Introduction: Navigating the Global Market for multi spindle screw machines

In today’s competitive manufacturing landscape, sourcing multi spindle screw machines poses a significant challenge for international B2B buyers. The quest for machinery that offers unparalleled productivity, precision, and flexibility is crucial, especially as industries demand higher production rates and complex machining capabilities. This guide serves as a comprehensive resource, delving into various types of multi spindle screw machines, their applications across diverse sectors, and the critical factors to consider when selecting suppliers.

From understanding the nuances of machine specifications to evaluating cost-effectiveness and potential return on investment, our guide equips businesses in Africa, South America, the Middle East, and Europe—such as Brazil and Nigeria—with the insights necessary for informed purchasing decisions. By exploring the latest advancements in multi spindle technology and the competitive landscape of suppliers, buyers can navigate the complexities of the global market with confidence.

Whether you are an established manufacturer looking to upgrade your equipment or a new player aiming to optimize production capabilities, this guide is tailored to empower you with the knowledge to make strategic investments. Understanding the features and benefits of different machines will ensure that you select the right solutions for your specific production needs, ultimately enhancing your operational efficiency and market competitiveness.

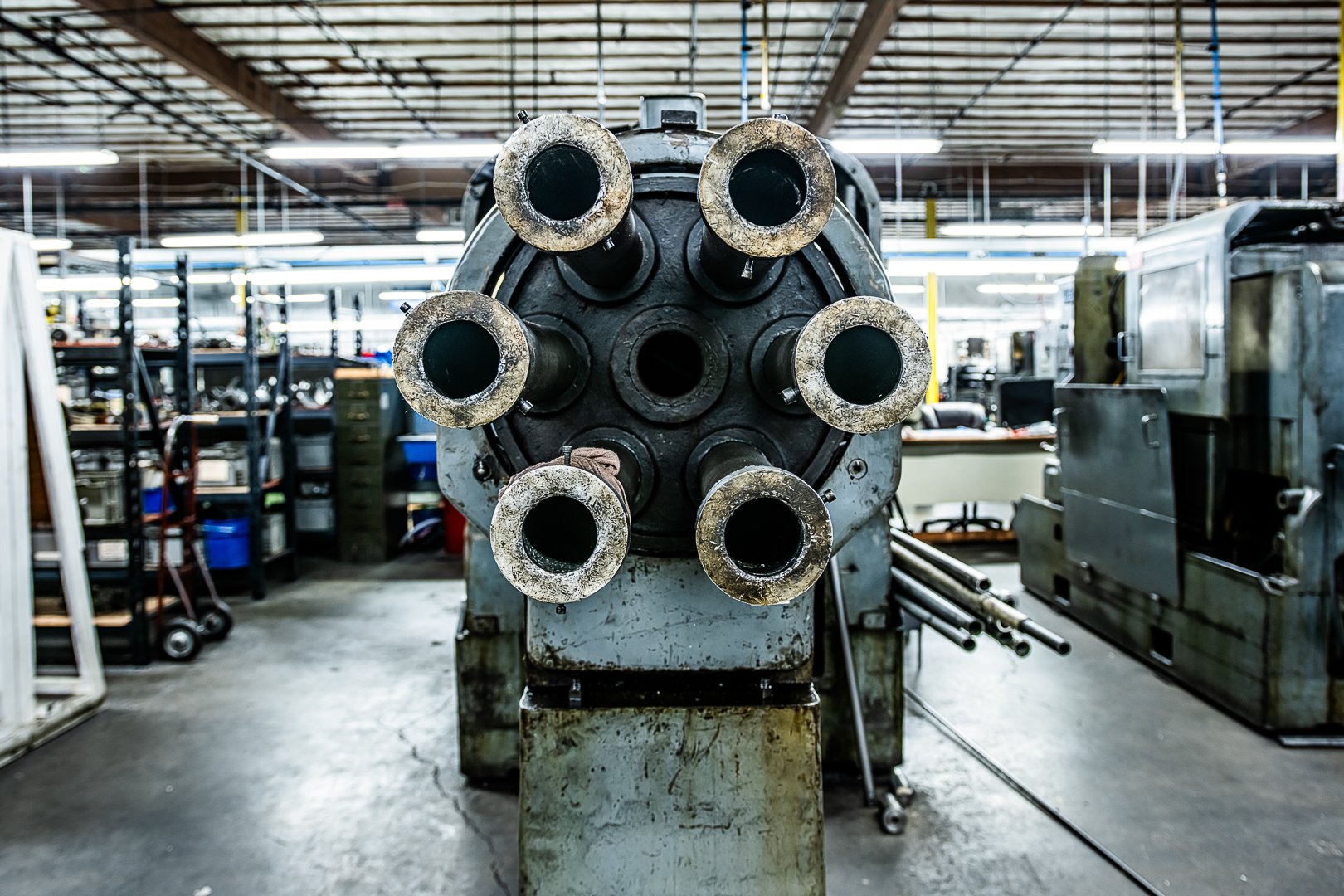

Understanding multi spindle screw machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Davenport Model B | Fastest multi-spindle machine; economical; proven design for over 130 years. | High-volume production of precision parts. | Pros: Cost-effective, reliable. Cons: Limited to simpler operations. |

| Hybrid Machine | Combines mechanical dependability with CNC precision; suitable for tough alloys. | Aerospace, automotive, and high-tech sectors. | Pros: Versatile, high precision. Cons: Higher initial investment. |

| Schütte SCX Series | Modular design; independent spindles; supports complex machining processes. | Automotive, hydraulics, and electrical components. | Pros: High flexibility, adaptable. Cons: Complex setup may require training. |

| Chucker Machines | Designed for secondary operations; integrates high precision and automation capabilities. | Manufacturing of preformed blanks and parts. | Pros: Efficient for secondary processes. Cons: Limited primary machining capabilities. |

| G Series | Focuses on small parts up to 20 mm; combines cam drive speed with CNC flexibility. | General mechanical engineering, small parts. | Pros: Fast, reliable for small components. Cons: Limited to smaller workpieces. |

What Are the Key Characteristics of the Davenport Model B Multi-Spindle Machine?

