Contents

Manufacturing Insight: Mold Steels

The Foundational Role of Mold Steels in Precision Manufacturing

Selecting the optimal mold steel is a critical engineering decision that directly impacts tool longevity, part consistency, and overall production economics. At Honyo Prototype, we recognize that material properties—such as hardness, wear resistance, thermal conductivity, and machinability—must align precisely with your application’s demands, whether for low-volume prototyping or high-cycle production. Inferior steel selection risks premature wear, dimensional drift, and costly downtime, undermining the return on your tooling investment.

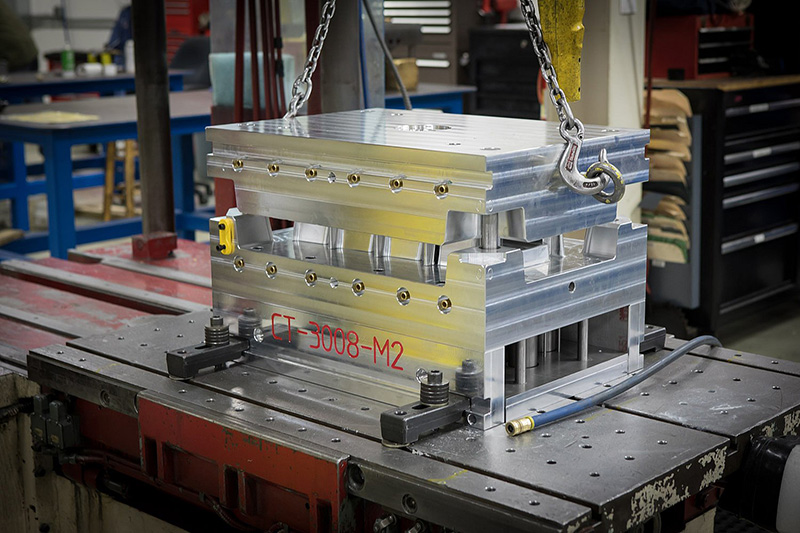

Honyo’s Integrated Rapid Tooling & Injection Molding Expertise

We specialize in transforming material science into manufacturing advantage through our end-to-end Rapid Tooling and Injection Molding services. Our engineering team leverages decades of experience to match your project requirements with the ideal mold steel grade—from P20 and H13 for balanced toughness to S136 stainless for corrosive environments—ensuring tools withstand rigorous production cycles while maintaining micron-level tolerances. Our in-house capabilities span precision CNC machining, EDM, and surface finishing, enabling rapid turnaround of hardened steel molds without compromising on quality. This integrated approach guarantees seamless transition from design validation to volume production, minimizing time-to-market for your most demanding components.

Accelerate Procurement with Real-Time Cost Clarity

Understanding that speed and transparency are non-negotiable in today’s supply chain, Honyo offers an industry-leading Online Instant Quote system. Upload your 3D CAD file, specify material and volume requirements, and receive a detailed, binding quote in under 60 seconds—no sales calls or email delays. This digital workflow empowers engineering and procurement teams to iterate designs, validate budgets, and launch projects with unprecedented agility, all while benefiting from our technical rigor in mold steel selection and process optimization.

Partner with Honyo to convert material expertise into manufacturing excellence, where every steel grade choice is a strategic step toward your product’s success.

