Introduction: Navigating the Global Market for mini cnc router

Investing in a mini CNC router can significantly enhance operational efficiency and precision in various applications, from woodworking to metal engraving. However, international B2B buyers often face challenges in sources that align with their specific needs—such as price, quality, and after-sales support. This comprehensive guide addresses these challenges by exploring the diverse types of mini CNC routers available, their applications across multiple industries, and essential considerations for supplier selection.

Within these pages, buyers will gain insights on critical factors, including cost structures, features that enhance productivity, and the capabilities needed for specialist functions like intricate designs or the handling of various materials. Special attention is given to the unique contexts of Africa, South America, the Middle East, and Europe, providing strategies tailored to the regional marketplaces in countries like Nigeria and Brazil.

The objective of this guide is not only to equip international B2B buyers with the knowledge necessary for informed purchasing decisions but also to empower them to navigate the complexities of the global market effectively. By understanding the critical elements of sourcing, readers can identify the best mini CNC routers that cater to their operational requirements, paving the way for growth and innovation within their businesses.

Understanding mini cnc router Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Engraving CNC Routers | Compact size, high precision, typically less than 500W | Sign making, engraving intricate designs | Pros: Cost-effective, easy to use. Cons: Limited cutting capacity. |

| Mini Milling Machines | Robust structure, larger work area, milling capability | Prototyping, small parts manufacturing | Pros: Versatile, suitable for various materials. Cons: Higher cost compared to purely engraving machines. |

| Hybrid CNC Routers | Combines routing with laser engraving features | Custom sign crafting, mixed-media projects | Pros: Multi-functional, great for varied applications. Cons: Complexity may lead to longer setup times. |

| DIY CNC Kits | Typically sold as assembly kits, customizable configurations | Hobbyists, educational institutions | Pros: Affordable, tailored solutions. Cons: Assembly time-intensive, potential learning curve for non-tech-savvy users. |

| Desktop CNC Routers | Space-efficient, often USB-compatible for ease of use | Prototyping, design modeling | Pros: Compact, user-friendly. Cons: Limited depth and material capability. |

What are Engraving CNC Routers and Their B2B Utility?

Engraving CNC routers are characterized by their compact size and high precision, often operating with a power capacity of less than 500W. They are predominantly used in sign-making and producing intricate designs, making them ideal for businesses focused on marketing materials or personalized gifts. When considering purchase, B2B buyers should evaluate their engraving speed, compatible software, and ease of tooling changes to maximize operational efficiency.

How Do Mini Milling Machines Serve B2B Manufacturers?

Mini milling machines provide a robust structure and usually feature larger work areas compared to their engraving counterparts. With capabilities for machining a variety of materials, these machines are utilized for prototyping small parts and detailed manufacturing tasks. B2B purchasers should assess the machine’s milling precision, software integration, and available tooling options to ensure alignment with application needs and production workflows.

What Advantages Do Hybrid CNC Routers Offer for Custom Projects?

Hybrid CNC routers combine routing and laser engraving functionalities, allowing businesses to create custom signage and engage in mixed-media crafting. They are particularly beneficial for companies seeking to diversify their product offerings without investing in multiple machines. Buyers must consider their operational environment, as hybrid models may necessitate more advanced training and greater initial setup requirements to harness their full potential.

Why Choose DIY CNC Kits for Educational and Hobbyist Use?

DIY CNC kits are often marketed towards hobbyists and educational institutions, as they provide customizable configurations and an affordable entry into CNC machining. While these kits can empower users to create tailored solutions, B2B buyers must be mindful of the assembly time involved and the potential learning curve that may hinder immediate productivity. Assessing community support and available resources is critical for maximizing the benefits of these kits.

What Makes Desktop CNC Routers Suitable for Prototyping?

Desktop CNC routers are designed to be space-efficient and typically support USB connections for user-friendly operation. They cater to prototyping and design modeling applications, making them fitting for startups and small enterprises. When considering a desktop unit, businesses should focus on the router’s dimensional capacities, software compatibility, and usability to ensure it meets their project requirements and workflow integration.

Key Industrial Applications of mini cnc router

| Industry/Sector | Specific Application of mini cnc router | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking and Carpentry | Precision engraving and cutting of customized designs | Enhances product differentiation and efficiency | Consider durability, spindle compatibility, and software integration. |

| Signage and Advertising | Production of intricate signage and promotional materials | Increases turnaround time and reduces waste | Ensure the machine has high precision and supports various materials. |

| Prototyping and Design | Rapid prototyping for product design | Supports innovation and faster time to market | Look for flexibility in materials and ease of software usability. |

| Electronics Manufacturing | Custom circuit board milling | Increases accuracy and reduces manufacturing costs | Assess compatibility with various PCB thicknesses and types. |

| Art and Craft Production | Crafting intricate designs for art pieces and decor | Facilitates artistic expression and scalability | Evaluate precision capabilities and material handling options. |

How Is a Mini CNC Router Used in Woodworking and Carpentry?

Mini CNC routers are widely used in woodworking and carpentry to create precise carvings, custom furniture designs, and decorative elements. These machines enable businesses to produce intricate patterns and personalized items efficiently, allowing for differentiation in a competitive market. Buyers should prioritize sourcing high-quality routers with robust spindles and reliable software to handle diverse woodworking applications while maintaining accuracy.

