Contents

Manufacturing Insight: Normalize Steel

Optimizing Steel Components Through Precision Normalization and CNC Machining

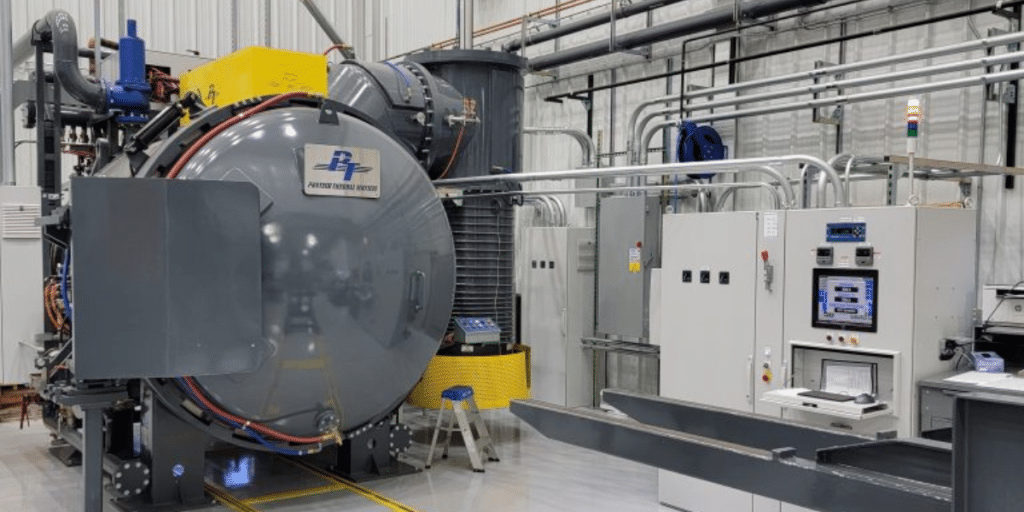

Normalization is a critical thermal processing step for steel alloys that refines grain structure, eliminates internal stresses, and enhances machinability—directly impacting the dimensional stability and surface integrity of precision-machined components. At Honyo Prototype, we integrate this controlled heat treatment seamlessly with our advanced CNC machining capabilities to ensure your steel parts meet stringent aerospace, medical, and industrial tolerances. Unlike post-machining stress relief, our in-house normalization process occurs prior to cutting, preventing distortion during high-precision operations and delivering consistent microstructural homogeneity across complex geometries.

Our CNC machining services leverage this optimized material state to achieve ±0.005mm tolerances on normalized 4140, 1045, and 4340 steels, supported by real-time process monitoring and ISO 9001-certified workflows. By controlling the full spectrum from thermal treatment to final inspection, we eliminate supply chain delays and quality variances inherent in outsourcing heat treatment. This integrated approach reduces scrap rates by up to 30% for clients producing load-bearing shafts, hydraulic manifolds, and tooling fixtures where material predictability is non-negotiable.

Accelerate your prototyping or low-volume production timeline with Honyo’s Online Instant Quote system. Upload CAD files to receive geometry-aware pricing and lead time estimates for normalized steel machining within minutes—not days—enabling faster design validation and production ramp-up.

Technical Capabilities

Material Selection Guide for Normalized Steel and Common Machining Materials in Precision 3/4/5-Axis Milling and Turning Applications

Normalized steel refers to carbon or alloy steel that has undergone a heat treatment process involving heating the material above its upper critical temperature, holding it at that temperature, and then air-cooling to room temperature. This process refines the grain structure, improves mechanical properties, and enhances machinability, making it ideal for tight-tolerance CNC machining operations.

Below is a comparison of normalized steel with other commonly machined materials—aluminum, steel (general), ABS, and nylon—focusing on suitability for high-precision 3-, 4-, and 5-axis milling and turning processes where tight tolerances (±0.0005″ to ±0.005″) are required.

| Material | Form Condition | Typical Tensile Strength (psi) | Hardness (Brinell / Rockwell) | Machinability Rating (Relative) | Dimensional Stability | Thermal Stability | Common Applications in Precision Machining |

|---|---|---|---|---|---|---|---|

| Normalized Steel (e.g., 4140, 1045) | Annealed/Normalized | 90,000 – 120,000 | 170–220 HB / ~15–25 HRC | Moderate (60–70% of free-machining steel) | High | Moderate | Tooling, fixtures, structural components requiring strength and precision |

| Aluminum (e.g., 6061-T6, 7075-T6) | T6 Temper or Annealed | 45,000 – 83,000 | 95–150 HB / ~5–15 HRC | Excellent (90–100%) | High (with proper stress relief) | Low to Moderate | Aerospace, enclosures, lightweight precision parts |

| Tool Steel (e.g., A2, D2) | Annealed | 80,000 – 100,000 | 200–240 HB / ~20–28 HRC | Poor to Moderate | High (after heat treat) | High (post-stabilization) | Molds, dies, high-wear tooling |

| ABS (Acrylonitrile Butadiene Styrene) | Extruded or Cast Sheet | 6,000 – 7,500 | 95–105 Shore D | Excellent | Moderate (prone to creep) | Low (high thermal expansion) | Prototypes, jigs, non-structural housings |

| Nylon (Polyamide, e.g., PA6, PA66) | Cast or Extruded | 9,000 – 12,000 | 80–85 Shore D | Good | Low to Moderate (hygroscopic) | Low (absorbs moisture, expands) | Bushings, gears, low-friction components |

