Contents

Manufacturing Insight: Military Cnc Services

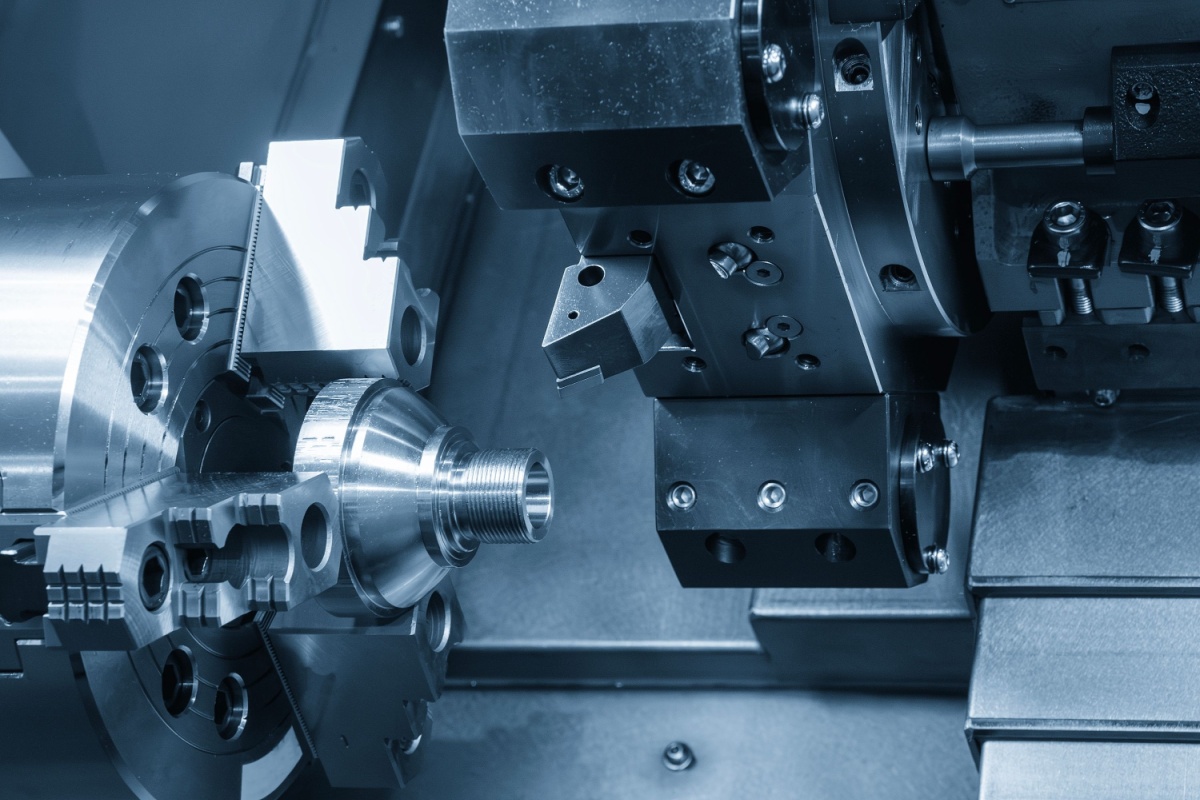

Military-Grade CNC Machining Services for Mission-Critical Applications

Honyo Prototype delivers precision CNC machining services engineered to meet the exacting demands of the defense and aerospace sectors. Our advanced manufacturing capabilities produce components that consistently achieve tolerances down to ±0.0002 inches, utilizing high-performance materials including titanium alloys, Inconel, hardened steels, and composite substrates. Every process adheres to strict AS9100 and ITAR compliance frameworks, ensuring traceability, security, and full alignment with MIL-STD and DFARS requirements.

