Contents

Manufacturing Insight: Milling Machine

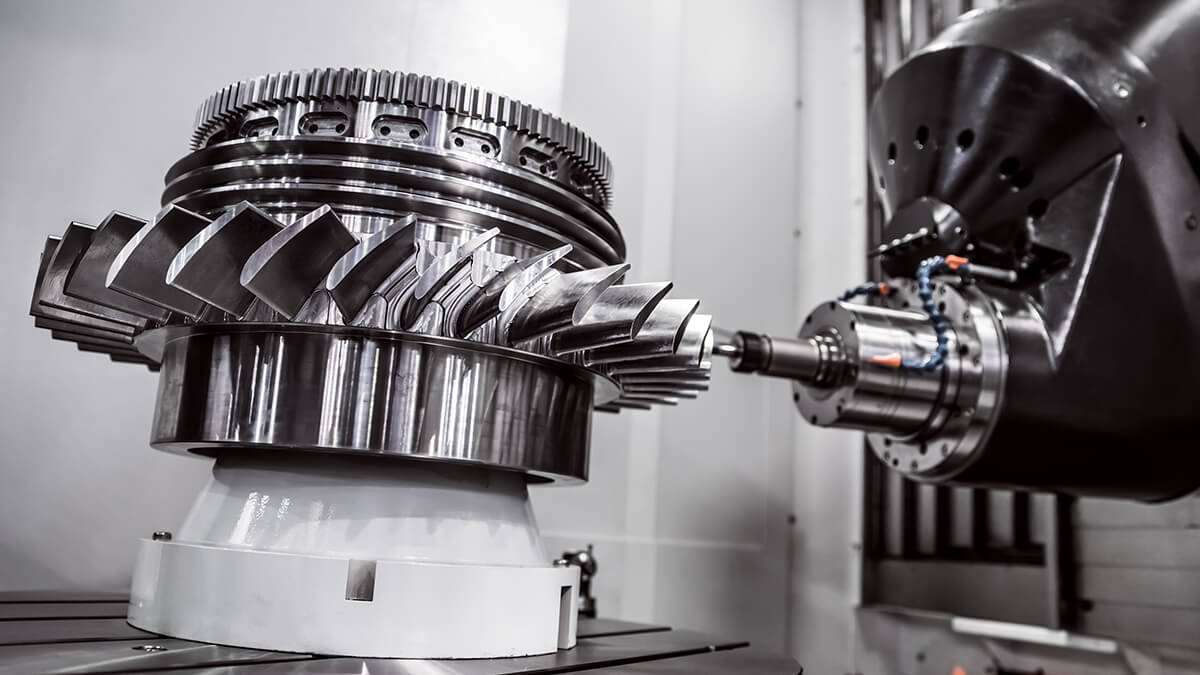

CNC milling serves as a foundational manufacturing process for producing complex, high-precision components across critical industries. At Honyo Prototype, our CNC milling services leverage state-of-the-art multi-axis machining centers to deliver exceptional accuracy, surface finish, and material versatility for both rapid prototyping and low-volume production runs. Our engineering team specializes in machining challenging materials including titanium, aluminum alloys, stainless steel, and engineering plastics while consistently holding tight tolerances down to ±0.005mm. We integrate advanced toolpath strategies and rigorous in-process inspection to ensure dimensional integrity and repeatability from the first part to the final batch. Accelerate your product development timeline by utilizing our Online Instant Quote platform, which provides detailed, manufacturing-ready cost estimates within 60 seconds—eliminating traditional RFQ delays and enabling immediate project validation. This seamless integration of precision machining capability and digital efficiency defines Honyo’s commitment to becoming your trusted manufacturing partner.

Technical Capabilities

Technical Specifications for CNC Milling Machines – Focus on 3/4/5-Axis Capabilities, Turning, and Tight Tolerance Machining

CNC milling machines used in precision manufacturing environments such as Honyo Prototype are engineered to deliver high accuracy, repeatability, and versatility across a range of materials including aluminum, steel, ABS, and nylon. These machines support multi-axis operations (3, 4, and 5-axis), often integrated with turning capabilities (mill-turn centers), enabling complex geometries and tight tolerance machining down to ±0.005 mm (±0.0002″) or tighter depending on part geometry and material.

The following table outlines key technical specifications relevant to high-precision milling and mill-turn operations:

| Parameter | Specification / Capability |

|---|---|

| Machine Type | CNC Vertical Machining Center (VMC), 5-Axis Indexed/Continuous, Mill-Turn Center |

| Axis Configuration | 3-Axis (X, Y, Z); 4-Axis (C rotary table); 5-Axis (A/C or B/C rotary axes) |

| Spindle Speed | 8,000 – 24,000 RPM (high-speed spindles for aluminum and plastics); lower for steel (6,000–12,000 RPM) |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) |

| Tolerance Capability | Typical: ±0.01 mm; Tight: ±0.005 mm; Ultra-tight: ±0.002 mm (with process control) |

| Tool Changer | Automatic Tool Changer (ATC), 16–30 tool capacity; optional 60+ for high-mix production |

| Control System | Fanuc, Siemens, or Heidenhain with 5-axis interpolation and probing integration |

| Work Envelope (Typical) | X: 500–1000 mm, Y: 400–600 mm, Z: 400–500 mm; larger beds available for production models |

| Materials Processed | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (PA6, PA66), PEEK |

| Surface Finish (Typical) | Ra 0.8–3.2 µm (milled); Ra 0.4 µm achievable with finishing passes |

| Coolant System | Through-spindle coolant (optional), flood, mist, or air blast (for plastics) |

| Probing System | On-machine touch probe for in-process inspection, tool setting, and workpiece alignment |

| Turning Capability | Integrated C-axis and live tooling (in mill-turn centers); diameter capacity up to Ø200 mm |

| Fixturing | Vacuum, mechanical clamps, modular fixturing, tombstones for 4/5-axis batch production |

