Introduction: Navigating the Global Market for miniature screws

In the dynamic world of manufacturing and assembly, sourcing miniature screws presents a unique set of challenges for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The intricacies of selecting the right miniature screws—whether for precision instruments, electronics, or intricate model assembly—can significantly impact the quality and efficiency of production. This guide is designed to empower international buyers by providing a comprehensive overview of the miniature screw market, covering essential topics such as types, applications, supplier vetting, and cost considerations.

Understanding the various types of miniature screws, including materials like brass, stainless steel, and nylon, is crucial for making informed purchasing decisions. Each material offers unique benefits that can influence durability, weight, and resistance to environmental factors. This guide will also delve into the critical aspects of supplier selection, ensuring that buyers can identify reputable manufacturers and distributors who meet their specific needs. Additionally, we will explore pricing structures and market trends that can affect sourcing strategies.

By equipping B2B buyers with actionable insights and in-depth knowledge of the miniature screw market, this guide aims to facilitate smarter purchasing decisions, ultimately enhancing operational efficiency and product quality across various sectors. Whether you are based in Nigeria, Germany, or elsewhere, navigating the global market for miniature screws has never been more accessible.

Understanding miniature screws Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flat Head Screws | Low-profile head; countersunk design. | Model assembly, electronics, precision devices. | Pros: Aesthetic finish, flush with surfaces. Cons: Limited torque application. |

| Hex Socket Head Cap Screws | Hexagonal socket for increased torque; robust design. | Machinery, automotive, and precision instruments. | Pros: High strength, excellent for tight spaces. Cons: Requires specific tools for installation. |

| Pan Head Machine Screws | Rounded head; offers good grip and stability. | Consumer electronics, appliances, toys. | Pros: Easy to install, versatile. Cons: May not fit flush in some applications. |

| Cross Recessed Flat Head Screws | Cross slot design; allows for better engagement with drivers. | Electronics, small machinery, and hobby projects. | Pros: Improved torque application, versatile. Cons: Can strip if over-tightened. |

| Plastic Screws | Made from materials like PEEK or RENY; lightweight and non-corrosive. | Medical devices, electronics, and outdoor products. | Pros: Corrosion-resistant, lightweight. Cons: Lower tensile strength compared to metal screws. |

What Are Flat Head Screws and Where Are They Used?

Flat head screws are characterized by their low-profile heads that sit flush with the surface when installed. This design is particularly advantageous in applications where aesthetics are crucial, such as in model assembly and electronic devices. B2B buyers should consider the material—often brass or stainless steel—when selecting flat head screws, as this impacts durability and corrosion resistance. They are easy to install but may not be suitable for high-torque applications due to their limited grip.

How Do Hex Socket Head Cap Screws Stand Out?

Hex socket head cap screws feature a hexagonal recess that allows for increased torque application, making them ideal for heavy-duty applications in machinery and automotive sectors. Their robust design ensures they can withstand significant stress, making them suitable for precision instruments as well. When purchasing, buyers should consider the strength and material, as these factors determine their performance in demanding environments. However, they require specific tools for installation, which can be a drawback for some users.

What Are the Advantages of Pan Head Machine Screws?

Pan head machine screws have a rounded head that provides a larger surface area for better grip and stability during installation. They are commonly used in consumer electronics and appliances where ease of installation is a priority. B2B buyers appreciate their versatility and the ability to accommodate different materials. However, they may not fit flush in applications requiring a sleek finish, which could be a consideration in design-oriented projects.

Why Choose Cross Recessed Flat Head Screws?

Cross recessed flat head screws are designed with a cross slot that enhances driver engagement, allowing for better torque application. This feature makes them suitable for a wide range of applications, including small machinery and hobby projects. B2B buyers should be cautious of over-tightening, as it can strip the screw. The versatility of these screws makes them a popular choice, but the potential for stripping should be a consideration in high-usage scenarios.

What Are the Benefits of Using Plastic Screws?

Plastic screws, made from materials like PEEK or RENY, are lightweight and non-corrosive, making them ideal for applications in medical devices and outdoor products. Their corrosion resistance is a significant advantage, especially in humid or chemically active environments. However, buyers should be aware that plastic screws typically offer lower tensile strength compared to their metal counterparts. This factor is crucial for applications requiring high strength, making it essential for buyers to assess their specific needs before making a purchase.

Key Industrial Applications of miniature screws

| Industry/Sector | Specific Application of Miniature Screws | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | Assembly of circuit boards and electronic devices | Ensures reliability and precision in electronic components | Material durability, size specifications, and lead times |

| Medical Devices | Construction of precision instruments and implants | Critical for safety and functionality in medical applications | Regulatory compliance, biocompatibility, and traceability |

| Aerospace and Defense | Fastening components in aircraft and military equipment | Enhances safety and performance in high-stress environments | Weight considerations, corrosion resistance, and certification |

| Automotive Industry | Securing small parts in vehicles and automotive electronics | Improves overall vehicle reliability and performance | Material strength, resistance to vibration, and quality assurance |

| Model and Hobby Industries | Building models, miniatures, and hobbyist projects | Provides a high level of detail and finish in craftsmanship | Variety in sizes, materials, and availability for bulk orders |

How Are Miniature Screws Used in Electronics Manufacturing?