What Role Does a Mini CNC Router Play in Signage and Advertising?

In the signage and advertising sector, mini CNC routers are employed to manufacture both aesthetic and functional signage. These routers can engrave logos and intricate designs on various materials, facilitating quick production runs and customization. B2B buyers should consider sourcing routers with robust material handling capabilities and software compatibility to streamline production and ensure high-quality finishes.

How Can Mini CNC Routers Enhance Prototyping and Design Processes?

Mini CNC routers provide a valuable asset for prototyping and design processes by allowing companies to quickly generate physical models and test ideas. This rapid prototyping reduces development cycles, enabling businesses to innovate and bring products to market faster. Buyers in this sector should focus on sourcing versatile machines that can handle a variety of materials and produce accurate, repeatable results.

Why Are Mini CNC Routers Important for Electronics Manufacturing?

In electronics manufacturing, mini CNC routers are crucial for creating custom circuit boards. Their precision allows for intricate designs and superior accuracy in milling, which are essential for reducing errors and manufacturing costs. Buyers should assess the ability of routers to accommodate different substrate thicknesses and types, ensuring that the selected machine aligns with specific production requirements.

How Do Mini CNC Routers Support the Art and Craft Production Sector?

Mini CNC routers are instrumental in the art and craft production sector for creating detailed art pieces, intricate craft projects, and personalized decor items. They allow artisans to replicate designs with consistent quality and scalability. When sourcing these machines, buyers should focus on precision capabilities and compatibility with various artistic materials to fully leverage the creative potential of CNC technology.

3 Common User Pain Points for ‘mini cnc router’ & Their Solutions

Scenario 1: Difficulty in Material Compatibility with Mini CNC Routers

The Problem: B2B buyers often face challenges in ensuring that their mini CNC routers can handle a diverse range of materials. This is particularly crucial for businesses in sectors like signage, woodworking, or prototyping that require flexibility. Buyers may find themselves stuck with machines that struggle with certain materials, leading to delays in production and wasted resources if they inadvertently choose a router that lacks the necessary specifications for harder materials like aluminum or specific composites.

The Solution: To overcome this challenge, businesses should conduct thorough research into the specifications of mini CNC routers, focusing on the material capabilities stated by manufacturers. When purchasing, prioritize routers certified for versatility in material handling. For instance, look for features such as adjustable spindle speeds, robust motor power, and compatibility with varying bit types. For businesses in regions selling products like wooden crafts or prototypes, machines like the OpenBuilds MiniMill, known for its versatility with both softer and harder materials, can be ideal. Additionally, engage with suppliers to gain insights about user experiences with material variety, ensuring the machine’s capabilities align with your specific requirements.

Scenario 2: Lack of Software Compatibility and Usability

The Problem: Many businesses struggle with software compatibility when integrating mini CNC routers into their existing workflows. The frustration often stems from routers that either come with inadequate software or require a steep learning curve for new systems. This can lead to inefficiencies, as employees waste valuable time figuring out how to operate the system or even facing downtime due to software malfunctions, which is particularly detrimental to companies aiming for rapid production cycles.

The Solution: When selecting a mini CNC router, choose a machine that includes user-friendly software that is compatible with common design programs like AutoCAD or Fusion 360. Comprehensive packages, such as those offered with the OpenBuilds MiniMill, typically include control software alongside user manuals and online tutorials, making it easier for teams to ramp up productivity without steep learning curves. Furthermore, consider investing in additional training for staff on the specific software used to operate the routers. This proactive approach not only mitigates potential operational roadblocks but also enhances the overall efficiency of your production processes.

Scenario 3: Challenges with Assembly and Setup

The Problem: A common pain point for B2B buyers of mini CNC routers is the complexity involved in assembly and setup. Many models require significant assembly, leading to potential misalignments that can affect performance and accuracy. In markets where operational speed is critical, delays due to lengthy and complex setup processes can result in unsatisfied clients and lost business opportunities.

The Solution: To tackle this issue, businesses should prioritize selecting mini CNC routers that are known for their straightforward assembly processes. Look for routers that are just “plug and play” models or those that come with comprehensive assembly guides and instructional videos. Brands like Monoprice often include all necessary components and detailed manuals, significantly speeding up setup time. Additionally, forming partnerships with suppliers who provide onsite training or assembly assistance can further alleviate challenges. Encourage teams to familiarize themselves with the router’s components and practice assembly in a low-pressure environment to ensure they can adapt to any potential issues during initial setup. This preparation can help streamline the installation process, enabling businesses to maximize productivity right from the get-go.

Strategic Material Selection Guide for mini cnc router

What Materials Are Best for Mini CNC Routers? A Matching Analysis

In selecting the appropriate materials for mini CNC routers, various factors play a crucial role, including mechanical properties, cost, and application suitability. Here, we analyze four common materials to provide actionable insights for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

Aluminum: The Lightweight Contender

Key Properties:

Aluminum has excellent thermal and electrical conductivity, along with a lightweight nature that makes it easy to handle. It has a melting point of approximately 660°C and provides good corrosion resistance when anodized.

Pros & Cons:

Aluminum is durable and can be machined at high speeds, allowing for efficient production of intricate designs. However, its cost can be moderate to high depending on the alloy, and specific machining tools may be required. Additionally, while it is resistant to corrosion, it can be susceptible to scratching and denting if not handled properly.