The Davenport Model B is renowned for its remarkable speed and cost-effectiveness, making it a staple in high-volume production environments. With a legacy spanning over 130 years, it is designed primarily for manufacturing precision parts quickly and efficiently. This machine excels in producing simpler components, offering buyers a reliable solution for mass production. However, its limited functionality for complex operations may deter some buyers looking for more versatile machining capabilities.

How Does the Hybrid Machine Enhance Multi-Spindle Machining?

The Hybrid Machine integrates the mechanical reliability of traditional multi-spindle designs with the precision of CNC technology. This combination allows for the machining of difficult materials, making it particularly suitable for sectors like aerospace and automotive. Buyers should consider the Hybrid for its versatility and precision, but they may need to justify the higher initial investment compared to conventional models. Its ability to handle complex parts and automatic bar loading features make it a valuable asset for modern production lines.

What Makes the Schütte SCX Series Stand Out in the Market?

The Schütte SCX Series offers a modular design with fully independent spindles, allowing it to handle a wide variety of machining processes efficiently. This flexibility makes it an excellent choice for industries such as automotive and hydraulics, where diverse and complex parts are frequently produced. While the SCX Series provides high adaptability, its sophisticated setup may require additional training for operators, which could be a consideration for businesses looking to minimize downtime.

What Are the Advantages of Using Chucker Machines?

Chucker machines are specifically designed for completing secondary operations on preformed blanks, making them an efficient choice for manufacturers focused on high-precision applications. They can be integrated with automated loading systems, enhancing productivity. While they excel in secondary processes, buyers should be aware that their primary machining capabilities are limited, which may necessitate the use of additional equipment for comprehensive manufacturing solutions.

Why Should Buyers Consider the G Series for Small Parts Production?

The G Series is tailored for the production of small turned parts, offering a unique blend of speed and reliability. This series combines the rapidity of cam drives with the flexibility of CNC technology, making it ideal for general mechanical engineering applications. Buyers will appreciate its efficiency in handling small components, but they should also be mindful that its capabilities are limited to parts with a diameter of up to 20 mm, which may not suit all production needs.

Key Industrial Applications of multi spindle screw machines

| Industry/Sector | Specific Application of multi spindle screw machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of high-volume fasteners and precision components | Increased efficiency and reduced labor costs | Machine precision, tooling options, and maintenance support |

| Aerospace | Machining complex components from high-strength alloys | Enhanced reliability and performance | Capability to handle diverse materials and tight tolerances |

| Medical Devices | Manufacturing of intricate parts like surgical instruments | High precision and compliance with regulations | Certifications, precision capabilities, and speed of production |

| Electronics | Production of small, intricate electronic connectors and housings | Faster time-to-market and reduced waste | Flexibility for small batch runs and automation integration |

| Hydraulics and Pneumatics | Fabrication of valve bodies and fittings | Cost savings through reduced cycle times | Adaptability for various part sizes and materials |

How Are Multi-Spindle Screw Machines Used in the Automotive Industry?

In the automotive sector, multi-spindle screw machines are essential for producing high-volume fasteners and precision components such as bolts, nuts, and brackets. These machines enable manufacturers to achieve significant efficiency gains, often yielding production rates four to six times higher than single-spindle alternatives. International buyers, particularly from regions like Brazil and Nigeria, should consider sourcing machines that offer precision tooling and robust maintenance support to ensure consistent output and minimize downtime.

What Role Do Multi-Spindle Machines Play in Aerospace Manufacturing?

Aerospace manufacturing relies heavily on multi-spindle screw machines for machining complex components from high-strength alloys. These machines are designed to deliver enhanced reliability and performance, crucial for meeting stringent industry standards. Buyers from Europe and the Middle East should prioritize machines capable of handling diverse materials and achieving tight tolerances, as this will ensure compliance with safety regulations and enhance the overall quality of the final products.

How Are Multi-Spindle Screw Machines Beneficial in Medical Device Production?

In the medical device industry, multi-spindle screw machines are utilized for the manufacturing of intricate parts such as surgical instruments and implantable devices. The high precision offered by these machines is vital for ensuring compliance with strict regulatory standards. Buyers should focus on sourcing machines that provide certifications, demonstrate precision capabilities, and offer fast production speeds, as these factors are critical for maintaining quality and meeting market demands.

Why Are Multi-Spindle Machines Important for Electronics Manufacturing?

In electronics, multi-spindle screw machines are employed to produce small, intricate components like connectors and housings. The ability to produce these parts rapidly allows businesses to reduce time-to-market and minimize waste. Buyers, especially in emerging markets, should seek machines that offer flexibility for small batch runs and the capacity for automation integration, which can significantly enhance production efficiency and responsiveness to market changes.

How Do Multi-Spindle Screw Machines Improve Production in Hydraulics and Pneumatics?

Multi-spindle screw machines are crucial in the hydraulics and pneumatics sectors for fabricating valve bodies and fittings. These machines streamline production processes by reducing cycle times and increasing output, leading to substantial cost savings. When sourcing machines for this application, businesses should consider the adaptability of the equipment for various part sizes and materials, ensuring they can meet diverse production requirements efficiently.

