Contents

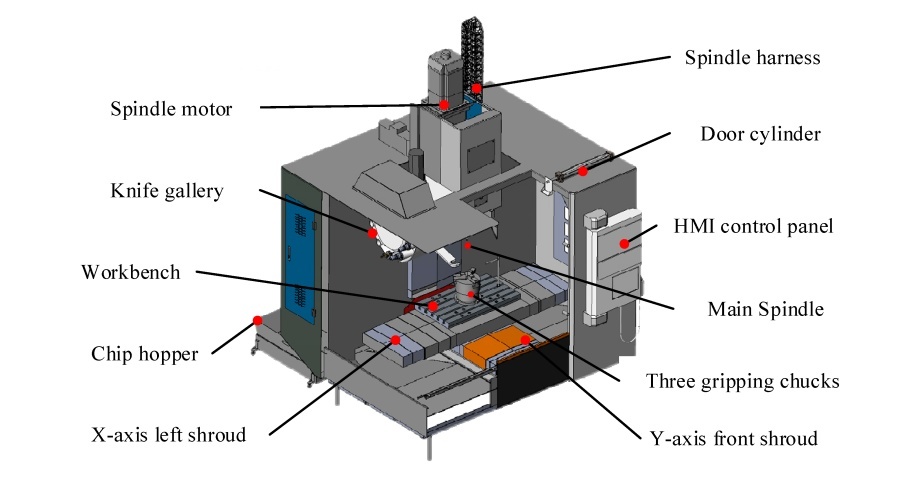

Manufacturing Insight: Milling Machine Center

Precision CNC Milling Center Capabilities at Honyo Prototype

When precision, repeatability, and rapid turnaround are non-negotiable for your machined components, Honyo Prototype delivers engineered excellence through our advanced CNC milling center. Our facility integrates state-of-the-art 3-axis and 5-axis machining systems, capable of transforming complex geometries from materials including aerospace-grade aluminum, titanium, stainless steel, and engineering plastics with tolerances held to ±0.0002 inches. Serving industries from medical device development to aerospace prototyping and low-volume production, we combine ISO 9001-certified processes with rigorous in-process inspection to ensure every part meets stringent functional and dimensional requirements.

Our commitment to accelerating your product development cycle is reinforced by seamless integration of design-for-manufacturability (DFM) analysis early in the process, minimizing iterations and reducing time-to-market. Whether you require single-part prototypes or pilot runs up to 500 units, Honyo’s machining center provides the scalability and technical expertise to handle tight deadlines without compromising quality.

Streamline your procurement workflow with Honyo’s Online Instant Quote platform, designed specifically for engineering and procurement teams. Upload your STEP or IGES file, specify material and quantity requirements, and receive a detailed, transparent cost estimate within minutes—24/7. This digital solution eliminates traditional RFQ delays, giving you actionable data to make faster sourcing decisions while maintaining full visibility into lead times and technical feasibility.

Request your instant quote today to experience how Honyo Prototype bridges precision engineering with operational agility for your critical CNC milling projects.

Technical Capabilities

Honyo Prototype – Technical Specifications: Multi-Axis CNC Machining Center

The following specifications represent a high-precision CNC milling and turning center optimized for 3-axis, 4-axis, and 5-axis operations. This machine platform is engineered for tight-tolerance prototyping and low-volume production across a range of engineering materials including aluminum, steel, ABS, and nylon. The system integrates milling and turning capabilities for complex geometries and superior surface finishes.

