers of nylon 66 sheets for international trade?

When vetting suppliers, consider their industry reputation, years of experience, and certifications such as ISO or ASTM standards. Request references from previous clients and assess their production capabilities, including quality control processes. Review their delivery timelines and responsiveness to inquiries. Conducting a site visit or utilizing third-party inspection services can also provide insights into their operational standards, ensuring they meet your requirements for reliability and quality. -

What are the typical minimum order quantities (MOQ) for nylon 66 sheets?

MOQs for nylon 66 sheets can vary significantly depending on the supplier and the specific product specifications. Generally, MOQs may range from 50 to 100 kg or more. It’s essential to discuss your needs with potential suppliers to understand their policies. Some suppliers may offer flexibility for smaller orders, especially if they are looking to build long-term relationships or if you can combine orders to meet MOQ requirements. -

What payment terms are common for international purchases of nylon 66 sheets?

Common payment terms in international trade include 30% to 50% upfront payment with the balance due upon shipment or delivery. Some suppliers may offer net 30 or net 60 days for established customers. It’s crucial to negotiate terms that align with your cash flow and operational needs while ensuring clarity in the purchase agreement to avoid disputes. Consider using secure payment methods such as letters of credit for larger transactions to mitigate risks. -

How do I ensure quality assurance (QA) for nylon 66 sheets?

To ensure QA, request detailed product specifications and certifications from suppliers. Implement a rigorous inspection process upon receipt of materials, checking for compliance with agreed standards. Establish a quality control plan that includes regular testing for mechanical properties and dimensional accuracy. Collaborating with suppliers who have robust QA processes can also enhance product reliability, reducing the risk of defects in your applications. -

What logistics considerations should I be aware of when importing nylon 66 sheets?

Logistics considerations include understanding import regulations, duties, and taxes in your country. Ensure that your supplier provides adequate shipping documentation, including customs declarations and bills of lading. Plan for potential delays by discussing lead times with the supplier and considering local transportation options upon arrival. Working with experienced freight forwarders can streamline the import process, ensuring compliance and timely delivery. -

Can I customize nylon 66 sheets for specific applications?

Yes, nylon 66 sheets can often be customized in terms of dimensions, thickness, color, and additional properties such as additives for enhanced performance. Many suppliers offer custom fabrication services to meet unique project requirements. When discussing customization, provide detailed specifications and, if possible, samples of the intended application to ensure that the final product meets your needs. Collaboration with suppliers during the design phase can lead to better outcomes and improved functionality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Nylon 66 Sheet Manufacturers & Suppliers List

1. Curbell Plastics – Nylon Type 6/6 Rods

Domain: curbellplastics.com

Registered: 2000 (25 years)

Introduction: Nylon Type 6/6, available in natural and black colors, offered in various diameters and lengths. Key product options include:

– Diameter options: 0.187 in, 0.25 in, 0.312 in, 0.375 in, 0.437 in, 0.5 in

– Length options: 5 ft, 10 ft

– Prices range from $3.77 to $143.91 depending on size.

2. Interstate Plastics – Nylon 6 6 Extruded Sheet

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “Nylon 6 6 Extruded Sheet”, “Price per Sheet”: “$25.15”, “Total Price”: “$25.15”, “Thickness Options”: [0.060, 0.090, 0.125, 0.187, 0.250, 0.312, 0.375, 0.500, 0.625, 0.750, 1.000, 1.250, 1.500, 2.000], “Fabrication Setup Fee”: “$65”, “Edge Options”: {“Rounded/Chamfered Edges (45 degrees)”: “$8”}, “Rounded Corner Options”: {“None”: “$0”, “1/2”: “$5”, “3/4”: “$5”, “1”: “$5”, “1-1/2…

3. ePlastics – Nylon Sheet

Domain: eplastics.com

Registered: 1998 (27 years)

Introduction: This company, ePlastics – Nylon Sheet, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

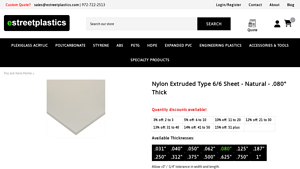

4. eStreet Plastics – Nylon Extruded Type 6/6 Sheet

Domain: estreetplastics.com

Registered: 2004 (21 years)

