Contents

Manufacturing Insight: Milling Auto Parts

Precision Milling for Automotive Excellence

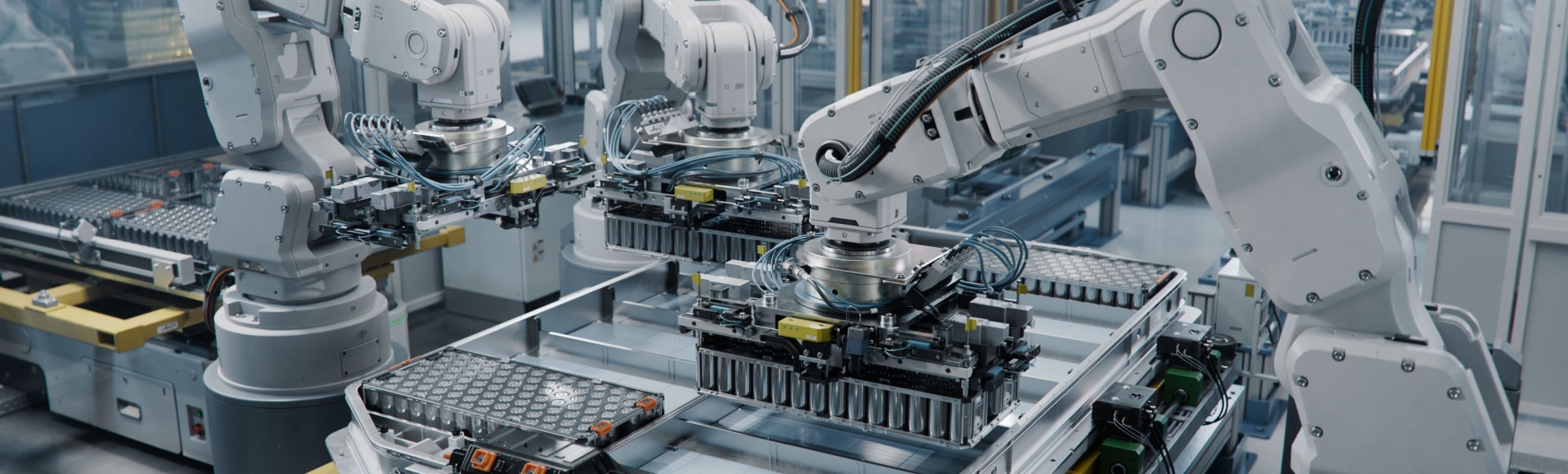

In automotive manufacturing, microns define safety, performance, and reliability. Honyo Prototype delivers mission-critical auto parts through advanced CNC milling services engineered to meet the sector’s uncompromising demands. Our 5-axis machining centers, coupled with rigorous in-process metrology, consistently achieve tolerances down to ±0.0002 inches on complex geometries—from transmission housings to suspension components—using certified materials like 6061-T6 aluminum, 4140 steel, and high-strength composites. Every part undergoes stringent first-article inspection per AS9102 standards, ensuring compliance with IATF 16949 protocols for zero-defect delivery.

Automotive-Grade Precision, Streamlined

We specialize in rapid prototyping and low-to-mid volume production runs for tier-1 suppliers and OEMs, turning engineering intent into validated hardware in as few as 5 business days. Our technical team collaborates directly with your engineers to optimize designs for machinability, reducing scrap rates and accelerating time-to-test without sacrificing structural integrity. From brake caliper brackets to EV battery tray components, Honyo applies material science expertise and adaptive toolpath strategies to conquer challenging features like thin walls, deep pockets, and integrated cooling channels.

Accelerate Your Development Cycle

Eliminate procurement delays with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats, specify materials and quantities, and receive a detailed manufacturing assessment—including lead time and DFM feedback—in under 2 minutes. This transparent, no-obligation tool empowers engineering teams to validate cost and feasibility during early design phases, turning conceptual iterations into actionable production plans faster than traditional RFQ processes.