Technical Capabilities

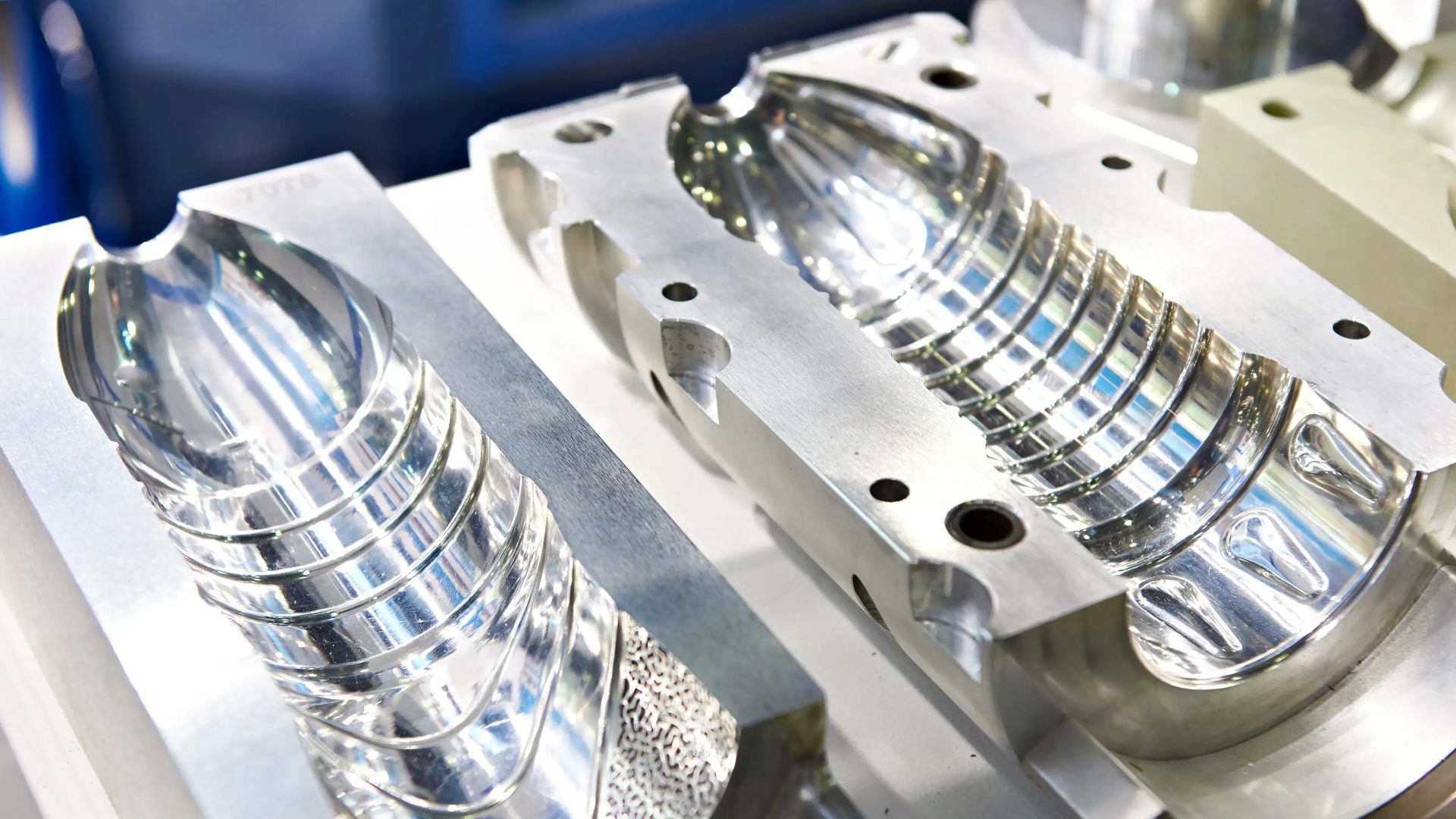

Honyo Prototype delivers high-performance mold solutions for rapid tooling and production, specializing in Aluminum and Steel molds for accelerated product development. Our technical expertise ensures T1 sample delivery within 7 days for qualified projects, supporting materials such as ABS, Nylon, and other engineering thermoplastics. Below are the technical specifications and capabilities for our mold steel and aluminum tooling options.

