Contents

Manufacturing Insight: Multi Spindle Cnc

Honyo Prototype: Precision Multi-Spindle CNC Machining for High-Volume Production Excellence

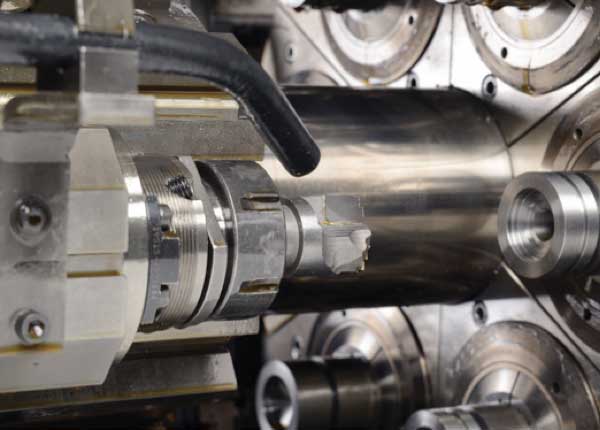

Honyo Prototype delivers industry-leading CNC machining services engineered for clients demanding exceptional precision, accelerated throughput, and cost efficiency in high-mix, high-volume production environments. Our advanced multi-spindle CNC capabilities represent a strategic advantage for manufacturers seeking to overcome traditional bottlenecks in complex component manufacturing. Unlike conventional single-spindle systems, Honyo’s multi-spindle CNC platforms perform simultaneous machining operations across multiple workpieces or features, drastically reducing cycle times while maintaining micron-level tolerances. This technology is particularly transformative for industries such as medical device manufacturing, aerospace subsystems, and automotive precision components, where part complexity, material integrity, and delivery speed are non-negotiable.

Our dedicated fleet of state-of-the-art multi-spindle CNC machines—including 4-spindle and 8-spindle configurations—integrates synchronized milling, turning, and drilling processes within a single setup. This eliminates cumulative handling errors, minimizes secondary operations, and ensures unparalleled repeatability across production runs. Honyo’s engineering team leverages proprietary fixture designs and adaptive toolpath strategies to maximize spindle utilization, translating directly into 200%+ productivity gains versus traditional methods without compromising surface finish or geometric accuracy. Material versatility spans titanium, stainless steel, aluminum alloys, and engineered plastics, all processed under stringent ISO 9001-controlled workflows.

For engineering and procurement teams evaluating production scalability, Honyo streamlines decision-making with an Online Instant Quote portal. Upload CAD files to receive a comprehensive, no-obligation machining assessment within hours—not days—including detailed cost breakdowns, lead time projections, and process recommendations tailored to multi-spindle optimization. This digital transparency empowers rapid validation of project feasibility while highlighting immediate opportunities for cost and time reduction. Partner with Honyo Prototype to transform your high-volume precision manufacturing challenges into competitive advantages, backed by decades of CNC innovation and responsive engineering collaboration. Calculate your project ROI today through our instant quoting system and experience the Honyo difference in operational excellence.

Technical Capabilities

Multi-Spindle CNC Technical Specifications

Multi-spindle CNC machines are engineered for high-efficiency precision machining, integrating multiple spindles to perform simultaneous operations across multiple workpieces or features. These systems are particularly suited for high-volume production environments requiring tight tolerances and complex geometries in materials such as aluminum, steel, ABS, and nylon. Below are the key technical specifications focused on 3/4/5-axis milling, turning capabilities, and tight tolerance performance.

| Feature | Specification |

|---|---|

| Spindle Configuration | 2 to 8 independent spindles (commonly 4 or 6), each with full 3-axis or multi-axis control depending on model |

| Axis Configuration | Simultaneous 3-axis, 4-axis (rotary B or C-axis), or 5-axis (dual rotary: A/B or B/C) on each spindle station |

| Spindle Speed Range | 8,000 – 24,000 RPM (high-speed ceramic or HSK spindles for precision) |

| Positioning Accuracy | ±0.002 mm (±0.00008″) |

| Repeatability | ±0.001 mm (±0.00004″) |

| Tolerance Capability | Achieves tight tolerances down to ±0.005 mm (±0.0002″) on critical dimensions |

| Tool Capacity per Spindle | 12–30 tools (depending on model), automatic tool changers (ATC) with < 2 sec tool swap |

| Control System | Siemens 840D, Fanuc 31i, or Heidenhain TNC7 with multi-channel synchronization |

| Work Envelope (Typical per Spindle) | X: 200–400 mm, Y: 150–300 mm, Z: 180–250 mm; optional extended beds for larger setups |

| Rotary Axis Range (4/5-Axis) | A-axis: ±120°, B-axis: ±360° continuous; C-axis: 360° indexing or continuous |

| Maximum Material Compatibility | Aluminum (6061, 7075), Steel (1018, 4140, stainless), Engineering Plastics (ABS, Nylon 6/66, PEEK, Delrin) |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar), mist and flood options |

| Chip Management | Automated chip conveyors, sealed enclosures to protect spindles and guideways |

| Surface Finish Capability | Ra 0.4–1.6 µm (16–63 µin) achievable with fine milling and polishing cycles |

| Production Throughput | 3–6x faster than single-spindle systems due to parallel processing |

| Machine Rigidity | Cast iron or polymer concrete base with linear guideways for vibration damping |

| Thermal Compensation | Active spindle and axis thermal control systems for long-term precision |

| Programming Interface | CAM integration (Mastercam, Siemens NX, HyperMill) with multi-spindle synchronization support |

These specifications enable multi-spindle CNC systems to deliver high-precision, high-throughput performance across aerospace, medical, automotive, and industrial components. The ability to maintain tight tolerances across diverse materials—from lightweight aluminum and engineering plastics like ABS and nylon to harder steels—makes these machines ideal for complex, high-mix production environments.

