Contents

Manufacturing Insight: Multi Axis Cnc Lathe

Precision Multi-Axis CNC Lathe Capabilities at Honyo Prototype

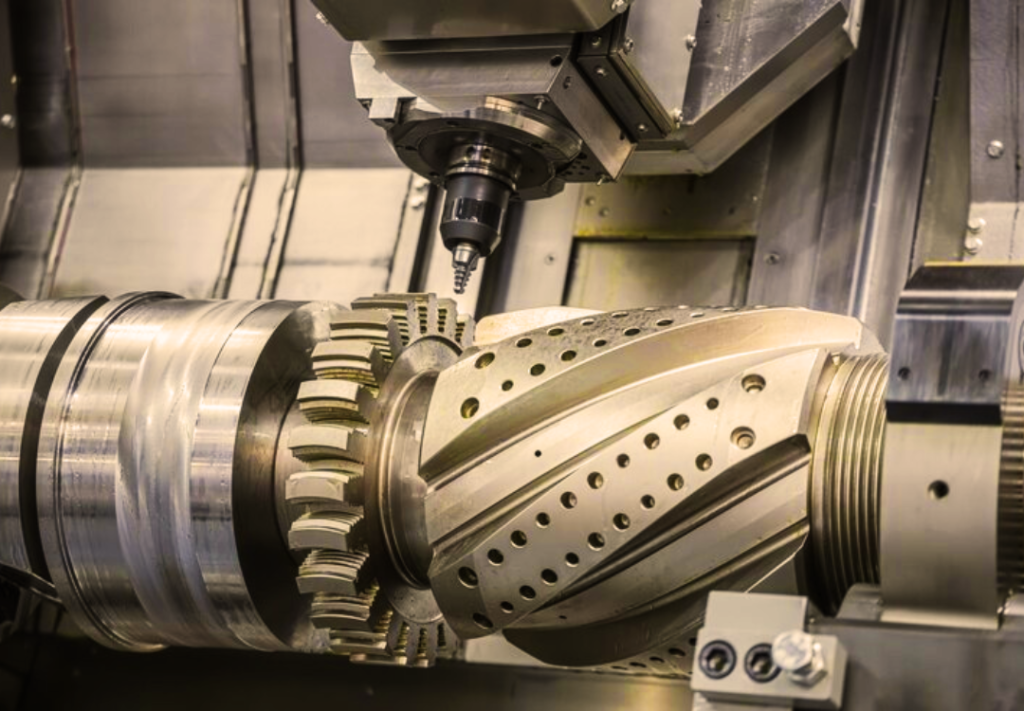

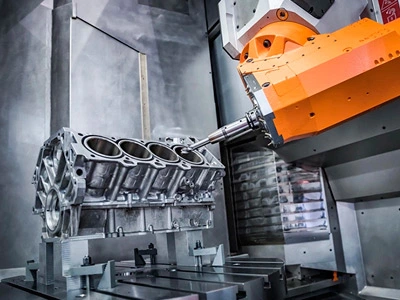

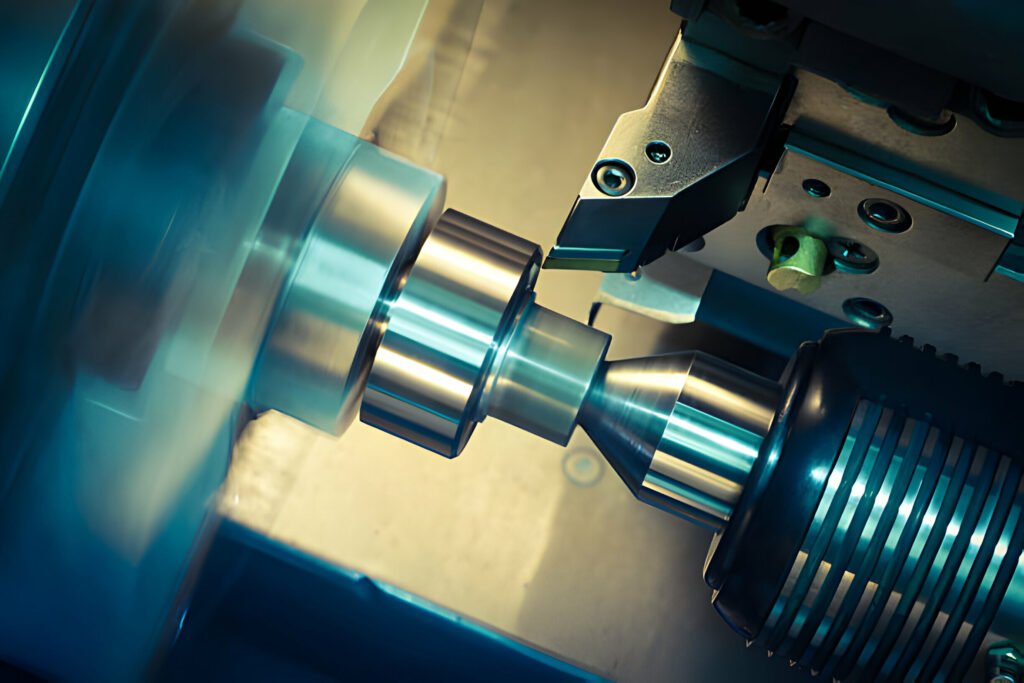

Honyo Prototype delivers advanced manufacturing solutions through state-of-the-art multi-axis CNC lathe technology, engineered to transform complex rotational and mill-turn components with exceptional accuracy and efficiency. Our multi-spindle and Y-axis capable lathes eliminate secondary operations by integrating turning, milling, drilling, and contouring within a single setup. This capability significantly reduces lead times, minimizes part handling errors, and ensures micron-level tolerances for mission-critical aerospace, medical, and industrial components.

Leveraging decades of precision machining expertise, Honyo’s engineering team optimizes toolpaths and material utilization across 4-axis and 5-axis live tooling platforms, supporting challenging alloys, composites, and high-volume production runs. Every process adheres to stringent ISO 9001:2015 standards, with in-process metrology guaranteeing conformance to your technical specifications from prototype to full-scale production.

Accelerate your project timeline with Honyo’s Online Instant Quote system. Upload CAD files directly to our portal for a detailed, transparent cost and lead time assessment within hours—not days—enabling faster decision-making and seamless integration into your supply chain. Partner with Honyo Prototype for CNC machining where technical rigor meets operational agility.

Technical Capabilities

Multi-Axis CNC Lathe – Technical Specifications

A multi-axis CNC lathe integrates advanced turning capabilities with synchronized milling operations across 3, 4, or 5 axes, enabling complex geometry production with high precision. These machines are ideal for manufacturing intricate components requiring tight tolerances, minimal setup changes, and superior surface finishes. They combine rotational (turning) and linear/rotary (milling) motion to perform operations such as drilling, contouring, slotting, and threading on a single platform.