Partner with Honyo Prototype to transform automotive innovation from blueprint to road-ready reality—with precision that drives performance.

Technical Capabilities

Honyo Prototype delivers precision-machined automotive components utilizing advanced 3-axis, 4-axis, and 5-axis CNC milling alongside CNC turning operations. Our capabilities are optimized for high repeatability, complex geometry, and tight-tolerance requirements common in engine systems, transmission housings, sensor mounts, and structural brackets. We support a wide range of automotive-grade materials including aluminum alloys, carbon and stainless steels, and engineering thermoplastics such as ABS and nylon.

Below is an overview of our technical specifications for milling and turning automotive parts:

| Parameter | Specification |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including Mill-Turn with live tooling) |

| Tolerance Capability | ±0.005 mm (±0.0002″) for critical features; standard tolerance ±0.025 mm (±0.001″) |

| Surface Finish | As-machined: Ra 3.2 µm (125 µin); post-processed options down to Ra 0.8 µm (32 µin) with polishing or grinding |

| Maximum Work Envelope (Milling) | 5-Axis: 1,200 × 800 × 600 mm (X, Y, Z); 3/4-Axis: up to 2,000 × 1,000 × 800 mm |

| Maximum Turning Diameter | 400 mm; maximum length: 1,000 mm |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed options available) |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Primary Materials | Aluminum: 6061-T6, 7075-T6, 2024-T3; Steel: 4140, 4340, 1018, 303/304/316 Stainless; Plastics: ABS (M20, M25), Nylon 6, Nylon 6/6, Glass-Filled Nylon |

| Material Form Support | Bar stock, plate, block; custom billet and pre-forms accepted |

| In-Process Metrology | On-machine probing for setup verification and feature alignment |

| Post-Processing Options | Deburring, anodizing (Type II & III), passivation, powder coating, bead blasting, custom marking |

| Quality Compliance | ISO 9001:2015 certified; full First Article Inspection (FAI) reports (AS9102 or PPAP available), CMM inspection |

