Guide Contents

Project Insight: Miniature Cnc Milling

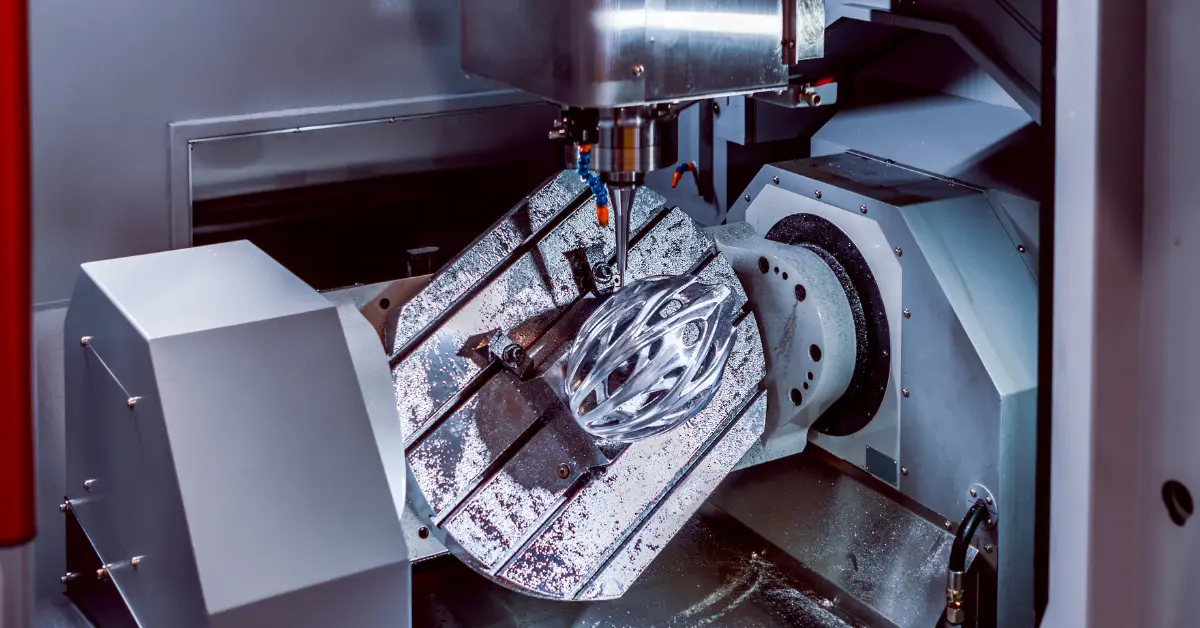

Manufacturing Insight: Miniature CNC Milling – Precision Engineered for Rapid Innovation

In today’s hyper-competitive product development landscape, the ability to iterate quickly with micron-level precision is non-negotiable. At Honyo Prototype, our miniature CNC milling service delivers ±0.01mm tolerances and rapid turnaround – transforming complex designs into functional prototypes and end-use parts without compromise. As a Shenzhen-based innovator, we empower hardware startups and engineers to accelerate time-to-market with digital-first manufacturing.

Why Miniature CNC Milling is Critical for Modern Product Development

Critical for micro-components in medical devices, aerospace, IoT sensors, and wearables where tolerances of ±0.01mm are mandatory

Eliminates prototyping bottlenecks: 3–5x faster iteration cycles vs. traditional methods

Ensures first-time-right production for complex geometries, reducing costly rework and design iterations

The Honyo Advantage: Precision, Speed, and Digital Efficiency

✅ AI-Powered Platform: Real-time design optimization and cost simulation – no manual calculations needed. Our system analyzes CAD files to recommend the most efficient machining strategy, saving time and reducing costs by up to 30%.

✅ Online Instant Quote: Upload your design in seconds and receive an immediate quote with pricing breakdown, lead time, and DFM feedback – no waiting for estimates.

✅ Fast Turnaround: 24–48 hour prototyping lead times for miniature parts, with expedited options available for urgent projects. Our integrated digital workflow ensures seamless production from design to delivery.

