Contents

Manufacturing Insight: Mill Machine Tooling

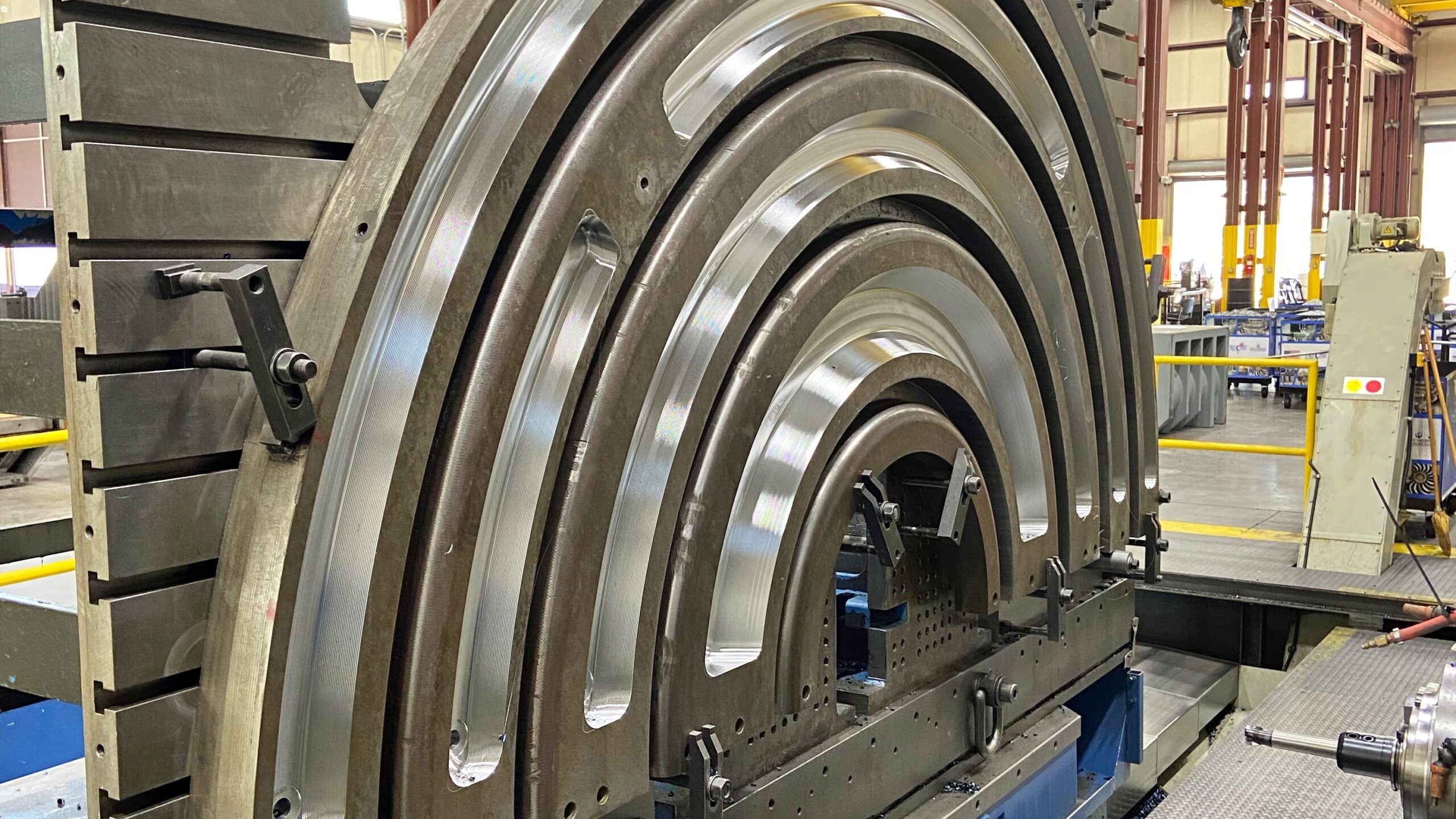

Precision Mill Machine Tooling Solutions from Honyo Prototype

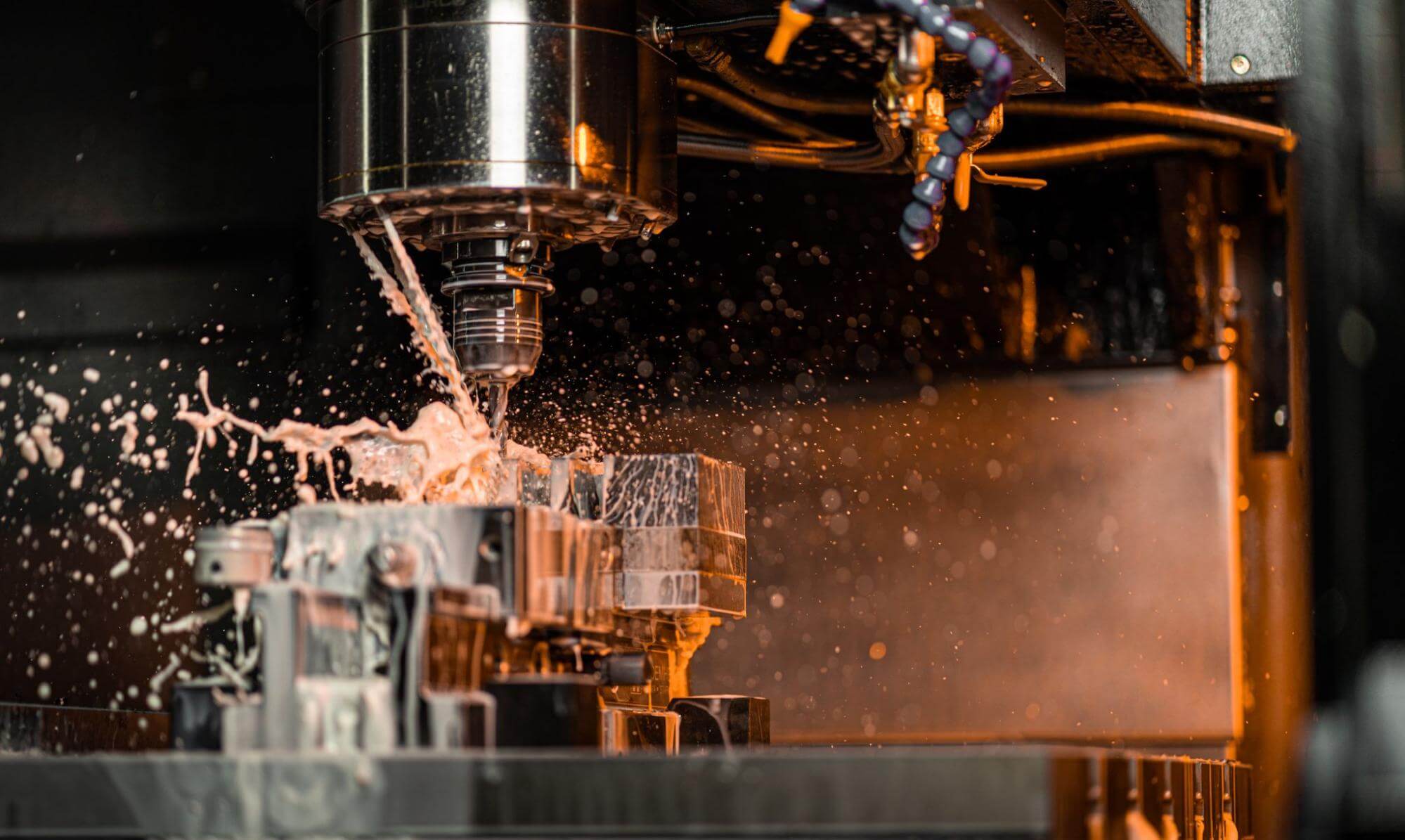

As a Senior Manufacturing Engineer at Honyo Prototype, I emphasize that advanced mill machine tooling forms the backbone of high-integrity CNC machining for demanding industrial applications. Our multi-axis CNC milling capabilities deliver exceptional precision across complex geometries, tight tolerances (±0.0002″), and diverse materials—from aerospace-grade alloys to medical polymers—ensuring your prototypes and low-volume production parts meet rigorous functional and regulatory standards. Honyo’s integrated approach combines state-of-the-art Haas and DMG MORI equipment with expert process engineering to optimize cycle times, surface finishes, and material utilization, directly accelerating your time-to-market.

Leverage our technical expertise without procurement delays: Honyo Prototype’s Online Instant Quote system provides validated pricing and lead times in under 60 seconds. Upload your STEP or IGES file to receive a manufacturability analysis and competitive quote, backed by our engineering team’s commitment to feasibility and cost efficiency. This seamless digital workflow empowers your design and sourcing decisions from the earliest development stages.

Technical Capabilities

Technical Specifications for Mill Machine Tooling

