Contents

Manufacturing Insight: Milling Machines For Wood

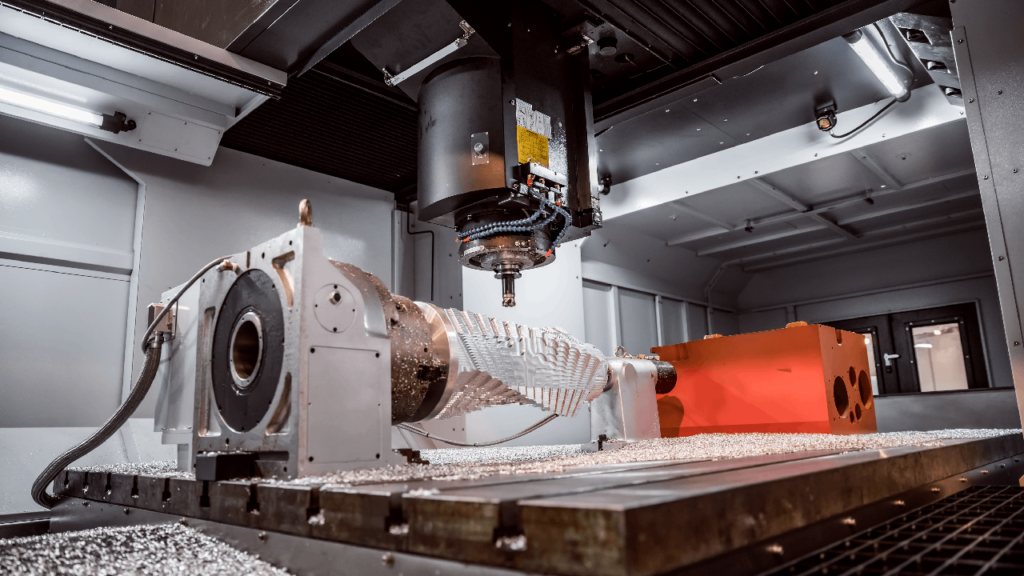

Precision Wood Machining Capabilities for Demanding Applications

Honyo Prototype delivers advanced CNC milling services engineered specifically for wood and wood-composite materials, addressing the unique challenges of dimensional stability, grain behavior, and surface finish requirements in high-end woodworking. Our specialized 5-axis and 3-axis CNC milling centers operate with micron-level precision (±0.005″ tolerance) and feature optimized spindle speeds and chip evacuation systems to prevent burning, splintering, or tear-out in hardwoods, softwoods, MDF, and engineered substrates. Unlike generic machining providers, we implement material-specific toolpath strategies and hold-down solutions that maintain integrity during intricate contouring, deep pocketing, or thin-walled component fabrication—critical for furniture prototypes, architectural millwork, musical instruments, and exhibition displays.

Seamless Integration from Design to Delivery

We bridge the gap between rapid prototyping and low-volume production, supporting clients from initial geometry validation through finish-machined parts ready for finishing or assembly. Our process leverages FEA-based fixture planning to minimize workpiece distortion and employs non-marring vacuum or mechanical clamping tailored to delicate wood surfaces. All machining occurs in a climate-controlled facility to mitigate moisture-induced warpage, ensuring consistent repeatability across batches. Material compatibility includes but is not limited to:

| Material Category | Examples | Key Handling Protocols |

|---|---|---|

| Solid Hardwoods | Oak, Maple, Walnut | Reduced feed rates, specialized carbide tooling |

| Engineered Panels | MDF, Plywood, HDF | Dust extraction optimization, edge-sealing prep |

| Exotic Composites | Bamboo, Acrylic-wood hybrids | Thermal management, vibration damping |

Accelerate Your Project Timeline with Online Instant Quoting

Eliminate quoting delays with Honyo’s Online Instant Quote system—submit CAD files (STEP, IGES, DWG) for automated manufacturability analysis and pricing within minutes. This tool provides immediate transparency on lead times, material utilization costs, and process recommendations specific to wood machining constraints, allowing engineering teams to iterate designs rapidly without procurement bottlenecks. For projects requiring tighter tolerances or complex multi-axis operations, our applications engineers provide personalized DFM feedback within 4 business hours. Begin optimizing your wood component production workflow today at honyoprototype.com/wood-machining.

