Contents

Manufacturing Insight: Military Cnc Machining

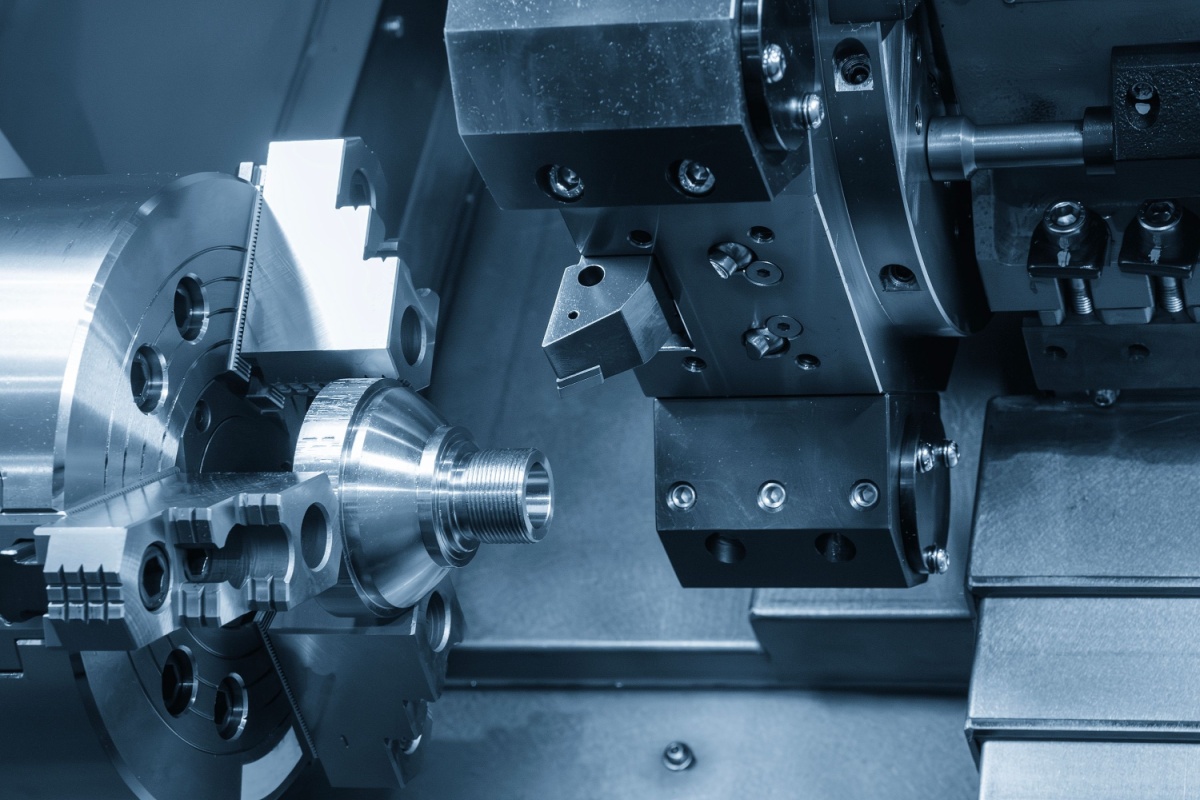

Precision Military CNC Machining: Engineered for Mission-Critical Demands

Honyo Prototype delivers advanced CNC machining solutions engineered specifically for the rigorous demands of military and defense applications. Our AS9100D and ITAR-compliant manufacturing ecosystem ensures every component meets exacting standards for performance, durability, and traceability in extreme operational environments. We specialize in complex geometries from mission-critical alloys including 7075-T7351 aluminum, Ti-6Al-4V titanium, and 4340 steel, consistently achieving tolerances down to ±0.0002 inches across 3-, 4-, and 5-axis platforms. Our dedicated cleanroom cells and full material certification protocols guarantee zero-defect output for avionics housings, weapon system components, and ruggedized communication hardware where failure is not an option.

Validated Military-Grade Material Capabilities

| Material Type | Common Military Applications | Key Process Strengths |

|———————|———————————–|————————————-|

| Aerospace Aluminum | UAV structural frames, mounts | High-speed milling, stress-relieved |

| Titanium Alloys | Landing gear, missile components | Deep cavity machining, minimal burr |

| High-Strength Steel | Armor systems, actuator parts | Hard turning, precision grinding |

Accelerate your defense prototyping and low-volume production cycles with Honyo’s Online Instant Quote system. Engineers upload CAD files for non-ITAR preliminary projects to receive geometry-validated pricing and lead times within 2 hours—enabling rapid iteration while maintaining our uncompromising quality framework for defense-critical deliverables. All military programs undergo mandatory ITAR-controlled workflow routing with dedicated project management from RFQ through final inspection documentation. Partner with Honyo Prototype for CNC machining where precision directly translates to mission readiness.