The following table outlines key technical specifications for mill machine tooling used in 3-axis, 4-axis, and 5-axis milling operations, including integration with turning capabilities for multi-axis machining centers. Focus is placed on achieving tight tolerances (±0.0005″ to ±0.005″) across a range of materials such as aluminum, steel, ABS, and nylon. These parameters are typical for high-precision CNC machining in prototyping and low-to-mid volume production environments.

| Parameter | Description |

|---|---|

| Machining Axes | 3-axis: X, Y, Z linear motion. 4-axis: Adds rotational A-axis (rotary table). 5-axis: Adds two rotational axes (e.g., A and B), enabling complex contouring and single-setup machining. |

| Spindle Speed Range | 8,000 – 24,000 RPM (high-speed spindles for aluminum and plastics); lower speeds (5,000 – 12,000 RPM) used for steel and hardened materials. |

| Positioning Accuracy | ±0.0002″ (5 µm) typical for high-end machining centers. |

| Repeatability | ±0.0001″ (2.5 µm) across all axes. |

| Tolerance Capability | Tight tolerances down to ±0.0005″ (12 µm) for critical dimensions; standard precision ±0.005″ (125 µm). Geometric tolerances (GD&T) including flatness, concentricity, and positional control achievable. |

| Tooling Types | End mills (carbide, HSS, coated), ball nose, bull nose, face mills, drills, taps, boring bars. High-precision shrink-fit or hydraulic tool holders for minimal runout (<0.0001″). |