3 Common User Pain Points for ‘multi spindle screw machines’ & Their Solutions

Scenario 1: High Setup Time Hindering Production Efficiency

The Problem: One of the primary challenges B2B buyers encounter with multi-spindle screw machines is the lengthy setup time required for changing production runs. This can be particularly problematic in industries where rapid shifts between product types are necessary, such as automotive or electronics. Each time a new part is introduced, operators must recalibrate the machine, which can lead to significant downtime. In regions like Africa and South America, where operational efficiency is paramount to compete in global markets, this issue becomes even more pressing.

The Solution: To mitigate the impact of extended setup times, buyers should consider investing in multi-spindle machines with advanced CNC interfaces that allow for quicker changeovers. Features such as tool holders that can be pre-loaded or quick-change tooling systems can drastically reduce the time spent on setups. Moreover, investing in training for operators on these advanced systems can enhance their skill in performing rapid changeovers. Buyers should also evaluate suppliers that offer robust technical support and training programs, ensuring that their teams are well-equipped to handle machine adjustments swiftly and effectively.

Scenario 2: Difficulty in Achieving Precision with Complex Parts

The Problem: As industries increasingly demand complex geometries and tighter tolerances, many B2B buyers struggle to achieve the desired precision with traditional multi-spindle screw machines. This is especially true for manufacturers in sectors like aerospace and medical devices, where precision is critical. The inability to meet these exact specifications not only affects product quality but can also lead to significant financial losses due to rework or scrap.

The Solution: To address precision challenges, buyers should look for multi-spindle machines that incorporate advanced technologies such as live tooling and multi-axis capabilities. Machines with independent spindles and compound slides can perform complex operations in a single setup, thereby reducing the likelihood of errors and enhancing accuracy. Buyers should also consider sourcing machines from manufacturers that offer comprehensive customization options to tailor the machine to specific production needs. Engaging with suppliers who have experience in high-precision machining can provide valuable insights and recommendations for optimizing operations to meet stringent tolerances.

Scenario 3: Limited Flexibility for Low-Volume Production Runs

The Problem: Many manufacturers rely on multi-spindle screw machines for high-volume production but find themselves ill-equipped to handle lower-volume runs or custom orders. This lack of flexibility can lead to missed opportunities in markets where customer demand is shifting towards smaller batch sizes, particularly in Europe and the Middle East where customization is becoming a standard expectation.

The Solution: To enhance flexibility, B2B buyers should consider hybrid multi-spindle machines that combine the robust capabilities of traditional setups with the adaptability of CNC technology. These machines can efficiently switch between high-volume runs and lower-volume custom jobs, allowing businesses to respond rapidly to market changes. Additionally, establishing partnerships with machine tool suppliers that offer modular attachments and auxiliary equipment can further enhance the flexibility of production lines. Buyers should also explore options for leasing or renting equipment for short-term projects, thereby maintaining operational agility without significant capital investment.

Strategic Material Selection Guide for multi spindle screw machines

What Materials are Commonly Used in Multi-Spindle Screw Machines?

When selecting materials for multi-spindle screw machines, several factors come into play, including performance properties, cost, and suitability for specific applications. Below is an analysis of four common materials used in this context, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Steel Perform in Multi-Spindle Screw Machines?

Key Properties: Steel is known for its high tensile strength and durability, making it suitable for high-pressure applications. It also offers good machinability and can withstand considerable wear and tear.

Pros & Cons: The primary advantage of steel is its robustness, which translates to longer tool life and reduced downtime. However, steel can be susceptible to corrosion if not properly treated, which may lead to increased maintenance costs. Additionally, while it is relatively cost-effective, the manufacturing complexity can increase with specific alloys.

Impact on Application: Steel is compatible with a variety of media, including oils and coolants used in machining processes. However, its corrosion susceptibility may limit its use in environments where exposure to moisture or corrosive substances is prevalent.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards such as ASTM or DIN for steel grades. Availability of specific alloys may vary, impacting lead times and costs.

What Role Does Aluminum Play in Multi-Spindle Screw Machines?

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance and thermal conductivity. It is also easier to machine compared to steel, allowing for faster production rates.

Pros & Cons: The lightweight nature of aluminum makes it ideal for applications requiring reduced weight, such as in aerospace components. However, its lower tensile strength compared to steel can be a limitation in high-stress applications. Additionally, while aluminum can be more expensive than some steel variants, its ease of machining can offset costs in high-volume production.

Impact on Application: Aluminum is often used in applications where weight savings are critical, such as automotive and aerospace. Its compatibility with various coolants and lubricants makes it suitable for diverse machining environments.

Considerations for International Buyers: In regions like the Middle East and Europe, compliance with standards such as JIS for aluminum alloys is crucial. Buyers should also consider the availability of specific grades that meet their application requirements.

Why Choose Brass for Multi-Spindle Screw Machines?

Key Properties: Brass is a copper-zinc alloy known for its excellent machinability and corrosion resistance. It has good thermal and electrical conductivity, making it suitable for electrical components.

Pros & Cons: The primary advantage of brass is its machinability, allowing for intricate designs and high production rates. However, brass can be more expensive than steel and aluminum, which may impact overall project budgets. Additionally, while it resists corrosion, it may not perform well in high-stress environments.

Impact on Application: Brass is commonly used in applications requiring electrical conductivity, such as connectors and fittings. Its compatibility with various media makes it versatile for different machining processes.

Considerations for International Buyers: Buyers should be aware of the specific brass grades required for their applications and ensure compliance with international standards like ASTM B16. Availability may vary by region, affecting procurement strategies.

How Does Stainless Steel Compare in Multi-Spindle Screw Machines?

Key Properties: Stainless steel is known for its exceptional corrosion resistance, strength, and durability. It can withstand high temperatures and pressures, making it suitable for demanding applications.