Impact on Application:

Aluminum is ideal for applications requiring lightweight structural components, and with a proper finish, it can be aesthetically pleasing. Its strong compatibility with various cutting tools allows it to be utilized across decorative and functional products.

Considerations for Buyers:

International buyers should ensure compliance with relevant standards such as ASTM B221 for extruded bars and shapes. Regions like Europe and the Middle East often have stringent regulations regarding the environmental impact of aluminum production and recycling capabilities.

Wood: The Traditional Choice

Key Properties:

Wood provides natural aesthetics with variable density depending on the type, affecting machining performance, durability, and finishing. It is also a sustainable material, with certain species offering more robust qualities than others.

Pros & Cons:

Wood is generally cost-effective and widely available. It can be easily cut, sanded, and finished. However, it is susceptible to warping, damage from pests, and moisture-related issues, which can limit its lifespan and requires special treatment in humid environments.

Impact on Application:

Ideal for cabinetry, signage, and various craft applications, wood demands precision machining to ensure quality finishes. The unique grain and color of different wood types also allow for customization.

Considerations for Buyers:

B2B buyers should prioritize wood from sustainable sources, adhering to standards like FSC (Forest Stewardship Council) certification, especially in Europe and parts of South America, where there is high awareness of environmentally friendly practices.

Acrylic: The Versatile Polymer

Key Properties:

Acrylic offers excellent optical clarity and impact resistance, coupled with a light weight nearly half that of glass. Its melting point is around 160°C, allowing for hot cutting techniques.

Pros & Cons:

Acrylic is relatively easy to machine and can be polished to attain a clear finish. However, it can be prone to scratching and can distort under high temperatures, requiring careful management during milling.

Impact on Application:

Acrylic is extensively used for signage, display cases, and decorative elements due to its visual appeal and versatility in color. Its compatibility with laser cutting technology makes it increasingly popular.

Considerations for Buyers:

Buyers should check for compliance with international standards like ISO 7823, particularly in markets focused on quality surface finishes, such as Europe. Understanding local regulations regarding plastic waste management in regions such as the Middle East is also crucial.

Steel: The Heavy-Duty Material

Key Properties:

Steel’s strength and weight give it high durability and significant wear resistance. It can withstand higher pressure and temperatures than most materials, along with excellent machinability, especially for certain carbon grades.

Pros & Cons:

Steel is immensely strong and provides high dimensional stability. However, it is more expensive compared to other materials and requires careful handling to avoid rust and corrosion, particularly in humid climates.

Impact on Application:

Highly suited for industrial applications, including fixtures and heavy machinery components, steel is often used when high strength and durability are paramount. Properly heat-treated steel can excel in precision machining tasks.

Considerations for Buyers:

B2B stakeholders should be aware of regional standards like ASTM A36 for structural steel, particularly in Africa and South America, where regulations regarding manufacturing and safety practices can vary.

Summary Table of Material Selection for Mini CNC Routers

| Material | Typical Use Case for Mini CNC Router | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Structural components, decorative elements | Lightweight, good corrosion resistance | Costly depending on alloy, scratching susceptibility | Medium |

| Wood | Cabinets, crafts, decorative signs | Cost-effective, sustainable | Warping, pest susceptibility | Low |

| Acrylic | Signage, display units | High clarity, easy machining | Prone to scratching, temperature sensitivity | Medium |

| Steel | Industrial applications, heavy components | Exceptional strength, wear resistance | Higher cost, corrosion risk | High |

By carefully considering these materials and their properties, B2B buyers can make informed decisions that align with their operational needs, budget, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for mini cnc router

What Are the Main Stages of the Manufacturing Process for Mini CNC Routers?

The manufacturing process for mini CNC routers involves a series of meticulously planned stages to ensure quality and reliability.

-

Material Preparation

This initial stage begins with sourcing high-grade materials suitable for precise machining. Commonly used materials include aluminum, steel, and various types of plastics. Suppliers often conduct rigorous inspections on raw materials, ensuring they meet specific standards such as hardness, tensile strength, and flexibility. For mini CNC routers, parts like frames, rails, and electronics are sourced from reputable suppliers who adhere to international and industry-specific standards. -

Forming and Machining

Next, the prepared materials go through various forming processes. Techniques such as extruding, machining, and laser cutting are common. In particular, components like the spindle and lead screws require high precision, usually achieved through CNC machining. Manufacturers often employ automated processes to maintain consistency and reduce variance in production runs. -

Assembly

Once components are machined, they move to the assembly stage. This involves combining various parts based on pre-defined designs, typically documented in CAD software. The assembly process may include aligning linear rails, securing stepper motors, and integrating the control systems. Skilled technicians often oversee assemblies to ensure alignment and operational efficacy, minimizing human error. -

Finishing

Finishing processes, such as anodizing and painting, enhance the durability and aesthetic of the mini CNC routers. These treatments protect against corrosion and wear, prolonging the lifespan of the equipment. Further inspections ensure the finish is even and free from defects.

How Is Quality Assurance Implemented in the Manufacturing Process?

Quality assurance is critical in maintaining high standards during the production of mini CNC routers. Suppliers concentrating on the international market often adopt rigorous quality management systems to meet various international standards.

-

What International Standards Guide Quality Assurance?