In the electronics manufacturing sector, miniature screws are essential for the assembly of circuit boards and electronic devices. These screws secure components like capacitors, resistors, and connectors, ensuring their proper alignment and functionality. The precision of miniature screws is vital, as even slight misalignments can lead to device failures. B2B buyers in this industry should prioritize sourcing screws that meet specific size and material standards to ensure compatibility with their assembly processes.

What Role Do Miniature Screws Play in Medical Devices?

Miniature screws are integral to the construction of precision instruments and implants in the medical field. They are used to secure delicate components within devices like surgical tools and diagnostic machines, where reliability is paramount. The screws must comply with stringent regulatory standards and be made from biocompatible materials to ensure patient safety. International buyers must consider sourcing from suppliers who provide documentation for regulatory compliance and traceability.

Why Are Miniature Screws Important in Aerospace and Defense?

In the aerospace and defense sectors, miniature screws are used to fasten components in aircraft and military equipment, where safety is critical. These screws must withstand high-stress environments, including extreme temperatures and vibrations. Buyers in this sector need to focus on sourcing screws that offer corrosion resistance and meet specific certification standards to ensure reliability in mission-critical applications.

How Are Miniature Screws Used in the Automotive Industry?

The automotive industry relies on miniature screws to secure small parts in vehicles, including electronic components and interior fittings. These screws contribute to the overall reliability and performance of vehicles, as they must endure vibrations and varying environmental conditions. B2B buyers should consider sourcing screws that offer high tensile strength and durability, ensuring they meet the rigorous demands of automotive applications.

What Is the Significance of Miniature Screws in Model and Hobby Industries?

In the model and hobby industries, miniature screws are crucial for building detailed models and miniatures. They allow hobbyists to achieve a high level of craftsmanship in their projects, from model trains to intricate dollhouses. Buyers in this market should look for a diverse range of screw sizes and materials to accommodate various projects, ensuring they can source screws in bulk to meet their needs.

3 Common User Pain Points for ‘miniature screws’ & Their Solutions

Scenario 1: Sizing Confusion in Miniature Screws

The Problem: B2B buyers often struggle with selecting the correct size of miniature screws for specific applications. With various standards (imperial vs. metric) and numerous size options available, the risk of misordering is high. This can lead to project delays, increased costs from returns, and even damage to sensitive equipment when inappropriate screws are used. Buyers may find themselves overwhelmed by the technical specifications, leading to frustration and inefficiencies.

The Solution: To mitigate sizing confusion, buyers should invest time in understanding screw sizing charts and standards. It’s critical to specify the exact requirements of the application, including length, diameter, and thread pitch. Utilizing digital tools such as online screw sizing calculators can simplify the selection process. Furthermore, establishing a close relationship with suppliers that offer comprehensive support, including sample products and detailed product specifications, can help ensure the correct screws are sourced. Regular training sessions on screw specifications for procurement teams can also enhance knowledge and minimize errors.

Scenario 2: Material Selection Challenges for Specific Applications

The Problem: Choosing the right material for miniature screws is a common pain point for B2B buyers, especially in industries like electronics and automotive where environmental conditions play a significant role. Buyers may be uncertain whether to opt for stainless steel, brass, or plastic, leading to concerns over durability, corrosion resistance, and overall performance. This indecision can result in project inefficiencies and potential product failures down the line.

The Solution: To effectively select the right material, buyers should conduct a thorough analysis of the operating environment and application requirements. Factors to consider include temperature fluctuations, exposure to moisture or chemicals, and mechanical stress. It is advisable to consult with material experts or manufacturers who can provide insights into the properties of different materials. Implementing a standard material selection guideline within the organization can streamline the decision-making process. Additionally, suppliers who offer material samples or product testing can assist buyers in making informed choices that align with their operational needs.

Scenario 3: Inconsistent Quality Across Suppliers

The Problem: B2B buyers frequently encounter issues with inconsistent quality when sourcing miniature screws from different suppliers. Variations in manufacturing processes can lead to discrepancies in screw dimensions, strength, and finish. This inconsistency can not only disrupt production schedules but can also compromise the integrity of the final products, leading to increased warranty claims and customer dissatisfaction.

The Solution: To address quality concerns, buyers should establish stringent quality control measures when selecting suppliers. This includes requesting certifications such as ISO 9001 that ensure adherence to quality management standards. Conducting thorough supplier audits and requiring detailed quality documentation for each batch of screws can help maintain consistency. Additionally, forming long-term partnerships with a select few suppliers can facilitate better communication and quality assurance processes. Regular feedback loops with suppliers regarding quality issues can also foster improvements and ensure that products meet the necessary specifications reliably.

Strategic Material Selection Guide for miniature screws

What Are the Key Properties of Common Materials Used for Miniature Screws?

When selecting miniature screws for various applications, understanding the properties of different materials is crucial. Here, we analyze four common materials: stainless steel, brass, aluminum, and plastic. Each material offers distinct advantages and disadvantages that can significantly impact performance and suitability for specific applications.

How Does Stainless Steel Perform in Miniature Screw Applications?

Stainless steel, particularly grades like SUS304 or SUS316, is widely used for miniature screws due to its excellent corrosion resistance and high tensile strength. It can withstand temperatures ranging from -200°C to 800°C, making it suitable for high-temperature applications. However, while stainless steel screws provide durability and a polished finish, they can be more expensive compared to other materials.