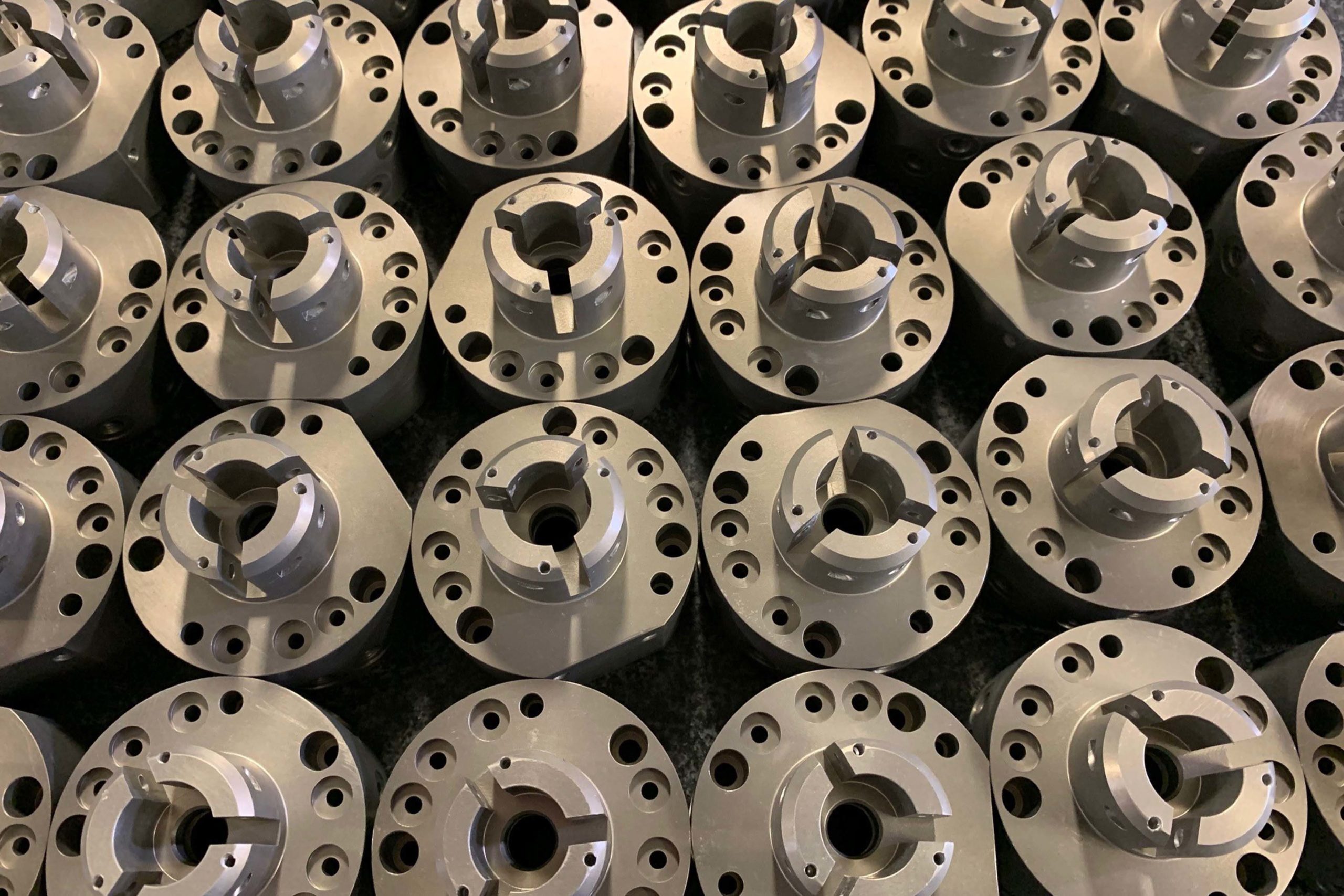

Our 5-axis simultaneous milling enables single-setup production of complex contours and deep cavities, reducing cumulative error and improving geometric accuracy. For rotating components such as pulleys or shafts, CNC turning ensures concentricity down to ±0.01 mm TIR. Multi-axis capabilities allow for angled features, undercuts, and non-orthogonal hole patterns without secondary operations.

Material selection is matched to functional requirements: aluminum for lightweight structural parts, steel for high strength and wear resistance, and ABS or nylon for non-structural, cost-sensitive, or insulating components. Tight tolerance control is maintained through thermal compensation, rigid fixturing, and real-time tool wear monitoring.

From CAD to Part: The Process

Honyo Prototype Automotive Milling Process Overview

Honyo Prototype executes precision CNC milling for automotive components through a rigorously controlled five-stage workflow designed for speed, quality, and compliance with automotive industry standards. The process begins when a client uploads a native CAD file (STEP, IGES, or native SolidWorks) to our secure portal. Our system immediately validates file integrity, geometry complexity, and unit consistency to prevent downstream errors.

AI-Powered Quoting Engine

Upon CAD validation, our proprietary AI quoting system analyzes 120+ technical parameters including material utilization, toolpath complexity, feature tolerances, and surface finish requirements. The engine cross-references real-time data from our machine park (12 Haas VF-5SS 5-axis mills, DMG MORI 3-axis centers) and material inventory (ISO 9001-certified aluminum 6061-T6, 7075-T6, steel 4140, and specialty alloys). Quotes include granular cost breakdowns for setup, machining, and secondary operations, typically delivered within 90 minutes with ±3% accuracy. Automotive-specific requirements like PPAP documentation or material traceability certificates are auto-flagged for inclusion.

Automotive-Optimized DFM Analysis

All quotes trigger an automated Design for Manufacturability review using Honyo’s automotive-specific rule set. Our engineers evaluate: wall thickness consistency against casting/molding constraints, GD&T feasibility per ASME Y14.5 standards, and feature accessibility for in-process probing. Critical to automotive applications, we verify compliance with IATF 16949 requirements for process capability (Cp/Cpk ≥1.33) and conduct material suitability checks against OEM specifications (e.g., GMW3032, Ford WSS-M99P1111-A). Clients receive annotated CAD markups with manufacturability suggestions within 24 hours, including tolerance stack-up simulations for powertrain or chassis components.