International standards such as ISO 9001 are frequently used to govern quality management processes. This set of guidelines establishes a framework for continuously improving production efficiency and effectiveness. For product safety, CE marking is vital in Europe, demonstrating that the product complies with safety, health, and environmental requirements. -

What Are Common Quality Control Checkpoints?

Quality control checkpoints may include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC focuses on inspecting incoming materials and components to ensure they conform to specified requirements.

- IPQC monitors the manufacturing process to catch defects before they lead to non-conforming products.

- FQC validates the final products against design specifications and functional requirements prior to shipment.

- What Testing Methods Are Commonly Used?

Common testing methods for mini CNC routers include functional testing, performance evaluation (speed, accuracy, and load testing), and environmental testing to ensure robust performance in varying conditions.

How Can B2B Buyers Verify the Quality Assurance Measures of Suppliers?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, ensuring the quality of mini CNC routers is crucial.

-

What Should Buyers Request from Suppliers?

Buyers are encouraged to request detailed quality assurance documentation, including certificates for compliance with international standards (like ISO 9001, CE), internal quality check reports, and testing results to verify the functionality and durability of the equipment. -

How Can Suppliers Facilitate Audits and Inspections?

Suppliers should be open to third-party inspections, allowing buyers to validate quality claims independently. Periodic audits can help maintain standards and highlight areas needing improvement. An effective supplier will welcome such audits as a testament to their product quality. -

What Are Some Nuances for International Buyers?

When sourcing from manufacturers in different countries, buyers should be aware of regional standards and regulatory compliance. For instance, some regions may have specific certifications that are vital for market acceptance in those areas. Understanding local customs regulations, tariffs, and potential delays in shipping can also help avoid unforeseen costs and issues.

How Do Manufacturers Ensure Consistency and Reliability in Mini CNC Routers?

Ensuring consistency and reliability requires stringent quality management processes throughout manufacturing.

-

What Role Does Documentation Play?

Manufacturers are often required to maintain accurate and thorough documentation of their quality processes. This includes production logs, material certifications, and inspection records. Such transparency allows for traceability in case of defects, enabling quick corrective actions. -

How Do Continuous Improvement Programs Affect Quality?

Many manufacturers implement Lean Six Sigma or other continuous improvement methodologies to identify inefficiencies and improve processes. By emphasizing defect reduction and waste elimination, they achieve higher quality products and customer satisfaction. -

Why Is Customer Feedback Integral to Quality Assurance?

Gathering post-sale customer feedback is invaluable for manufacturers aiming to improve their offerings continuously. It helps identify areas of strength and potential weaknesses, guiding necessary adjustments in design or manufacturing processes.

In summary, B2B buyers looking for mini CNC routers should prioritize manufacturers who adhere to robust manufacturing processes and quality assurance protocols. By understanding these processes, buyers can make informed decisions, ensuring they invest in high-quality machinery that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mini cnc router’

When sourcing a mini CNC router, it’s critical for B2B buyers to conduct thorough research and adhere to a systematic approach to ensure they obtain a machine that meets their operational needs. This guide provides actionable steps that will help streamline the procurement process, ensuring that you make informed decisions.

Step 1: Identify Your Specific Requirements

Begin by clearly defining what you need from a mini CNC router. Consider the types of materials you will be working with, the scale of your projects, and the desired accuracy and precision.

- Material Types: Determine if you’ll primarily work with wood, plastics, or metals and ensure the router can handle these materials.

- Project Scale: Assess if your operations require intricate detailed work or larger cuts, as this will dictate the necessary size and capabilities.

Step 2: Research Various Models and Features

Explore different models and their features to understand the market offerings better. Evaluating multiple options helps you make an informed choice catering to your technical specifications.

- Common Features: Look for routers that offer various spindle speeds, work area sizes, and weight capacities.

- Special Features: Identify if you need additional features like laser engraving capability or multi-tool usage for versatility in applications.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers to ensure reliability and quality. Scrutinizing supplier credentials can protect you from purchasing subpar equipment.

- Supplier Background: Request company profiles, including their history and experience in the industry.

- Customer References: Seek feedback from businesses in similar industries to gauge the performance and durability of the CNC routers offered.

Step 4: Check Certifications and Compliance

Ensure that the machines comply with international and regional safety standards. This step is vital for avoiding potential liabilities and ensuring smooth operations.

- Safety Standards: Investigate if the equipment has certifications from relevant bodies like ISO, CE, or UL that signify adherence to safety and quality benchmarks.

- Usage Compliance: Confirm if the router is compliant with local regulations regarding machinery and noise levels to prevent issues in your workspace.

Step 5: Request Samples or Demos

Whenever possible, request to see demos or samples of the router’s output before making a purchase. This firsthand experience can offer invaluable insights into the machine’s capabilities.

- Operational Tests: Check how the machine performs with your intended materials and processes to ensure it meets your expectations.

- Output Quality: Analyze the quality of finished products to assess precision and repeatability crucial for your operation.

Step 6: Assess Warranty and After-Sales Support

Investigate the warranty and support services offered by the supplier, as these can significantly influence your long-term operational efficiency.

- Warranty Length: Look for extensive warranties that cover parts and labor, ensuring peace of mind regarding potential faults.

- Support Availability: Evaluate the responsiveness of the supplier’s technical support team in case you encounter issues post-purchase.