Pros & Cons: The key advantage of stainless steel is its longevity and resistance to corrosion, which reduces maintenance costs over time. However, it is generally more expensive than regular steel and can be more challenging to machine, potentially increasing production costs.

Impact on Application: Stainless steel is ideal for applications in the medical, food, and aerospace industries, where hygiene and corrosion resistance are paramount. Its compatibility with various media, including aggressive chemicals, makes it a preferred choice in many sectors.

Considerations for International Buyers: Compliance with international standards such as ASTM and EN is crucial when sourcing stainless steel. Buyers should also consider the specific grades required for their applications, as availability may differ across regions.

Summary Table of Material Selection for Multi-Spindle Screw Machines

| Material | Typical Use Case for multi spindle screw machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-pressure components in automotive and aerospace | High durability and strength | Susceptible to corrosion | Medium |

| Aluminum | Lightweight parts in aerospace and automotive | Excellent corrosion resistance | Lower tensile strength | Medium |

| Brass | Electrical connectors and fittings | Excellent machinability | Higher cost than steel | High |

| Stainless Steel | Medical and food industry applications | Exceptional corrosion resistance | More expensive and harder to machine | High |

This analysis provides a comprehensive overview of material selection considerations for multi-spindle screw machines, helping international B2B buyers make informed decisions based on performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for multi spindle screw machines

What Are the Main Stages of Manufacturing Multi-Spindle Screw Machines?

The manufacturing process for multi-spindle screw machines encompasses several key stages that ensure precision and efficiency. These stages include material preparation, forming, assembly, and finishing, each critical to achieving the desired quality and performance of the final product.

How is Material Prepared for Multi-Spindle Screw Machines?

Material preparation is the foundational step in the manufacturing process. It involves selecting high-quality raw materials, typically metal alloys like steel or aluminum, which are essential for durability and precision. The materials are cut into manageable sizes, often in the form of bars, which will be fed into the machine. This stage may also include processes like heat treatment to enhance material properties, ensuring they can withstand the rigors of machining.

What Techniques Are Used in the Forming Stage?

During the forming stage, the prepped materials are placed in the multi-spindle machine. The machine’s multiple spindles allow for simultaneous operations on several workpieces, drastically increasing production efficiency. Key techniques in this stage include:

- Turning: The primary operation where the material is rotated against cutting tools to achieve the desired shape and dimensions.

- Drilling and Tapping: These operations create holes and threaded inserts as required by the design specifications.

- Secondary Operations: Using tools for additional processes like milling or threading, which may be integrated into the machine for efficiency.

The ability to perform multiple operations in one cycle not only reduces production time but also minimizes handling, which can lead to errors.

How is Assembly Conducted in Multi-Spindle Manufacturing?

Assembly in multi-spindle screw machine manufacturing typically involves the integration of various components produced during the forming stage. This may include the assembly of intricate parts or subassemblies that require precise alignment. Some machines are designed to automate this process, reducing manual labor and increasing consistency.

The assembly stage also focuses on ensuring that all components meet the specified tolerances, which is vital for the overall functionality of the machine.

What Finishing Processes Are Important for Multi-Spindle Machines?

Finishing processes are essential for enhancing the aesthetics and functionality of the final product. Common techniques include:

- Deburring: Removing sharp edges and burrs left from machining to ensure safety and proper fitting.

- Surface Treatment: Processes like plating, anodizing, or coating to improve corrosion resistance and surface finish.

- Quality Inspection: A final quality check to ensure that all specifications are met before the product is shipped.

These finishing touches are crucial for the machine’s performance and longevity, particularly in demanding applications like aerospace or automotive manufacturing.

What Quality Assurance Measures Are in Place for Multi-Spindle Screw Machines?

Quality assurance (QA) is a critical component in the manufacturing of multi-spindle screw machines, ensuring that products meet both international and industry-specific standards.

Which International Standards Are Relevant for Quality Assurance?

International standards such as ISO 9001 play a significant role in quality management systems across manufacturing sectors. This standard emphasizes the need for a systematic approach to quality management, focusing on customer satisfaction and continual improvement.

In addition to ISO 9001, industry-specific certifications such as CE marking (for compliance with European health, safety, and environmental protection standards) and API (American Petroleum Institute) standards for equipment used in oil and gas industries are crucial. These certifications provide assurance that the products meet rigorous safety and performance criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several critical checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial step assesses the quality of raw materials before they are used in production. Suppliers are often required to provide certificates of compliance to confirm that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators conduct regular inspections to ensure that the machines are functioning correctly and that the parts being produced meet dimensional specifications.

-

Final Quality Control (FQC): Once production is complete, a thorough inspection is conducted to verify that the final product adheres to all specifications and standards. This may include dimensional checks, surface finish assessments, and functional testing.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers adhere to rigorous quality control practices. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their quality management systems and processes. This can include reviewing their certifications, inspecting their facilities, and assessing their QC practices.

-

Request Quality Reports: Suppliers should be able to provide detailed quality reports, including data from IQC, IPQC, and FQC processes. This documentation should outline any defects found and corrective actions taken.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures. These inspections can help validate compliance with international standards and industry-specific requirements.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control. Variations in regulatory standards, shipping practices, and local manufacturing capabilities can affect product quality.

Buyers should be particularly aware of:

-

Regulatory Compliance: Different regions may have specific regulations that affect quality standards. Understanding local requirements can prevent costly compliance issues.

-

Cultural Differences in Quality Expectations: Different markets may have varying perceptions of quality. It’s essential for buyers to communicate their quality expectations clearly to suppliers.

-

Supply Chain Transparency: Establishing a transparent supply chain can help buyers monitor the quality of components throughout the manufacturing process, from material sourcing to final assembly.

