Guide Contents

Project Insight: Military Cnc Machining Services

Manufacturing Insight: Military-Grade Precision & Speed in Product Development

Why Precision and Speed Are Non-Negotiable in Defense Applications

Military systems operate under extreme conditions where tight tolerances of ±0.01mm are critical for safety and reliability—ensuring components withstand vibration, stress, and environmental extremes.

Rapid prototyping and production cycles are essential to meet evolving mission requirements and accelerate deployment timelines in dynamic threat environments.

Complex geometries in modern defense hardware demand advanced machining capabilities that balance precision with speed, eliminating manual rework and delays.

Honyo Prototype: Your Digital Manufacturing Partner for Mission-Critical Parts

Online Instant Quote: AI-driven platform delivers real-time pricing and lead times within seconds—no manual quotes, no delays.

5-Axis Precision Machining: Advanced 3/4/5-axis capabilities with ±0.01mm tolerances for intricate, high-stress components critical to military applications.

72-Hour Prototype Turnaround: Expedited production for urgent defense projects without compromising quality or compliance.

End-to-End Digital Workflow: Seamless CAD-to-delivery process with transparent tracking, ensuring efficiency and accountability at every stage.

Honyo Prototype—where innovation meets precision, turning your designs into mission-ready reality.

Honyo Capabilities & Technology

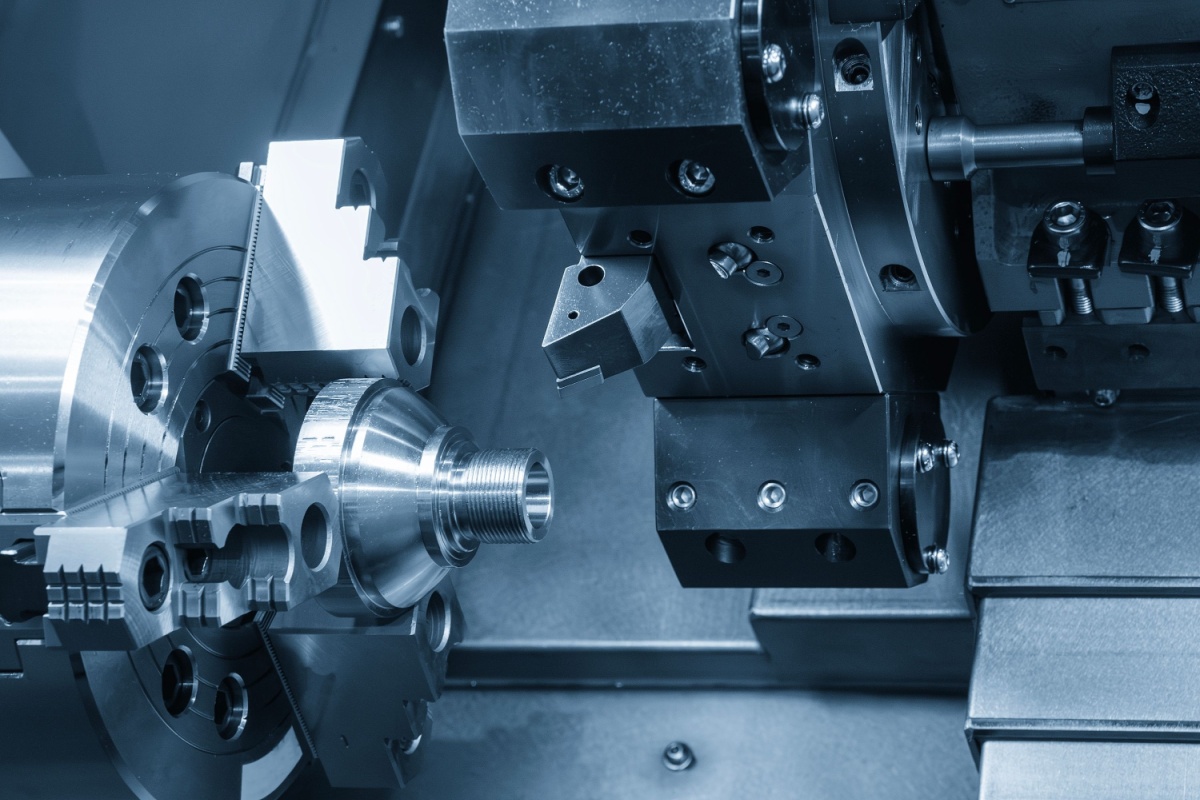

Honyo’s Military-Grade CNC Machining Capabilities

Advanced Multi-Axis Precision Engineering

3/4/5-axis CNC machining for complex geometries critical to defense systems (e.g., UAV components, missile guidance systems, and tactical equipment)

Tight tolerances of ±0.01mm ensuring mission-critical reliability under extreme operational conditions

Precision machining for both functional prototypes and end-use parts – eliminating redesign cycles and ensuring first-time-right manufacturing

High-strength alloy expertise (titanium, Inconel, aerospace-grade aluminum) with zero compromise on structural integrity

Scalable Production from Prototype to Full Deployment

Seamless transition from 1 prototype to 10,000+ production parts – ideal for agile defense innovation cycles

Zero minimum order quantities (MOQs) – perfect for startups and low-volume specialized military components

Dedicated production lines for rapid scaling without quality degradation or lead time inflation

Military-Grade Quality Assurance

ISO 9001-certified facility with QC protocols rigorously aligned with MIL-STD and AS9100 aerospace standards