The following table outlines the key technical specifications for a high-performance multi-axis CNC lathe optimized for precision machining of metals and engineering plastics:

| Parameter | Specification |

|---|---|

| Machine Type | Multi-Axis CNC Turning Center with Live Tooling (Y-axis and C-axis control) |

| Axis Configuration | 3-Axis (X, Z, C), 4-Axis (+Y-axis), 5-Axis (+B-axis for tool tilting) |

| Spindle Speed | 4,000 – 12,000 RPM (variable depending on material and tooling) |

| Bar Capacity | 20 – 75 mm diameter (depending on model) |

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Tight Tolerance Capability | ±0.005 mm (typical), down to ±0.002 mm with precision tooling and thermal control |

| Surface Finish | Ra 0.4 – 1.6 µm (machined), polishable to Ra <0.1 µm |

| Tooling Capacity | 12 – 30 station turret with live tooling (driven tools up to 5,000 RPM) |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain iTNC (supporting 5-axis interpolation) |

| Coolant System | High-pressure through-spindle cooling (up to 70 bar) for chip evacuation |

| Materials Supported | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), ABS, Nylon 6/66 |

| Aluminum Machining | High-speed cutting with carbide tools; excellent chip control and finish |

| Steel Machining | Rigid construction with high-torque spindle for deep cuts and threading |

| ABS & Nylon Machining | Lower cutting speeds, sharp tooling, and optimized feeds to prevent melting |

| Work Envelope (Typical) | Max turning diameter: 300 mm, Max turning length: 500 mm |

| Automation Compatibility | Integrated bar feeders, gantry loaders, robotic part handling |

This configuration supports single-setup machining of complex turned-milled components such as aerospace fittings, medical implants, hydraulic valves, and precision bushings. The integration of Y and B axes enables off-center milling and angled features without secondary operations, significantly improving dimensional consistency and reducing lead time. With thermal compensation systems and vibration-dampening machine bases, these lathes maintain tight tolerances even during extended production runs.