Step 7: Evaluate Total Cost of Ownership

Finally, factor in the total cost of ownership beyond the initial purchase price. Elements such as maintenance, operational costs, and potential upgrades should influence your decision.

- Maintenance Costs: Research regular maintenance requirements and associated costs to prevent unexpected expenditure.

- Operational Costs: Calculate energy consumption and material costs when determining the viability of the machine for long-term use.

By following this comprehensive checklist, B2B buyers can confidently source a mini CNC router optimized for their unique requirements and operational demands, ultimately leading to improved efficiency and project outcomes.

Comprehensive Cost and Pricing Analysis for mini cnc router Sourcing

What Are the Key Cost Components in Sourcing a Mini CNC Router?

In the realm of mini CNC routers, understanding the core cost components is essential for international B2B buyers. The primary components include:

- Materials: The choice of materials significantly affects costs. Quality metals, plastics, and composites used in manufacturing the router’s body and components influence both the performance and durability.

- Labor: Skilled labor is required for assembling and testing mini CNC routers. Labor costs vary by region and can be a crucial factor for manufacturers located in low-wage countries versus those in higher-cost economies.

- Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment depreciation. A manufacturer’s location can also influence these overhead costs.

- Tooling: Specialty tools and molds needed for producing various components introduce additional costs. Custom tooling may also be required for unique designs, impacting the overall budget.

- Quality Control (QC): Implementing rigorous QC processes is essential, particularly for industrial applications where precision is paramount. This involves testing equipment and materials, which can add to the cost but ensures superior product quality.

- Logistics: Freight charges and customs duties must be considered when importing CNC routers. Understanding Incoterms (such as FOB—Free on Board or CIF—Cost, Insurance, and Freight) can help buyers manage their logistics costs effectively.

- Margin: Manufacturer or supplier margins play a pivotal role in determining the final price. Diversifying suppliers can present opportunities to negotiate better margins especially for bulk orders.

How Do Pricing Influencers Impact Mini CNC Router Costs?

Several factors can influence the pricing structure of mini CNC routers:

- Volume/MOQ (Minimum Order Quantity): Larger orders typically benefit from reduced per-unit pricing. Suppliers are often willing to lower costs for bulk purchases, a strategic consideration for businesses with an anticipated high usage rate.

- Specifications and Customization: Custom features, such as enhanced precision mechanisms or specialized attachments, can raise prices. Buyers should weigh the need for specific features against budget constraints.

- Materials Sourcing: Availability and quality of materials directly influence pricing. High-quality, specialized materials may be exponentially more expensive, affecting the choice between cost and performance.

- Quality Certifications: Routers that meet international standards (ISO, CE, etc.) often command higher prices due to the associated quality assurance costs. Buyers should consider whether these certifications are necessary for their target markets.

- Supplier Factors: Trustworthy relationships with recognized manufacturers can provide leverage during price negotiations. Suppliers with established reputations might offer better warranty terms, further influencing total costs.

What Tips Can Help Buyers Leverage Cost-Efficiency?

For B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, the following strategies can enhance sourcing effectiveness:

- Negotiation: Approach price discussions with an understanding of both your needs and the supplier’s cost structure. Leverage volume orders and long-term relationships to negotiate better terms.

- Total Cost of Ownership (TCO): Evaluate the TCO rather than just initial purchase price. This includes maintenance, operational efficiency, and longevity of the equipment, ensuring better long-term cost management.

- Pricing Nuances for International Purchases: Be cognizant of currency fluctuations, tariffs, and local import taxes when making international purchases. This can significantly impact the final price in your local currency.

Buyers should exercise due diligence, comparing several suppliers and seeking quality certifications, which often correlate with better performance and reliability, ensuring you select the best fit for your operational needs and budgetary constraints. Remember, indicative prices fluctuate based on market dynamics; thus, always confirm with suppliers before proceeding with orders.

Alternatives Analysis: Comparing mini cnc router With Other Solutions

When considering manufacturing solutions for precise cutting, engraving, and milling tasks, B2B buyers often encounter various technologies, including the mini CNC router. Evaluating alternatives can provide insights into which technology best aligns with organizational needs, budget constraints, and operational efficiency. This section explores the mini CNC router alongside two viable alternatives: the traditional CNC milling machine and laser cutting systems.

Comparison Table

| Comparison Aspect | Mini CNC Router | Traditional CNC Milling Machine | Laser Cutting System |

|---|---|---|---|

| Performance | High precision for detailed work | Superior for heavy-duty tasks | Fast cutting speeds, ideal for thin materials |

| Cost | Generally affordable (around $999) | Higher initial investment ($3,000+) | Moderate cost (from $2,000 to $10,000) |

| Ease of Implementation | User-friendly and quick setup | Requires more setup and training | Simple operation, especially for software integration |

| Maintenance | Low to moderate maintenance needs | Higher maintenance due to complexity | Low maintenance; concern mainly around the laser tube |

| Best Use Case | Small-scale woodworking, crafts | Industrial machining and tough materials | Sheet metal cutting, intricate designs |

Detailed Breakdown of Alternatives

What Advantages Does a Traditional CNC Milling Machine Offer?