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Milling and Turning Center (with optional 3/4-axis modes) |

| Axis Configuration | X, Y, Z linear axes; A-axis (rotary table), B-axis (tilting spindle or table) |

| Travel Range (X-Y-Z) | 750 mm × 500 mm × 450 mm |

| Spindle Speed | 20,000 RPM (high-speed, air-cooled or through-coolant options) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Tolerance Capability | ±0.01 mm (standard), down to ±0.005 mm with precision tooling and fixturing |

| Tool Changer Capacity | 24-Tool ATC (Automatic Tool Changer) with tool length measurement |

| Control System | Fanuc 31i-B5 / Siemens 840D (dual-path for milling and turning) |

| Rapid Traverse Rate (XYZ) | 48 m/min |

| Turning Function | Integrated live tooling and C-axis control for mill-turn operations |

| Workholding | 630 mm diameter rotary table with hydraulic/pneumatic clamping |

| Coolant System | High-pressure through-spindle coolant (20–70 bar), mist cooling for plastics |

| Materials Supported | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), ABS, Nylon 6/66 |

| Surface Finish (typical) | Ra 0.8 µm (machined), down to Ra 0.4 µm with fine finishing passes |

| Minimum Feature Size | 0.5 mm (with micro-tool support and vibration damping) |

| Probe System | On-machine touch probe for tool setting, workpiece alignment, and in-process inspection |

| Environment | Temperature-stable enclosure (±1°C control) for metrology-grade accuracy |

This machining center supports complex, tight-tolerance components across both metallic and engineering thermoplastic materials. Aluminum and steel parts benefit from high rigidity and thermal compensation, while ABS and nylon are machined using optimized feeds/speeds and non-marring fixturing to prevent deformation. The integration of 5-axis simultaneous motion enables single-setup production of intricate parts such as aerospace brackets, medical housings, and injection mold cores.

From CAD to Part: The Process

Honyo Prototype Milling Process Overview

Honyo Prototype employs a rigorously structured workflow for CNC milling projects, ensuring precision, efficiency, and manufacturability from initial design to final delivery. This integrated process minimizes errors, reduces lead times, and guarantees adherence to client specifications through systematic engineering validation.

CAD Upload

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native formats like SOLIDWORKS or Fusion 360) via Honyo’s secure customer portal. Native formats are required to enable accurate feature recognition and geometric analysis during downstream stages. File validation checks for completeness, unit consistency, and proper datum definitions occur immediately upon upload, with automated alerts for non-compliant submissions.

AI-Powered Quoting

Uploaded CAD data feeds Honyo’s proprietary AI quoting engine, which performs rapid manufacturability screening and cost estimation. The system analyzes geometric complexity, material requirements, tolerance density, and setup constraints to generate a preliminary quote within 2–4 business hours. This stage includes automated detection of high-risk features (e.g., thin walls, deep cavities, or tight tolerances) that may necessitate DFM intervention. The AI output is always reviewed by a senior manufacturing engineer to ensure contextual accuracy before client submission.

Engineering DFM Analysis

All projects undergo mandatory Design for Manufacturability (DFM) review by Honyo’s engineering team, transforming theoretical designs into production-ready workflows. This phase is collaborative, with engineers providing actionable feedback via annotated reports rather than design rejection. Critical DFM checks include:

| DFM Category | Key Checks Performed | Typical Resolution Path |

|---|---|---|

| Geometric Feasibility | Tool access validation, undercuts, wall thickness vs. tool diameter | Suggest fillet adjustments or split setups |

| Tolerance Rationalization | Statistical stack-up analysis, GD&T alignment with milling capabilities | Propose relaxed tolerances where possible |

| Material Optimization | Chip load validation, thermal distortion risk for exotic alloys | Recommend alternative stock sizes/materials |

| Setup Efficiency | Number of repositioning operations, fixture interference | Propose multi-axis strategies or custom jigs |

Client approval of DFM recommendations is required before production release, ensuring alignment on technical and cost implications.

