Contents

Manufacturing Insight: Mini Wood Cnc Machine

Introducing Precision Woodworking with Honyo’s Mini CNC Machine Solution

Honyo Prototype delivers advanced CNC machining capabilities tailored for intricate wood projects, leveraging our specialized mini CNC machine platform. This compact system provides exceptional accuracy and repeatability for detailed engraving, inlay work, and small-part fabrication, addressing the space and cost constraints faced by design studios, educational institutions, and specialty woodworkers. Our engineering team optimizes toolpaths and material parameters specifically for wood substrates, ensuring clean cuts, minimized tear-out, and superior surface finishes on materials ranging from balsa to hardwoods.

Beyond the Machine: Honyo’s Integrated Manufacturing Expertise

While our mini CNC platform enables accessible prototyping and low-volume production, Honyo Prototype’s value extends to comprehensive process engineering. We apply decades of subtractive manufacturing experience to validate designs for manufacturability, select optimal tooling geometries, and implement rigorous quality control protocols—even for the most delicate wood components. This holistic approach transforms conceptual designs into dimensionally stable, production-ready parts, eliminating common pitfalls like thermal distortion or tool deflection inherent in smaller-scale CNC operations.

Accelerate Your Project Timeline with Seamless Quoting

Initiate your wood CNC project within minutes using Honyo Prototype’s Online Instant Quote system. Upload your 3D model or technical drawings to receive a detailed, transparent cost estimate and lead time projection—validated by our engineering team—without waiting for manual review. This digital workflow ensures rapid validation of design feasibility while maintaining the technical rigor expected from an industry-leading manufacturing partner.

Key Service Parameters for Wood CNC Projects

| Feature | Specification | Benefit |

|————————|—————————————-|——————————————|

| Machine Work Envelope | 300 x 300 x 100 mm | Ideal for desktop-scale prototypes |

| Positioning Accuracy | ±0.02 mm | Critical for joinery and fine detailing |

| Supported File Formats | STEP, IGES, STL, DXF | Streamlined CAD integration |

| Typical Lead Time | 3-5 business days (after approval) | Accelerates design iteration cycles |

Partner with Honyo Prototype to transform intricate wood concepts into precision-engineered realities, supported by responsive engineering collaboration and our commitment to technical excellence. Begin your project immediately through our Online Instant Quote portal.

Technical Capabilities

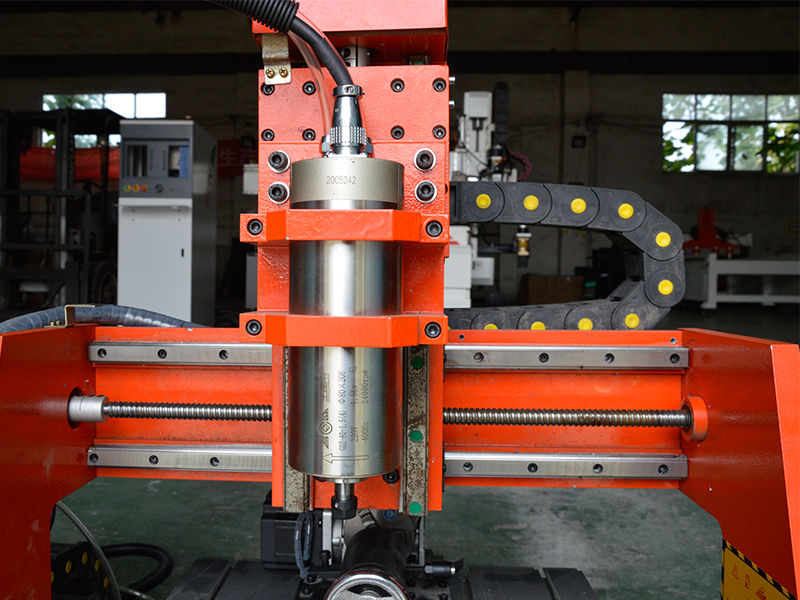

Technical Specifications for Mini Wood CNC Machine with Multi-Axis Capabilities

While primarily marketed as a “mini wood CNC machine,” advanced models in this category are engineered for multi-material processing, supporting not only wood but also metals and engineering plastics. These compact systems are ideal for prototyping, small-batch production, and educational applications. High-end variants support 3, 4, or even 5-axis milling, with optional turning capabilities and tight tolerance machining.