Traditional CNC milling machines are robust and capable of handling heavier materials, making them preferable for high-precision industrial applications. Their exceptional performance in large-scale operations allows manufacturers to execute intricate designs with unmatched durability. However, these machines come with a higher upfront cost and require comprehensive training for operators to maximize their potential. Maintenance can also be more intensive due to the mechanical complexity involved.

How Does a Laser Cutting System Compare?

Laser cutting systems offer fast cutting speeds and are particularly efficient for materials like wood, acrylic, and thin metals. They can create intricate designs without the need for tool changes, making them ideal for precision projects and detailed engraving. The operational simplicity of laser cutting systems allows new users to achieve high-quality results quickly. However, the initial investment can vary significantly based on the system’s capabilities, and they might be limited in handling thicker materials compared to CNC routers and milling machines.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right manufacturing solution depends largely on your specific applications, material types, and overall production goals. If precision in a more compact workspace is critical, a mini CNC router may be the optimal choice thanks to its balance of affordability and functionality. For high-volume industrial operations requiring heavy-duty work, a traditional CNC milling machine would be more suitable despite its higher costs. Alternatively, if speed and intricate designs are your priorities, consider laser cutting systems. Careful evaluation of these alternatives against your requirements will lead to informed purchasing decisions that can enhance operational efficiency and profitability.

Essential Technical Properties and Trade Terminology for mini cnc router

When considering a mini CNC router, understanding its technical properties and trade terminology is essential for making informed purchasing decisions. Here, we outline critical specifications and common terms that will help you navigate the landscape of B2B CNC machinery.

What Are the Key Technical Specifications for Mini CNC Routers?

-

Work Area Dimensions

This indicates the maximum size of material (length, width, and height) that can be processed by the CNC router. For instance, a router with an X-axis of 4.5 inches, a Y-axis of 7 inches, and a Z-axis of 3 inches suits small-scale projects well. Understanding these dimensions ensures that the machine can effectively handle your desired applications, reducing the risk of operational limitations. -

Cutting Speed

Measured in millimeters or inches per minute, cutting speed defines how fast the CNC router can move while cutting material. Higher speeds enhance productivity but may affect cutting quality when not properly managed. It’s critical to align your production needs with the capability of the mini CNC router to ensure efficiency and precision in operations. -

Accuracy and Tolerance

Accuracy refers to the degree of error in the machining process, typically expressed in inches or millimeters. Tolerances are the permissible limits of variation in dimensions. For example, a tolerance of 0.001 inches signifies high precision. In B2B environments, meeting tight tolerances can be essential for parts that require exact fits, thus impacting the overall quality of the final product. -

Drive System

The drive system, whether belt-driven, lead screw-driven, or rack-and-pinion, affects both the precision and speed of the cutting process. For instance, lead screw systems tend to provide higher accuracy than traditional belt systems. Understanding the drive mechanism will help buyers assess the long-term reliability and performance expectations of the routers. -

Spindle Power

Spindle power, measured in watts, determines the cutting capability. Higher spindle power permits cutting through denser materials, which is particularly important for industrial applications. Buyers must consider their typical material types to match the spindle power with their production requirements effectively. -

Software Compatibility

The ability to work with specific design and control software is crucial for effective operation. Many mini CNC routers come with their proprietary software, while compatibility with popular design software like Fusion 360 is vital for seamless workflow integration. This compatibility ensures that users can maximize productivity and create complex designs with ease.

What Are Common Trade Terms Related to Mini CNC Routers?

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. When sourcing CNC routers, understanding the OEM can provide insight into the quality and reliability of the equipment, impacting decision-making. -

MOQ (Minimum Order Quantity)

MOQ signifies the lowest quantity of a product that can be ordered. In the context of mini CNC routers, negotiations may be necessary to meet minimums that could affect inventory and cash flow for smaller firms or startups. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing and related terms for specific products. Understanding how to formulate an effective RFQ can enhance procurement efficiency and ensure competitive pricing for CNC routers. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Knowing these terms will help buyers understand the financial and logistical implications of shipping mini CNC routers across borders, crucial for planning budgets and timelines. -

Lead Time

The lead time refers to the duration from placing an order to delivery. Understanding lead times is vital for project planning and managing customer expectations. Minimized lead times can provide a competitive edge in the market.

By familiarizing yourself with these essential properties and terminology, you can make informed decisions when purchasing a mini CNC router, catering to the demands of your specific application or industry.

Navigating Market Dynamics and Sourcing Trends in the mini cnc router Sector

Market Overview & Key Trends in the Mini CNC Router Sector

The market for mini CNC routers is experiencing robust growth, driven by a combination of technological advancements, an increasing demand for personalized products, and the rise of the maker culture. Key trends include the integration of smart technology and IoT capabilities, allowing for remote operation and monitoring, which enhances productivity for businesses operating across various sectors, including woodworking, metalworking, and education. Additionally, the COVID-19 pandemic has sparked a shift towards DIY projects and small-scale manufacturing as companies and individuals look to pivot in uncertain times, thus increasing interest in mini CNC routers.

From a sourcing perspective, B2B buyers from Africa, South America, the Middle East, and Europe are increasingly focused on finding cost-effective yet high-quality solutions that can accommodate diverse materials and applications. Suppliers that offer comprehensive bundles—such as routing kits that include bits, software, and accessories—are particularly appealing to businesses seeking to streamline procurement processes. Furthermore, collaboration tools and online marketplaces have emerged, facilitating easier sourcing and allowing buyers to compare products and prices from multiple manufacturers efficiently.