In-process inspection via CMM, optical comparators, and surface roughness analyzers for 100% dimensional compliance

Full traceability for every component – including material certificates, process logs, and final inspection reports

Digital-First Efficiency Platform

Instant online quotes with AI-driven cost optimization – no manual estimates, transparent pricing in seconds

Real-time DFM (Design for Manufacturability) feedback to eliminate redesign delays and reduce costs by up to 30%

Expedited 48-hour prototype turnaround for critical defense projects with priority shipping options globally

Materials & Surface Finishes

Material Options & Finishes for Military-Grade Precision

Material Selection Guide for Demanding Applications

Military applications demand materials that balance strength, durability, and environmental resilience. Our expert team ensures optimal material choices for mission-critical components:

Aluminum 6061: Ideal for structural components requiring corrosion resistance and moderate strength. Widely used in military vehicle parts and non-critical structural elements.

Aluminum 7075: High-strength aerospace-grade alloy. Preferred for critical load-bearing components in aircraft, drones, and tactical equipment where strength-to-weight ratio is paramount.

Stainless Steel 304: General-purpose corrosion resistance for indoor military hardware. Cost-effective for non-marine environments.

Stainless Steel 316: Enhanced chloride resistance for naval applications and harsh environments. Meets stringent MIL-SPEC requirements for saltwater exposure.

Brass: Excellent electrical conductivity and corrosion resistance. Used in connectors, fittings, and instrumentation components requiring precision machining.

PEEK: High-performance thermoplastic for extreme temperatures (-200°C to 260°C) and chemical exposure. Critical for seals, bearings, and electrical insulation in aerospace and defense systems.

Key Selection Factors: Balance mechanical properties, environmental resilience (e.g., MIL-STD-810 compliance), lifecycle cost, and weight constraints. Our engineers eliminate over-engineering while ensuring peak performance.

Surface Finish Options for Enhanced Performance

Military-grade finishes must withstand extreme conditions while maintaining precision aesthetics and functionality:

Hard Anodizing (Type III): 25–50μm thickness for superior wear resistance and corrosion protection. Ideal for high-stress components like landing gear or weapon housings. Available in black or custom colors for tactical camouflage.

Passivation: Removes free iron from stainless steel surfaces per ASTM A967, critical for marine and outdoor hardware to prevent rust and pitting.

