Guide Contents

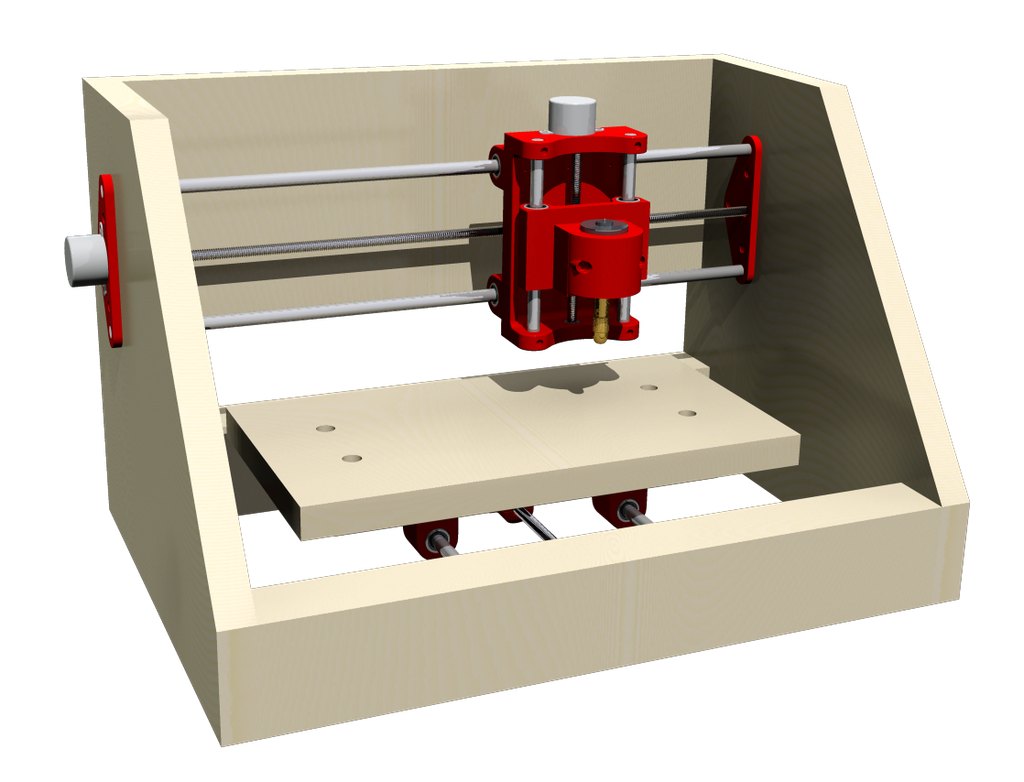

Project Insight: Mini Wood Cnc Machine

Manufacturing Insight: mini wood cnc machine

In today’s fast-paced product development landscape, speed and precision aren’t just advantages—they’re non-negotiable. For hardware startups and engineers, every day counts when iterating on functional prototypes or preparing for production. But achieving both without breaking the bank requires a strategic approach. At Honyo Prototype, we’ve redefined how you access industrial-grade CNC capabilities—without the overhead of owning equipment.

The Hidden Costs of DIY CNC Machines

Upfront investment: $800–$100,000+ for machines alone, plus tooling, maintenance, and calibration costs

Technical expertise required: Specialized training for operators, leading to delays in prototyping cycles

Space and infrastructure: Dedicated workshop space, dust collection systems, and power requirements

Risk of errors: Subpar precision (±0.1mm+) causing costly redesigns and production delays

Precision Engineering Without the Overhead

Tight tolerances: Consistent ±0.01mm accuracy for functional prototypes and end-use parts

Multi-axis mastery: 3/4/5-axis machining for complex geometries, intricate details, and intricate woodwork

Material versatility: Industrial-grade handling of hardwoods, plywood, acrylics, and composites with zero warping

Zero capital risk: Pay per part—no machine depreciation, upkeep, or hidden operational costs

Accelerate Time-to-Market with Smart Manufacturing

Online Instant Quote: Get real-time pricing in seconds via our AI-powered platform—no back-and-forth emails

AI-Optimized Design Validation: Automated DFM (Design for Manufacturing) checks to eliminate errors before production

24-48 Hour Prototyping: Fast turnaround from design to delivery, with express options for urgent projects

Scalable Production: Seamlessly transition from single prototypes to high-volume runs with identical quality standards

Honyo Prototype: Where innovation meets precision. Let’s build your next breakthrough—faster, smarter, and with zero compromise.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Industrial-Grade Precision for Complex Wood Components

3/4/5-axis machining capabilities for intricate geometries and multi-faceted designs

Tight tolerances of ±0.01mm ensuring functional accuracy for end-use parts

Advanced toolpath optimization for smooth surface finishes and minimal material waste

Scalable Production Without Compromise

From 1 prototype to 10,000+ units with consistent quality

Zero minimum order quantities (MOQs)—perfect for startups testing designs

Flexible production scheduling to adapt to evolving project needs

AI-Powered Instant Quote Platform

Upload CAD files for real-time pricing in seconds—no manual quotes

AI-driven Design for Manufacturability (DFM) feedback to reduce costs and improve designs

Transparent cost breakdown with no hidden fees or surprises

24-48 Hour Turnaround with ISO-Certified Quality

Rapid production cycles delivering parts in as little as 24–48 hours

ISO 9001-compliant quality control at every stage of production

Dedicated support team for urgent projects and expedited shipping options

Honyo Prototype: Where innovation meets precision. Shenzhen, China

Materials & Surface Finishes

Material Options & Finishes for Mini Wood CNC Components

Precision Materials Engineered for Performance

Aluminum 6061: Ideal for structural frames and bases, offering a perfect balance of strength, weight, and corrosion resistance. Machined to ±0.01mm tolerances for seamless integration into your mini wood CNC machine.