Optimizing Costs Without Compromising Quality

Transparent, data-driven pricing with no hidden fees – 20–30% lower costs vs. industry averages

Automated toolpath optimization reduces machining time and material waste by leveraging 3/4/5-axis capabilities for complex geometries

Scalable solutions from single prototypes to low-volume production – no minimum order requirements

Partner with Honyo Prototype

Founder-led expertise: Susan Leo’s 15+ years in precision manufacturing ensures every part meets aerospace-grade standards

Global shipping with customs support for seamless international delivery

Dedicated engineering support available within 1 hour for complex projects

At Honyo Prototype, we don’t just machine parts – we accelerate innovation.

Upload your CAD today and get a precision-engineered quote in seconds.

Honyo Capabilities & Technology

Precision Miniature CNC Milling Capabilities

Engineered for complexity, optimized for speed, built for innovation

Advanced Multi-Axis Machining

3/4/5-axis precision machining for intricate geometries and complex assemblies

Single-setup processing eliminates handling errors while maintaining micron-level accuracy

AI-optimized toolpaths reduce cycle times by up to 40% without compromising surface finish

Unmatched Precision & Tolerances

Consistent +/- 0.01mm tolerances for functional prototypes and end-use components

Thermal compensation systems and vibration-dampened spindles ensure stability in micro-scale operations

In-process metrology with CMM and optical inspection for real-time quality validation

Scalable Production from Prototype to Volume

Zero MOQs – seamlessly transition from 1 prototype to 10,000+ production parts

Flexible scheduling for urgent prototypes or high-volume runs with no compromise on quality

Material agnostic capabilities supporting metals (aluminum, titanium, stainless steel), plastics, and composites

Quality Assurance: ISO Certified Excellence

ISO 9001:2015 certified quality management system with documented traceability

100% inspection protocol for critical dimensions and surface integrity

Six Sigma-driven process controls ensuring defect rates below 0.1%

Digital Efficiency: AI-Powered Instant Quotes

Real-time pricing via cloud-based platform with instant quote generation in <60 seconds

AI-driven DFM (Design for Manufacturability) analysis identifies cost-saving optimizations before production

Automated RFQ workflow slashes procurement cycle times by 50% vs. traditional methods

Rapid Turnaround Guaranteed

Prototypes delivered in 3 business days with express options for critical deadlines

End-to-end digital workflow with real-time production tracking and transparent communication

Dedicated project managers ensuring on-time delivery while maintaining precision standards

Materials & Surface Finishes

Material Options & Finishes for Miniature CNC Milling

Precision Material Selection Guide

Choose materials engineered for microscopic complexity. Our expert recommendations ensure optimal performance for functional prototypes and end-use parts:

Aluminum 6061: Lightweight, corrosion-resistant, and exceptionally machinable for intricate geometries. Ideal for aerospace sensors, medical devices, and consumer electronics where ±0.01mm tolerances must hold under stress.

Aluminum 7075: High-strength alloy for structural miniature components. Retains integrity in drone frames or precision tooling—perfect when weight-to-strength ratios are critical.

Stainless Steel 304/316: Food-safe (304) and marine-grade (316) corrosion resistance. Our CNC process preserves micro-threads and delicate features for surgical instruments or underwater sensors.

Brass: Superior electrical conductivity and ease of machining. Ideal for miniature connectors, RF components, and decorative elements requiring tight tolerances and aesthetic polish.

PEEK: High-temp stability (250°C+) and chemical inertness. Biocompatible for medical implants or aerospace seals where dimensional consistency is non-negotiable.

Surface Finishes That Preserve Precision

Avoid tolerances drift with finishes optimized for miniature parts. Every process is calibrated to maintain ±0.01mm accuracy:

Anodizing (Type II/III): Enhances wear resistance without measurable thickness gain. Critical for moving parts in micro-mechanisms where surface hardness must not compromise fit.

Precision Polishing: Mirror-smooth finishes on micro-features (e.g., optical lenses or watch components) without altering critical dimensions.