By focusing on these areas, B2B buyers can effectively navigate the complexities of international manufacturing and quality assurance in the multi-spindle screw machine market, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘multi spindle screw machines’

Introduction

Sourcing multi-spindle screw machines requires a careful approach to ensure that you invest in the right equipment for your production needs. This guide provides a systematic checklist to help international B2B buyers navigate the complexities of purchasing these high-precision machines. By following these steps, you can minimize risks and maximize efficiency in your procurement process.

Step 1: Define Your Technical Specifications

Before beginning your search, it’s essential to clearly outline the technical specifications required for your production. Consider factors such as the type of materials you will be machining, the complexity of parts, and the expected production volumes. This clarity will help you communicate your needs effectively to potential suppliers.

- Material Compatibility: Ensure the machine can handle the materials you plan to use, especially if they are difficult to machine.

- Part Complexity: Determine if you need capabilities for complex machining processes like C and Y-axis movements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in multi-spindle screw machines. Look for companies with a strong reputation in your target regions, such as Africa, South America, the Middle East, and Europe.

- Industry Experience: Focus on suppliers with extensive experience and a proven track record in your industry.

- Product Range: Evaluate the variety of machines offered to ensure they meet your specifications.

Step 3: Evaluate Supplier Certifications

Before finalizing your choice, verify that suppliers hold relevant certifications that guarantee quality and safety standards. Certifications such as ISO 9001 demonstrate a commitment to quality management.

- Quality Assurance: Check if the supplier adheres to international manufacturing standards.

- Sustainability Practices: Consider suppliers who follow environmentally friendly practices, which can be crucial in today’s market.

Step 4: Assess Machine Features and Capabilities

Examine the specific features of the machines offered by suppliers. Look for advanced capabilities like CNC interfaces, hybrid technology, and precision tolerances, which can significantly enhance productivity.

- Cycle Times: Investigate the average cycle times of the machines to determine their efficiency.

- Flexibility: Assess how easily the machine can be adapted for different part types or production volumes.

Step 5: Request Demonstrations and Samples

Before making a purchase, request demonstrations or samples of the machines in action. This step allows you to see firsthand how the equipment performs and meets your requirements.

- Live Demonstrations: Arrange for on-site demonstrations if possible, or request video demonstrations.

- Sample Parts: Ask for sample parts produced by the machines to evaluate quality and precision.

Step 6: Review After-Sales Support and Warranty

Strong after-sales support is crucial for minimizing downtime and ensuring smooth operations post-purchase. Review the warranty terms and the availability of technical support.

- Service Agreements: Inquire about service agreements that cover maintenance and repairs.

- Training Options: Check if the supplier offers training for your staff on machine operation and maintenance.

Step 7: Compare Costs and Financing Options

Finally, analyze the total cost of ownership, including initial purchase price, maintenance, and operational costs. Explore financing options that can facilitate your investment.

- Hidden Costs: Look for any additional costs related to installation, training, or spare parts.

- Leasing vs. Buying: Consider whether leasing the machine might be a more feasible option based on your financial situation.

By following this checklist, you will be well-equipped to make an informed decision when sourcing multi-spindle screw machines tailored to your production needs.

Comprehensive Cost and Pricing Analysis for multi spindle screw machines Sourcing

What Are the Key Cost Components in Sourcing Multi-Spindle Screw Machines?

Understanding the cost structure of multi-spindle screw machines is crucial for B2B buyers seeking to optimize their procurement strategies. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality alloys and specialty materials used in precision machining can lead to increased expenses. It’s essential to balance material quality with cost-effectiveness to ensure durability and performance.

-

Labor: Labor costs are influenced by the complexity of the machine and the skill level required for assembly and maintenance. Skilled technicians are necessary for high-precision machines, which can raise labor costs. It is advisable to consider the availability of skilled labor in your region when evaluating total costs.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and administrative costs. Efficient production processes can help minimize overhead, thus reducing the final price of the machines.

-

Tooling: Tooling costs can vary based on the specific requirements of the machines. Custom tooling designed for unique applications may incur higher initial costs but can improve production efficiency and reduce cycle times.

-

Quality Control (QC): Implementing rigorous quality control processes adds to the cost but is essential for ensuring that the machines meet industry standards and specifications. This is particularly important for industries like aerospace and automotive, where precision is paramount.

-

Logistics: Transportation and handling costs can vary significantly based on the machine’s size and weight. International shipping considerations, such as customs duties and taxes, should also be factored into the overall cost.

-

Margin: Suppliers will add a profit margin based on their operational costs and market positioning. Understanding the margin expectations can aid in negotiations.

How Do Price Influencers Affect Multi-Spindle Screw Machine Costs?

Several factors can influence the pricing of multi-spindle screw machines:

-

Volume/MOQ: Manufacturers often offer lower prices per unit for larger orders. Understanding the minimum order quantities (MOQ) can help buyers negotiate better pricing structures.

-

Specifications and Customization: Custom features or specifications can lead to higher costs. Buyers should clearly define their needs to avoid unnecessary expenses while still achieving desired functionality.

-

Material Quality and Certifications: Machines made from high-grade materials or those that come with certifications (e.g., ISO, CE) typically command higher prices. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The reputation and experience of the supplier can also impact pricing. Established suppliers may charge more due to their reliability and customer service, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: The terms of shipping and delivery defined by Incoterms can significantly affect total costs. Understanding whether costs include shipping, insurance, and duties is crucial for accurate budgeting.

What Buyer Tips Can Help in Negotiating Prices for Multi-Spindle Screw Machines?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Wisely: Use your knowledge of market prices and competitor offerings to negotiate better terms. Understanding the supplier’s flexibility can lead to cost reductions.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also maintenance, tooling, and operational costs over the machine’s life cycle. This holistic view can help justify a higher upfront investment for a machine that offers lower long-term costs.

