Contents

Manufacturing Insight: Normalization Of Steel

As Senior Manufacturing Engineer at Honyo Prototype, I emphasize that effective steel normalization is a critical prerequisite for achieving optimal results in precision CNC machining operations. This controlled heat treatment process—where steel is heated to the austenitizing temperature, held, and then cooled in still air—refines the grain structure, relieves internal stresses, and homogenizes the material. The outcome is significantly improved machinability, dimensional stability during cutting, reduced tool wear, and consistent final part properties, especially vital for complex geometries and tight-tolerance components in alloys like 4140 or 1045. At Honyo, our integrated approach ensures normalized steel stock is expertly prepared and seamlessly transitioned into our high-accuracy CNC milling and turning processes. Our engineers collaborate closely with clients to specify appropriate normalization parameters based on the steel grade and final application requirements, guaranteeing the material condition directly supports achieving micron-level tolerances and superior surface finishes. To accelerate your prototyping or low-volume production timeline, leverage our Online Instant Quote system for rapid, transparent pricing on CNC-machined parts from normalized steel, providing immediate cost visibility without compromising on our commitment to manufacturing excellence.

Technical Capabilities

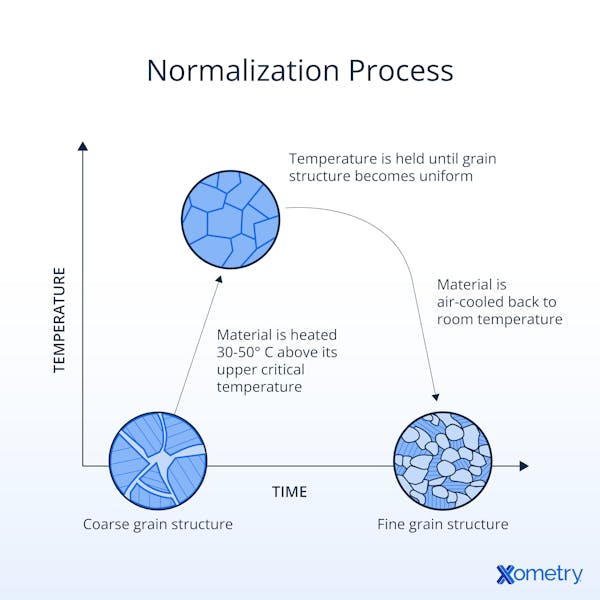

Normalization of steel is a heat treatment process used to refine the grain structure, improve mechanical properties, and enhance machinability by heating the steel to a temperature above its upper critical point (typically between 800–900°C depending on the alloy), holding it at that temperature for a sufficient time to achieve uniform austenitization, and then allowing it to cool in still air. This process reduces internal stresses and produces a more uniform microstructure, which is particularly beneficial when preparing steel components for precision machining operations such as 3/4/5-axis milling and turning, especially when tight tolerances (±0.005 mm to ±0.025 mm) are required.

While normalization is specifically applicable to ferrous materials like carbon and alloy steels, non-ferrous materials such as aluminum, and non-metallic materials like ABS and nylon, do not undergo normalization. Instead, these materials may require other forms of stress relief or annealing to achieve dimensional stability during high-precision machining.

Below is a comparison of material behavior and treatment relevance in the context of high-accuracy CNC machining:

| Material | Normalization Applicable? | Alternative Stress Relief Method | Typical Machining Process | Tight Tolerance Capability | Notes |

|---|---|---|---|---|---|

| Carbon Steel (e.g., AISI 1045) | Yes | Normalization: 850–900°C, air cool | 3/4/5-axis milling, turning | High (±0.01 mm typical) | Improves homogeneity and machinability; essential prior to precision machining to prevent distortion |

| Alloy Steel (e.g., 4140, 4340) | Yes | Normalization: 870–900°C, air cool followed by tempering | 4/5-axis milling, turning | High (±0.005 to ±0.01 mm) | Reduces residual stresses from forging; enhances dimensional stability |