Emerging markets are investing significantly in manufacturing capacity and innovation, requiring suppliers to remain flexible and responsive to specific regional demands. This adaptation can manifest as localized support and training, recognizing the varied experience levels in CNC operations among international buyers. As such, the mini CNC router market is setting the stage for exponential growth, particularly as customization and rapid prototyping become even more critical in modern manufacturing.

How Does Sustainability Impact Sourcing Decisions for Mini CNC Routers?

As B2B buyers become increasingly aware of their environmental impact, sustainability has emerged as a pivotal factor in sourcing mini CNC routers. Companies are now prioritizing products from manufacturers that adhere to environmentally friendly practices, such as using ‘green’ materials and ensuring ethical production processes. This trend is particularly relevant in regions like Europe, where stringent regulations around sustainability are driving procurement decisions.

Ethical sourcing encompasses a commitment to minimize waste, reduce emissions, and avoid harmful materials—elements that resonate with modern consumers and end-users. Certifications such as ISO 14001 and adherence to eco-labels can play a crucial role in selecting suppliers. These assurances provide buyers with more confidence in their sourcing decisions, guiding them toward manufacturers that demonstrate a commitment to sustainable development.

Moreover, the demand for circular economy practices is influencing the design and materials used in mini CNC routers. Suppliers who utilize recycled materials or offer end-of-life programs can differentiate themselves in a competitive market. By taking such initiatives, manufacturers not only enhance their brand reputation but also tap into the expanding pool of environmentally conscious buyers, potentially increasing their market reach and driving sales.

Brief Evolution/History of Mini CNC Routers

The evolution of mini CNC routers began in the early 2000s when CNC technology became more accessible to hobbyists and small businesses. Initially seen as tools for large-scale industrial applications, advances in technology significantly reduced costs, making mini CNC routers feasible for smaller operations. This democratization of technology enabled creative individuals and small manufacturers to produce intricate designs, allowing for customization and mass personalization.

Over time, the integration of software solutions designed for easier operation, such as OpenBuilds and Vectric, has simplified the user experience, broadening the appeal of CNC routers beyond seasoned professionals to include novices and educators. The move towards open-source designs and online communities further spurred innovation, fostering a collaborative environment where ideas and resources can be shared. Today, mini CNC routers symbolize a perfect blend of technology and creativity, positioning themselves at the forefront of modern manufacturing capabilities and DIY culture.

Frequently Asked Questions (FAQs) for B2B Buyers of mini cnc router

-

How do I solve issues with a mini CNC router not connecting to my computer?

Troubleshooting connection issues often starts with checking cable integrity and compatibility. Ensure that the USB or connection cable is securely plugged into both the CNC router and your computer. Verify that the necessary drivers are installed; sometimes manufacturers provide specific drivers for different operating systems. Additionally, consider using updated software versions and checking the settings within your CNC software to ensure proper communication between devices. If issues persist, consult the manufacturer’s support resources or forums for detailed guidance. -

What is the best mini CNC router for small-scale woodworking projects?

The ideal mini CNC router for woodworking varies by project needs. For intricate carvings, models like the OpenBuilds MiniMill are recommended due to their precision capabilities and compact design. If you require versatility for different materials, the FoxAlien CNC machines offer a range of specifications suited for both soft and hard materials, including options for laser attachments. Evaluate factors like work area dimensions, material compatibility, and desired features such as automation or ease of setup to select the best model for your projects. -

What customization options should I consider when ordering a mini CNC router?

Customization can enhance the utility of a mini CNC router depending on your specific applications. Key options to explore include spindle upgrades for higher RPM, varying work surfaces for different materials, and the addition of accessories like dust collection systems or laser attachments. It’s also wise to discuss software compatibility and any additional features required, such as remote operation capabilities. Ensure to communicate your specific production needs to the supplier for tailored solutions. -

What is the minimum order quantity (MOQ) for mini CNC routers?

Minimum order quantities can vary significantly by supplier and the specific model of CNC router. Some manufacturers may allow small quantities for first-time buyers or provide sample units, while others require an MOQ of five to ten units, especially for customized products. It’s advisable to directly communicate with suppliers for their MOQ terms, as negotiating terms can often be beneficial, especially for international orders. Be prepared to discuss your projected volume to find a suitable arrangement. -

What are the typical payment terms when importing mini CNC routers?

Payment terms for B2B transactions in importing mini CNC routers typically vary among suppliers. Common methods include advance payments, letters of credit, or net payment terms (e.g., net 30 or net 60 days) after receipt of goods. Some may require a deposit upfront with the balance due upon shipment or delivery. It’s important to confirm these terms early to avoid misunderstandings, especially regarding currency conversions, international banking fees, and payment security measures to protect your investment. -

How can I vet suppliers of mini CNC routers effectively?

Vetting suppliers is crucial to ensure quality and reliability. Begin by checking their industry reputation through reviews, testimonials, and third-party ratings. Request references from previous clients, particularly those in your region. Assess their manufacturing processes and certifications, such as ISO compliance, to gauge quality control measures. Additionally, inquire about their after-sales support and warranty policies, ensuring they can provide assistance in case of issues with the machinery post-purchase. -

What quality assurance (QA) measures should I look for in a mini CNC router?