-

Understand Pricing Nuances: Be aware that pricing can vary significantly based on geographic location, economic conditions, and local market demand. Buyers should conduct thorough market research to ensure they are getting competitive pricing.

-

Evaluate Supplier Relationships: Building a long-term relationship with suppliers can lead to better pricing and terms. Suppliers may offer discounts for repeat business or loyalty.

Disclaimer on Indicative Prices

While this analysis provides a framework for understanding costs and pricing, actual prices for multi-spindle screw machines can vary widely based on specific requirements, configurations, and market conditions. Buyers are encouraged to obtain detailed quotes from multiple suppliers to ensure a comprehensive understanding of potential costs.

Alternatives Analysis: Comparing multi spindle screw machines With Other Solutions

Understanding Alternatives to Multi-Spindle Screw Machines

When evaluating manufacturing solutions, it’s crucial to consider various alternatives that can meet production demands efficiently. Multi-spindle screw machines are renowned for their high productivity and precision in producing complex parts. However, alternative technologies may offer specific advantages depending on the application, production volume, and operational context. This section will compare multi-spindle screw machines with two viable alternatives: CNC Turning Machines and Single-Spindle Lathes.

Comparison Table

| Comparison Aspect | Multi Spindle Screw Machines | CNC Turning Machines | Single-Spindle Lathes |

|---|---|---|---|

| Performance | High throughput, suitable for mass production with fast cycle times. | Versatile with high precision; suitable for complex geometries and varied batch sizes. | Lower throughput; ideal for small batch production with simple parts. |

| Cost | Higher initial investment but lower cost per part in high volume. | Moderate initial cost; higher operational costs per part compared to multi-spindle machines. | Lower initial investment; cost-effective for small production runs. |

| Ease of Implementation | Requires skilled operators; setup may be complex but is efficient for large runs. | Easier to program; adaptable for different part designs but may require frequent retooling. | Simple setup and operation; less training required for operators. |

| Maintenance | Generally low due to robust design but may require specialized technicians. | Moderate maintenance needs; easier access to parts may reduce downtime. | Low maintenance; simpler technology leads to fewer issues. |

| Best Use Case | High-volume production of identical parts in automotive, aerospace, and medical industries. | Complex parts requiring precision in various industries, including aerospace and medical. | Small to medium production runs of less complex components in various sectors. |

Detailed Breakdown of Alternatives

CNC Turning Machines

CNC turning machines are highly versatile and capable of producing complex geometries with precision. They utilize computer numerical control to automate the machining process, allowing for intricate designs that may be challenging for multi-spindle machines. While they have a moderate initial cost and can handle various batch sizes, operational costs can increase for high-volume production due to slower cycle times compared to multi-spindle solutions. CNC machines are best suited for industries that require flexibility and precision, such as aerospace and medical device manufacturing.

Single-Spindle Lathes

Single-spindle lathes are the most straightforward alternative, ideal for low-volume production and simpler components. They offer a lower initial investment, making them attractive for smaller businesses or those just entering the manufacturing sector. However, their throughput is significantly lower than that of multi-spindle machines, making them less suitable for high-volume applications. Single-spindle lathes excel in scenarios where part complexity is low, and production runs are small, such as in prototyping or custom machining tasks.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right manufacturing solution requires a careful assessment of your specific production needs, including volume, complexity, and budget. Multi-spindle screw machines are excellent for high-volume production where speed and efficiency are paramount. In contrast, CNC turning machines offer flexibility for complex designs, while single-spindle lathes provide a cost-effective solution for smaller runs. By analyzing these factors, B2B buyers can make informed decisions that align with their operational goals and market demands, ultimately enhancing their competitiveness in the global landscape.

Essential Technical Properties and Trade Terminology for multi spindle screw machines

What Are the Key Technical Properties of Multi-Spindle Screw Machines?

Multi-spindle screw machines are engineered to deliver high productivity and precision in manufacturing. Understanding their technical properties is crucial for B2B buyers looking to optimize their production processes. Here are some essential specifications:

-

Spindle Count: The number of spindles (typically ranging from 5 to 9) directly impacts productivity. More spindles allow for simultaneous operations on multiple workpieces, significantly increasing output. For high-volume production, a machine with more spindles can yield production levels 4 to 6 times higher than single-spindle machines.

-

Cycle Time: This refers to the time it takes to complete one full operation cycle. Multi-spindle machines, such as those from Davenport, boast some of the fastest cycle times in the industry. Reduced cycle times lead to lower operational costs and improved efficiency, making it a critical factor for manufacturers focused on maximizing throughput.

-

Tolerance Levels: Precision is paramount in industries like aerospace and automotive. Multi-spindle machines are capable of achieving tight tolerances, often within ±0.001 inches or better, depending on the material and machining process. High tolerance levels ensure product quality and reduce waste, which is essential for maintaining competitive pricing.

-

Material Compatibility: These machines can handle a variety of materials, including aerospace alloys and plastics. The ability to process different materials is vital for manufacturers who need flexibility in their production lines. It allows businesses to diversify their product offerings without investing in multiple machines.

-

CNC Integration: Many modern multi-spindle machines come equipped with CNC (Computer Numerical Control) capabilities. This technology enhances precision and allows for complex part designs, which can be crucial for industries that require intricate components. CNC integration also facilitates easier programming and setup, reducing lead times for new product runs.

-

Footprint: The physical space a machine occupies can impact operational efficiency, especially in facilities with limited floor space. Many advanced multi-spindle machines are designed to have a smaller footprint without compromising on productivity. This feature allows businesses to optimize their manufacturing layout and increase overall efficiency.