Pros: High strength, corrosion resistance, and aesthetic appeal.

Cons: Higher cost and potential for galling during installation.

Impact on Application: Ideal for environments exposed to moisture or chemicals, such as in the automotive or marine industries.

Considerations for Buyers: Compliance with international standards like ASTM and DIN is essential, especially for markets in Europe and the Middle East.

What Advantages Does Brass Offer for Miniature Screws?

Brass is another popular choice for miniature screws, known for its excellent machinability and good corrosion resistance, particularly in non-oxidizing environments. It is often used in electrical applications due to its conductivity. However, brass is softer than stainless steel, which can limit its use in high-stress applications.

Pros: Good electrical conductivity, ease of machining, and aesthetic finish.

Cons: Lower strength compared to stainless steel and susceptibility to dezincification in certain environments.

Impact on Application: Commonly used in electrical connectors and decorative applications.

Considerations for Buyers: Ensure compliance with JIS standards for electrical applications, especially in regions like Japan and South America.

How Does Aluminum Compare for Miniature Screws?

Aluminum screws are lightweight and resistant to corrosion, making them suitable for applications where weight is a critical factor, such as in aerospace or automotive industries. They can withstand moderate temperatures but may not perform well under extreme conditions. The cost of aluminum screws is generally lower than that of stainless steel.

Pros: Lightweight, good corrosion resistance, and cost-effective.

Cons: Lower strength and potential for deformation under heavy loads.

Impact on Application: Ideal for lightweight assemblies and applications where weight reduction is essential.

Considerations for Buyers: Familiarity with ISO standards is vital, particularly for buyers in Europe.

What Role Does Plastic Play in Miniature Screw Selection?

Plastic screws, often made from materials like nylon or PEEK, offer unique advantages, including chemical resistance and non-conductivity. They are suitable for applications where metal screws might corrode or where electrical insulation is required. However, plastic screws generally have lower strength and temperature resistance compared to metal options.

Pros: Corrosion resistance, lightweight, and electrical insulation.

Cons: Limited load-bearing capacity and lower temperature resistance.

Impact on Application: Useful in electronic devices and environments with corrosive substances.

Considerations for Buyers: Ensure compliance with relevant safety standards, particularly in the electronics sector.

Summary Table of Material Selection for Miniature Screws

| Material | Typical Use Case for miniature screws | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Automotive, marine applications | High strength and corrosion resistance | Higher cost and galling potential | High |

| Brass | Electrical connectors, decorative use | Good conductivity and machinability | Softer, lower strength | Medium |

| Aluminum | Aerospace, automotive lightweight parts | Lightweight and cost-effective | Lower strength, deformation risk | Low |

| Plastic | Electronics, corrosive environments | Chemical resistance and insulation | Limited load capacity, low temperature resistance | Low |

This guide provides B2B buyers with the essential insights needed to make informed decisions regarding the selection of miniature screws based on material properties, application suitability, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for miniature screws

What Are the Key Stages in the Manufacturing Process of Miniature Screws?

The production of miniature screws involves several critical stages that ensure precision and quality. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials, typically metals like stainless steel, brass, or aluminum. These materials must meet specific mechanical and chemical properties to ensure durability and performance. Suppliers often conduct preliminary inspections of the material to verify compliance with industry standards before proceeding.

-

Forming: The forming stage is crucial for creating the desired shapes and sizes of screws. Techniques such as cold heading and machining are commonly used. Cold heading involves shaping the metal at room temperature, which enhances its strength. For very small screws, precision machining techniques like CNC (Computer Numerical Control) machining may be employed to achieve intricate designs.

-

Assembly: This stage may involve additional components, such as washers or nuts, depending on the screw’s intended application. Automated assembly systems are increasingly used to ensure consistency and reduce production times.

-

Finishing: After forming and assembly, screws undergo finishing processes, including surface treatments like plating, anodizing, or passivation. These treatments enhance corrosion resistance and improve aesthetic appeal. Quality checks are performed at this stage to ensure that the screws meet specifications for surface finish and dimensional tolerances.

How Is Quality Assurance Implemented During the Manufacturing of Miniature Screws?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that the final products meet industry standards and customer expectations. Various international and industry-specific standards are applied, with ISO 9001 being one of the most recognized for general quality management systems.

-

International Standards: Compliance with ISO 9001 ensures that manufacturers implement effective quality management systems, focusing on continuous improvement and customer satisfaction. Additionally, industry-specific standards such as CE marking for products sold in Europe or API specifications for oil and gas applications can also be relevant, depending on the screw’s application.

-

Quality Control Checkpoints: Throughout the manufacturing process, several checkpoints are established:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During production, random sampling and inspections are conducted to monitor processes and detect any deviations from quality standards.

– Final Quality Control (FQC): At the end of production, a comprehensive inspection is performed, including dimensional checks, functional tests, and surface quality assessments. -

Common Testing Methods: Testing methods commonly used include tensile testing, hardness testing, and dimensional inspections. For miniature screws, it is vital to ensure that the screws can withstand the specified loads without deformation.

What Should B2B Buyers Know About Verifying Supplier Quality Control?

For B2B buyers, especially those operating in diverse international markets, verifying a supplier’s quality control processes is essential. Here are actionable insights:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures. During an audit, buyers should assess the supplier’s adherence to quality standards, equipment used, and employee training programs.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand the testing methods employed and the results achieved. These reports should outline compliance with relevant international standards and any certifications obtained.

