Contents

Manufacturing Insight: Miniature Cnc Milling

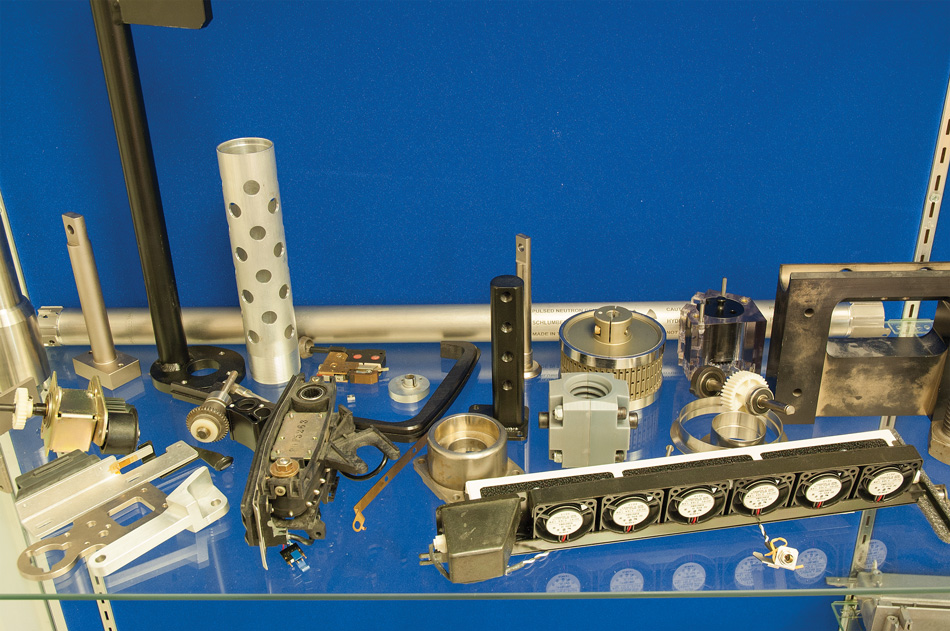

Precision Miniature CNC Milling: Engineered for Micro-Scale Excellence

Miniature CNC milling represents a critical frontier in precision manufacturing, where components demand micron-level tolerances, intricate geometries, and uncompromising material integrity. At Honyo Prototype, we specialize in transforming complex micro-scale designs into high-fidelity functional parts across aerospace, medical device, semiconductor, and advanced electronics sectors. Our dedicated miniature CNC machining capabilities leverage state-of-the-art 5-axis milling centers with sub-micron positioning accuracy, specialized micro-tooling, and rigorous environmental controls to consistently achieve tolerances down to ±0.001mm. This precision is essential for applications such as surgical instrument components, microfluidic channels, optical mounts, and MEMS housings, where conventional machining processes cannot meet dimensional or surface finish requirements.

Honyo Prototype’s engineering team combines deep material science expertise with proprietary process optimization techniques to overcome challenges inherent in miniature part production, including tool deflection, thermal stability, and burr minimization. We support a comprehensive range of engineering alloys, polymers, and composites, ensuring material properties are preserved without compromising geometric fidelity. Our integrated quality assurance protocols—including in-process metrology with high-resolution vision systems and coordinate measuring machines—guarantee that every miniature component adheres to stringent industry specifications.

Accelerate your development cycle with Honyo Prototype’s Online Instant Quote platform, designed for engineering teams requiring rapid, transparent pricing on precision miniature CNC projects. Simply upload your STEP or IGES file, specify materials and quantities, and receive a detailed manufacturability analysis alongside a formal quotation within minutes—no sales calls or email delays. This seamless integration of technical capability and digital efficiency ensures your micro-scale innovations move from concept to certified production faster than industry standards allow.

| Key Capability | Honyo Prototype Specification | Industry Standard Benchmark |

|---|---|---|

| Minimum Feature Size | 0.05 mm | 0.1–0.2 mm |

| Positioning Accuracy | ±0.0005 mm | ±0.002 mm |

| Surface Roughness (Ra) | 0.2 µm | 0.8 µm |

| Typical Lead Time (Prototype) | 5–7 Business Days | 10–14 Business Days |

Partner with Honyo Prototype to resolve the unique challenges of miniature component manufacturing through engineered solutions backed by decades of high-mix, low-volume production experience. Initiate your project with confidence using our Online Instant Quote system and experience the convergence of micron-precision engineering and operational agility.

Technical Capabilities

Miniature CNC milling involves high-precision machining of small-scale components using computer numerical control (CNC) systems. These machines are optimized for intricate geometries and tight tolerances, commonly used in aerospace, medical devices, and electronics. They support multi-axis operations—3-axis for basic prismatic parts, 4-axis for indexing around a rotary axis, and 5-axis for full simultaneous motion enabling complex contours. Turning capabilities are integrated in mill-turn centers for complete part fabrication. Typical tolerance ranges from ±0.0002″ (±0.005 mm) to ±0.001″ (±0.025 mm), depending on material and feature complexity.