From CAD to Part: The Process

Honyo Prototype Multi-Spindle CNC Process Overview

Honyo Prototype employs a streamlined, technology-driven workflow for multi-spindle CNC machining projects, designed to accelerate time-to-market while ensuring precision and cost efficiency. Our process integrates advanced digital tools with deep manufacturing expertise, specifically optimized for complex high-mix, low-volume production runs typical in prototyping and bridge manufacturing. Below is a detailed explanation of each phase.

CAD Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or 3D PDFs via our secure customer portal. The system performs an immediate format validation and geometric integrity check, flagging potential issues like non-manifold edges or unit mismatches. Unlike generic quoting platforms, our infrastructure recognizes multi-spindle-specific constraints during this stage, such as part symmetry requirements and gang-tooling feasibility. All data is encrypted and assigned a unique job ID for traceability, with automated notifications confirming receipt within 15 minutes.

AI-Powered Quoting with Engineering Oversight

Our proprietary AI quoting engine analyzes the validated CAD geometry, extracting critical parameters including feature counts, material removal volume, and tolerance clusters. For multi-spindle operations, the AI specifically evaluates spindle synchronization opportunities, potential for simultaneous operations across spindles, and optimal part orientation to minimize index time. The system cross-references real-time data on machine availability, material costs, and labor rates to generate a preliminary quote within 2 business hours. Crucially, this AI output undergoes mandatory review by a Senior Manufacturing Engineer who validates spindle allocation strategy and adjusts for nuanced factors like custom fixture requirements or secondary operations. Clients receive a transparent quote breakdown showing cost drivers specific to multi-spindle efficiency gains.

Collaborative DFM Optimization

The Design for Manufacturability phase is where Honyo delivers significant value for multi-spindle projects. Our engineering team conducts a joint virtual review with the client, focusing exclusively on multi-spindle optimization opportunities. Key interventions include reconfiguring part features to enable simultaneous machining across spindles, suggesting minor design tweaks to eliminate single-spindle bottlenecks, and proposing gang-tooling setups that reduce cycle time by 30-50%. We provide annotated CAD markups showing spindle-specific toolpaths and revised GD&T callouts that leverage multi-spindle capabilities. This phase typically reduces overall production time by 25% while maintaining critical tolerances, with formal DFM report approval required before proceeding.

Precision Multi-Spindle Production Execution

Production occurs on our dedicated Tsugami S206-8SY or similar 8-spindle Swiss-type CNC machines, configured for tight-tolerance medical, aerospace, and fluid handling components. Each job begins with a first-article inspection using calibrated CMMs to verify spindle synchronization accuracy within ±0.005mm. During machining, our IoT-enabled systems monitor spindle load, vibration, and thermal drift in real-time, automatically adjusting feed rates to maintain surface integrity across all spindles. For high-mix batches, we implement dynamic scheduling where changeovers are minimized through modular fixturing systems, allowing seamless transitions between part numbers. All critical dimensions undergo in-process checks at 500-part intervals, with full SPC data logged to the client portal.

Quality-Controlled Delivery and Logistics

Final inspection combines 100% visual examination with statistical sampling per AS9102 or ISO 13485 requirements, depending on industry. Multi-spindle-specific validation includes cross-spindle dimension consistency reports and rotational symmetry analysis. Parts are packaged in ESD-safe, serialized containers with humidity indicators for sensitive materials. Our logistics team coordinates delivery via DHL or FedEx with real-time GPS tracking, typically achieving 72-hour turnaround from production completion to client dock. Rush orders leverage our multi-spindle parallel processing capability to compress lead times by up to 60% versus single-spindle alternatives, with delivery confirmation including full traceability documentation linking each part to its specific spindle and tooling set.

Process Performance Metrics

The following table summarizes typical outcomes for multi-spindle CNC projects at Honyo Prototype compared to industry benchmarks:

| Metric | Honyo Prototype | Industry Average | Improvement |

|---|---|---|---|

| Quote-to-Approval Time | 24-48 hours | 5-7 days | 85% faster |

| DFM-Driven Cycle Time Reduction | 25-40% | 10-15% | 2.5x impact |

| First-Pass Yield (Medical Grade) | 99.2% | 94.5% | +4.7% |

| Avg. Lead Time (1000 parts) | 5 business days | 12 business days | 58% faster |

This integrated approach ensures clients leverage multi-spindle technology not just for speed, but for achieving previously unattainable part complexity within prototype and low-volume production constraints. All processes adhere to our ISO 9001:2015 and IATF 16949-certified quality management system, with full documentation available upon request.

Start Your Project

Looking to enhance your production efficiency with multi-spindle CNC technology? Contact Susan Leo at [email protected] to discuss your project requirements and discover how our precision manufacturing solutions can meet your needs.

Honyo Prototype operates a state-of-the-art factory in Shenzhen, China, specializing in high-speed, high-accuracy multi-spindle CNC machining for rapid prototyping and low-to-mid volume production.

Let’s collaborate to optimize your manufacturing process. Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.