Contents

Manufacturing Insight: Mold Steel Material

Material Selection as the Foundation for Precision Injection Molded Components

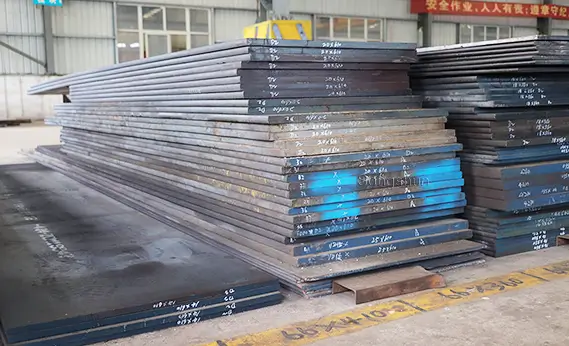

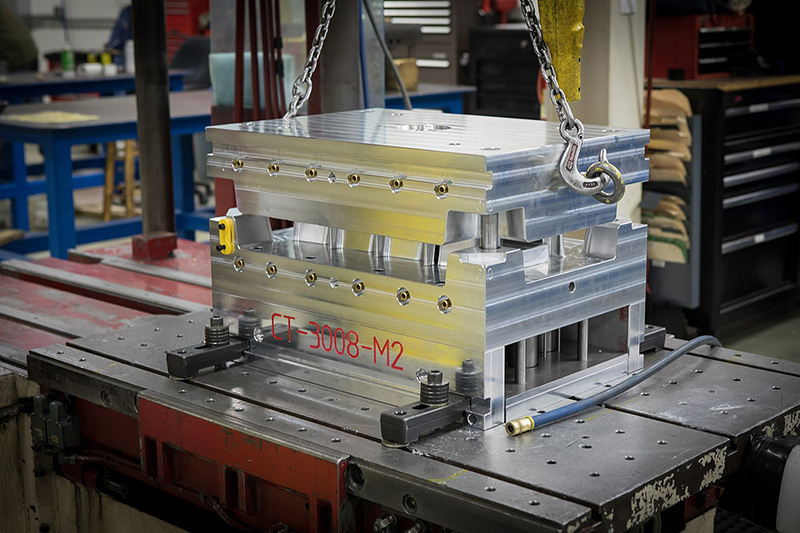

The performance and longevity of any injection molded part are intrinsically tied to the strategic selection of mold steel material. Critical factors such as hardness, thermal conductivity, wear resistance, and corrosion properties directly impact cycle times, part fidelity, surface finish, and overall tool lifespan. At Honyo Prototype, we recognize that optimal steel grade selection—whether P20 for prototyping, H13 for high-temperature applications, or S136 for corrosion resistance—is not merely a specification but a core engineering decision that dictates production efficiency and component quality.

Leveraging our Rapid Tooling expertise, Honyo integrates advanced mold steel capabilities with precision machining and heat treatment processes to deliver production-ready molds in significantly reduced lead times. Our technical team collaborates with clients from the initial design phase to evaluate material suitability against application demands, ensuring the mold steel aligns with volume requirements, resin characteristics, and geometric complexity. This proactive approach minimizes iterations and accelerates time-to-market without compromising on durability or dimensional accuracy.

Complementing our Rapid Tooling services, Honyo’s end-to-end Injection Molding solutions utilize these rigorously engineered molds to produce high-integrity components across industries including medical, automotive, and consumer electronics. Every stage—from steel procurement and mold fabrication to molding and validation—is executed under stringent ISO-compliant protocols to guarantee repeatability and adherence to tight tolerances.

To streamline your path from concept to physical part, Honyo offers an Online Instant Quote platform. Simply upload your CAD file to receive a detailed manufacturability analysis and competitive pricing within hours, empowering data-driven decisions for your next project.

| Service Integration Point | Technical Value Proposition |

|---|---|

| Mold Steel Material Selection | Grade optimization based on resin type, cycle volume, and part geometry |

| Rapid Tooling Execution | Mold fabrication in 7–15 days using CNC, EDM, and surface texturing |

| Injection Molding | 50–1,000+ part runs with real-time process monitoring and SPC |

| Online Instant Quote | CAD-based DFM feedback and pricing in under 4 business hours |

Accelerate your development cycle with mold steel solutions engineered for performance and speed. Upload your design today to experience Honyo’s rapid, precision-driven manufacturing ecosystem.

Technical Capabilities

Mold steel material selection is critical for achieving optimal performance, durability, and cycle time in injection molding processes. At Honyo Prototype, we specialize in rapid tooling solutions including Aluminum and Steel molds, enabling T1 sample delivery within 7 days. Our mold materials are selected based on production volume, part complexity, material compatibility, and surface finish requirements.