Aluminum 7075: Aerospace-grade strength for high-stress components like spindle mounts and drive systems. Ensures durability under continuous heavy loads without compromising precision.

Stainless Steel 304/316: Corrosion-resistant options for wet or harsh environments. 316 grade excels in coolant exposure or outdoor use, critical for longevity in industrial settings.

Brass: Conductive and low-friction properties make it ideal for electrical contacts and bushings in motion systems. Ensures smooth operation and electrical reliability.

PEEK: High-performance polymer for high-temperature and wear-prone parts. Perfect for bearings, seals, and components requiring consistent performance under stress.

Surface Finishes That Enhance Longevity & Aesthetics

Anodizing (Type II/III): Boosts aluminum’s corrosion resistance and wear properties. Type III hard anodizing for high-friction areas like rails and slides.

Electroless Nickel Plating: Uniform coating for stainless steel components, enhancing hardness and chemical resistance without dimensional changes.

Powder Coating: Custom color options with durable, scratch-resistant finishes for visible parts—ideal for branding or workshop aesthetics.

Mirror Polishing: Ultra-smooth surfaces for visible components, reducing friction and elevating the professional appearance of your machine.

Smart Material Selection for Your CNC Machine

Structural Components: Opt for Aluminum 6061 for frames and bases. Need higher strength? Switch to 7075 for critical load-bearing sections.

Environmental Challenges: Use Stainless Steel 316 in humid or corrosive environments to prevent rust and extend machine life.

Motion Systems: Brass bushings and PEEK bearings minimize wear in high-speed motion, ensuring precision over thousands of cycles.

Cost-Effective Innovation: Leverage Honyo’s AI-powered platform to compare material trade-offs in real-time—save time and optimize costs without sacrificing quality.

Why Honyo Prototype Delivers Precision Faster

✨ Online Instant Quote: Upload your design and get an AI-optimized quote in seconds—no waiting for manual estimates.

⚡ AI-Powered Material Guidance: Our smart system analyzes your application to recommend the best material and finish combo—tailored to your specific needs.

🚀 Fast Turnaround: Prototypes in 3 days, production runs in 7 days. All backed by our Shenzhen facility with 24/7 precision machining capabilities.

“Precision isn’t just a specification—it’s the foundation of your machine’s reliability. At Honyo Prototype, we engineer every component to perform under real-world demands.”

— Susan Leo, Founder

From Quote to Part: Our Process

Streamlined Workflow: From Design to Delivery in Days, Not Weeks

Skip the capital expense of purchasing a CNC machine. Honyo Prototype delivers industrial-grade precision for wood components through our on-demand service—no equipment investment, no maintenance costs, just fast, accurate parts. Our AI-powered platform transforms your CAD files into production-ready prototypes or end-use parts with unmatched speed and transparency.

1. Upload Your CAD File

Submit designs in standard formats (STEP, STL, IGES, etc.) via our secure online portal

AI instantly validates file compatibility and wood-specific requirements (e.g., grain orientation, toolpath optimization)

Eliminate manual review delays—your project starts processing in seconds

2. Get Instant AI-Powered Quote

Real-time pricing for wood materials (plywood, MDF, hardwoods) based on geometry, quantity, and complexity

Transparent breakdown: material costs, machining time, setup fees, and shipping

No hidden charges—see exact costs before approving, with no back-and-forth emails

3. DFM Analysis & Optimization

AI-driven review for wood-specific manufacturability (e.g., chip evacuation, tool selection, material waste reduction)

Proactive suggestions to enhance structural integrity, reduce costs, and improve surface finishes

Collaborative refinements with our wood machining specialists—all within the platform

4. Precision Production & Fast Delivery

Advanced 3/4/5-axis CNC routers for wood with ±0.01mm tolerances and smooth, splinter-free finishes

Full in-house production with automated quality checks at every stage

Typically delivered in 3–5 business days—accelerating your product development cycle from concept to functional prototype or end-use part

Why Honyo?

While DIY CNC routers cost $800–$2,500+ (with precision limitations) and industrial machines exceed $100,000, we eliminate upfront costs entirely. Our service delivers professional-grade wood parts at a fraction of the price—faster, with zero technical overhead. Innovate smarter, not harder.

Start Your Project with Honyo

Start Your Project with Honyo Prototype

Precision Without the Overhead

Skip the $10K+ investment in machinery—our service delivers industrial-grade precision (±0.01mm) at a fraction of the cost.

No maintenance, training, or downtime. Just functional prototypes and end-use parts, delivered on time.

AI-Powered Efficiency

Get an instant quote in seconds via our AI-driven platform—no paperwork, no delays.

Real-time cost breakdowns for 3/4/5-axis machining, optimized for wood and composite materials.

Fast-Track Your Prototype to Production

24–48 hour turnaround for functional prototypes.

Scalable solutions for both small batches and high-volume end-use parts—no minimum order limits.

Let’s Build Together

Founder Susan Leo and our engineering team are ready to optimize your project from concept to completion.

Contact: [email protected] | +86 139 2843 8620

Visit our Shenzhen/Dongguan facilities for a firsthand look at our precision manufacturing ecosystem.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.