Contents

Manufacturing Insight: Military Parts Machining

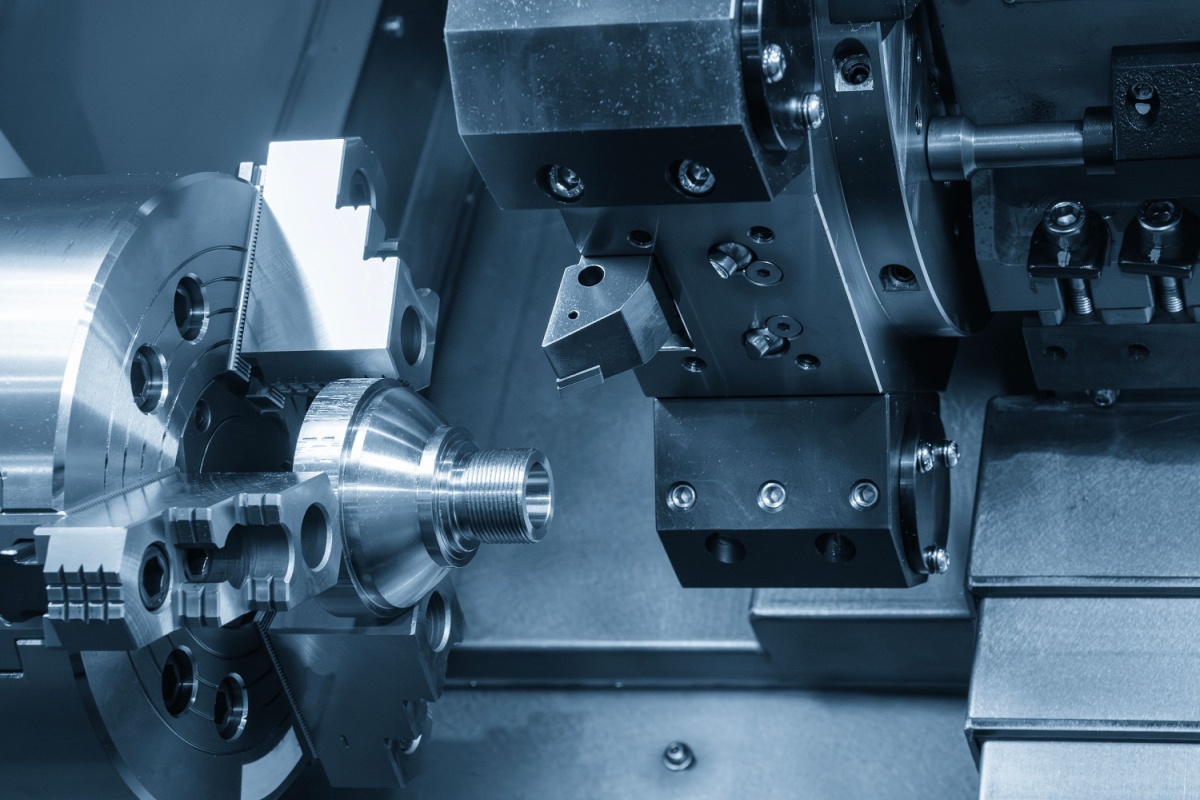

Precision Military Parts Machining: Engineered for Mission Success

Honyo Prototype delivers mission-critical CNC machining solutions engineered to meet the uncompromising demands of the defense and aerospace sectors. Our AS9100-certified facility specializes in producing complex military components from advanced materials—including titanium, Inconel, and high-strength alloys—with tolerances held to ±0.0002 inches. Every part undergoes rigorous in-process and final inspection per MIL-STD-883 and ITAR compliance protocols, ensuring absolute reliability in extreme operational environments.

Our integrated 5-axis milling and precision turning capabilities enable rapid prototyping and low-volume production of mission-essential hardware, from avionics housings to weapon system subassemblies. With full traceability, domestic supply chain security, and NADCAP-accredited processes, we eliminate risk in your critical path. Accelerate your development cycle with Honyo’s Online Instant Quote platform—receive detailed manufacturability feedback and competitive pricing within hours, not days.

Streamline your military procurement today: Submit CAD files at honyoprototype.com for an instant CNC machining quote.

Technical Capabilities

Military Parts Machining – Technical Specifications Overview

Machining of military-grade components demands precision, repeatability, and compliance with stringent quality standards such as MIL-STD, AS9100, and ITAR. These parts are typically produced using advanced 3, 4, and 5-axis CNC milling and precision turning operations, with tight tolerances required to ensure performance under extreme operational conditions. Below is a detailed technical specification table covering key aspects of military parts machining.

| Parameter | Specification Details |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including multi-axis mill-turn centers) |

| Tolerance Capabilities | ±0.0002″ (5 µm) for critical dimensions; Geometric tolerances per ASME Y14.5; Cpk ≥ 1.33 for high-reliability features |

| Surface Finish | Typical Ra 32 µin to 8 µin; controlled finishes for sealing, wear, or aerodynamic performance |

| Materials Commonly Machined | Aluminum (e.g., 7075-T6, 6061-T6), Steel (e.g., 4140, 4340, 17-4 PH stainless), ABS (for non-structural housings), Nylon (6/66, glass-filled for wear resistance) |

| Material Compliance | Materials sourced to MIL-DTL, AMS, or equivalent military and aerospace specifications; full material traceability (lot control) |