-

Third-party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These agencies can perform inspections at various stages of production and provide certification that may be required for international trade.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate several nuances when it comes to quality control:

-

Understanding Regional Standards: Different regions may have specific standards and regulations that apply to miniature screws. For instance, European buyers may require CE marking, while buyers in the Middle East might focus on local compliance certifications.

-

Cultural and Language Differences: Effective communication is crucial for ensuring that quality expectations are clearly understood. Buyers should be prepared to address any language barriers and cultural differences that may affect quality assurance practices.

-

Logistical Considerations: The global supply chain can introduce variability in quality. Buyers should consider how shipping, handling, and storage conditions may affect product integrity. Establishing clear agreements on quality expectations and logistics can mitigate these risks.

Conclusion

Understanding the manufacturing processes and quality assurance measures for miniature screws is vital for B2B buyers across various international markets. By focusing on material preparation, forming, assembly, and finishing, alongside robust quality control practices, suppliers can deliver high-quality products that meet diverse customer needs. Buyers should prioritize supplier verification through audits, quality reports, and third-party inspections, while also being mindful of the specific quality control nuances tied to their regional markets. This comprehensive approach will help ensure the procurement of reliable, high-performance miniature screws that align with their business requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘miniature screws’

Introduction

This guide provides a comprehensive checklist for B2B buyers seeking to procure miniature screws, an essential component in various industries, including electronics, precision instruments, and hobby modeling. Understanding the sourcing process is crucial for ensuring quality, reliability, and cost-effectiveness. By following these steps, you can make informed decisions that align with your project requirements.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical requirements for the miniature screws you need. Consider factors such as size, thread type, material (e.g., stainless steel, brass, or nylon), and intended application.

- Key Considerations:

- Determine the diameter and length required for your project.

- Specify any environmental conditions the screws must withstand, such as corrosion or heat.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify potential suppliers of miniature screws. Look for suppliers with a strong reputation and extensive experience in your industry.

- Where to Look:

- Online marketplaces, industry-specific directories, and trade shows.

- Review supplier websites for product catalogs and customer testimonials.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international standards. This step is vital to ensure the screws meet quality and safety regulations.

- What to Check:

- ISO certifications, which indicate a commitment to quality management.

- Compliance with industry standards relevant to your application.

Step 4: Request Samples for Testing

Always request samples of the miniature screws before placing a bulk order. Testing samples allows you to assess the quality and suitability of the screws for your specific application.

- Testing Parameters:

- Check for dimensional accuracy and material integrity.

- Conduct stress and load tests to ensure they meet performance expectations.

Step 5: Assess Pricing and Payment Terms

Once you have narrowed down your suppliers, compare pricing and payment terms. This step is crucial for budgeting and ensuring that your procurement process remains financially viable.

- Considerations:

- Look for bulk purchase discounts or loyalty programs.

- Clarify payment terms, including deposits, credit options, and payment methods.

Step 6: Confirm Delivery and Lead Times

Understanding the supplier’s delivery capabilities and lead times is essential to align with your project schedules. Confirm these details to avoid delays that could impact your operations.

- Key Points:

- Inquire about shipping options and costs.

- Ensure the supplier can meet your required delivery dates.

Step 7: Establish Communication and Support Channels

After selecting a supplier, establish clear communication channels for ongoing support. Good communication is vital for addressing any issues that may arise during the order process.

- Communication Strategies:

- Set up regular check-ins or updates regarding your order status.

- Ensure you have access to customer support for any inquiries or concerns.

By following this checklist, B2B buyers can streamline the procurement of miniature screws, ensuring they select the right products from reliable suppliers while optimizing costs and timelines.

Comprehensive Cost and Pricing Analysis for miniature screws Sourcing

What Are the Key Cost Components in Miniature Screws Sourcing?

When sourcing miniature screws, understanding the cost structure is essential for effective budgeting and procurement. The primary cost components include:

-

Materials: The choice of materials significantly impacts cost. Common materials for miniature screws include stainless steel, brass, and aluminum. Stainless steel screws tend to be more expensive due to their durability and corrosion resistance, while plastic options can be more cost-effective for specific applications.

-

Labor: Labor costs vary based on the manufacturing location and complexity of the screws. Regions with lower labor costs can provide substantial savings, but this may come at the expense of quality or lead times.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and indirect labor. High overhead can affect pricing, particularly for manufacturers with advanced technology or strict quality controls.

-

Tooling: Custom tooling can be a significant upfront investment, particularly for bespoke screw designs. Buyers should consider whether the tooling costs can be amortized over a large order quantity to achieve better pricing.

-

Quality Control (QC): Ensuring quality in miniature screws is critical, especially for precision applications. Enhanced QC measures may lead to higher costs, but they are essential for avoiding failures in the final product.

-

Logistics: Transportation and shipping costs can vary widely, especially for international orders. Consideration of Incoterms is vital, as they dictate responsibilities for shipping, insurance, and tariffs.

-

Margin: Suppliers typically mark up their costs to ensure profitability. Understanding the supplier’s margin can help buyers negotiate better prices.

How Do Price Influencers Affect Miniature Screws Costs?

Several factors can influence the pricing of miniature screws, including:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often attract significant discounts. Buyers should assess their needs to determine whether it’s feasible to order larger quantities, potentially lowering the per-unit cost.

