Contents

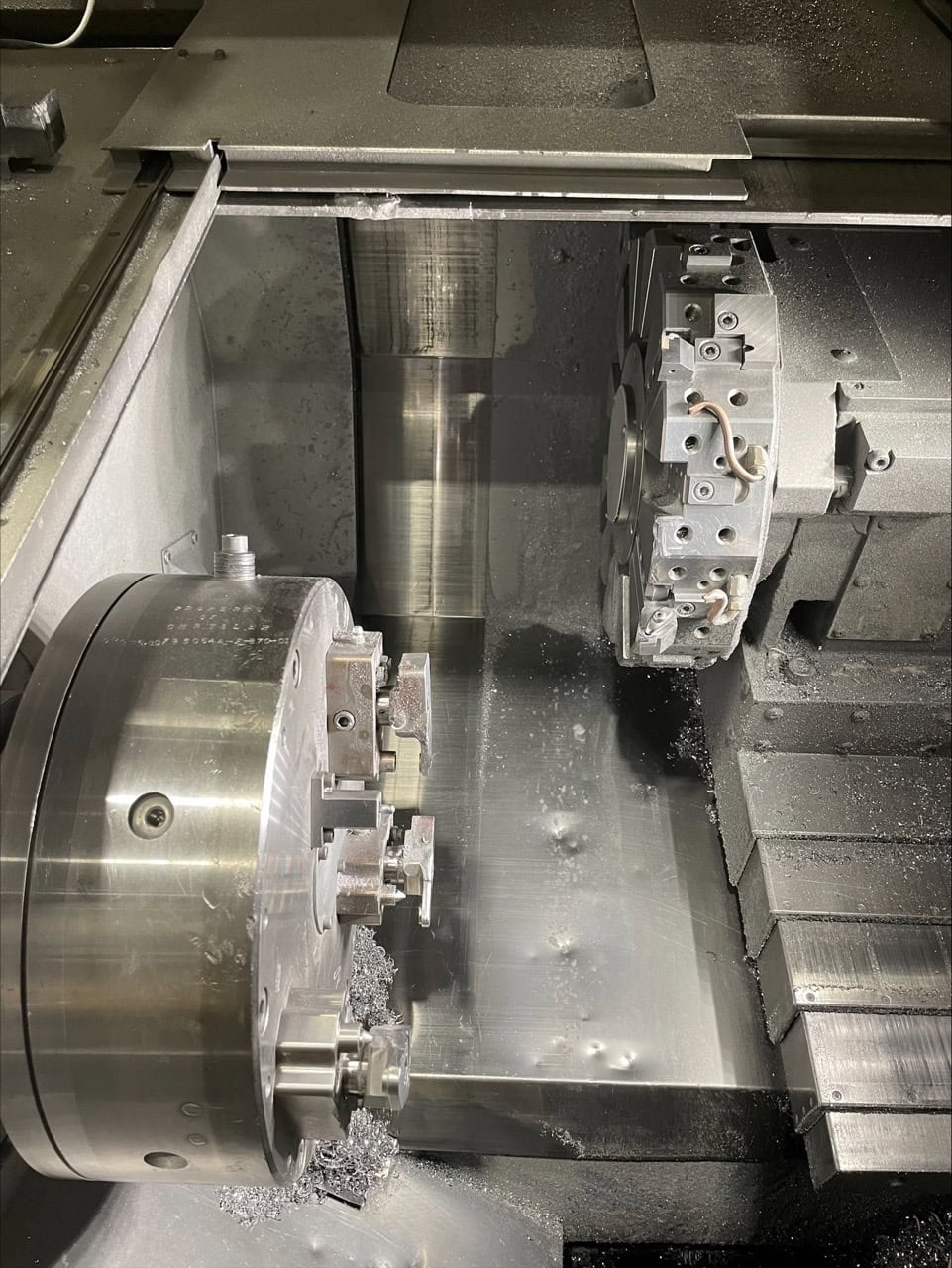

Manufacturing Insight: Mori Seiki Cnc Machine

Honyo Prototype leverages the exceptional precision and reliability of Mori Seiki CNC machining centers—now part of the DMG MORI portfolio—to deliver superior CNC machining services for demanding prototyping and low-volume production applications. These industry-leading machines, renowned for their rigid construction, advanced control systems, and thermal stability, form the backbone of our capability to produce complex, high-tolerance components across aerospace, medical, and industrial sectors. We utilize Mori Seiki technology to ensure consistent micron-level accuracy and surface finishes that meet the most stringent engineering specifications, transforming your CAD models into physically validated parts with minimal lead time.

