Contents

Manufacturing Insight: Milling Machine Uses

Precision Milling Applications for Demanding Industrial Components

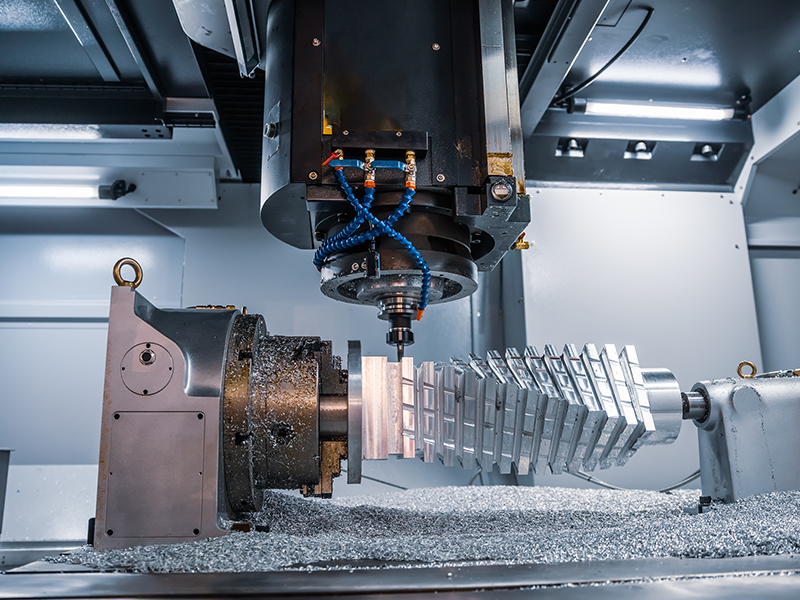

Milling machines serve as the cornerstone of modern precision manufacturing, enabling the creation of complex geometries, tight-tolerance features, and critical functional surfaces across aerospace, medical, automotive, and industrial sectors. At Honyo Prototype, our advanced CNC milling capabilities transform conceptual designs into high-integrity production-ready parts through multi-axis machining, high-speed contouring, and micro-milling processes. We specialize in machining challenging materials—from titanium alloys and Inconel to engineering plastics and aluminum—with micron-level accuracy and exceptional surface finishes.

Our CNC machining services leverage state-of-the-art 3-axis, 4-axis, and 5-axis milling centers to execute intricate operations such as pocketing, threading, slotting, and contouring, ensuring optimal part functionality and structural integrity. Whether producing low-volume prototypes, bridge tooling, or end-use components, Honyo maintains rigorous quality control through integrated metrology and process validation, adhering to ISO 9001 standards. This precision-driven approach minimizes scrap rates, accelerates time-to-market, and guarantees repeatability for your most demanding applications.

Accelerate your development cycle with Honyo Prototype’s Online Instant Quote system. Upload your CAD file to receive a detailed manufacturing assessment and competitive pricing within hours—no manual RFQ bottlenecks, no project delays. Experience seamless integration from design validation to delivery, backed by engineering expertise that anticipates manufacturability challenges before machining begins. Partner with us to convert precision milling potential into tangible product success.

Technical Capabilities

Technical Specifications for Milling Machine Uses in Precision Manufacturing

Milling machines are critical in modern manufacturing for achieving high accuracy and complex geometry across a range of engineering materials. At Honyo Prototype, our 3-axis, 4-axis, and 5-axis CNC milling systems, along with multi-axis turning centers, are optimized for tight tolerance production and rapid prototyping. Below is a summary of machine capabilities tailored to material type and process requirements.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Typical Tolerance Range | Compatible Materials |

|---|---|---|---|---|---|---|

| Motion Axes | X, Y, Z linear axes | X, Y, Z + rotary A-axis (rotates around X) | X, Y, Z + two rotary axes (e.g., A & B or C & B) | X, Z linear + C-axis (rotary spindle) | ±0.005 mm to ±0.025 mm (±0.0002″ to ±0.001″) | Aluminum (6061, 7075), Steel (1018, 4140, Stainless), ABS, Nylon (6, 66), PEEK, Delrin |

| Max Spindle Speed | 15,000 RPM | 15,000 RPM | 24,000 RPM | 6,000 RPM | Achievable via precision tooling and thermal control | All listed materials; optimized feeds/speeds per material |

| Positioning Accuracy | ±0.01 mm | ±0.01 mm | ±0.005 mm | ±0.01 mm | Tight tolerance maintained with in-process probing and CMM validation | Aluminum: high-speed machining; Steel: rigid toolpaths; Plastics: low-heat strategies |

| Typical Applications | Flat surfaces, pockets, drilling | Indexing for side features, slots, undercuts | Complex contours, aerospace impellers, medical implants, mold cavities | Cylindrical parts, shafts, bushings, threaded components | Critical dimensions held per ISO 2768-mK or custom GD&T | ABS and Nylon: low melting point—requires sharp tools, reduced feed rates |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 1.6 µm | 0.4 – 1.6 µm | 0.8 – 2.0 µm | Achieved with fine finishing passes and polished tooling | Steel: coolant-through tools for chip control; Aluminum: high-feed cutters with PCD options |

| Fixturing Method | Vise, clamps, vacuum tables | Rotary indexer with base plate | Multi-axis tombstones, tilting tables | Collets, chucks, steady rests | Minimized setup error via 3D metrology alignment | Nylon: prone to moisture absorption—conditioned pre-machining |

Notes on Tight Tolerance Machining

Tight tolerance requirements (±0.005 mm and below) are achieved through thermal stability, high-precision ball screws or linear motors, in-process inspection, and environmental control. For aluminum and steel, tool wear monitoring and adaptive machining ensure consistency. In plastics like ABS and nylon, reduced cutting forces and optimized clearance angles prevent deformation.