Electrostatic Painting: Uniform coating on complex geometries—no overspray on tiny edges. Ideal for consumer electronics housings requiring vibrant colors without dimensional loss.

Passivation (Stainless Steel): Removes free iron for maximum corrosion resistance in medical or marine environments. Ensures microscopic surfaces remain contamination-free.

Nickel Plating: Adds conductivity and wear resistance for electrical contacts. Applied with micron-level precision to avoid interfering with functional tolerances.

Smart Optimization for Your Project

Why Honyo Delivers Unmatched Value

Online Instant Quote: Upload your CAD file and instantly see real-time pricing adjustments for material/finish combinations—no hidden fees or manual calculations.

AI-Powered Recommendations: Our platform analyzes your design’s geometry and functional requirements to suggest the optimal material-finish combo for cost, performance, and lead time.

Fast Turnaround Guarantee: Finished parts delivered in 3–5 days, even with complex surface treatments. Our integrated in-house finishing eliminates outsourcing delays and accelerates time-to-market.

“Miniature parts demand precision—not compromises. At Honyo, we leverage AI-driven material intelligence to turn your designs into reality faster, smarter, and within budget.”

— Susan Leo, Founder

From Quote to Part: Our Process

How It Works: From CAD to Part

1. Upload Your CAD File

Drag-and-drop simplicity: Support for STEP, STL, IGES, and other industry-standard formats.

Automated validation: Instant checks for file integrity, geometry errors, and manufacturability risks—no manual review delays.

2. Instant AI-Powered Quote

Real-time pricing in seconds: No waiting days for quotes—get transparent, itemized costs upfront.

Breakdown you can trust: Material costs, machining time, setup fees, and finishing charges clearly itemized.

AI-driven optimization: Smart adjustments to tolerances, geometry, and material choices to minimize costs without sacrificing ±0.01mm precision.

3. DFM Analysis & Optimization

Proactive design feedback: AI flags potential issues (e.g., thin walls, sharp corners) and suggests cost-saving tweaks before production.

Expert validation: Our engineers review critical features to ensure functionality, durability, and manufacturability.

Iterate faster: Receive actionable insights to refine your design in hours—not weeks.

4. Precision Manufacturing & Delivery

Miniature-focused precision: 3/4/5-axis CNC milling with ±0.01mm tolerances for intricate, functional components.

End-to-end quality control: ISO-certified in-house production with real-time monitoring at every stage.

Rapid turnaround: Prototypes delivered in 3–5 business days—scalable for high-volume production with zero compromise on speed or accuracy.

✨ Why startups choose us: We eliminate guesswork. Our AI platform transforms complex engineering challenges into simple, transparent workflows—so you ship functional prototypes faster, iterate smarter, and scale with confidence.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Engineered for Microscale Innovation

Specialized miniature CNC milling for micro-components with ±0.01mm tolerances—ideal for medical devices, aerospace components, and high-precision electronics prototypes.

3/4/5-axis machining capabilities for complex geometries, tight clearances, and demanding materials (titanium, stainless steel, PEEK, and aerospace alloys).

AI-Powered Instant Quotes & Cost Optimization

Upload your CAD file for real-time pricing in seconds—no manual estimates or hidden fees.

Proprietary AI analyzes toolpaths, material usage, and setup to reduce costs by up to 30% while maintaining micron-level accuracy.

Transparent cost breakdown (material, machining, finishing) with actionable DFM (Design for Manufacturability) recommendations to optimize your design.

24-Hour Prototyping Turnaround

Shenzhen/Dongguan production hubs enable rapid iteration—prototypes delivered in as little as 24 hours.

Seamlessly scale from single prototypes to high-volume production with zero lead-time surprises.

Let’s Build Together

Founder Susan Leo and our engineering team are ready to help.

Email: [email protected]

Phone: +86 139 2843 8620

Visit: Shenzhen & Dongguan facilities for hands-on collaboration and technical consultation

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.