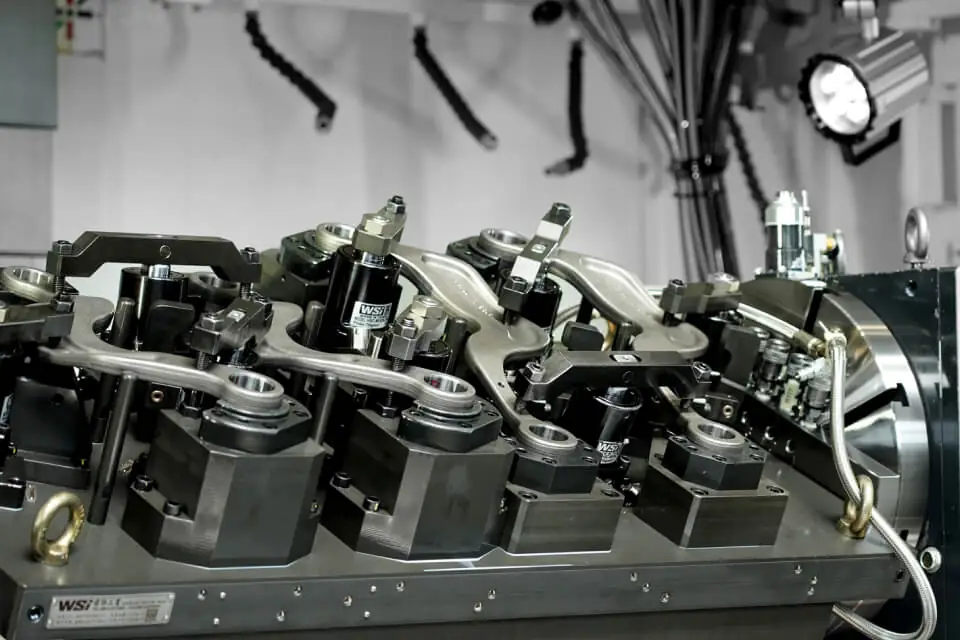

Precision Production Execution

Approved designs move to production under our digital twin-controlled workflow. Each job receives:

Material certification with full traceability (heat number, mill test reports)

First-article inspection via Zeiss CONTURA CMM with SPC data logging

In-process verification using Renishaw probing systems for critical datums

Environmental controls maintaining ±0.5°C temperature stability in machining cells

For complex geometries like transmission housings or brake calipers, we deploy 5-axis simultaneous milling with adaptive toolpath strategies to minimize vibration-induced chatter. All automotive runs include real-time process monitoring with torque/feed sensors to detect tool wear deviations exceeding 5 microns.

Certified Delivery Protocol

Final inspection generates IATF 16949-compliant documentation including:

Full FAI report per AS9102B standards

Material test certificates with RoHS/REACH compliance

Dimensional reports with color-mapped deviation heatmaps

PPAP Level 3 documentation (where specified)

Parts ship in ESD-safe, shock-absorbing packaging with serialized labels linked to our blockchain-based quality ledger. Standard lead time for milled auto prototypes is 7–10 business days from CAD approval, with expedited 72-hour options for urgent validation needs. All deliveries include a digital quality passport accessible via client portal for audit trail continuity.

This integrated process ensures automotive clients receive production-intent prototypes with zero rework cycles, validated against Tier 1 supplier quality benchmarks before physical part creation.

Start Your Project

For precision-milled automotive components, trust Honyo Prototype’s advanced manufacturing capabilities. Our Shenzhen-based factory delivers high-quality, custom auto parts with tight tolerances and fast turnaround times.

Contact Susan Leo today to discuss your milling requirements and receive a detailed quote.

Email: [email protected]

Leverage our expertise in CNC milling for reliable, repeatable results tailored to your automotive applications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.