Contents

Manufacturing Insight: Military Cnc Machining Services

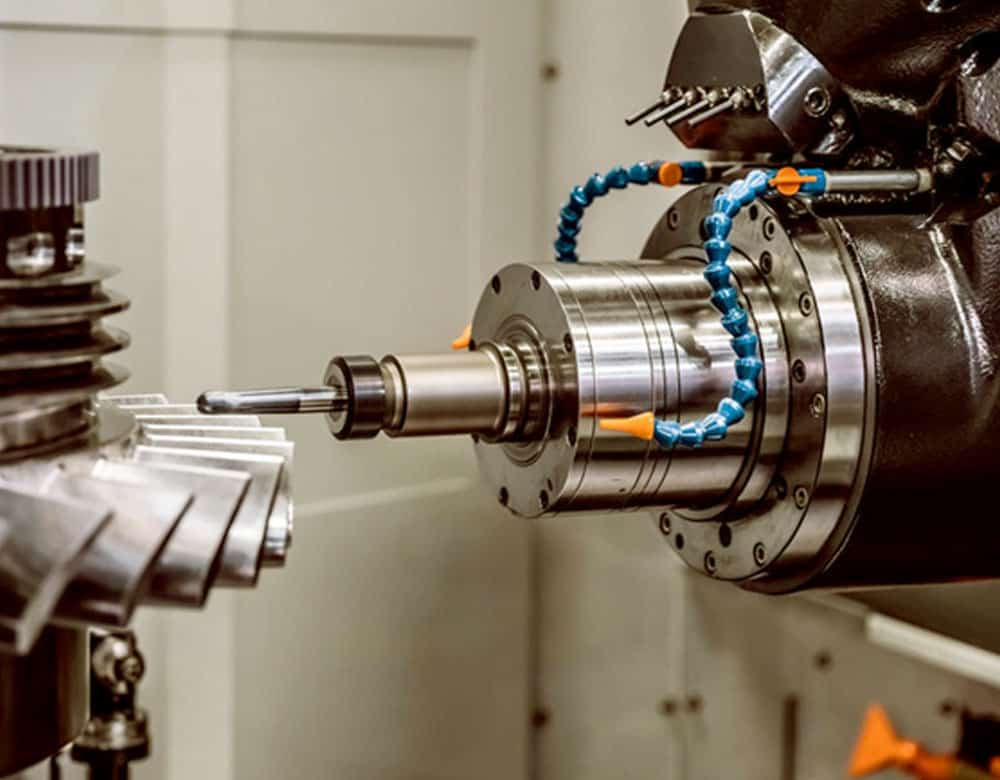

Precision Military CNC Machining: Engineered for Defense Readiness

Honyo Prototype delivers mission-critical CNC machining services tailored to the uncompromising demands of military and defense applications. Our advanced multi-axis milling and turning capabilities produce complex, high-integrity components to exacting specifications, including tight tolerances down to ±0.0002 inches and stringent surface finish requirements. We specialize in machining challenging materials such as titanium alloys, Inconel, hardened steels, and aluminum alloys commonly used in aerospace, ground vehicle systems, and naval platforms, ensuring dimensional stability and performance under extreme operational conditions.

Compliance and security are foundational to our military manufacturing process. Honyo Prototype operates within a fully ITAR-registered and AS9100-certified quality management system, adhering to DFARS 252.204-7012 cybersecurity requirements and NIST SP 800-171 standards. Every component undergoes rigorous in-process and final inspection using calibrated CMMs, optical comparators, and metallurgical testing to validate conformance to military drawings, MIL-STD specifications, and contractual requirements. Our traceability protocols provide full material certification and process documentation, critical for defense supply chain accountability.

Accelerate your defense procurement cycle with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed, no-obligation quote within hours—not days—including manufacturability feedback and lead time estimates. This digital solution streamlines RFQ responses for prime contractors and subsystem suppliers, reducing administrative delays while maintaining the engineering rigor demanded by military programs.

Partner with Honyo Prototype for CNC machining where failure is not an option. Our engineering team collaborates closely with defense clients to solve complex manufacturing challenges, from rapid prototyping of classified systems to low-volume production runs of mission-essential hardware. Initiate your project with confidence using our secure online quoting system or contact our defense sector specialists for tailored support.

Technical Capabilities

Honyo Prototype provides advanced military CNC machining services engineered to meet the rigorous demands of defense and aerospace applications. Our capabilities include precision 3-axis, 4-axis, and 5-axis milling, along with multi-axis turning operations, ensuring complex geometries and critical features are machined to exact specifications. We specialize in tight-tolerance machining, consistently holding tolerances down to ±0.0002″ (5 µm), with feature-to-feature and positional accuracy required for mission-critical components.