Introduction: {“Product Name”: “Nylon Extruded Type 6/6 Sheet – Natural – .080″ Thick”, “Product Code”: “X-910008”, “Available Thicknesses”: [“.031”, “.040”, “.050”, “.062”, “.080”, “.125”, “.187”, “.250”, “.312”, “.375”, “.500”, “.625”, “.750”, “1”], “Size Options”: [{“Dimensions”: “12” x 12″”, “Price”: “$8.99”}, {“Dimensions”: “12” x 24″”, “Price”: “$17.99”}, {“Dimensions”: “24” x 24″”, “Price”: “$33.99”}, {“…

5. Professional Plastics – Nylon Sheets & Rods

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: NYLON Sheet & Nylon Rod – Order Online. Leader in Plastic Sheets, Rods, Tubing, Profiles, & Parts since 1984. Nylon – EXTRUDED, Nylon 6/6 UNFILLED. Available materials include Plexiglass Sheet, PEEK Sheets & Rod, Cast Acrylic Sheet, Polycarbonate Sheets, HDPE Sheets, Acetal Sheet & Rod, UHMW Sheet & Rod, and Vespel SP-1. Top Selling Materials include ABS, Acetal / Delrin®, Acrylic / Plexiglass, an…

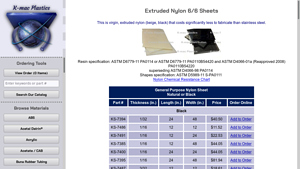

6. KMAC Plastics – Nylon 6/6 Sheets

Domain: kmac-plastics.net

Registered: 2012 (13 years)

Introduction: Nylon 6/6 Sheets, Extruded, .031 to 4.00 Inch Thick. Available in virgin extruded nylon (beige, black). Cost-effective alternative to stainless steel. Resin specifications: ASTM D6779-11 PA0114, ASTM D6779-11 PA0110B54420, ASTM D4066-01a (Reapproved 2008) PA0110B54220, ASTM D4066-98 PA0114. Shapes specification: ASTM D5989-11 S-PA0111. Chemical resistance chart available. Various part numbers, thi…

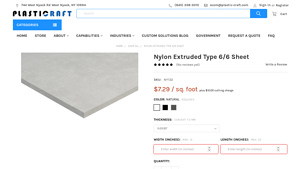

7. Plastic Craft – Nylon Extruded Type 6/6 Sheet

Domain: plastic-craft.com

Registered: 1997 (28 years)

Introduction: {‘product_name’: ‘Nylon Extruded Type 6/6 Sheet’, ‘SKU’: ‘NY132’, ‘UPC’: ”, ‘MPN’: ”, ‘type’: ‘Extruded Type 6/6’, ‘shape’: ‘Sheet’, ‘price’: {‘now’: ‘$0.00’, ‘was’: ”}, ‘color’: ”, ‘thickness_options’: [‘0.03125″‘, ‘0.04″‘, ‘0.05″‘, ‘0.0625″‘, ‘0.09375″‘, ‘0.125″‘, ‘0.1875″‘, ‘0.25″‘, ‘0.3125″‘, ‘0.375″‘, ‘0.5″‘, ‘0.625″‘, ‘0.75″‘, ‘0.875″‘, ‘1″‘, ‘1.25″‘, ‘1.5″‘, ‘1.75″‘, ‘2″‘, ‘2.5″‘, ‘3″‘]…

Strategic Sourcing Conclusion and Outlook for nylon 66 sheet

As the demand for nylon 66 sheets continues to rise across diverse industries, strategic sourcing emerges as a critical factor for international B2B buyers. Key takeaways include the material’s exceptional strength, low friction, and abrasion resistance, which make it a suitable alternative to metals and rubber in various applications, from construction to electronics. By leveraging strategic sourcing practices, businesses can optimize their supply chains, ensuring access to high-quality materials while managing costs effectively.

Furthermore, understanding regional market dynamics is essential for buyers in Africa, South America, the Middle East, and Europe. Engaging with reliable suppliers who offer customized solutions can enhance operational efficiency and product performance. As the global market evolves, buyers are encouraged to stay informed about advancements in nylon technology and sustainability practices, which are becoming increasingly important in procurement decisions.

Looking ahead, international B2B buyers should embrace a proactive approach to sourcing nylon 66 sheets. By fostering partnerships with reputable suppliers, companies can ensure they remain competitive in a rapidly changing landscape. Now is the time to act—invest in strategic sourcing to unlock the full potential of nylon 66 for your business needs.