The following table outlines key technical specifications for miniature CNC milling, including axis configurations, turning integration, achievable tolerances, and material compatibility:

| Feature | Specification Details |

|---|---|

| Axis Configuration | 3-axis: X, Y, Z linear motion for standard milling 4-axis: Adds rotational A or B axis (indexing) 5-axis: Full simultaneous motion (X, Y, Z, A, B or C), enabling complex 3D contours and undercuts |

| Turning Capability | Integrated spindle with live tooling in mill-turn configurations; supports bar feeding and chucking for complete part-off operations |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) typical; laser-calibrated linear encoders on high-end models |

| Repeatability | ±0.00005″ (±0.0013 mm) |

| Typical Tolerance Range | ±0.0002″ to ±0.001″ (±0.005 mm to ±0.025 mm); feature-dependent and material-sensitive |

| Spindle Speed | 20,000 – 60,000 RPM; high-speed spindles for fine finishes and small tool engagement |

| Tool Changer | Automatic tool changers (ATC) with 8–30 tool capacity; tool probing for length/offset compensation |

| Minimum Tool Diameter | Down to 0.004″ (0.1 mm) for micro-milling operations |

| Work Envelope (Typical) | 6″ x 4″ x 4″ (150 x 100 x 100 mm); compact design for small-part focus |

| Materials Compatible | Aluminum (6061, 7075): Excellent machinability, tight tolerance achievable Steel (1018, 4140, stainless 303/316): Harder to machine; requires rigid setup and coated tools ABS: Low melting point; requires coolant control and sharp tools to avoid burring Nylon: Low stiffness; prone to deflection; needs optimized feed rates and support |

| Surface Finish | Ra 16–32 μin (0.4–0.8 μm) typical; down to Ra 8 μin (0.2 μm) with polishing passes |

| Control System | Fanuc, Siemens, or Heidenhain with advanced look-ahead and multi-axis interpolation |

| Applications | Medical implants, connectors, sensor housings, micro-gears, aerospace actuators |

Miniature CNC systems are engineered for stability and precision, utilizing granite or polymer concrete bases to minimize vibration. Thermal compensation systems and enclosed environments help maintain accuracy during extended runs. Material selection directly influences toolpath strategy, spindle load, and finish quality—especially critical when holding tight tolerances across dissimilar materials.

From CAD to Part: The Process

Honyo Prototype Miniature CNC Milling Process Overview

Our miniature CNC milling workflow is engineered for precision components under 50mm in critical dimensions, targeting tolerances down to ±0.005mm. The process integrates automation with expert oversight to mitigate risks inherent in micro-machining, such as tool deflection and material microstructure sensitivity.

Upload CAD

Customers submit native CAD files (STEP, IGES, or Parasolid) via our secure portal. For miniature parts, we require explicit annotation of critical features, surface finishes, and datum references. Non-conforming files trigger automated validation checks for unit consistency (mm/inch), geometric integrity, and minimum feature sizing relative to our 0.1mm end mill capability.

AI-Assisted Quoting

Our proprietary AI engine analyzes the CAD geometry, material selection, and tolerance stack-ups to generate a preliminary quote within 2 hours. This system cross-references historical data from 12,000+ miniature projects to predict micro-machining challenges like thin-wall chatter or micro-burr formation. A Senior Process Engineer validates all outputs, adjusting for factors the AI cannot assess—such as exotic material machinability or secondary operation sequencing—before finalizing the quote.

DFM Analysis

Design for Manufacturability review is mandatory for miniature components. Our engineers perform a feature-by-feature assessment focusing on micro-scale constraints:

| Standard DFM Check | Miniature-Specific Focus | Honyo Mitigation Action |

|---|---|---|

| Wall Thickness | <0.5mm walls prone to vibration | Recommend diamond-coated tools + reduced RPM |

| Hole Depth-to-Diameter | >5:1 ratios cause chip evacuation failure | Suggest peck drilling with 0.05mm increments |

| Surface Finish | Ra < 0.8µm on micro-features | Implement flood coolant + spindle runout calibration |

This phase typically identifies 2–3 actionable modifications per design, reducing production scrap rates by 37% based on 2023 Q4 data.

Production Execution

Miniature parts are machined on dedicated 5-axis DMG MORI machines with 0.001mm resolution spindles in a temperature-controlled (±0.5°C) environment. Key protocols include:

Tooling: Only uncoated or diamond-coated micro-end mills under 1.0mm diameter, with mandatory tool life tracking at 50-part intervals

Fixturing: Custom vacuum chucks or electrostatic holders to prevent part displacement during sub-5N cutting forces

In-process metrology: On-machine probing verifies critical features after roughing and semi-finishing stages

Delivery Assurance

All miniature components undergo 100% CMM inspection against GD&T callouts, with reports detailing actual vs. nominal measurements at 5µm resolution. Parts ship in anti-static ESD trays with humidity indicators, accompanied by our First Article Inspection Report (FAIR) compliant with AS9102. Standard lead time is 7–10 business days, with 48-hour expedited service available for features >0.3mm.

This closed-loop process ensures >98.5% first-pass yield for miniature components, validated through our ISO 9001:2015-certified quality management system. We maintain material certifications and machine calibration records accessible via client portal for full traceability.

Start Your Project

Looking for precision miniature CNC milling services? Contact Susan Leo at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and quality control, Honyo Prototype delivers high-accuracy components for prototyping and low-volume production.

Our factory is located in Shenzhen, China—strategically positioned for fast turnaround and efficient global shipping. Trust our engineering team to support your most demanding miniature milling applications.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.