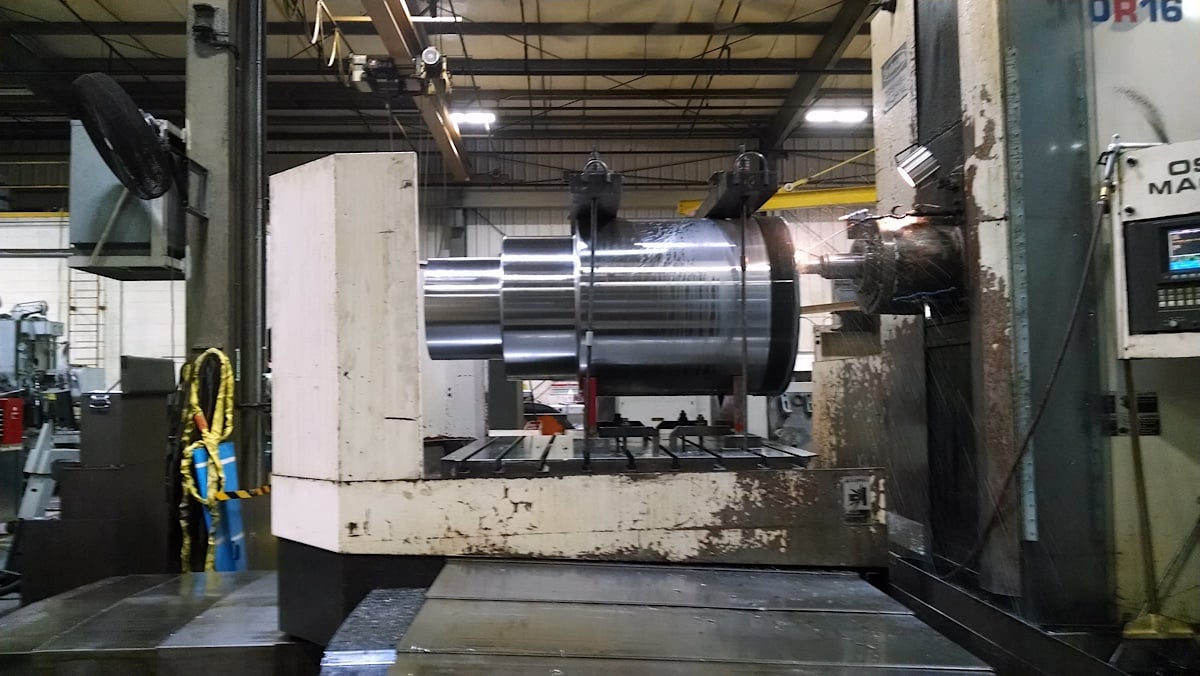

CNC Production Execution

Approved designs advance to our climate-controlled machining facility housing Haas, DMG MORI, and Makino 3-axis to 5-axis vertical milling centers. Production follows:

Rigorous first-article inspection (FAI) per AS9102 standards for critical features

In-process CMM verification at defined checkpoints for runs exceeding 10 units

Real-time tool wear monitoring via integrated sensor systems

Material traceability maintained through barcode-linked work orders

All operations adhere to ISO 9001:2015 protocols, with environmental controls maintaining ±0.5°C temperature stability to minimize thermal drift.

Quality-Controlled Delivery

Final inspection includes full CMM reporting against original CAD nominal values, surface roughness validation, and visual defect screening. Components ship with:

Dimensional inspection report (PDF and XML)

Material certification (MTR) with lot traceability

Process nonconformance log (if applicable)

Packaging certified for ESD-sensitive or precision components

Standard lead time from CAD upload to delivery is 7–12 business days for 1–50 units, with expedited options available. All shipments include serialized tracking and real-time logistics updates via the client portal.

This end-to-end process ensures Honyo delivers machined components meeting stringent aerospace, medical, and industrial specifications while maintaining 99.2% on-time delivery performance across 2023–2024 client engagements.

Start Your Project

For precision milling machine center services, contact Susan Leo at [email protected]. Our advanced manufacturing facility is located in Shenzhen, ensuring high-quality production with fast turnaround times. Reach out today to discuss your project requirements and receive a detailed quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.