| Specification | Detail |

|---|---|

| Machine Type | Compact CNC Milling Machine with Optional Turning |

| Available Axes | 3-axis (X, Y, Z), 4-axis (with rotational A or B axis), 5-axis (dual rotary: A+B or trunnion table) |

| Work Envelope (Typical) | 300 x 300 x 100 mm (12″ x 12″ x 4″) – varies by model |

| Spindle Speed Range | 6,000 – 24,000 RPM (ER11 or ISO20 collet) |

| Spindle Power | 300W – 1,500W (air or liquid cooled) |

| Positioning Accuracy | ±0.01 mm (±0.0004″) |

| Repeatability | ±0.005 mm (±0.0002″) |

| Control System | LinuxCNC, GRBL, or Mach4 with optional touchscreen interface |

| Drive System | Stepper motors (standard), optional servo motors for 4/5-axis and turning |

| Tool Changer | Manual tool change; optional automatic tool changer (ATC) on high-end models |

| Maximum Material Compatibility | Wood, MDF, Aluminum (6061, 7075), Mild Steel (A36), ABS, Nylon (PA6, PA66), Delrin, PVC |

| Cutting Tolerance (Typical) | ±0.025 mm (±0.001″) for aluminum and plastics, ±0.05 mm (±0.002″) for steel |

| Cooling Options | Air blast standard; mist or flood coolant optional for metal cutting |

| Fixturing | T-slots, vacuum table (wood/plastics), or custom vices for metals |

| Software Compatibility | Fusion 360, SolidWorks CAM, Mastercam, Vectric, CAMBAM |

| Turning Capability | Optional live tooling and tailstock for mill-turn operations (e.g., face turning, grooving) |

| Max Feed Rate | 2,000 – 5,000 mm/min (depending on axis load and material) |

| Construction Frame | Rigid aluminum extrusion or cast iron base with linear guideways |

| Weight | 60 – 150 kg (130 – 330 lbs) |

Material Processing Notes

The machine achieves tight tolerances across a range of materials. Aluminum and ABS are commonly machined with high surface finish and precision. Steel requires reduced feed rates, rigid setups, and carbide tooling but is feasible for small components. Nylon and other engineering plastics are easily processed with sharp tools and proper chip evacuation to prevent melting.

Applications

Ideal for precision prototyping, educational labs, hobbyist metalworking, and small-scale manufacturing where footprint and cost are constraints but multi-axis flexibility and accuracy are required.

From CAD to Part: The Process

Honyo Prototype Mini Wood CNC Machine Manufacturing Workflow

Honyo Prototype executes a streamlined, technology-driven process for mini wood CNC machine component production, ensuring precision, cost efficiency, and rapid turnaround. The workflow begins when a client uploads their CAD file to our secure portal. Our system immediately validates file integrity, checks for standard format compatibility (e.g., STEP, IGES, DXF), and confirms geometric completeness. This initial step eliminates common submission errors, reducing iterative communication delays.

The uploaded CAD triggers our proprietary AI quoting engine, which analyzes part geometry, material requirements, and operational parameters specific to wood substrates. Unlike generic quoting tools, our AI cross-references real-time data on wood species availability (e.g., Baltic birch, MDF, hardwoods), grain-direction sensitivities, and CNC toolpath complexity for miniature-scale features. The output is a detailed quote within 2 business hours, including cost breakdowns, material recommendations, and preliminary lead time estimates—without requiring manual engineering review for standard designs.

Following quote acceptance, the Digital File Management (DFM) phase commences. Honyo’s engineering team conducts a rigorous manufacturability review focused on wood-specific constraints:

| DFM Check Category | Wood-Specific Considerations for Mini CNC Parts |

|---|---|

| Material Utilization | Optimization for sheet stock yield, minimizing waste on small panels; grain orientation impact on strength |

| Feature Feasibility | Minimum wall thickness validation (>1.5mm for stability); undercuts requiring specialized tooling |

| Tolerance Validation | Accounting for wood expansion/contraction (±0.1mm typical); avoidance of overly tight fits |

| Process Alignment | Toolpath simulation for miniature details; spindle speed adjustments to prevent tear-out |

Engineers collaborate directly with clients to resolve flagged issues—such as adjusting fillet radii to prevent chipping or modifying joinery for assembly—before final approval. This phase typically completes in 1–3 business days, with documented revision trails.

Production leverages our dedicated wood CNC cell featuring 5-axis machining centers calibrated for low-density materials. Key protocols include:

Vacuum-assisted workholding to prevent vibration-induced inaccuracies on thin substrates

Toolpath optimization for reduced heat generation (critical to avoid wood scorching)

In-process metrology checks at 25% and 75% completion stages using calibrated dial indicators

All operations adhere to ISO 9001 traceability standards, with material certificates and machine logs archived per order.

Delivery encompasses final inspection against ASME Y14.5 standards, followed by custom crating with anti-static padding to protect finished surfaces. We provide shipment tracking via major carriers (DHL, FedEx) with delivery confirmation. Typical lead time from DFM approval to doorstep is 5–7 business days for standard orders, with expedited options available. Clients receive a digital quality dossier including dimensional reports and finish verification photos prior to dispatch.

This integrated approach ensures mini wood CNC components achieve target functionality while mitigating wood’s inherent variability—translating complex designs into reliable, production-ready parts with minimal client rework.

Start Your Project

Interested in a high-precision mini wood CNC machine for prototyping or small-scale production? Contact Susan Leo at [email protected] to request specifications, pricing, and lead times.

Honyo Prototype operates a dedicated manufacturing facility in Shenzhen, ensuring tight quality control and fast turnaround for global clients. Whether you’re automating a workshop or scaling up production, our engineering team supports custom configurations and OEM integration.

Reach out today to discuss your application and receive a tailored solution.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.