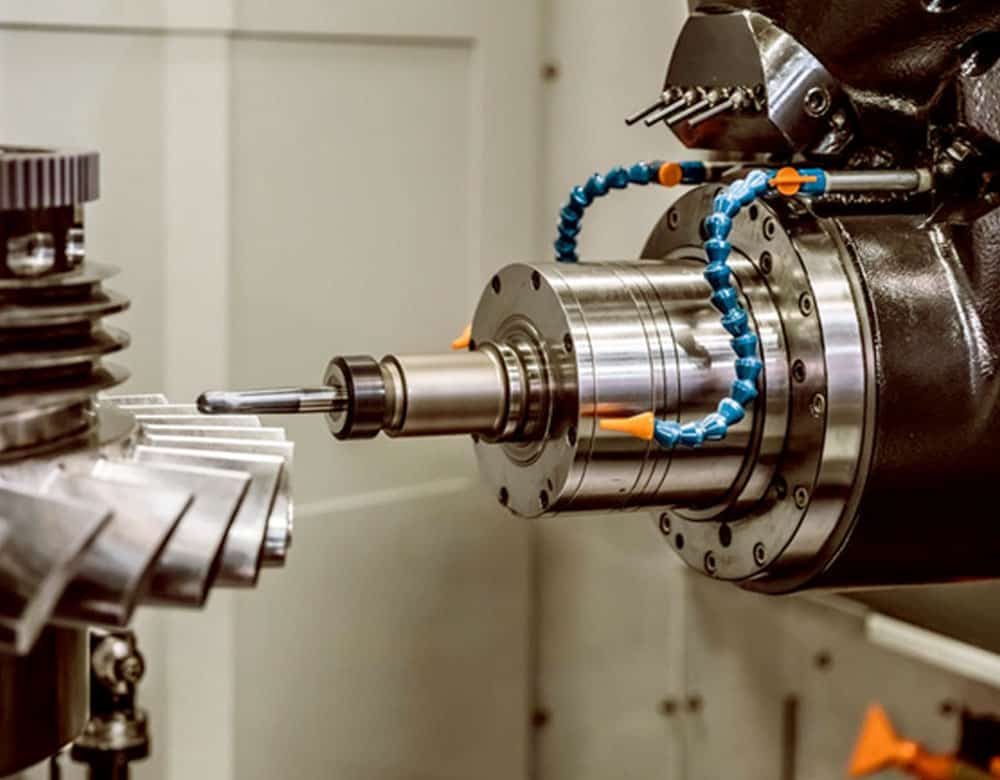

Our facility supports the full lifecycle of military hardware development, from rapid prototyping of next-generation systems to low-volume production of sustainment parts. In-house 5-axis milling, precision turning, and multi-axis Swiss machining enable complex geometries required for avionics housings, weapon system components, and ruggedized electronics enclosures. Rigorous first-article inspection (FAI) per AS9102 standards and NDT testing protocols guarantee dimensional integrity and material performance under extreme operational conditions.

Accelerate your procurement cycles with Honyo’s Online Instant Quote platform. Upload CAD files for military-specific components to receive detailed manufacturability feedback and competitive pricing within hours—not days. This tool streamlines RFQ processes while maintaining the security protocols essential for defense projects, allowing engineering teams to iterate designs faster and move from concept to field-ready hardware with unprecedented efficiency.

Partner with Honyo Prototype for CNC machining where failure is not an option. Request your instant quote today to experience defense-grade precision engineered for mission success.

Technical Capabilities

Military CNC Services – Technical Specifications

Honyo Prototype delivers precision CNC machining services tailored for military and defense applications requiring high reliability, repeatable accuracy, and compliance with stringent performance standards. Our capabilities include 3-axis, 4-axis, and 5-axis milling, CNC turning, and tight-tolerance machining across a range of engineering-grade materials such as aluminum, steel, ABS, and nylon. These services support mission-critical components used in aerospace, defense systems, communications equipment, and ruggedized electronics enclosures.

Below is a detailed overview of our technical specifications for military-grade CNC machining:

| Specification Category | Details |

|---|---|

| Machining Processes | 3-Axis Milling, 4-Axis Milling (rotary indexing), 5-Axis Simultaneous Milling, CNC Turning (Swiss and Standard), Mill-Turn with Y-axis |

| Tolerance Capability | ±0.0002″ (5 µm) for critical features; typical tolerances held at ±0.001″ (25 µm); tight positional and geometric tolerances (GD&T compliant) |

| Surface Finish | As-machined: 32–125 µin Ra; post-processed options: bead blast, anodize, passivation, powder coat |

| Materials Supported | Aluminum (6061-T6, 7075-T6, 2024-T3), Steel (4140, 4340, 17-4 PH, 303/304/316 Stainless), ABS (high-impact, machinable grade), Nylon (6, 6/6, glass-filled) |

| Max Work Envelope (Milling) | 5-Axis: 700 x 400 x 350 mm; 3/4-Axis: Up to 1000 x 600 x 500 mm (on selected machines) |

| Max Work Envelope (Turning) | Diameter: Up to 51 mm (Swiss), 300 mm (standard lathe); Length: Up to 300 mm |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed machining for aluminum and plastics) |

| Positioning Accuracy | ±0.001 mm (0.00004″) per ISO 230-2 |

| Repeatability | ±0.0015 mm (0.00006″) |

| Quality Standards | ISO 9001:2015 certified; ITAR registered; FAI (First Article Inspection) reports available; compliance with MIL-STD-810, AS9100 upon request |

| Secondary Operations | Deburring, precision cleaning, heat treating (partnered), plating, laser marking, in-house CMM inspection |