| Coolant Delivery | High-pressure through-spindle coolant (up to 1,000 psi) for steel; mist or air blast preferred for aluminum and plastics to prevent chip welding and thermal deformation. |

| Workholding | Precision vices, modular fixturing, vacuum tables (for plastics), rotary/tilt tables (4th/5th axis). Custom fixtures for complex geometries and high repeatability. |

| Materials Processed | Aluminum (6061, 7075), Steel (1018, 4140, stainless 303/316), ABS, Nylon (6, 66). Each material requires optimized tool geometry, coatings (e.g., TiAlN for steel, ZrN for aluminum), and cutting parameters. |

| Cutting Parameters (Typical) | Aluminum: High feed rates (200–500 IPM), depth of cut 0.1–0.3″. Steel: Lower speeds (SFM: 150–400), moderate feed. ABS/Nylon: Low heat buildup strategies; sharp tools, air cooling, reduced cutting forces. |

| Surface Finish | Achievable Ra values: 16–32 µin (aluminum/steel), 32–63 µin (ABS/nylon) without post-processing; polishable to <8 µin with fine finishing passes. |

| Machine Rigidity & Thermal Control | Linear scales on all axes, thermal compensation systems, and vibration-dampening bases to maintain dimensional stability during prolonged runs. |

This configuration supports high-accuracy, multi-feature part production across diverse materials, enabling complex geometries with minimal setups—critical for aerospace, medical, and precision industrial applications.