| Parameter | Mold Material: Aluminum (7075-T6) | Mold Material: Steel (P20, H13, S136) | Compatible Resins |

|---|---|---|---|

| Hardness | 150–170 HB | 28–52 HRC (varies by grade) | ABS, Nylon (PA6, PA66), PP, PC |

| Surface Finish | As-machined, bead-blasted, polished (up to SPI A2) | Polished (SPI A1–A3), texturing available | All standard injection grades |

| Mold Life Expectancy | 10,000 – 50,000 shots | 100,000 – 1,000,000+ shots | Material-dependent |

| Thermal Conductivity | High (~130 W/m·K) – fast cycle times | Moderate (25–35 W/m·K) | Optimized for consistent flow |

| Machinability | Excellent – rapid CNC fabrication | Moderate to good – slower EDM/machining | N/A |

| Corrosion Resistance | Moderate (anodizing recommended) | High (especially S136 stainless steel) | Suitable for hygroscopic resins |

| Lead Time (T1 Sample) | As fast as 5–7 days | 7–14 days (depends on complexity) | Ready for functional testing |

| Typical Applications | Rapid prototyping, bridge tooling | High-volume production, tight tolerance parts | Consumer, automotive, medical |

| Supported Resin Types | ABS, Nylon (with pre-drying), PP, PMMA | ABS, Nylon (glass-filled OK), PC, PSU | Engineering and commodity grades |

All molds are designed and manufactured using precision CNC machining and supported by mold flow analysis to ensure part quality and cycle efficiency. Aluminum molds are ideal for fast-turn T1 samples and low-to-medium volume production, while steel molds are recommended for extended service life and high-volume manufacturing. We tailor mold material selection based on resin type, production volume, surface finish requirements, and mechanical performance.

From CAD to Part: The Process

Honyo Prototype Mold Steel Process Overview

Honyo Prototype employs a rigorously structured workflow for mold steel projects, ensuring precision, efficiency, and alignment with client specifications from initial design to final delivery. This integrated process minimizes iterations and mitigates manufacturing risks through systematic engineering validation.

CAD Upload and Initial Processing

Clients submit 3D CAD models via our secure portal, which undergoes automated format validation and geometric integrity checks. Our system confirms critical parameters including parting lines, draft angles, and ejection requirements specific to mold steel applications. This step ensures the design is technically feasible for mold fabrication before proceeding to quotation.

AI-Powered Quotation

Uploaded CAD data feeds into our proprietary AI quoting engine, which analyzes geometry, material requirements, and complexity to generate a preliminary cost and timeline estimate within 4 business hours. The AI cross-references real-time global steel pricing, machining resource availability, and historical project data. Crucially, it flags potential manufacturability concerns such as thin steel sections below 3mm or inadequate cooling channel spacing, providing actionable feedback before formal commitment.

