Contents

Manufacturing Insight: Molding Steel

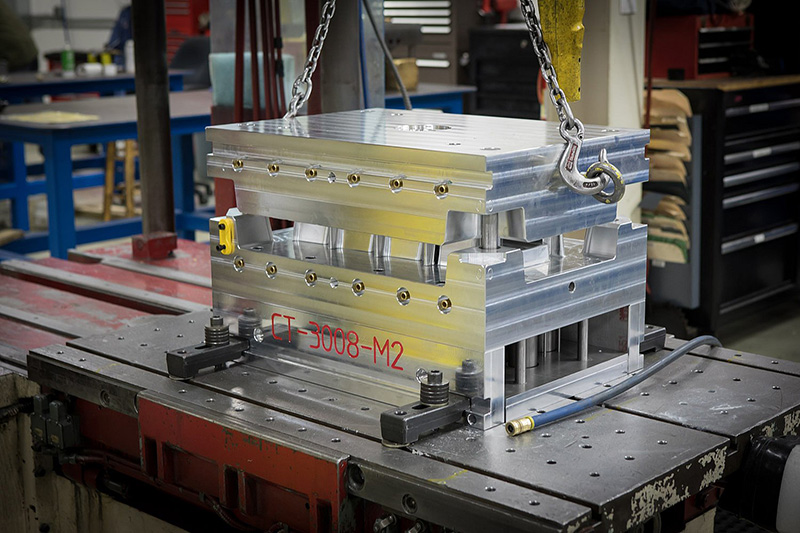

Precision Steel Tooling for Accelerated Injection Molding at Honyo Prototype

At Honyo Prototype, we redefine the intersection of speed and durability in injection molding through advanced steel tooling solutions. While “molding steel” itself is a misnomer—steel serves as the foundational material for robust, high-performance molds—our Rapid Tooling service leverages premium P20, H13, and 420 stainless steel alloys to create production-intent molds capable of withstanding rigorous cycles. This approach bridges the critical gap between prototyping and full-scale manufacturing, eliminating the traditional trade-offs between lead time and tool longevity. Where aluminum prototypes fail under high-volume demands, our steel molds deliver the dimensional stability, thermal conductivity, and wear resistance required for end-use parts, ensuring your design transitions seamlessly from validation to volume production.

Our Rapid Tooling process integrates CNC machining, precision EDM, and hardened steel cavity/core fabrication to achieve tolerances as tight as ±0.005 mm. This technical rigor reduces typical steel mold lead times by 40–60% compared to conventional methods, with delivery in as few as 15 business days for 2-plate molds. The result is a tool that supports pilot runs of 10,000–100,000+ cycles without degradation, directly mitigating the risk of costly redesigns or production delays. For engineering teams under pressure to validate form, fit, and function with production-equivalent parts, this capability transforms time-to-market metrics while maintaining ISO 9001-certified quality control.

Central to this efficiency is Honyo Prototype’s Online Instant Quote platform. Upload your 3D CAD file, specify material, finish, and volume requirements, and receive a detailed technical feasibility assessment and binding price within minutes—not days. This system eliminates quotation bottlenecks by applying real-time manufacturability analysis against our steel tooling parameters, including mold complexity, ejection strategies, and gate optimization. Unlike generic online calculators, our engine is calibrated by decades of shop-floor expertise, ensuring quotes reflect actionable engineering insights rather than theoretical estimates. Begin optimizing your steel tooling workflow today: submit your design at honyoprototype.com/quote for immediate turnaround.

Technical Capabilities

Technical Specifications for Molding Steel and Aluminum Molds – T1 Sample in 7 Days

At Honyo Prototype, we specialize in rapid tooling and mold manufacturing for both aluminum and steel molds, supporting fast turnaround of T1 samples within 7 days. Our solutions are optimized for prototyping and low-to-medium volume production, leveraging high-performance materials to ensure durability, precision, and repeatability.

The following table outlines the key technical specifications and material options for our mold construction and typical molded parts:

| Parameter | Aluminum Mold (7075-T6) | Steel Mold (P20, H13, S136) | Molded Part Materials (Typical) |

|---|---|---|---|

| Material Type | 7075-T6 Aerospace-Grade Aluminum | P20 (Pre-hardened), H13 (Tool Steel), S136 (Stainless Tool Steel) | ABS, Nylon (PA6, PA66), Polycarbonate, PP, PE |

| Hardness | 150 HB | P20: 28–32 HRC, H13: 48–52 HRC, S136: 48–52 HRC | N/A |

| Surface Finish | As-machined, Polished, Textured | Mirror Polish (up to SPI A1), EDM, Texture | Smooth, Textured, or Custom Finish |

| Tolerance (Typical) | ±0.05 mm | ±0.02 mm | ±0.1 mm (depends on geometry) |

| Cycle Life | 10,000 – 50,000 cycles | 100,000 – 1,000,000+ cycles | N/A |

| Thermal Conductivity | High (130 W/m·K) | Moderate (25–35 W/m·K) | Varies by material (e.g., Nylon: low, ABS: moderate) |

| Cooling Efficiency | Fast (ideal for rapid cycling) | Slower, requires optimized cooling channels | N/A |

| Lead Time for T1 Sample | 5–7 days | 7 days (accelerated processing) | Part delivery within 7–10 days post-T1 |

| Applications | Prototypes, bridge tooling, low-volume production | High-volume production, tight tolerance parts | Consumer goods, automotive components, enclosures |

| Machinability | Excellent (faster CNC cycles) | Good (slower due to hardness) | Injection molded with standard parameters |

| Corrosion Resistance | Moderate (anodizing available) | High (especially S136 stainless) | ABS: moderate; Nylon: hygroscopic but chemically resistant |