Quality assurance measures for mini CNC routers include rigorous testing protocols during and after the manufacturing process. Inquire about the supplier’s QA procedures, including tolerance levels, machine calibration, and material quality checks. Assess available warranties and return policies, as these can indicate the manufacturer’s confidence in their products. Consider asking for a sample machine to evaluate its performance firsthand before making larger orders, particularly if your applications require high precision. -

What logistics considerations should I plan for when importing mini CNC routers internationally?

Logistics for importing mini CNC routers involve evaluating shipping methods, costs, and delivery timelines. Discuss with suppliers about available shipping options (air vs. sea) and the best practices for packaging to prevent damage during transit. Ensure you understand customs duties, potential tariffs, and any import regulations specific to your country. It’s wise to collaborate with an experienced freight forwarder to navigate international shipping complexities, ensuring timely and secure delivery of your equipment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Mini Cnc Router Manufacturers & Suppliers List

1. Monoprice – Benchtop CNC Router Engraver Kit

Domain: monoprice.com

Registered: 2001 (24 years)

Introduction: Monoprice Benchtop CNC Router Engraver/Carver Kit

2. OpenBuilds – MiniMill CNC Machine

Domain: us.openbuilds.com

Registered: 2012 (13 years)

Introduction: {“name”:”OpenBuilds MiniMill CNC Machine”,”SKU”:”UPC: 819368029208″,”price”:”$593.99 (MSRP: $989.99)”,”description”:”The OpenBuilds MiniMill is an award-winning, compact CNC milling machine tailored for small-scale machining and milling tasks. It serves as a precise 3D carving and engraving device capable of crafting intricate engravings and stunning 3D projects. Its open design and portable natur…

3. CNC Masters – Mini CNC Router/Engraver

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for a mini CNC router/laser engraver, budget around €500 to €1000, capable of routing/milling 5mm to 10mm nylon, perspex, and some hardwoods. Aluminum capability is a bonus.

4. Maxnc – CNC Ready Mini Mill

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 1. Maxnc 10 CNC Ready Mini Mill Milling Machine With 3 Axis – Pre-Owned – Price: $625.00 – Free shipping.

2. Mini CNC 3018-SE V2 Router Machine Engraver with Transparent Enclosure + Spindle – Brand New, Unbranded – Price: $177.66 or Best Offer – Free shipping.

3. 1500W USB 4 Axis CNC 6040Z Router Engraving Carving Milling Machine & Controller – Brand New, Unbranded – Price: $1,099.46 or Best Offer…

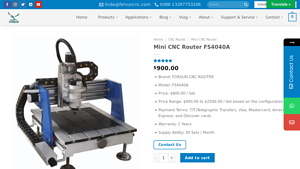

5. FORSUN – Mini CNC Router FS4040A

Domain: forsuncnc.com

Registered: 2020 (5 years)

Introduction: { “Name”: “Mini CNC Router FS4040A”, “Brand”: “FORSUN”, “Price”: “$900.00”, “Warranty”: “2 Years”, “Supply_Ability”: “30 Sets / Month”, “Machine_Description”: “Compact and powerful, suitable for smaller studios and hobby users. Primarily used for engraving, punching, and cutting various materials such as PVC, acrylic, and wood.”, “Dimensions”: { “X_Y_Axis_Travel”: “400X400mm”, “Z_Axis_Travel”: “12…

6. Carbide 3D – Desktop CNC Mills & Routers

Domain: shop.carbide3d.com

Registered: 2013 (12 years)

Introduction: { “products”: [ { “name”: “Nomad 3 – Desktop CNC Mill”, “price”: “2800.00”, “type”: “Desktop CNC Mill” }, { “name”: “Shapeoko 4 CNC Router”, “price”: “from 1800.00”, “type”: “CNC Router” }, { “name”: “Shapeoko Pro CNC Router”, “price”: “from 2400.00”, “type”: “CNC Router” }, { “name”: “Shapeoko 5 Pro CNC Router”, “price”: “from 3250.00”, “type”: “CNC Router” }, { “name”: “Shapeoko HDM”, “price”: “…

7. Grizzly – Precision CNC Routers

Domain: grizzly.com

Registered: 1991 (34 years)

Introduction: This company, Grizzly – Precision CNC Routers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for mini cnc router

As international markets evolve, the importance of strategic sourcing for mini CNC routers cannot be overstated. B2B buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize understanding the nuances of product specifications, vendor reliability, and local manufacturing capabilities. Emphasizing quality over cost will enable businesses to cultivate long-term partnerships with suppliers, ensuring access to the latest technologies and support.

Moreover, leveraging digital platforms can streamline procurement processes, allowing buyers to easily compare product offerings and pricing from various manufacturers like FoxAlien, Monoprice, and OpenBuilds. This adaptability is crucial for companies looking to remain competitive in diverse marketplaces.

Looking ahead, businesses are encouraged to remain proactive in their sourcing strategies, adopting agile practices to respond to shifts in demand and supply chains. By prioritizing manufacturers that offer robust support systems, inclusive product ranges, and value-added services, B2B buyers can enhance their operational efficiencies and innovate their offerings. Now is the time to take decisive steps in sourcing mini CNC routers that align with your strategic goals, positioning your business for growth in an increasingly interconnected world.