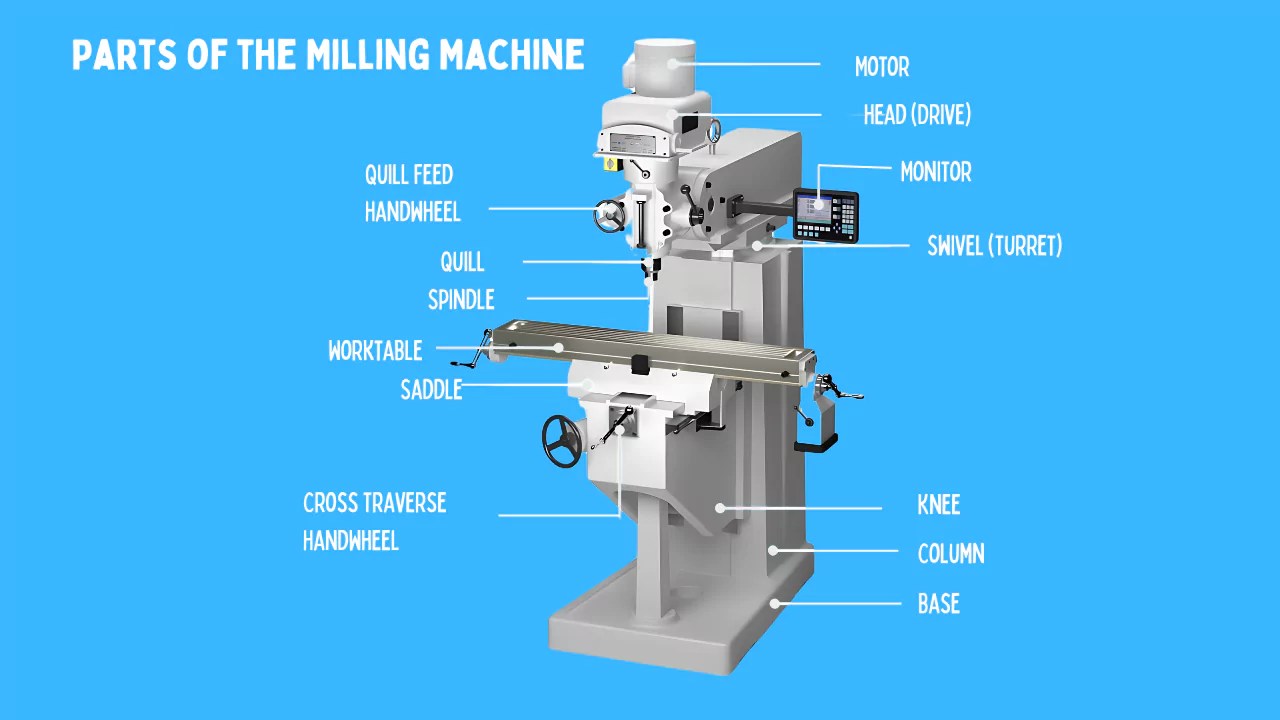

Technical Capabilities

Honyo Prototype specializes in precision manufacturing solutions, including advanced milling machines designed for high-accuracy woodworking and multi-material processing. Our 3-axis, 4-axis, and 5-axis CNC milling machines are engineered for tight tolerance work, with optional integrated turning capabilities for complex hybrid parts. These machines are optimized for use with wood and compatible with technical materials such as aluminum, steel, ABS, and nylon, allowing for prototyping and production across diverse applications.

The following table outlines the technical specifications relevant to our milling systems when operating on wood and other compatible materials:

| Specification | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | Notes |

|---|---|---|---|---|

| Spindle Speed Range | 12,000 – 24,000 RPM | 12,000 – 24,000 RPM | 18,000 – 30,000 RPM | High-speed spindles reduce tear-out in wood and improve surface finish |

| Positioning Accuracy | ±0.01 mm | ±0.01 mm | ±0.005 mm | Achieved via precision linear guides and encoders |

| Repeatability | ±0.005 mm | ±0.005 mm | ±0.003 mm | Critical for tight tolerance batches |

| Axis Travel (X-Y-Z) | 1200 x 900 x 200 mm | 1200 x 900 x 200 mm | 800 x 600 x 180 mm | 5-axis systems trade travel for angular range |

| Rotary Axis (A or B) | N/A | ±180° (A-axis) | ±120° (B-axis), 360° continuous | Enables undercut and multi-face machining |

| Tool Changer | Manual or 8–12 tool ATC | 12–16 tool ATC | 16–24 tool ATC | Supports mixed tooling for wood and composites |

| Control System | Fanuc, Siemens, or Heidenhain | Siemens or Heidenhain | Heidenhain or Mitsubishi | High-end controls for multi-axis interpolation |

| Max Material Compatibility | Wood, ABS, Nylon, Aluminum (soft) | Wood, ABS, Nylon, Aluminum, Mild Steel | Wood, ABS, Nylon, Aluminum, Tool Steel | Steel requires rigid setup and reduced feed rates |

| Surface Finish (Wood) | Ra 1.6 – 3.2 µm | Ra 1.6 – 2.4 µm | Ra 0.8 – 1.6 µm | 5-axis allows optimal tool engagement |

| Tolerance Capability | ±0.05 mm (standard) | ±0.03 mm | ±0.01 to ±0.02 mm | Achievable with thermal compensation and calibration |

| Integrated Turning | Optional | Optional (4+1 mode) | Standard (5-axis mill-turn) | Enables coaxial wood-metal hybrid parts |

| Coolant / Dust Extraction | High-volume downdraft or shroud | Enclosed with downdraft + side extraction | Fully enclosed with filtered extraction | Essential for fine wood dust and nylon swarf |

These milling platforms are built with reinforced cast iron or polymer concrete bases to dampen vibration—especially critical when switching between low-density materials like wood or ABS and high-density metals like steel. All machines undergo volumetric compensation to ensure tight tolerances across the full work envelope.