Below is a comparison of commonly used mold materials and their technical characteristics:

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Mold Life (Cycles) | Machinability | Common Use Cases | Compatible with Resins (e.g., ABS, Nylon) |

|---|---|---|---|---|---|---|---|

| Aluminum 7075-T6 | 45–50 | 500–580 | 130 | 10,000 – 100,000 | Excellent | Rapid prototyping, low to medium volume production | Yes – suitable for ABS, Nylon, and other engineering resins |

| P20 Steel | 28–32 | 900–1100 | 28–30 | 100,000 – 500,000 | Good | Medium to high volume production molds | Yes – widely used with ABS, Nylon, PC, and filled materials |

| H13 Tool Steel | 48–52 | 1300–1600 | 25–30 | 500,000+ | Moderate | High-volume, high-temperature applications | Yes – ideal for high-temperature resins like Nylon and PEEK |

| ABS (as molded part) | N/A | 40–50 | 0.15 | N/A | N/A | Low-stress prototypes, housings | Not applicable – used as end-part material |

| Nylon 6/6 (as molded part) | N/A | 70–85 | 0.25 | N/A | N/A | Functional parts, gears, connectors | Not applicable – used as end-part material |

All molds are precision CNC machined with tight tolerances (±0.02 mm typical) and can be surface finished to SPI standards (A2, B1, etc.). Aluminum molds enable faster lead times and are ideal for T1 sampling within 7 days, while steel molds (P20, H13) offer extended service life for production runs.

We support molding with a wide range of thermoplastics including ABS and Nylon, ensuring material compatibility with mold design, cooling layout, and ejection systems.

From CAD to Part: The Process

Honyo Prototype Mold Steel Material Process Overview

Our end-to-end process for mold steel material projects ensures precision, efficiency, and metallurgical integrity from initial design to final delivery. Below is the technical workflow specific to mold steel applications.

CAD Upload and Material Specification Validation

Clients submit 3D CAD models via our secure portal with explicit material requirements (e.g., P20, S136, H13). Our system immediately validates steel grade compatibility against the part geometry, wall thickness, and functional demands. Critical parameters like corrosion resistance, hardness targets (e.g., 52-54 HRC for S136), and thermal stability are cross-referenced against industry standards (AISI, JIS, or DIN). Unspecified material requests trigger an automated query to prevent downstream deviations.

AI-Powered Quoting with Metallurgical Cost Modeling

The AI engine analyzes the CAD model to generate a dynamic quote within 4 business hours. For mold steel, this includes:

Steel cost calculation based on current market rates and block size optimization

Heat treatment cycle time and cost integration (e.g., vacuum hardening for H13)

Predictive warpage analysis for complex cores/cavities

Toolpath simulation for hardened steel machining (e.g., high-speed milling parameters for 48+ HRC materials)

Quotes detail steel certification requirements (e.g., mill test reports per EN 10204 3.1) and non-negotiable tolerances for critical surfaces.

DFM Analysis Focused on Steel Processability

Our DFM review is specialized for mold steel constraints. Engineers examine:

Draft angles relative to steel shrinkage rates during cooling

Rib thickness to prevent sink marks in high-hardness steels

Ejector pin placement avoiding stress concentrators in tempered zones

Cooling channel proximity to cavity surfaces to minimize thermal fatigue

We proactively identify risks like insufficient hardness in thin sections or inadequate through-tempering for thick P20 blocks. Revised CAD suggestions include annotated 3D markups with steel-specific annotations.

Production Execution with Material Traceability

Upon approval, steel procurement begins with certified suppliers. Each block receives a unique ID tracked through:

Spectrometer verification of chemical composition upon receipt

Pre-hardening stress relief (if applicable) with documented temperature logs

CNC machining using carbide tools optimized for specific steel grades (e.g., coated inserts for abrasive H13)

Post-machining dimensional validation via CMM with thermal compensation

Vacuum heat treatment with quench monitoring to achieve uniform microstructure

All process data (hardness test results, distortion measurements) is stored against the material ID.

Delivery with Comprehensive Material Documentation

Final delivery includes:

Physical mold components with protective coating (e.g., rust preventative oil for non-stainless steels)

Digital package containing:

Certified mill test report with traceable heat number

Hardness verification map (Rockwell or Vickers) across critical zones

As-machined CMM report with GD&T callouts

Heat treatment process certificate showing austenitizing/tempering cycles

Lifetime material warranty covering metallurgical defects

Steel Grade Capability Reference

| Steel Grade | Typical Hardness (HRC) | Key Applications | Lead Time Impact |

|————-|————————|—————————|——————|

| P20 | 28-32 | Prototype injection molds | Standard |

| H13 | 48-52 | High-temp die casting | +3 days (heat treat) |

| S136 | 50-54 | Corrosive plastic molds | +5 days (polish cert) |

| NAK80 | 37-43 | Optical lens molds | Standard |

This integrated approach ensures mold steel components meet stringent performance criteria while minimizing time-to-market. All processes adhere to ISO 9001:2015 and IATF 16949 standards for automotive-grade tooling.

Start Your Project

Looking for high-quality mold steel material for your next project? Trust Honyo Prototype for precision-engineered solutions backed by industry expertise.

Our factory in Shenzhen ensures fast turnaround and strict quality control, meeting the demanding requirements of injection molding and die casting applications.

Contact Susan Leo today at [email protected] for technical specifications, material recommendations, and competitive pricing. Let’s build precision together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.