-

Specifications and Customization: Custom specifications can increase costs due to the need for specialized tooling and manufacturing processes. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Selection: As previously mentioned, material choice can greatly affect price. High-performance materials, such as PEEK or SUSXM7, may be necessary for certain applications but will come at a premium.

-

Quality and Certifications: International standards or certifications (e.g., ISO, RoHS) may be required for certain applications. Suppliers who provide certified products may charge more, but this can be essential for compliance in regulated markets.

-

Supplier Factors: Reliability, reputation, and location of suppliers can affect pricing. Established suppliers with a track record of quality may charge more than lesser-known manufacturers.

-

Incoterms: The chosen Incoterms can influence the final cost significantly. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to avoid unexpected charges.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Miniature Screws?

To maximize cost-efficiency when sourcing miniature screws, consider the following strategies:

-

Negotiation: Always negotiate pricing and terms with suppliers. Leverage your understanding of cost components to discuss price adjustments based on your purchasing power or long-term commitments.

-

Total Cost of Ownership (TCO): Look beyond the purchase price. Consider factors such as shipping, storage, and potential quality issues that could lead to rework or product failure. TCO analysis can reveal the true cost of sourcing decisions.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa or South America should be aware of currency fluctuations, import tariffs, and local regulations that could impact final costs. Building relationships with local suppliers may also help mitigate some of these challenges.

-

Supplier Diversification: Relying on a single supplier can expose you to risks, including price hikes or supply chain disruptions. Diversifying your supplier base can enhance negotiation leverage and ensure continuity in supply.

-

Market Research: Keeping abreast of market trends and price changes can help you make informed decisions and identify the best times to purchase.

Disclaimer

Prices for miniature screws can vary widely based on the factors discussed above. The information provided is indicative and should be used as a guideline for budgeting and sourcing strategies. Always obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing miniature screws With Other Solutions

When evaluating fastening solutions for intricate projects, it’s essential to consider alternatives to miniature screws. Various methods and technologies can fulfill similar roles in assembly and construction, each with unique strengths and weaknesses. This analysis compares miniature screws against two viable alternatives: adhesive bonding and snap-fit fasteners, focusing on key performance aspects.

| Comparison Aspect | Miniature Screws | Adhesive Bonding | Snap-Fit Fasteners |

|---|---|---|---|

| Performance | High strength, precision fit | Strong bond, but may weaken with heat or moisture | Good for quick assembly, limited load capacity |

| Cost | Moderate, depending on materials | Generally lower cost but varies by type | Cost-effective for high-volume production |

| Ease of Implementation | Requires tools and precision | Can be messy; curing time needed | Easy to assemble, no tools required |

| Maintenance | Low, but may require tightening | Minimal, but repair can be difficult | Low, but not reusable if disassembled |

| Best Use Case | Precision instruments, models | Electronics, non-load bearing applications | Toys, consumer products, automotive components |

What Are the Advantages and Disadvantages of Adhesive Bonding?

Adhesive bonding offers a seamless aesthetic and is particularly effective for joining dissimilar materials. Its versatility makes it ideal for applications in electronics and non-load bearing scenarios, where a robust bond is necessary without the need for physical fasteners. However, adhesives can have drawbacks, such as sensitivity to temperature and moisture, which may compromise the bond over time. Additionally, the application process can be messy, and the curing time can delay production.

How Do Snap-Fit Fasteners Compare to Miniature Screws?

Snap-fit fasteners facilitate rapid assembly and disassembly without the need for tools, making them an excellent choice for consumer products and toys. Their design allows for quick production and assembly, leading to lower labor costs in high-volume applications. However, snap-fit fasteners may not withstand heavy loads, limiting their use in more demanding environments. Once removed, they are often not reusable, which can lead to waste in certain applications.

Conclusion: How Should B2B Buyers Choose the Right Fastening Solution?

Selecting the appropriate fastening solution depends on several factors, including the specific application, required performance characteristics, and budget constraints. Miniature screws are best suited for precision work where strength and reliability are paramount. In contrast, adhesive bonding may be favorable for applications where aesthetics and weight reduction are prioritized, while snap-fit fasteners can streamline assembly processes in mass production settings. B2B buyers should carefully assess their project requirements and consider the long-term implications of each fastening method to make an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for miniature screws

What Are the Key Technical Properties of Miniature Screws?

When considering miniature screws for various applications, understanding their technical specifications is critical for ensuring compatibility and performance. Here are several essential properties:

1. Material Grade

Miniature screws are commonly made from materials such as stainless steel, brass, and aluminum. Stainless steel (like SUS304) offers excellent corrosion resistance and strength, making it ideal for outdoor or industrial applications. Brass provides good conductivity and resistance to tarnishing, while aluminum is lightweight and suitable for applications where weight is a concern. Choosing the right material affects the longevity and performance of the screw in its intended environment.

2. Thread Size and Type

The thread size and type are crucial for ensuring proper fit and function. Common sizes include metric (M1, M2) and imperial (0-80, 1-72). The choice of thread type—such as coarse or fine—affects the screw’s holding power and ease of installation. Understanding these specifications is vital for manufacturers and assemblers to avoid issues such as stripping or insufficient grip.