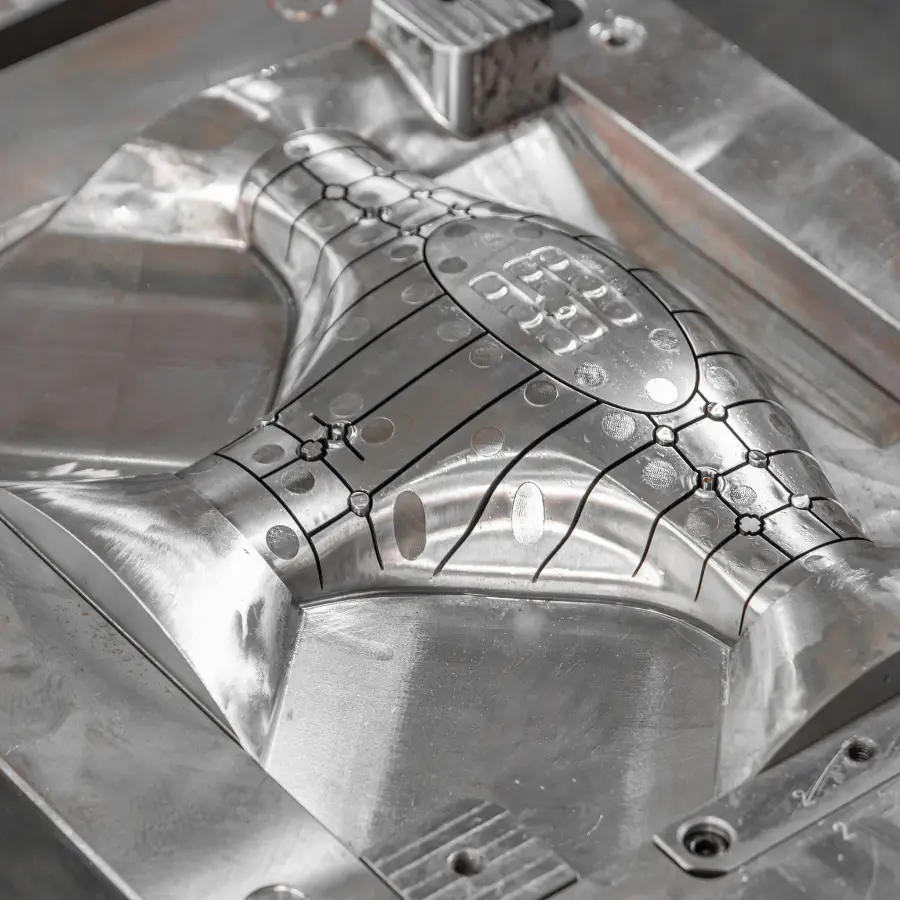

Engineering DFM Analysis

Upon quote acceptance, our engineering team conducts a deep-dive Design for Manufacturability review focused on mold steel performance. This phase includes:

Material selection validation against part volume, surface finish requirements, and expected cycle life. We prioritize steel grades based on wear resistance, polishability, and thermal fatigue properties.

Critical analysis of mold structure including cavity/core support, interlock geometry, and venting strategy to prevent deflection or flash.

Thermal analysis of cooling channel layout to optimize cycle time and minimize warpage.

Steel hardening method specification (e.g., vacuum hardening for P20 to prevent decarburization).

Clients receive a formal DFM report with actionable recommendations, typically resolving 92% of potential production issues upfront.