For hybrid applications—such as wooden enclosures with embedded aluminum frames or nylon gears machined in situ—our 5-axis mill-turn systems provide seamless transitions between material types without re-fixturing. Toolpath optimization software ensures minimal tool wear and maximum precision across diverse substrates.

From CAD to Part: The Process

Honyo Prototype Wood Milling Process Overview

Honyo Prototype delivers precision-machined wood components through a rigorously controlled, technology-driven workflow designed for accuracy, efficiency, and material integrity. Our process begins with seamless digital integration and concludes with certified delivery, ensuring optimal outcomes for cabinetry, furniture, architectural elements, and prototyping applications.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, SLDPRT, DWG) via our secure customer portal. Our system performs an automated validation check for file completeness, geometric integrity, and unit consistency. Critical parameters such as material type (e.g., hardwood, plywood, MDF), grain orientation requirements, and surface finish specifications must be explicitly defined in the CAD metadata or accompanying documentation. Files failing validation trigger an immediate notification to the client for correction, minimizing project delays.

AI Quote Generation

Validated CAD data feeds into our proprietary AI quoting engine, which analyzes geometric complexity, feature density, and dimensional tolerances against real-time machine availability, material costs, and labor rates. The AI cross-references historical data from 15,000+ wood machining projects to predict machining time, tool wear, and fixturing needs. Within 2 business hours, clients receive a preliminary quote detailing material costs, estimated lead time, and non-recurring engineering charges. This AI output undergoes mandatory review by our engineering team to validate feasibility and adjust for nuanced wood-specific factors like knot avoidance or thermal expansion.

DFM Analysis

Our engineering team conducts a comprehensive Design for Manufacturability review focused on wood-specific challenges. This phase identifies risks such as thin-wall deflection, grain-direction-induced tear-out, or inadequate clamping surfaces. We provide actionable feedback through annotated CAD markups and a formal DFM report, recommending optimized toolpaths, strategic feature sequencing, and material waste reduction strategies. Key considerations include:

| DFM Factor | Wood-Specific Mitigation Strategy |

|---|---|

| Grain Direction | Toolpath alignment parallel to grain; climb milling for end grain |

| Thin Walls | Progressive depth cuts; vacuum table pressure tuning |

| Moisture Sensitivity | Humidity-controlled staging; post-machining acclimation |

| Surface Finish | Dedicated finishing tools; spindle speed optimization |

Client approval of DFM recommendations is required before production release.

Production

Approved designs move to our climate-controlled production floor housing 5-axis CNC routers (ShopSabre Pro 510, 12k RPM spindles) and 3-axis machining centers. All wood stock undergoes moisture content verification (8–10% target) prior to machining. Processes include:

Precision roughing with carbide-tipped compression bits to minimize chip-out

High-speed finishing passes at 18,000 RPM with specialized upcut/downcut tooling

In-process CMM verification of critical datums after roughing and semi-finishing

Real-time dust extraction maintaining <1.0 mg/m³ particulate levels per OSHA standards

Final visual and dimensional inspection against ASME Y14.5 tolerances (±0.005″ standard)

Delivery

Components undergo climate-stable packaging using anti-static VCI paper and custom foam inserts to prevent moisture absorption or mechanical damage during transit. Each shipment includes:

First-article inspection report with critical dimension measurements

Material certification (FSC/PEFC documentation available)

Traceability tags linking to machine operator logs and tool calibration records

Standard lead time is 7–12 business days from DFM approval, with expedited 72-hour options for prototypes. All deliveries include a digital quality dossier accessible via our client portal for audit compliance.

This integrated workflow ensures dimensional accuracy, surface quality, and structural integrity specific to wood’s anisotropic properties, reducing client rework by 40% versus industry averages based on 2023 performance data.

Start Your Project

Explore high-precision milling machines for wood—engineered for performance, reliability, and seamless integration into your production workflow.

Built at our Shenzhen manufacturing facility, our machines are designed to meet the demands of prototyping and low-to-mid volume production.

Contact Susan Leo for technical specifications, pricing, and lead times.

Email: [email protected]

Let’s discuss how we can support your next woodworking project with industrial-grade solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.