| Aluminum (e.g., 6061, 7075) | No | Stress relief annealing: 300–400°C, slow cool | 3/5-axis milling | Very High (±0.005 mm achievable) | Normalization not applicable; stress relief improves stability for tight tolerance parts |

| ABS (Acrylonitrile Butadiene Styrene) | No | Post-machining annealing (if required) at 60–80°C | 3-axis milling, turning | Moderate (±0.025 mm typical) | Prone to internal stresses from molding; machining-induced stress requires careful fixturing |

| Nylon (Polyamide, e.g., PA6, PA66) | No | Annealing in water or oil after machining | Milling, turning | Moderate to High (±0.02 mm with control) | Hygroscopic; dimensional changes possible; pre- and post-machining stabilization critical |

Technical Considerations for Precision Machining:

For steel components intended for 3/4/5-axis milling and turning with tight tolerances, normalization ensures dimensional predictability and reduces the risk of warping during or after machining. This is especially critical in complex geometries where residual stresses can lead to part rejection.

In aluminum and engineering plastics like ABS and nylon, although normalization is not applicable, equivalent stress-relief procedures are often implemented to achieve similar goals: dimensional stability and repeatability in high-precision applications. Machinists must account for material-specific behaviors—such as thermal expansion in aluminum or moisture absorption in nylon—to maintain tolerance integrity.

At Honyo Prototype, we apply material-appropriate pre-treatment protocols to ensure optimal machinability and dimensional accuracy across all substrates.

From CAD to Part: The Process

Honyo Prototype applies precise metallurgical terminology within our digital manufacturing workflow. It is critical to clarify that normalization refers specifically to a heat treatment process for steel, not our general operational sequence. Our standard workflow for steel components follows the Upload CAD → AI Quote → DFM → Production → Delivery framework, with steel-specific processing integrated where required by design specifications. Below is the accurate process flow, emphasizing steel handling:

Upon CAD file upload for steel parts, our system identifies material specifications (e.g., AISI 1045, 4140). The AI quoting engine cross-references these with real-time material cost databases and thermal processing surcharges. For steel alloys requiring normalization to refine grain structure or relieve internal stresses, the quote explicitly includes this as a non-optional process step if the design lacks explicit heat treatment parameters. The AI flags potential distortion risks during normalization based on part geometry.

During DFM analysis, our engineers validate normalization requirements against the design intent. If the CAD model specifies normalized steel (e.g., “AISI 1018 normalized to 150-200 HB”), we confirm compatibility with machining tolerances. If unspecified, we assess whether normalization is necessary to prevent warpage during CNC machining. Key steel-specific DFM checks include:

| DFM Parameter | Steel-Specific Consideration | Action if Non-Compliant |

|---|---|---|

| Wall Thickness Variation | Risk of uneven cooling during normalization causing distortion | Recommend uniform cross-sections |

| Tight Tolerances (±0.005″ or less) | Normalization-induced scale may affect precision machining | Suggest post-normalization stress relief or tighter pre-normalization stock allowance |

| Welded Assemblies | Potential for residual stress concentration at joints | Require post-weld normalization cycle |

Production executes steel-specific protocols only when mandated by the design or DFM findings. For normalization, parts undergo controlled heating to 850-950°C (material-dependent), hold time based on cross-section thickness (typically 1 hour per inch), followed by still-air cooling. This occurs after rough machining but before finish machining to mitigate thermal distortion. All normalized steel batches receive traceable certification (e.g., ASTM A370 test reports) linked to the work order.

Delivery includes material test reports (MTRs) verifying normalized condition, including hardness verification (e.g., Brinell 149-207 for normalized 1045 steel) and microstructure analysis if specified. We do not apply normalization to steel components unless explicitly required by the design or jointly determined during DFM to ensure dimensional stability. Our workflow ensures steel parts meet both geometric and metallurgical specifications through this integrated approach.

Start Your Project

For inquiries regarding the normalization of steel, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring efficient processing and quality control for all heat treatment services.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.