Material-Specific Considerations:

Aluminum: High-speed machining with sharp carbide tools, high feed rates, and air or mist cooling to prevent built-up edge. Ideal for 5-axis complex structures.

Steel: Requires rigid setups, lower RPM, and high-torque spindles. Tight tolerance held with thermal compensation and tool wear monitoring.

ABS & Nylon: Machined with sharp, polished tools at moderate speeds; chip evacuation and low heat input critical to prevent melting or deformation.

Tight Tolerance Machining: Achieved through thermal stability, in-process probing, tool pre-setters, and closed-loop feedback systems. Environmental control (temperature, humidity) is maintained in precision facilities.

These specifications reflect the capabilities required for prototyping and low-to-mid volume production in aerospace, medical, robotics, and industrial equipment sectors where Honyo Prototype operates.

From CAD to Part: The Process

Honyo Prototype Milling Process: From CAD to Delivery

Honyo Prototype executes a streamlined, technology-driven workflow for milling projects, ensuring precision, efficiency, and manufacturability. Our process begins with rigorous digital validation and culminates in certified delivery, optimized for rapid prototyping and low-volume production. Below is the end-to-end sequence:

CAD Upload & Validation

Clients upload native CAD files (STEP, IGES, Parasolid) or 2D drawings via our secure portal. Our system performs automated geometry validation, checking for non-manifold edges, unit inconsistencies, and file corruption. Invalid submissions trigger immediate feedback with specific error diagnostics, preventing downstream delays. Validated files proceed to the quoting engine within minutes.

AI-Powered Quoting

Honyo’s proprietary AI engine analyzes the validated CAD geometry, material selection, tolerances, and surface finish requirements against real-time shop floor data (machine availability, tooling costs, labor rates). The algorithm cross-references historical project databases to predict manufacturability risks and generate a granular cost breakdown. Quotes include lead time estimates, material waste calculations, and optional value-engineering suggestions—all delivered within 2 business hours.

DFM Collaboration & Approval

Engineers conduct a formal Design for Manufacturability review, focusing on milling-specific constraints: tool access, wall thickness, cavity depth-to-width ratios, and fixture requirements. Critical findings (e.g., undercuts requiring 5-axis, non-standard tooling needs) are presented via annotated 3D visualizations in a collaborative portal. Clients approve, reject, or discuss modifications with our engineering team before production lock-in. This phase typically reduces machining time by 15–30% through proactive design refinement.

Production Execution

Approved jobs enter our digital production queue. For 3-axis to 5-axis milling:

Material Prep: Bar stock or plate is stress-relieved, deburred, and laser-engraved with traceability codes.

CAM Programming: Mastercam generates toolpaths with adaptive clearing strategies; simulations verify collision avoidance.

Machine Setup: Dedicated technicians load stock, calibrate probes, and validate datum points per AS9100 protocols.

Machining: Parts run on Haas or DMG MORI centers with in-process CMM checks for critical features. High-tolerance runs (±0.005mm) use temperature-stabilized environments.

Quality Assurance & Delivery

All components undergo first-article inspection (FAI) per ASME Y14.5, with reports detailing CMM results, surface roughness, and material certs. Dimensional data is compared against nominal CAD via 3D scan overlays where applicable. Parts are cleaned, deburred, and packaged in anti-static, serialized containers. Final shipment includes:

FAI report with non-conformance documentation (if any)

Material traceability certificates

Packing list with QR-linked production logs

Digital delivery confirmation via client portal

Process Metrics

Key performance indicators for milling projects are maintained through this workflow:

| Phase | Avg. Duration | Key Output | Quality Gate |

|---|---|---|---|

| CAD Validation | < 30 min | Validated geometry file | File integrity score ≥95% |

| AI Quoting | ≤ 2 business hours | Cost/timeline breakdown | Accuracy ±7% vs. actual |

| DFM Review | 1–3 business days | Approved engineering change order | Client sign-off required |

| Production | 3–15 days* | Machined part batch | FAI pass rate ≥99.2% |

| Delivery | 1–2 days post-FAI | Certified shipment | On-time delivery 98.5% |

*Varies by complexity; simple 3-axis jobs ship in 72 hours

This integrated approach eliminates traditional handoffs between departments, leveraging digital continuity to compress timelines while maintaining aerospace-grade quality standards. Every stage is auditable through our QMS, ensuring full traceability from raw material to client receipt.

Start Your Project

Interested in high-precision milling machine services for your next project? Contact Susan Leo at [email protected] to discuss your requirements. Our advanced machining capabilities are supported by a state-of-the-art factory located in Shenzhen, ensuring fast turnaround and consistent quality for prototyping and low-volume production.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.