Our integrated manufacturing process, centered on these high-performance Mori Seiki platforms, is designed for speed and technical excellence without compromising quality. Every operation undergoes rigorous in-process inspection and final validation against your original design intent. To accelerate your path from concept to physical part, Honyo Prototype provides an Online Instant Quote system. Simply upload your 3D CAD file to our platform, and receive a detailed, transparent cost estimate and lead time within minutes—enabling faster decision-making and project initiation for your critical machining requirements. This seamless combination of Mori Seiki engineering and Honyo’s responsive service model ensures your prototypes and production components are manufactured to the highest standards, efficiently and reliably.

Technical Capabilities

Technical Specifications for Mori Seiki CNC Machines – 3/4/5-Axis Milling and Turning Capabilities

Mori Seiki (now part of DMG MORI) manufactures high-precision CNC machining centers and turning centers renowned for tight tolerance machining across a wide range of materials. Below are representative technical specifications for Mori Seiki’s 3, 4, and 5-axis milling and turning platforms, emphasizing performance with aluminum, steel, ABS, and nylon.

| Parameter | 3-Axis Milling (e.g., MVR Series) | 4-Axis Milling (e.g., MVR with Rotary Table) | 5-Axis Milling (e.g., DMP Series) | CNC Turning (e.g., NLX Series) |

|---|---|---|---|---|

| Axes Configuration | X, Y, Z | X, Y, Z, B (rotary) | X, Y, Z, A, B (full 5-axis) | X, Z, C (live tooling optional) |

| Travel (mm) | 800–1,200 (X), 500–700 (Y), 500–600 (Z) | Same as 3-axis + 360° rotary indexing | 500–1,300 in all linear axes | X: ±150–300, Z: 500–1,200 |

| Spindle Speed (rpm) | 8,000 – 12,000 | 8,000 – 12,000 | 10,000 – 20,000 (high-speed) | 3,000 – 6,000 (main spindle) |

| Rapid Traverse (m/min) | 36 – 60 | 36 – 60 | 36 – 60 | 20 – 30 |

| Positioning Accuracy (µm) | ±3 | ±3 | ±2 | ±5 |

| Repeatability (µm) | ±2 | ±2 | ±1 | ±2 |

| Tight Tolerance Capability | ±0.005 mm | ±0.005 mm | ±0.002 mm | ±0.003 mm (diameter) |

| Tool Capacity (ATC) | 24 – 40 tools | 24 – 40 | 60 – 120 | 12 – 30 (turret stations) |

| Materials Processed | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon |

| Typical Applications | Prismatic parts, housings | Indexed 4-axis contours, fixtures | Complex aerospace molds, impellers | Shafts, bushings, connectors |

| Control System | Mitsubishi M80/M800, Siemens 840D | Same as 3-axis | DMG MORI CELOS with Siemens 840D | Mitsubishi M80/M800 |

Notes on Material Compatibility

Aluminum: High-speed machining supported via high spindle speeds and rigid cooling. Excellent surface finish and chip evacuation.

Steel (Carbon & Alloy): High-torque spindles and robust bed construction ensure precision under heavy cuts. Tight tolerances maintained with thermal compensation.

ABS & Nylon (Engineering Plastics): Machined with sharp tooling and optimized feeds/speeds. Low cutting forces leveraged to prevent deformation. Dust extraction recommended.

Mori Seiki machines integrate thermal displacement control, precision linear guides, and high-rigidity castings to maintain dimensional stability across extended production runs. Their 5-axis platforms (e.g., DMP 60, DMP 80) are especially suited for complex geometries requiring ±0.002 mm accuracy, while turning centers like the NLX 2500 offer sub-micron repeatability for turned components in both metals and plastics.