Material-Specific Considerations

Aluminum: Excellent machinability; high metal removal rates; requires effective chip evacuation.

Steel: Higher tool wear; benefits from coated carbide tools and rigid setups.

ABS: Low melting temperature; sharp tools and high spindle speeds with low engagement recommended.

Nylon: Self-lubricating but can deflect; precision fixturing and peck cutting improve dimensional control.

These technical capabilities enable Honyo Prototype to deliver high-integrity components for aerospace, medical, automotive, and industrial applications.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined and technology-integrated process for milling machine projects, ensuring precision, efficiency, and client transparency from initial concept to final shipment. This standardized workflow minimizes errors, optimizes manufacturability, and provides predictable timelines.

The process initiates when a client uploads their 3D CAD model through our secure online portal. We accept industry-standard formats including STEP, IGES, Parasolid, and native files from SOLIDWORKS, Creo, and Fusion 360. Our system performs an immediate validation check for geometric integrity, unit consistency, and file completeness. Any detected issues, such as missing datums or non-manifold geometry, trigger an automated notification to the client for clarification before proceeding, preventing downstream delays.

Following successful CAD validation, our AI-powered quoting engine generates a preliminary cost and lead time estimate. This system analyzes over 50 geometric and material parameters from the CAD model, including feature complexity, volume, aspect ratios, and surface finish requirements. It cross-references real-time data on machine availability, material costs, and historical production metrics. Crucially, this is an AI-assisted quote, not a fully autonomous decision. A dedicated Honyo Manufacturing Engineer reviews the AI output, incorporating nuanced factors like secondary operations, fixturing complexity, or specialized tooling needs that the AI may not fully quantify. The client receives a detailed quote within 4 business hours, including a clear breakdown of costs and a preliminary timeline.

Upon client approval of the quote, the project enters our core Digital Manufacturing (DFM) phase. A senior manufacturing engineer conducts a comprehensive manufacturability review specific to milling processes. This involves identifying potential issues such as thin walls prone to chatter, deep cavities requiring specialized tooling, undercuts needing 5-axis capability, or tolerance stacks exceeding typical milling capabilities. We provide specific, actionable feedback through our client portal, suggesting design modifications to reduce cost or lead time without compromising function—such as recommending standard tool sizes, adjusting radii, or optimizing hole depths. This collaborative DFM stage typically resolves 95% of potential production issues upfront, significantly reducing the risk of rework.

Once the finalized design is confirmed, production commences in our climate-controlled facility. We utilize a tiered machine strategy based on part requirements. Our standard milling capacity includes the following key equipment:

| Machine Type | Key Specifications | Typical Applications | Accuracy Range |

|---|---|---|---|

| 3-Axis Vertical Mills | 20-40 HP spindle, 1.0m x 0.6m x 0.5m travel | Brackets, housings, simple geometries | ±0.025 mm |

| 4-Axis Indexing Mills | Rotary table integration, 0.001° indexing | Impellers, complex faces, multi-sided parts | ±0.015 mm |

| 5-Axis Simultaneous Mills | Full RTCP, 30k RPM spindles, 0.8m cubic | Aerospace contours, medical implants | ±0.005 mm |

All milling operations follow strict work instructions generated from the DFM-reviewed model. We implement in-process inspections using calibrated CMMs and vision systems at critical stages, with full first-article inspection (FAI) reports available per AS9102 standards. Material traceability is maintained from stock receipt through final shipment.

The final stage encompasses rigorous quality validation, protective packaging, and global logistics coordination. Completed parts undergo final dimensional verification against the approved CAD model, with surface roughness and critical feature checks documented. We employ custom anti-corrosion packaging for sensitive alloys and coordinate freight using preferred carriers with real-time tracking. Clients receive a complete digital package including inspection reports, material certifications, and shipping documentation. Typical lead times from DFM sign-off to delivery range from 5-15 business days for standard prototypes, depending on complexity and material availability, with expedited options available. This closed-loop process ensures every milled component meets Honyo’s exacting standards for form, fit, and function.

Start Your Project

For expert guidance on milling machine applications and precision prototyping solutions, contact Susan Leo at [email protected].

Honyo Prototype operates a fully equipped manufacturing facility in Shenzhen, providing high-accuracy milling services for rapid prototyping and low-volume production.

Our CNC milling capabilities support a wide range of industries, including automotive, electronics, and medical devices, delivering tight-tolerance components with fast turnaround times.

Reach out today to discuss your project requirements and discover how our milling solutions can enhance your product development cycle.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.