What Are Common Trade Terms Used in Multi-Spindle Screw Machine Transactions?

Understanding industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some key terms related to multi-spindle screw machines:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable sources for spare parts and components.

-

MOQ (Minimum Order Quantity): This is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory and cash flow effectively, especially when dealing with high-cost machinery.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to invite them to bid on specific products or services. This process helps buyers gather pricing and terms, enabling them to make informed purchasing decisions.

-

Incoterms: Short for International Commercial Terms, these are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers negotiate shipping costs and clarify liability during transit.

-

Lead Time: This refers to the time it takes from placing an order to receiving the goods. Understanding lead times is vital for production planning and inventory management, as delays can impact overall operations.

-

Secondary Operations: These are additional manufacturing processes that may be required after the initial machining, such as drilling or milling. Recognizing the need for secondary operations can help buyers evaluate the total cost of ownership and operational efficiency of their machinery.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions regarding multi-spindle screw machines, ultimately enhancing their production capabilities and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the multi spindle screw machines Sector

What Are the Key Market Drivers and Trends in Multi-Spindle Screw Machines?

The global market for multi-spindle screw machines is witnessing significant growth, driven by increasing demand for high-volume, precision-engineered components across various industries such as automotive, aerospace, medical, and electronics. The shift towards automation and Industry 4.0 technologies is revolutionizing manufacturing processes, enabling companies to enhance productivity and reduce operational costs. The integration of CNC capabilities into multi-spindle machines allows for greater flexibility and precision, catering to the complex requirements of modern manufacturing.

Emerging trends indicate a growing preference for hybrid machines that combine the mechanical reliability of traditional multi-spindle designs with advanced digital controls. This convergence of technologies is appealing to international B2B buyers seeking to optimize their production lines while minimizing downtime. Additionally, as global supply chains continue to evolve, companies are increasingly focusing on sourcing machines that offer adaptability to various materials and production volumes. Markets in Africa, South America, the Middle East, and Europe are particularly poised for growth due to their expanding manufacturing sectors and the need for efficient, high-speed machining solutions.

How Does Sustainability Impact Sourcing Multi-Spindle Screw Machines?

Sustainability is becoming a pivotal consideration in the sourcing of multi-spindle screw machines. The environmental impact of manufacturing processes, particularly concerning energy consumption and waste generation, is under scrutiny from both regulatory bodies and consumers. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, including the use of ‘green’ certifications and environmentally friendly materials in their manufacturing processes.

Investing in machines that are designed for energy efficiency not only helps reduce operational costs but also aligns with global sustainability goals. Manufacturers are responding by developing machines that consume less energy and generate less waste during production. Furthermore, ethical sourcing practices are gaining traction, with buyers looking for suppliers who maintain transparent supply chains and prioritize worker welfare. This trend is particularly relevant for international markets, where local regulations may mandate higher sustainability standards.

How Have Multi-Spindle Screw Machines Evolved Over Time?

The evolution of multi-spindle screw machines dates back over a century, with significant advancements transforming them into the high-precision tools they are today. Initially, these machines were simple mechanical devices designed for basic turning operations. However, as manufacturing needs became more complex, the machines evolved to incorporate multiple spindles, allowing for simultaneous machining of parts, significantly enhancing productivity.

The introduction of CNC technology marked a pivotal point in this evolution, enabling greater precision and flexibility in machining operations. Modern multi-spindle machines now feature advanced capabilities, such as independent spindle control, which allows for the machining of intricate components with varying specifications. This evolution not only reflects advancements in technology but also the changing demands of the global market, where efficiency and precision are paramount. Today, leading manufacturers offer a diverse range of multi-spindle screw machines, catering to the needs of various industries while ensuring fast cycle times and minimal setup changes.

Frequently Asked Questions (FAQs) for B2B Buyers of multi spindle screw machines

-

How do I choose the right multi-spindle screw machine for my production needs?

Selecting the right multi-spindle screw machine involves evaluating your production volume, part complexity, and material types. Assess your specific requirements, such as cycle times and precision tolerances. It’s essential to consider the machine’s flexibility to adapt to various part designs and the availability of auxiliary attachments. Additionally, consult with manufacturers to explore the capabilities of different models, such as those with CNC interfaces or high-precision features, to ensure the machine aligns with your operational goals. -

What are the advantages of using multi-spindle screw machines over single-spindle machines?

Multi-spindle screw machines offer significant productivity advantages, yielding production levels 4 to 6 times higher than single-spindle counterparts. They are designed to perform multiple operations simultaneously, drastically reducing cycle times and increasing efficiency for high-volume production. The ability to handle complex machining processes with precision makes them ideal for industries like automotive and aerospace. Furthermore, modern multi-spindle machines can also incorporate CNC technology, enhancing their versatility and adaptability to various manufacturing demands. -

What customization options are available for multi-spindle screw machines?

Many manufacturers offer customization options to cater to specific production needs. Customizations can include specialized tooling, enhanced spindle configurations, and additional auxiliary attachments for secondary operations. It’s advisable to discuss your unique requirements with potential suppliers to understand the extent of customization they provide. This can include adapting the machine for specific materials or part sizes, which is particularly important for industries that demand precision and flexibility. -

What is the minimum order quantity (MOQ) for multi-spindle screw machines?

The MOQ for multi-spindle screw machines can vary significantly depending on the manufacturer and specific machine models. Generally, established manufacturers may have a higher MOQ, particularly for custom builds, while others may offer flexibility for smaller quantities. It’s advisable to engage directly with suppliers to negotiate terms that suit your purchasing power and production timeline. Understanding your projected demand can help you communicate effectively with manufacturers regarding your needs. -

What payment terms should I expect when purchasing multi-spindle screw machines?