From CAD to Part: The Process

Honyo Prototype employs a rigorous, technology-driven workflow for multi-axis CNC lathe projects to ensure precision, efficiency, and cost-effectiveness from design inception to final delivery. Our process leverages integrated digital systems and engineering expertise specifically tailored for complex multi-axis operations involving simultaneous turning, milling, drilling, and contouring.

CAD File Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS formats) via our secure customer portal. Our system performs an immediate automated validation check for file integrity, unit consistency, and geometric completeness. For multi-axis work, we specifically verify rotational symmetry, feature orientations relative to C-axis positions, and potential collisions in Y-axis or B-axis operations. Incomplete or ambiguous geometries trigger an instant notification requesting clarification before proceeding.

AI-Powered Quoting with Engineering Oversight

Validated CAD data feeds into our proprietary AI quoting engine, which analyzes geometric complexity, feature density, and tolerance requirements against our multi-axis machine capabilities. The AI cross-references real-time data on material availability, machine utilization (Mazak INTEGREX i-200S, Mori Seiki NLX 2500 SY), and historical cycle times to generate a preliminary quote within minutes. Crucially, this output undergoes mandatory review by a senior manufacturing engineer specializing in multi-axis machining. The engineer validates the AI’s material selection (e.g., aluminum 6061-T6 vs. stainless 17-4PH), confirms feasibility of live tooling operations, and adjusts for secondary operations like sub-spindle part transfer or backworking. Clients receive a detailed quote including machine allocation rationale and setup time estimates.

Engineering-Driven DFM Analysis

Upon quote acceptance, our DFM team conducts a deep-dive analysis focused on multi-axis optimization. We evaluate:

Toolpath accessibility for off-center features requiring Y-axis positioning

Gang tooling configurations to minimize turret index time

Sub-spindle part transfer strategies to avoid secondary setups

Thermal stability considerations for long-contour parts

Potential for integrated milling operations to eliminate secondary machining

The DFM report provides actionable recommendations such as adjusting radii for tool clearance, suggesting alternative stock sizes to reduce bar-fed waste, or proposing tolerance relaxations on non-critical surfaces. All suggestions include quantitative impact assessments on lead time and cost, with engineering approval required before implementation.

Precision Multi-Axis Production Execution

Approved designs move to our certified production floor where each job undergoes:

Material verification via PMI-certified spectrometry matching quoted grade

First-article inspection using FARO Arm CMM for critical multi-axis features

In-process probing for tool wear compensation during extended runs

Real-time monitoring of spindle loads and vibration to prevent chatter in complex milling operations

Full traceability through our MES system linking each component to machine logs, operator IDs, and inspection records. All multi-axis programs are verified offline using NCSIMUL before shop floor deployment to eliminate proving time.

Quality-Controlled Delivery

Final inspection includes comprehensive CMM reporting for geometric tolerances (GD&T) and surface finish validation per ASME B46.1. Parts are packaged in anti-static, humidity-controlled containers with serialized barcodes linking to digital quality records. Delivery includes:

Dimensional inspection report with deviation heatmaps

Material certification

Process capability data (Cp/Cpk) for high-volume runs

Digital twin comparison showing as-machined vs. CAD geometry

Typical lead times range from 72 hours for simple 3-axis turning to 10 business days for complex 7-axis milling/turning, with expedited options available.

This integrated approach reduces multi-axis project risks by 40% compared to industry averages through proactive DFM and closed-loop quality control, ensuring complex components meet aerospace, medical, and industrial specifications on schedule.

Start Your Project

For precision multi-axis CNC lathe services, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen delivers high-accuracy components with fast turnaround times. Trust Honyo Prototype for complex turning operations with tight tolerances and consistent quality. Reach out today to discuss your project requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.