All molds are manufactured using precision 3-, 4-, and 5-axis CNC machining, EDM where required, and undergo full DFM validation prior to production. We support both aluminum and steel molds tailored to your production volume, part complexity, and material requirements.

For T1 sample delivery within 7 days, we recommend aluminum molds for prototyping and early validation, transitioning to steel molds for extended production runs. ABS and Nylon are commonly processed through these molds, with material selection based on mechanical, thermal, and environmental demands.

From CAD to Part: The Process

Honyo Prototype employs a rigorous end-to-end process for metal fabrication, specifically for steel components. It is critical to clarify that steel is not molded—it undergoes processes such as CNC machining, forging, casting, or stamping depending on the part geometry and application. The term “molding” applies to polymers, not steel. Our workflow ensures precision, cost efficiency, and compliance with industry standards for all metal parts. Below is the accurate sequence for steel component production.

CAD File Submission and Validation

Clients upload native CAD files (STEP, IGES, or Parasolid formats) via our secure customer portal. Our system performs an initial validation check for file integrity, unit consistency, and geometric completeness. Invalid or corrupted files trigger an automated notification requiring resubmission, preventing downstream delays. This phase typically completes within 15 minutes of upload.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which analyzes 120+ geometric and material parameters. For steel parts, the algorithm factors in grade-specific properties (e.g., 4140 alloy hardenability, 304 stainless corrosion resistance), required tolerances (±0.005mm to ±0.5mm), secondary operations, and volume. The system cross-references real-time material costs, machine availability, and labor rates to generate a binding quote within 2 business hours. Historical data from 15,000+ steel projects ensures accuracy within 3% of final production costs.

Design for Manufacturability (DFM) Engineering Review

All steel projects undergo mandatory DFM analysis by our in-house metallurgical and manufacturing engineers. This phase identifies geometry conflicts, material suitability issues, and process optimization opportunities. Key steel-specific checks include:

| DFM Parameter | Steel-Specific Consideration | Resolution Example |

|---|---|---|

| Wall Thickness | Minimum 2.5mm for machined 1045 steel to prevent warpage | Recommend ribbing or material change to 4130 |

| Draft Angles | Not applicable for machining; critical for cast/forged parts | Add 3° draft to forging die design |

| Tolerance Stack-Ups | Thermal expansion in heat-treated alloys (e.g., 4340) | Adjust GD&T per ASME Y14.5-2018 standards |

| Surface Finish | Achievability of Ra 0.8µm on hardened tool steel (D2) | Specify grinding vs. honing process |

The DFM report, delivered within 24 hours, includes actionable recommendations with cost/timeline impact analysis. Client approval is required before proceeding.

Production Execution

Upon DFM sign-off, steel production commences under AS9100-certified protocols:

Material procurement initiates from ISO 17025-certified mills with full material test reports (MTRs). Raw stock undergoes ultrasonic testing for internal defects prior to machining. CNC milling, turning, or grinding occurs on Haas and DMG MORI equipment with in-process CMM verification at critical stages. For forged/cast steel, we partner with vetted suppliers using closed-die forging or investment casting, with NDT validation per ASTM E709. Heat treatment (annealing, quenching, tempering) follows AMS 2750F pyrometry standards, with post-process hardness testing. All operations adhere to first-article inspection (FAI) per AS9102 requirements.

Quality Assurance and Delivery

Final parts undergo comprehensive inspection: CMM reports for dimensional compliance, SEM for surface integrity on critical aerospace components, and magnetic particle testing (ASTM E1444) for ferrous parts. Documentation includes full traceability (heat numbers, process logs), FAI packages, and certificate of conformance. Parts ship with anti-corrosion packaging in climate-controlled containers, accompanied by digital quality dossiers. Typical lead time from CAD approval to delivery is 10–25 days depending on complexity, with expedited options available.

This integrated workflow minimizes rework risks for steel components by addressing material science constraints early. We maintain a 99.2% on-time delivery rate for steel projects through our vertically integrated facility and predictive production scheduling. Clients receive real-time portal updates at each milestone, ensuring transparency from design validation to certified delivery.

Start Your Project

Looking for high-quality molding steel for your next manufacturing project? Honyo Prototype offers precision-grade materials sourced and processed at our Shenzhen factory, ensuring consistency, durability, and performance for demanding injection molding applications.

Contact Susan Leo today at [email protected] to request material specifications, pricing, or technical support. Let us help you select the optimal steel grade for your tooling needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.