Payment terms can vary widely based on the supplier and the transaction size. Common terms include a deposit upon order confirmation, followed by the balance before shipment. Some suppliers may offer financing options or extended payment plans, especially for larger orders. Always clarify payment terms upfront and consider negotiating terms that align with your cash flow requirements. Understanding the implications of payment terms on delivery schedules is crucial for effective financial planning. -

How can I ensure quality assurance when sourcing multi-spindle screw machines?

To ensure quality assurance, it’s vital to conduct thorough research on potential suppliers. Look for manufacturers with established reputations and certifications in quality management systems, such as ISO 9001. Request documentation of previous projects and customer testimonials to gauge their reliability. Additionally, consider visiting the manufacturing facility or requesting a factory acceptance test (FAT) before shipment to verify that the machine meets your specifications and quality standards. -

What logistics considerations should I keep in mind when importing multi-spindle screw machines?

When importing multi-spindle screw machines, consider factors such as shipping methods, customs duties, and delivery timelines. Engage with logistics providers experienced in handling industrial machinery to ensure proper handling and compliance with import regulations. Understanding the total landed cost, including shipping, insurance, and taxes, is critical for accurate budgeting. Additionally, coordinate with your supplier regarding packaging and shipping methods to minimize the risk of damage during transit. -

How do I vet potential suppliers of multi-spindle screw machines?

Vetting potential suppliers involves a multi-step approach: research their market reputation, check for industry certifications, and evaluate their experience in producing multi-spindle machines. Request references from previous clients and inquire about their after-sales support and service capabilities. It’s also beneficial to assess their production capacity and lead times. Engaging in direct conversations to discuss your needs can provide insights into their responsiveness and willingness to support your business objectives.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Multi Spindle Screw Machines Manufacturers & Suppliers List

1. Davenport Machine – Multi-Spindle Screw Machines

Domain: davenportmachine.com

Registered: 1996 (29 years)

Introduction: This company, Davenport Machine – Multi-Spindle Screw Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Schütte USA – Multi-Spindle Automatic Machines

Domain: schutteusa.com

Registered: 2008 (17 years)

Introduction: Multi-Spindle Automatic Machines from Schütte USA offer a comprehensive lineup with over 135 years of innovation. Key features include: high-precision spindle drum positioning with a 3-part Hirth coupling, complex machining processes with C and Y axis capabilities, flexibility with a range of auxiliary attachments, and robustness for difficult materials. Product range caters to various industries …

3. Cox Manufacturing – Acme Gridley Multi-Spindle Screw Machines

Domain: coxmanufacturing.com

Registered: 2003 (22 years)

Introduction: Acme Gridley Multi-Spindle Screw Machines are known for their reliability and productivity in the turned parts industry. They come in four, six, and eight spindle configurations, making them suitable for high volume production runs. The machines excel in producing parts from materials such as brass, aluminum, stainless steels, and titanium. The bar capacity ranges from small 7/16″ models to large …

4. MYLAS – MY-TURN GT42/52 CNC Turning Center

Domain: mylascnc.com

Registered: 2018 (7 years)

Introduction: CNC Multi-tasking Turning Center Machine: Double Spindle Single Turret with Simple Sub Tool System MY-TURN GT42/52. Features include: Double Spindles, BMT 12 station turret, 4 gang tools, superimposed cutting for fast cycle times. Front machining capabilities: BMT 45, 12 Stations, up to 24 Tools, 7.5/11 kW Spindle Power, 55 mm Through Hole. Back machining: GT42 supports 4 x 20 mm ID Tools; GT52 su…

5. Machine Tools – Multiple Spindle Automatic Screw Machines

Domain: machinetools.com

Registered: 1995 (30 years)

Introduction: This company, Machine Tools – Multiple Spindle Automatic Screw Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Practical Machinist – Multi-Spindle Screw Machine Rates

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: Hourly rates for multi-spindle screw machines vary, with some shops on the east coast charging around $100 per hour for Acme Gridley machines. A larger machine shop owner mentioned that CNC multi-spindles can run at $120 per hour, as they are used for higher-end parts. The discussion also highlights the interest in Acme and Wickman machines for larger diameter parts, and the challenges of utilizin…

7. Hastings Machine – Multi-Spindle Screw Machining

Domain: hastingsmachine.com

Registered: 1999 (26 years)

Introduction: Multi-Spindle Screw Machining utilizes Acme-Gridley multi-spindle screw machines. Capable of producing products with material diameters ranging from 1/4″ to 2-3/4″. Features 6 and 8 spindle flexibility, allowing for machining of most features on one piece of equipment, which minimizes cost and cycle time. Profile capabilities include round, hex, and square shapes. Material capabilities include Col…

Strategic Sourcing Conclusion and Outlook for multi spindle screw machines

The landscape of multi-spindle screw machines is evolving rapidly, driven by the demand for precision, speed, and efficiency across various industries. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding the unique capabilities of multi-spindle machines, such as those from Davenport and Schütte, is crucial for optimizing production processes. These machines not only enhance productivity with reduced cycle times but also provide flexibility to adapt to diverse manufacturing needs.

Strategic sourcing plays a pivotal role in ensuring that businesses select the right equipment tailored to their specific production requirements. By investing in advanced multi-spindle machines, companies can significantly reduce operational costs while maximizing output. Moreover, the integration of CNC technology and automation in these machines allows for handling complex machining tasks with ease, ensuring high-quality production.

As global markets continue to expand, now is the time for international buyers to leverage the capabilities of multi-spindle screw machines. Engaging with reputable manufacturers and suppliers will empower businesses to stay ahead of the competition. Explore the latest offerings and consider how multi-spindle technology can transform your operations for a more efficient and productive future.