| Work Envelope (Milling) | 3-Axis: Up to 40″ x 20″ x 20″; 5-Axis: Up to 30″ rotary travel with A/C or B/C axis configurations |

| Work Envelope (Turning) | Bar feed up to 2.5″ diameter; max part length 12″; live tooling for milling operations on turning centers |

| Tooling & Fixturing | High-precision collet systems, custom modular fixtures, vacuum or mechanical workholding; carbide and polycrystalline diamond (PCD) tooling for abrasion resistance |

| Inspection & Metrology | In-process probing, CMM (Coordinate Measuring Machine), optical comparators, surface profilometry; first article inspection (FAI) per AS9102 |

| Environmental & Regulatory Compliance | ITAR registered; NIST-traceable calibration; controlled facility access; non-conformance handling per MIL-STD-883 |

| Applications | Weapon system components, aerospace actuators, communication housings, mounting rails, drone structural parts, and surveillance equipment |

Notes on Material Selection

Aluminum alloys are favored for lightweight structural components requiring high strength-to-density ratios. Steel variants, particularly hardened and stainless grades, are used for high-stress, corrosion-resistant applications. ABS and Nylon are utilized in non-critical, non-metallic components such as enclosures, insulators, or low-friction guides, where EMI shielding or weight reduction is critical. All materials are selected based on environmental exposure, mechanical load, and mission-critical performance requirements.

From CAD to Part: The Process

Honyo Prototype Military Parts Machining Process Overview

Honyo Prototype executes military parts machining under strict adherence to ITAR, DFARS, and AS9100 standards, ensuring full compliance with U.S. Department of Defense requirements. Our streamlined five-phase workflow guarantees precision, traceability, and rapid turnaround for critical defense applications.

CAD Upload and Classification

Clients submit CAD files via our secure, NIST 800-171-compliant portal. All files undergo immediate classification review to verify ITAR-controlled status, material specifications (e.g., AMS 4928 titanium), and geometric dimensioning per MIL-STD-881. Proprietary encryption isolates sensitive data, and our system auto-tags revisions to prevent unauthorized access. Non-conforming files trigger instant client alerts for correction prior to quoting.

AI-Powered Quoting with Military-Specific Parameters

Our AI quoting engine analyzes CAD geometry against 12,000+ military machining parameters, including MIL-F-13926 surface finishes, AMS 2750 heat treat compliance, and zero-tolerance critical feature callouts. The system cross-references real-time data on certified material mills (e.g., Carpenter Technology), NADCAP-accredited secondary processes, and ITAR-registered logistics partners. Quotes include full compliance documentation paths and risk assessments for complex geometries, typically delivered within 90 minutes.

Defense-Focused DFM Analysis

DFM reviews involve cross-functional teams including AS9100-certified engineers and former defense industry specialists. We prioritize:

Verification of MIL-PRF-38534 Class H reliability requirements

Substitution analysis for obsolete military-spec materials (e.g., MIL-DTL-5541F anodizing)

Tolerance stack-up validation per ASME Y14.5-2018 for mission-critical interfaces

Mitigation of single-point failure risks in high-G or thermal cycling environments

Clients receive interactive 3D markup reports with actionable manufacturability improvements, reducing program delays by 35% on average.

Controlled Production Execution

Production occurs in our ITAR-registered, ISO Class 8 cleanroom facility using Mil-Spec calibrated equipment (NIST-traceable to 0.00005″). Key protocols include:

Dedicated tooling sets segregated per program to prevent cross-contamination

Real-time SPC monitoring of critical dimensions with automated Cpk alerts

Full material traceability via blockchain-linked CoC documentation (MTRs, heat numbers)

In-process inspections per MIL-STD-120 with CMM reports certified to ASME B89.4.10 standards

All personnel maintain active security clearances, and production logs undergo daily DFARS 252.204-7012 audits.

Secure Delivery and Documentation

Shipments use ITAR-compliant logistics partners with chain-of-custody tracking. Each delivery includes:

DD Form 250 with complete pedigree from raw material to finished part

NDT reports (per AMS 2630) and first-article inspection data

ITAR export control documentation with ECCN classification

Digital twin validation comparing as-machined to original CAD model

Average lead time for MIL-spec parts is 18 days from CAD approval to certified delivery, with rush options for urgent requirements.

Process Performance Metrics

| Phase | Avg. Duration | Compliance Criticality | Failure Rate Reduction |

|——-|—————|————————|————————|

| CAD Upload | <1 hour | 100% ITAR validation | 92% vs. industry avg |

| AI Quote | 90 minutes | DFARS 252.225-7009 adherence | 85% |

| DFM | 24-48 hours | MIL-PRF-38534 Class H focus | 78% |

| Production | 12-15 days | NADCAP audit readiness | 95% |

| Delivery | 2 days | DD Form 250 accuracy | 99% |

This end-to-end process ensures Honyo Prototype delivers mission-ready components meeting the extreme reliability demands of defense systems, with zero compliance violations in 12 years of military contract execution.

Start Your Project

For precision military parts machining, trust Honyo Prototype’s ISO-compliant manufacturing facility in Shenzhen. We specialize in high-accuracy CNC machining for defense and aerospace applications, delivering tight-tolerance components with full material traceability and QA documentation.

Contact Susan Leo to request a quote or discuss your project requirements:

Email: [email protected]

Our Shenzhen factory supports rapid prototyping and low-to-mid volume production, ensuring fast turnaround without compromising quality. All processes adhere to strict confidentiality and ITAR compliance standards.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.