3. Tolerance

Tolerance refers to the allowable variation in screw dimensions, which can affect the fit and performance of the fastener. Tight tolerances are critical in precision applications, such as electronics or medical devices, where even minor deviations can lead to malfunctions. High tolerance levels ensure that screws fit snugly and securely, enhancing overall product quality.

4. Head Type

The head type of miniature screws can vary widely, including flat, pan, hex, and socket heads. Each design serves different functional needs; for instance, flat heads are often used in applications where a flush finish is required, while hex heads allow for higher torque during installation. Selecting the appropriate head type is essential for ensuring ease of use and structural integrity.

5. Finish and Coating

The finish or coating applied to miniature screws can enhance their performance and appearance. Common finishes include zinc plating, black oxide, and anodizing. These coatings can provide additional corrosion resistance, improve aesthetics, and reduce friction during installation. It’s important for buyers to consider the specific environmental conditions the screws will face when selecting a finish.

What Trade Terminology Should B2B Buyers Know About Miniature Screws?

Understanding industry terminology is crucial for effective communication and negotiation in the B2B landscape. Here are some key terms related to miniature screws:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products for other companies to sell under their brand. In the context of miniature screws, buyers often look for OEM suppliers to ensure that the screws meet specific quality and design standards required for their products.

2. MOQ (Minimum Order Quantity)

MOQ denotes the minimum number of units a supplier is willing to sell. This term is critical for B2B buyers as it directly affects inventory management and cash flow. Understanding MOQ helps buyers plan their orders and negotiate better pricing based on volume.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing for specific products or services. In the miniature screw market, an RFQ allows buyers to compare prices and terms from multiple suppliers, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding the transportation of goods. Understanding these terms is essential for B2B transactions involving miniature screws, as they dictate who is responsible for shipping costs, insurance, and risk during transit.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For miniature screws, lead times can vary based on factors like manufacturing capabilities and shipping logistics. Buyers must consider lead time when planning production schedules to avoid delays.

By grasping these essential properties and trade terms, B2B buyers can make more informed decisions when sourcing miniature screws, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the miniature screws Sector

What Are the Current Market Dynamics and Key Trends in the Miniature Screws Sector?

The miniature screws market is experiencing significant growth driven by advancements in technology and increasing demand from various sectors, including electronics, automotive, and medical devices. Key trends include the shift towards automation and precision engineering, which are essential for the production of compact and high-performance components. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers that can deliver high-quality, precise fasteners that meet specific industry standards.

Emerging technologies such as 3D printing and CNC machining are reshaping the sourcing landscape, allowing for customization and rapid prototyping of miniature screws. This trend is particularly beneficial for buyers who require specific dimensions or materials. Furthermore, the rise of e-commerce platforms is facilitating easier access to international suppliers, enabling buyers from diverse markets to source miniature screws directly and efficiently. As the market evolves, it is crucial for buyers to stay informed about these dynamics to optimize their sourcing strategies and ensure they align with industry innovations.

How Is Sustainability and Ethical Sourcing Affecting the Miniature Screws Market?

Sustainability has become a pivotal concern in the miniature screws sector, reflecting a broader global trend towards responsible manufacturing practices. The environmental impact of production processes, particularly in terms of resource consumption and waste generation, is prompting buyers to seek suppliers who prioritize eco-friendly practices. This includes the use of recyclable materials and energy-efficient manufacturing processes.

Ethical sourcing is equally important, as buyers are increasingly aware of the social implications of their procurement choices. Suppliers that demonstrate compliance with labor standards and fair trade practices are favored in the marketplace. Certifications such as ISO 14001 for environmental management and OHSAS 18001 for occupational health and safety are becoming essential for suppliers looking to differentiate themselves. By prioritizing sustainability and ethical sourcing, international B2B buyers can enhance their brand reputation and meet the growing consumer demand for responsible products.

What Is the Brief Evolution and History of Miniature Screws in the B2B Market?

The history of miniature screws can be traced back to the early industrial revolution when precision engineering began to emerge. Initially used in simple mechanical devices, the demand for smaller, more intricate screws grew with the advent of electronics and precision instruments in the 20th century. As technology progressed, the manufacturing processes for miniature screws evolved, incorporating advanced materials and innovative techniques to meet the rising standards for quality and performance.

In recent years, the globalization of supply chains has further transformed the miniature screws market. International collaboration has enabled manufacturers to leverage specialized capabilities and materials from various regions, catering to a broader range of applications. Today, miniature screws are indispensable components across multiple industries, reflecting the ongoing evolution of technology and manufacturing practices that continue to shape the B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of miniature screws

-

How do I select the right miniature screws for my application?

Choosing the right miniature screws involves understanding the specific requirements of your application. Factors to consider include the screw size, material (such as stainless steel, brass, or plastic), thread type, and head style. It’s crucial to assess the environmental conditions—like exposure to moisture or chemicals—that could impact screw performance. Additionally, consulting with suppliers for technical specifications and samples can help ensure that you select the most suitable screws for your projects. -

What are the advantages of using miniature screws in precision engineering?

Miniature screws offer several advantages in precision engineering, including their ability to secure small components without adding unnecessary weight. They are essential for applications in electronics, medical devices, and intricate machinery where space is limited. Their small size allows for more compact designs, while materials like stainless steel provide durability and resistance to corrosion. Ultimately, using the right miniature screws enhances product reliability and performance. -

What is the minimum order quantity (MOQ) for miniature screws?