Powder Coating: Durable, UV-resistant finish for visual identification and corrosion protection. Custom colors for vehicle markings or equipment branding.

Mirror Polishing: Ra <0.05μm for optical components, precision instrumentation, and high-visibility parts requiring zero surface defects.

Black Oxide: Non-reflective, corrosion-resistant finish for firearms and tactical gear. Meets MIL-DTL-13924 standards for stealth applications.

Streamlined Procurement Process

Why Honyo Prototype Delivers Military-Grade Precision Faster

Online Instant Quote: Our AI-powered platform analyzes your CAD file in seconds, delivering transparent pricing for materials, finishes, and complexity—no hidden fees or delays.

Fast Turnaround: Prototype in 3–5 days; production orders in 1–2 weeks. We prioritize urgent military contracts with dedicated expedited processing lanes.

Precision Guarantee: Tight tolerances of ±0.01mm across all 3/4/5-axis machining operations. Every part undergoes ISO 17025-certified QC to exceed MIL-SPEC requirements.

Expert Guidance: Founder Susan Leo and our engineering team provide end-to-end consultation—optimizing designs for manufacturability, cost, and mission readiness from day one.

Innovative Edge: Leverage our cloud-based collaboration tools to iterate designs in real-time. We turn military-grade prototypes into production-ready parts faster than traditional suppliers—without compromising precision or compliance.

From Quote to Part: Our Process

How It Works: From CAD to Part

Honyo Prototype’s digital-first workflow eliminates delays and guesswork—turning your design into precision parts in record time. Here’s how it works:

Upload Your CAD File

Drag-and-drop simplicity: Submit STEP, STL, or native CAD files in seconds—no technical expertise needed.

Instant validation: Our system checks for errors and manufacturability before processing, ensuring seamless next steps.

AI-Powered Instant Quote

Real-time pricing engine: Proprietary algorithms analyze geometry, materials, and tolerances (±0.01mm) to deliver an accurate quote in <60 seconds.

Transparent cost breakdown: See exactly what drives your price—machine type, material, complexity—with no hidden fees.

No waiting, no surprises: Get your quote instantly online, then proceed with confidence.

DFM Analysis & Optimization

Expert engineering review: Our senior aerospace engineers identify design improvements to enhance manufacturability and reduce costs.

Proactive suggestions: Receive actionable recommendations for wall thickness, tolerances, and material selection—optimized for your application.

Collaborative refinement: Iterate with our team via your dashboard—no email ping-pong, just faster time-to-production.

Precision Manufacturing & Delivery

Military-grade CNC capabilities: 3/4/5-axis machining with ±0.01mm tolerances for functional prototypes and end-use parts.

Shenzhen advantage: Localized production with automated workflows ensures rapid turnaround—often 3–5 days for prototypes.

Quality assured: In-process inspections and final QA checks to meet exact specifications, with real-time tracking from start to finish.

Engineered for innovation. Delivered with precision.

Start Your Project with Honyo

Start Your Project with Honyo

AI-Powered Precision, Delivered at Speed

Online Instant Quote: Upload your CAD file and receive an accurate, real-time price estimate in under 60 seconds—no hidden fees, no delays.

AI-Optimized Workflow: Our platform analyzes design complexity to optimize machining parameters for tight tolerances (+/- 0.01mm) and accelerated production cycles.

48-Hour Turnaround Guarantee: From prototype to end-use parts, we deliver military-grade precision faster than industry averages—perfect for hardware startups with tight deadlines.

Founder-Led Excellence for Mission-Critical Applications

Susan Leo and our engineering team combine decades of aerospace/defense expertise with cutting-edge manufacturing innovation to solve your toughest challenges.

Visit our Shenzhen and Dongguan facilities for hands-on collaboration and quality assurance at every stage.

Contact us today: [email protected] | +86 139 2843 8620

Ready to accelerate your project? Get Your Free Quote Now

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.