Key Notes on Machining Performance:

Normalized steel provides a balanced combination of strength, machinability, and dimensional consistency, especially when compared to fully hardened steels. Its uniform microstructure post-normalization reduces internal stresses, which is critical when achieving tight tolerances in multi-axis milling and complex turning operations.

For 3/4/5-axis CNC processes, material stability directly impacts tool life, surface finish, and feature accuracy. Aluminum is often preferred for rapid prototyping and lightweight parts due to its high machinability and excellent chip evacuation. However, normalized steel is selected when higher strength, wear resistance, and structural integrity are required.

ABS and nylon are used in non-metallic precision applications but require careful fixturing and specialized cutting strategies due to material deflection, thermal expansion, and moisture absorption. These plastics are typically machined with sharp tools, high spindle speeds, and light cuts to maintain dimensional accuracy.

In tight-tolerance environments, material pre-conditioning (e.g., stress relieving, aging, or normalization) is essential—especially for steel and aluminum—to minimize post-machining distortion.

From CAD to Part: The Process

Clarification on Terminology and Process Integration

Normalization is a specific heat treatment process applied to steel to refine grain structure and improve mechanical properties, not a standalone phase in Honyo Prototype’s end-to-end workflow. It occurs exclusively during the Production stage when required by part specifications or material science protocols. Below is the precise integration of normalization within Honyo’s validated workflow, emphasizing technical rigor and material integrity.

Upload CAD

Clients submit detailed CAD models (STEP, IGES, or native formats) specifying material grade (e.g., AISI 1045, 4140), critical tolerances, and any heat treatment requirements. Our system auto-verifies geometric completeness and flags missing material attributes. For steel components requiring normalization, the CAD must explicitly indicate this need; otherwise, our AI engine will prompt the client during quoting.

AI Quote Generation

Honyo’s proprietary AI analyzes the CAD geometry, material selection, and dimensional complexity to generate a technical-commercial quote within 2 hours. For steel parts, the AI cross-references material databases (e.g., ASM Handbook) to:

Confirm if normalization is necessary based on steel grade and functional requirements

Estimate thermal processing time and associated costs

Flag potential risks (e.g., distortion in thin-walled sections post-normalization)

Quotes include explicit line items for heat treatment if applicable, with ASTM A830 or ISO 630 compliance noted.

DFM (Design for Manufacturability) Review

Our engineering team conducts a formal DFM assessment, focusing on steel-specific manufacturability. For normalization-bound parts, we validate:

Section thickness uniformity to prevent uneven cooling rates

Fixture requirements to minimize warpage during thermal cycling

Compatibility with subsequent processes (e.g., machining after normalization)

Required post-normalization hardness testing (e.g., Rockwell B scale per ASTM E18)

Clients receive a DFM report with actionable recommendations, including normalization parameter justification (e.g., soak temperature 890°C ±10°C for 1045 steel).

Production Execution

Normalization is executed here under strict process controls:

1. Pre-heat inspection: Verify steel batch certification (mill test reports) and initial hardness

2. Thermal processing:

Heat to austenitizing temperature (material-dependent, e.g., 870–910°C for medium-carbon steels)

Hold for 30–60 minutes (based on cross-section thickness)

Air-cool in still atmosphere to room temperature

3. Post-heat validation:

Hardness testing at 3+ locations per part (documentation provided)

Microstructure verification via optical microscopy (if specified)

Dimensional checks for distortion (GD&T per ASME Y14.5)

All parameters are logged in our MES (Manufacturing Execution System) with traceability to heat lot numbers.

Delivery and Documentation

Final parts ship with comprehensive quality dossiers including:

Heat treatment process sheet (time-temperature profiles)

Hardness test reports (with measurement locations)

Dimensional inspection report (pre- and post-normalization)

Material certification traceability

For normalized steel, we provide microstructure analysis upon request (additional fee), ensuring compliance with aerospace (AMS 2759/2) or automotive (SAE J414) standards where applicable.

Critical Technical Note

Normalization is never an automatic step—it is triggered solely by material specifications, functional requirements, or DFM recommendations. Honyo’s workflow ensures this heat treatment is applied only when metallurgically justified, avoiding unnecessary cost or process-induced defects. Our AS9100-certified process guarantees repeatability, with normalization parameters rigorously validated against client-specified standards.

Start Your Project

To normalize steel, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, where we deliver precision thermal processing and metal fabrication services tailored to your prototyping and production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.