From CAD to Part: The Process

Honyo Prototype executes milling machine tooling projects through a rigorously defined workflow designed for precision, efficiency, and seamless client integration. Our process begins with secure CAD file submission via our client portal, where STEP or native format files undergo automated validation for geometric integrity and manufacturing readiness. This initial upload triggers immediate system processing without manual intervention.

The AI Quote engine then analyzes the validated CAD geometry, automatically extracting critical features including part complexity, material requirements, tolerance density, and fixture considerations. This system cross-references real-time machine availability, material costs, and historical production data from over 15,000 completed milling projects to generate a comprehensive preliminary quote within 90 seconds. The quote includes detailed cost breakdowns for machining operations, material surcharges, and non-recurring engineering fees, all presented through an interactive client dashboard for instant review.

Subsequent to quote acceptance, the project enters our formal Design for Manufacturability (DFM) phase. Senior manufacturing engineers conduct a multi-layered technical review focusing on milling-specific constraints: tool access verification, minimum feature size validation against spindle capabilities, wall thickness analysis for chatter prevention, and strategic fixture point optimization. We provide actionable DFM feedback within 24 business hours, including annotated CAD markups and tolerance rationalization suggestions to eliminate unnecessary costs while maintaining functional requirements. This phase requires explicit client approval before proceeding to production.

Production execution occurs within our climate-controlled CNC machining facility using Haas and DMG MORI 3-5 axis milling centers equipped with Renishaw probing systems. Each setup follows documented work instructions derived from the approved DFM report, with first-article inspection performed via Zeiss coordinate measuring machines against ASME Y14.5 standards. In-process checks occur at critical operation milestones using calibrated handheld metrology equipment to ensure dimensional stability throughout production runs.

Final delivery encompasses comprehensive documentation packaged with the physical components: CMM inspection reports showing actual vs. nominal dimensions, material certification traceable to mill lot numbers, and a digital process log detailing machine parameters and operator validations. Parts ship via client-specified carriers with real-time logistics tracking, while our quality management system automatically archives all project data for future revision control and rapid reorders.

The following table summarizes our end-to-end milling tooling workflow:

| Process Stage | Technical Execution Details | Client Deliverables |

|---|---|---|

| CAD Upload | Automated geometry validation for manufacturability thresholds; file format conversion to neutral STEP; metadata extraction for feature recognition | Confirmation of file acceptance; preliminary complexity assessment |

| AI Quote | Parametric cost modeling based on feature extraction; dynamic material pricing integration; machine hour calculation using historical cycle time databases | Interactive quote with cost drivers; lead time projection; revision tracking |

| DFM Analysis | Tolerance stack-up simulation; toolpath feasibility assessment; fixture strategy development; chatter risk mitigation planning | Annotated CAD feedback; tolerance rationalization report; formal DFM signoff requirement |

| Production | Verified CNC programs with machine-specific post-processing; in-process SPC monitoring; first-article inspection per AQL 1.0; thermal compensation protocols | Real-time production updates; first-article CMM report; material certs |

| Delivery | Final dimensional validation; protective packaging per IPC-1601; consolidated shipping documentation; digital twin archive creation | Certified inspection package; shipment tracking; lifetime digital record access |

Start Your Project

Looking for high-precision mill machine tooling solutions? Honyo Prototype offers professional-grade tooling services with fast turnaround times. Our manufacturing facility in Shenzhen ensures strict quality control and efficient production for OEM and prototype applications.

Contact Susan Leo for technical specifications, pricing, or project inquiries.

Email: [email protected]

Leverage our expertise in CNC milling, tool design, and production to enhance your manufacturing performance.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.