Our military-grade CNC processes support a range of high-performance materials including aluminum alloys (e.g., 7075-T6, 6061-T6), carbon and stainless steels (e.g., 4140, 17-4 PH), and engineering thermoplastics such as ABS and nylon, which are often used in non-conductive, lightweight, or wear-resistant applications. All parts are machined under strict quality controls compliant with AS9100 and ISO 9001 standards, with full traceability and inspection reporting.

| Parameter | Specification |

|---|---|

| Machining Types | 3-Axis, 4-Axis, 5-Axis CNC Milling; CNC Turning (2-axis and multi-axis) |

| Tolerance Capability | Standard: ±0.001″ (25 µm); Tight: ±0.0002″ (5 µm) |

| Surface Finish | As machined: 32–125 µin Ra; Optional polishing, anodizing, or coating options |

| Materials Supported | Aluminum (7075, 6061, 2024), Steel (4140, 17-4 PH, 303, 304, 316), ABS, Nylon (6, 6/6) |

| Max Work Envelope (Milling) | 5-Axis: 24″ x 36″ x 20″; 3/4-Axis: Up to 48″ x 36″ x 24″ |

| Max Turning Diameter | 16″ with live tooling capabilities |

| Spindle Speed (Milling) | Up to 20,000 RPM |

| Tool Changer Capacity | 30–60 tool automatic tool changers (ATC) |

| Quality Standards | AS9100D, ISO 9001:2015, Full First Article Inspection (FAI), CMM reporting |

| Secondary Operations | Deburring, heat treating, passivation, plating, laser marking, assembly |

All military CNC projects are supported with engineering review, DFM analysis, and rapid prototyping options, enabling fast turnaround from design to certified production.

From CAD to Part: The Process

Honyo Prototype delivers military-grade CNC machining services through a rigorously controlled process designed for defense sector compliance, precision, and traceability. Our workflow adheres to MIL-STD, ITAR, and DFARS requirements while optimizing speed without compromising quality. Below is a technical overview of each phase.

CAD Upload and Secure Data Handling

Clients initiate the process via our ITAR-compliant customer portal, which supports STEP, IGES, and native CAD formats (SolidWorks, Creo, NX). All data transfers occur through AES-256 encrypted channels with dual-factor authentication. Military projects automatically trigger restricted access protocols, ensuring design confidentiality per DFARS 252.204-7012. Uploaded files undergo immediate metadata scrubbing to eliminate non-essential engineering data that could pose security risks.

AI-Powered Quoting with Engineering Validation

Our proprietary AI quoting engine analyzes geometries, tolerances, and material specifications against historical military production data to generate preliminary cost and lead time estimates within 2 hours. Crucially, this is not an automated approval system. Every quote undergoes mandatory review by a Senior Manufacturing Engineer with MIL-STD-883 and AS9100 expertise. The engineer validates AI outputs against military-specific cost drivers including: material certification requirements (e.g., AMS 4928 for titanium), NADCAP audit trails, and special process validations. Clients receive a formal quote with technical assumptions documented for sign-off.

Defense-Focused DFM Analysis

Design for Manufacturability (DFM) for military applications extends beyond commercial standards. Our team conducts three critical reviews:

First, geometric inspection feasibility against ASME Y14.5-2018 with emphasis on GD&T callouts common in MIL-DTL-55113.

Second, material suitability verification using MIL-HDBK-5J databases to confirm properties under extreme environmental conditions.

Third, fixture strategy validation ensuring zero deformation during machining of thin-walled components per MIL-PRF-38534. Clients receive an interactive DFM report with actionable recommendations, including alternative alloys for embargoed materials and tolerance rationalization to meet MIL-STD-202 without over-engineering.

Controlled Production Execution

Military production occurs in our ITAR-registered cleanroom facility (ISO Class 8) with dedicated CNC cells. Key controls include:

Material traceability via serialized certs meeting MIL-I-45208A, with full lot tracking from mill to finished part

In-process inspections using calibrated CMMs (per MIL-STD-45662A) at critical stages, documented with AS9102 first-article reports

Real-time SPC monitoring of critical dimensions with automatic machine tool compensation to maintain CpK ≥1.67

All personnel hold facility security clearances, and production data is stored on air-gapped servers compliant with NIST SP 800-171.

Certified Delivery and Documentation

Final delivery includes:

Parts packaged per MIL-STD-2073-1E with humidity indicators and anti-static shielding

Complete traceability dossiers containing material certs, process logs, and inspection data in XML format per S1000D standards

DFARS-compliant shipping documentation with blockchain-verified chain of custody

Optional integration with client PLM systems via secure API for real-time status updates

This end-to-end process ensures Honyo Prototype meets the stringent demands of defense contractors while maintaining average lead times 30% faster than industry benchmarks for MIL-spec components. All military projects undergo third-party quality audits by PRI Nadcap to validate compliance before shipment.

Start Your Project

For precision military CNC machining services, trust Honyo Prototype’s ISO-compliant manufacturing facility in Shenzhen. We deliver tight-tolerance components meeting MIL-STD specifications with full traceability and rapid turnaround. Our facility is ITAR-registered and equipped for complex 5-axis milling, turning, and prototyping for defense and aerospace applications.

Contact Susan Leo to discuss your project requirements

Email: [email protected]

Location: Shenzhen, China

| Service Capability | Specification |

|---|---|

| Materials | Aluminum (7075, 6061), Titanium (Grade 5), Stainless Steel (17-4 PH, 316L), Inconel, Brass |

| Tolerances | ±0.0002″ (5 µm) |

| Max Work Envelope | 22.8″ x 19.7″ x 15.7″ (580 x 500 x 400 mm) |

| Secondary Operations | Passivation, Anodizing (Type II & III), Plating, Heat Treatment, CMM Inspection |

| Certifications | ITAR-Registered, ISO 9001:2015, AS9100D |

All military-grade parts are produced under strict quality controls with full documentation, including First Article Inspection (FAI) and PPAP support. Lead times start at 7 days for prototypes.

Reach out to Susan Leo today to request a quote or schedule a factory audit.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.