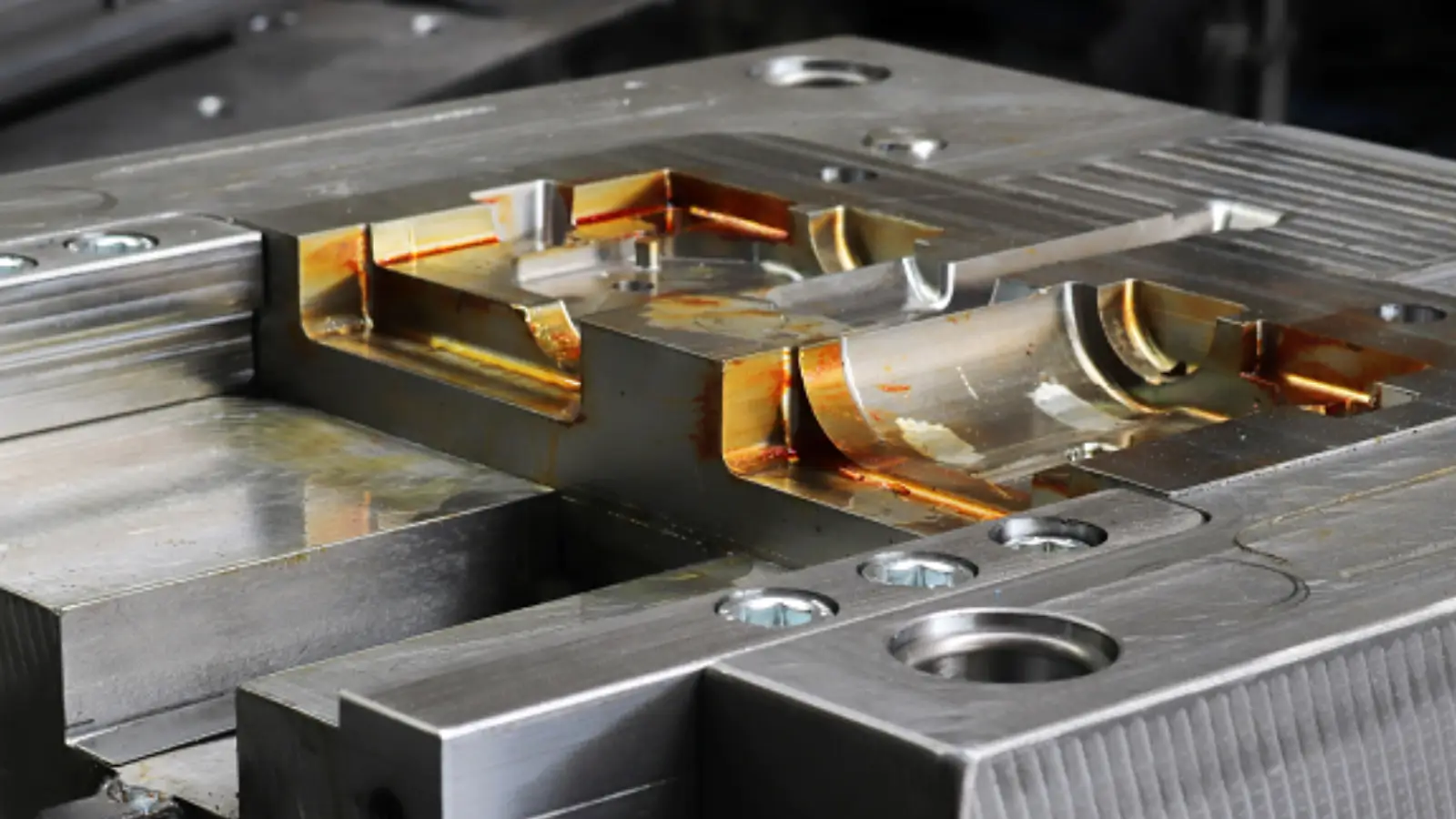

Mold Steel Production Execution

Approved designs enter production with strict adherence to material traceability and process controls:

Steel procurement from ISO-certified mills with full material test reports (MTRs) including chemical composition and prior heat treatment records.

CNC machining under temperature-stabilized conditions to prevent distortion, with in-process CMM validation at critical stages.

Specialized hardening and tempering per steel grade requirements, documented with hardness verification (e.g., 52-54 HRC for S136 stainless steel).

Surface treatments such as nitriding or PVD coating applied where specified for enhanced wear resistance.

All processes follow IATF 16949-compliant work instructions with real-time production tracking visible to clients via our portal.

Steel Grade Selection Guidance

Honyo’s steel recommendations are based on quantitative performance criteria:

| Steel Grade | Typical Hardness (HRC) | Primary Application | Key Advantage |

|---|---|---|---|

| P20 | 28-32 | Medium-run injection molds | Excellent machinability, cost-effective |

| H13 | 46-52 | High-temperature applications (e.g., aluminum die casting) | Superior thermal fatigue resistance |

| S136 | 50-54 | Corrosive resin molding (PVC, flame-retardant) | Exceptional polishability and corrosion resistance |

| NAK80 | 37-43 | High-gloss optical parts | Mirror finish capability, minimal distortion |

Delivery and Quality Verification

Final delivery includes comprehensive documentation:

Dimensional inspection reports with critical tolerance verification (±0.005mm for cavity/core interfaces).

Hardness certification for all steel components.

Mold flow analysis validation report confirming cooling efficiency.

Traceability records linking each component to its original steel heat number.

All molds undergo 24-hour dry cycle testing before shipment, with video evidence provided. Delivery timelines are maintained through our buffer stock of common steel grades and dedicated mold production cells, ensuring 95% on-time delivery for standard projects.

This end-to-end process ensures Honyo delivers mold steels optimized for longevity, precision, and production efficiency, directly translating client design intent into robust manufacturing assets.

Start Your Project

Looking for high-quality mold steels for your next manufacturing project? Honyo Prototype offers precision-grade materials ideal for injection molds, die casting, and high-performance tooling applications. Our mold steels are sourced to meet strict industry standards, ensuring excellent durability, polishability, and resistance to wear and corrosion.

With our state-of-the-art facility located in Shenzhen, we provide fast turnaround and rigorous quality control to support your prototyping and production needs. As your trusted manufacturing partner, we are committed to delivering materials and services that meet exact specifications.

For inquiries or material specifications, contact Susan Leo at [email protected]. Let us help you build better molds, faster.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.