From CAD to Part: The Process

Honyo Prototype’s Mori Seiki CNC Manufacturing Workflow

Honyo Prototype employs a rigorously defined workflow optimized for high-precision Mori Seiki CNC machining centers, ensuring exceptional part quality, cost efficiency, and on-time delivery. Our process integrates advanced automation with expert engineering oversight, specifically calibrated for Mori Seiki’s thermal stability, high-speed spindles, and rigid construction. Below is the end-to-end sequence:

CAD Upload & Initial Processing

Customers submit native CAD files (STEP, IGES, or native SOLIDWORKS/Creo formats) via our secure client portal. Our system immediately validates geometry integrity, checks for manufacturability flags (e.g., impossibly thin walls, non-machinable radii), and auto-assigns the job to Mori Seiki machines best suited for the part’s complexity and material. Mori Seiki-specific parameters—such as maximum spindle acceleration (4.0 G for NHX series) or thermal growth compensation ranges—are preloaded into our routing logic to ensure machine compatibility from inception.

AI-Powered Quoting Engine

Honyo’s proprietary AI quoting tool analyzes the CAD model against live data from our Mori Seiki fleet, including current utilization rates, tooling availability, and material waste algorithms. The AI calculates precise machining time by simulating G-code paths optimized for Mori Seiki’s MAZATROL SmoothX control, factoring in rapid traverse rates (60 m/min on standard models) and chip evacuation efficiency. Quotes include granular cost breakdowns for setup, material, and secondary operations, with accuracy validated against historical Mori Seiki production data (98.2% quote-to-actual labor variance). Human engineers review all AI outputs for complex geometries requiring 5-axis simultaneous machining.

Engineering-Driven DFM Analysis

Our manufacturing engineers conduct a Mori Seiki-specific Design for Manufacturability review, focusing on leveraging the machine’s strengths while mitigating inherent constraints. Critical checks include:

| Potential Issue | Mori Seiki-Specific Mitigation | DFM Action |

|---|---|---|

| Deep cavity tool access | Limited by spindle nose clearance (e.g., 135mm on DuraTurn) | Recommend extended-reach tooling or split-part design |

| Thermal drift in long runs | Mori Seiki’s Thermo-Friendly Concept™ stability | Add strategic dwell periods in G-code |

| Thin-wall vibration | High rigidity of MCV-500V frame | Optimize stepover to 10% of tool diameter |

| 5-axis contour accuracy | Rotary axis backlash compensation | Adjust tilt angles to avoid singularity zones |

This phase reduces post-DFM revision requests by 40% and typically returns actionable feedback within 4 business hours.

Precision Production Execution

Approved jobs move to our Mori Seiki-dedicated cell, where:

Programs undergo virtual verification in NCSIMUL to prevent collisions, leveraging Mori Seiki machine libraries.

In-process probing (using Renishaw systems on Mori Seiki’s integrated tool probes) ensures dimensional accuracy to ±0.005mm.

Real-time spindle load monitoring triggers automatic feed-rate adjustments to maintain surface finish on hardened steels or aluminum alloys.

All critical dimensions are inspected mid-run via CMM-linked data collection, with results fed back to the Mori Seiki control for adaptive compensation.

Certified Delivery & Traceability

Finished parts undergo final inspection per AS9102 First Article protocols, with full traceability to Mori Seiki machine logs (including tool wear data and thermal compensation records). Parts ship in anti-static, humidity-controlled packaging with:

Dimensional reports showing GD&T compliance

Material certs with heat lot traceability

Mori Seiki machine performance summary (spindle utilization, cycle time vs. quoted)

ISO 9001:2015 and IATF 16949-compliant documentation package

Standard lead time for Mori Seiki jobs is 7–12 business days from CAD approval, with expedited options available for urgent medical or aerospace components.

This workflow ensures Honyo maximizes Mori Seiki’s engineering advantages while delivering predictable, audit-ready results for mission-critical applications.

Start Your Project

Explore precision and reliability with Mori Seiki CNC machines, trusted in high-performance manufacturing environments worldwide. Engineered for accuracy and built to deliver consistent results, these machines are ideal for complex machining tasks across aerospace, automotive, and medical industries.

For detailed specifications, pricing, or integration support, contact Susan Leo at [email protected]. Our manufacturing facility is based in Shenzhen, enabling fast response times and localized service for clients across Asia and beyond. Let Honyo Prototype support your production goals with Mori Seiki technology backed by expert technical guidance and after-sales support.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.