Minimum order quantities (MOQs) for miniature screws can vary significantly among suppliers and depend on factors like material type and manufacturing processes. Generally, MOQs can range from as low as 100 pieces to several thousand. It’s advisable to discuss your specific needs with suppliers to negotiate favorable terms, especially if you’re testing a new product line. Understanding the MOQ can help you manage inventory costs and production timelines effectively. -

How can I ensure the quality of miniature screws from international suppliers?

To ensure quality, vet potential suppliers by reviewing their certifications, manufacturing processes, and quality control measures. Request product samples to assess the screw’s fit and finish. Additionally, consider third-party quality inspections or audits, especially for larger orders. Building a relationship with suppliers and maintaining open communication can also help address any quality concerns promptly. Regular feedback and performance reviews are essential for long-term success. -

What payment terms are commonly offered by suppliers of miniature screws?

Payment terms can vary widely among suppliers, typically ranging from upfront payment to net 30 or net 60 days after delivery. Some suppliers may offer discounts for early payments or bulk orders. It’s crucial to discuss payment options upfront to align with your cash flow needs. Additionally, consider using secure payment methods and trade financing options to mitigate risks when dealing with international suppliers. -

How do I handle logistics and shipping for miniature screws from overseas suppliers?

When sourcing miniature screws internationally, coordinate logistics by selecting reliable freight forwarders experienced in handling small components. Discuss shipping options, including air freight for urgent orders or sea freight for cost-effective solutions. Always account for customs regulations and duties, as they can impact delivery times and overall costs. Establishing clear communication with suppliers regarding shipping timelines will help you manage expectations and maintain production schedules. -

What customization options are available for miniature screws?

Many suppliers offer customization options for miniature screws, including variations in size, thread type, material, and coatings. Customization can help meet specific application requirements, such as increased corrosion resistance or unique head designs. Engaging with suppliers early in the design process allows for better collaboration on tailored solutions. Be prepared to provide detailed specifications and potentially pay higher costs for customized orders. -

What are the best practices for sourcing miniature screws internationally?

When sourcing miniature screws internationally, conduct thorough research to identify reputable suppliers with a track record of reliability and quality. Utilize platforms like trade shows and B2B marketplaces to connect with manufacturers. Request samples to evaluate product quality and engage in clear communication about specifications and lead times. Additionally, consider establishing contracts that outline terms of delivery, quality assurance, and payment to safeguard your interests in the transaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Miniature Screws Manufacturers & Suppliers List

1. Micro-Mark – Miniature Hardware

Domain: micromark.com

Registered: 1997 (28 years)

Introduction: Miniature Hardware including Tiny Screws & Nuts available at Micro-Mark.

2. US Micro Screw – Custom Micro Screws and Miniature Fasteners

Domain: usmicroscrew.com

Registered: 2009 (16 years)

Introduction: US Micro Screw specializes in custom manufactured micro screws and miniature fasteners. Key product details include:

– Micro screw sizes starting from M0.6 / #000 and larger.

– Ultra thin head capabilities with thicknesses down to 0.2mm.

– All thread options available: machine screws, plastic thread forming screws, and custom threads.

– Low minimum order quantity of 1,000 pieces for custom ord…

3. Micro Fasteners – Fasteners & Screws

Domain: microfasteners.com

Registered: 1996 (29 years)

Introduction: Micro Fasteners offers a wide range of fasteners including socket screws, machine screws, locknuts, washers, sheet metal screws, self-tapping screws, wood screws, and other related items in both U.S. and metric sizes. The product categories include New Products, Sale Items, Fastener Assortments, Metric Nylon Machine Screws, Self-tapping (Sheet Metal) and Wood Screws, Hardware Set Screws, Rivets, T…

4. McMaster – Miniature Screws

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Miniature Screws, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