All components are machined using hardened carbide tooling, high-precision collet systems, and real-time tool length compensation. In-process inspection and final CMM validation ensure conformance to engineering drawings and military specifications. Material certifications (mill test reports) are provided for traceability in mission-critical deployments.

From CAD to Part: The Process

Honyo Prototype delivers certified military-grade CNC machining services through a rigorously controlled workflow designed for compliance, precision, and traceability. Our process adheres strictly to ITAR, DFARS, AS9100 Rev D, and NADCAP standards, ensuring all components meet stringent defense sector requirements. Below is the detailed sequence:

CAD Upload and Initial Validation

Clients submit CAD files via our secure, ITAR-compliant portal with mandatory classification markings (e.g., ITAR-controlled, UNCLASSIFIED). Our system immediately verifies file integrity, geometric completeness, and baseline adherence to military drawing standards (ASME Y14.5, MIL-STD-100). Any missing critical attributes—such as material specifications per AMS or MIL specs, surface finish callouts (e.g., AMS 2404), or non-visual inspection requirements—are flagged for client clarification before proceeding.

AI-Powered Quoting with Compliance Layer

Our proprietary AI engine generates instant cost and lead-time estimates by analyzing geometric complexity, material requirements (e.g., Ti-6Al-4V per AMS 4928, 4340 steel per AMS 6257), and machine-hour calculations. Crucially, this phase integrates automated compliance checks: ITAR jurisdiction verification, material pedigree validation against DFARS 252.225-7014, and facility capability alignment (e.g., Class 7 cleanroom for optics). Quotes include mandatory documentation costs (e.g., 3.1B material certs, C of C per MIL-I-45208) and are reviewed by a Senior Manufacturing Engineer for high-risk components.

Dual-Stage DFM Analysis

Honyo executes a two-tiered Design for Manufacturability review. First, automated algorithms assess tool accessibility, minimum wall thickness against MIL-STD-1553 tolerances, and fixture stability. Second, a designated AS9102-certified engineer conducts manual validation against military-specific constraints:

Verification of critical feature callouts per MIL-PRF-38534 for electronic housings

Stress concentration analysis for dynamic loads (MIL-STD-810H)

Secondary operation planning for plating/coating per AMS 2469

Thread engagement validation for fasteners (NASM8846)

All deviations trigger formal ECN workflows with the client, documented per AS9100 configuration management clauses.

Controlled Production Execution

Machining occurs in segregated, access-controlled cells with real-time monitoring. Key military-specific protocols include:

Material traceability via serialized bar stock with full heat treat and chemical certification

In-process inspections using calibrated CMMs (NIST-traceable) at defined hold points per MIL-STD-45662A

First-article inspection reports (FAIR) per AS9102, including 3D scan overlays against nominal CAD

Cleanliness verification (particulate counts per ISO 14644-1) for fluid system components

Laser marking per MIL-STD-130 for UID compliance, verified via 2D symbol validation

Certified Delivery and Documentation

Final shipment includes:

Complete traceability dossiers (material certs, process records, FAIR) in encrypted digital format

Physical packaging meeting MIL-STD-2073-1E for hazardous environments

Chain-of-custody logs with dual-signature verification

Certificate of Conformance explicitly citing relevant military standards (e.g., “Compliant with MIL-F-13926 Class 3”)

All deliveries undergo final QA audit by our AS9100-appointed representative, with non-conformances managed via ITAR-approved correction workflows. Typical lead time for Tier 1 defense contractors is 12–18 business days from CAD approval to certified shipment, with expedited ITAR-compliant air freight options.

Start Your Project

Looking for precision military CNC services you can trust? Honyo Prototype delivers high-accuracy machining solutions tailored to the rigorous demands of defense and aerospace applications. Our Shenzhen-based factory is equipped with advanced CNC technology and operated by a team committed to quality, reliability, and on-time delivery.

For dedicated support and project inquiries, contact Susan Leo at [email protected]. Let’s build mission-critical components together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.