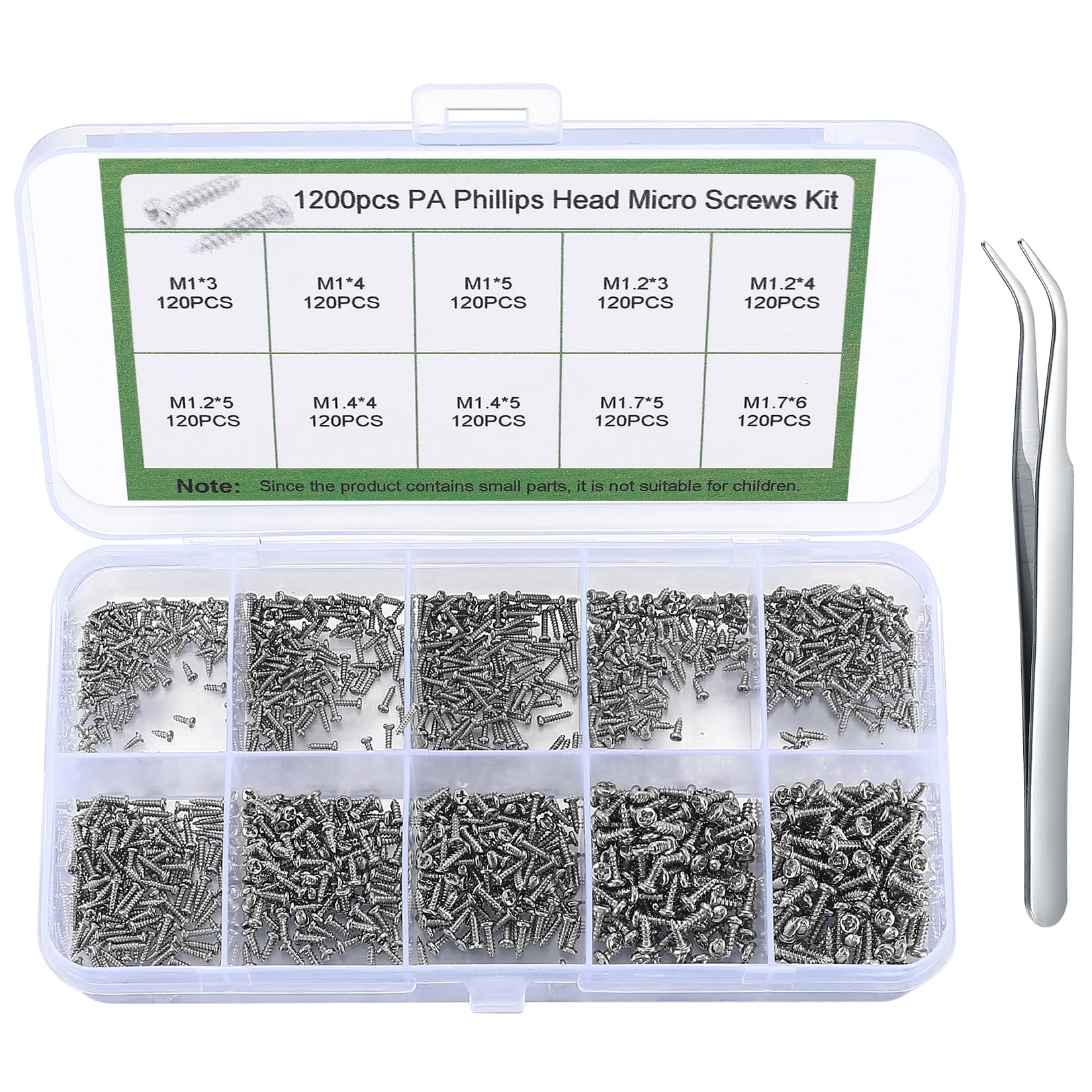

5. RANMEI – Mini Screw Kit 1200Pcs

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, RANMEI – Mini Screw Kit 1200Pcs, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. JCIS Electronics – Mini Screws & Fasteners

Domain: newcoproducts.com

Registered: 1996 (29 years)

Introduction: JCIS Electronics Mini Screws, Fasteners, Metric Micro Screws, USA Standard Fasteners, DIN / European Metric Fasteners, JIS / Japanese Fasteners, Assortments of various bolts, nuts, screws, and washers including A2 Stainless, Yellow Zinc, Black Zinc, and Aluminum options. Includes DIN 931, DIN 933, DIN 960, DIN 961, DIN 7603, and various machine screws and sheet metal screws.

7. MicroFast – Micro Size Screws, Nuts, and Washers

Domain: jcfasteners.com

Registered: 2004 (21 years)

Introduction: MicroFast Micro Size Screws, Nuts and Washers including MicroFast Machine Screws, Self-Tapping Screws, Self-Drilling Screws, Hex Self-Drilling Screws, Pan Self-Drilling Screws, CSK Self-Drilling Screws, Wafer Head Self-Drilling Screws, various types of Self Tapping Screws (Slotted, Phillips, Torx, Allen), JCPlas Thread Forming Screws for Plastics, MicroFast Micro Nuts & Washers, Security Fasteners…

8. Reddit – Sewing Machine Screw

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Teeny tiny screw for an old sewing machine; potential local sources include Ace Hardware and a sewing machine repair shop near Eastgate in Chapel Hill. Recommendations suggest checking with Mike, who operates out of a yarn store for sewing machine repairs. Ace Hardware in Woodcroft shopping center has a decent selection of machine screws. McMaster.com is also recommended for hardware needs.

9. NBK – SNZS-ALK Pan Head Machine Screws

Domain: nbk1560.com

Registered: 2000 (25 years)

Introduction: SNZS-ALK_Pan Head Machine Screws for Precision Instruments (Miniature Screws with Nylon Patch)

Strategic Sourcing Conclusion and Outlook for miniature screws

The landscape of miniature screws is evolving, presenting significant opportunities for strategic sourcing. By prioritizing quality and compatibility, businesses can enhance their product offerings and ensure durability in critical applications. Understanding regional preferences and materials—such as brass, stainless steel, and aluminum—will enable international buyers to make informed decisions that align with their operational needs.

In regions like Africa, South America, the Middle East, and Europe, the demand for high-quality miniature screws is driven by diverse industries, from electronics to precision instruments. Cultivating strong relationships with reliable suppliers can streamline procurement processes, minimize costs, and mitigate supply chain disruptions. Additionally, embracing digital platforms for sourcing can facilitate access to a broader range of products and suppliers, enhancing competitiveness in the global market.

Looking ahead, it is essential for B2B buyers to stay abreast of technological advancements and market trends impacting miniature screw manufacturing. By adopting a proactive sourcing strategy, businesses can position themselves favorably in an increasingly interconnected marketplace. Engage with suppliers today to explore innovative solutions that drive efficiency and quality in your projects.