Technical Capabilities

Honyo Prototype – Military CNC Machining Technical Specifications

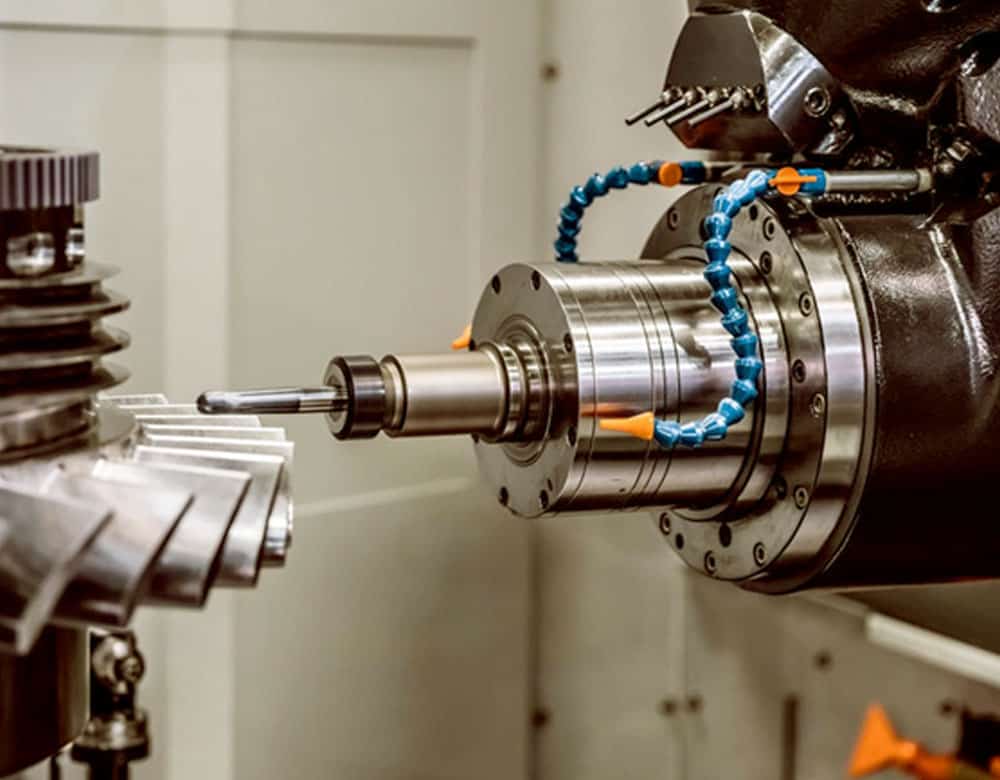

Military-grade CNC machining requires precision, repeatability, and compliance with stringent quality standards such as MIL-STD and ITAR. At Honyo Prototype, we specialize in high-accuracy 3-axis, 4-axis, and 5-axis milling, as well as precision turning, for mission-critical defense and aerospace components. Our processes support a wide range of engineering-grade materials including aluminum, steel, ABS, and nylon, with tight tolerances consistently held to ±0.0005″ (0.013 mm) and surface finishes down to 32 µin (0.8 µm) RA when required.

The following table outlines the key technical specifications for our military CNC machining capabilities:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Max Work Envelope (X×Y×Z) | 20″ × 16″ × 12″ | 20″ × 16″ × 12″ | 18″ × 14″ × 10″ | Ø16″ × 24″ length |

| Spindle Speed | Up to 15,000 RPM | Up to 15,000 RPM | Up to 18,000 RPM | Up to 4,500 RPM (live tools: 6,000 RPM) |

| Positioning Accuracy | ±0.0002″ (0.005 mm) | ±0.0002″ (0.005 mm) | ±0.0001″ (0.0025 mm) | ±0.0002″ (0.005 mm) |

| Repeatability | ±0.0001″ (0.0025 mm) | ±0.0001″ (0.0025 mm) | ±0.0001″ (0.0025 mm) | ±0.0001″ (0.0025 mm) |

| Standard Tolerance | ±0.001″ (0.025 mm) | ±0.001″ (0.025 mm) | ±0.0005″ (0.013 mm) | ±0.0005″ (0.013 mm) |

| Tight Tolerance Capability | ±0.0005″ (0.013 mm) | ±0.0005″ (0.013 mm) | ±0.0002″ (0.005 mm) | ±0.0002″ (0.005 mm) |

| Surface Finish (Typical) | 64–125 µin (1.6–3.2 µm) | 64–125 µin (1.6–3.2 µm) | 32–64 µin (0.8–1.6 µm) | 32–64 µin (0.8–1.6 µm) |

| Primary Materials | Aluminum (6061, 7075), Steel (4140, 17-4 PH), ABS, Nylon | Same as 3-axis with added angular access | Same as 4-axis with full 5-axis simultaneous motion | Aluminum, Steel, ABS, Nylon (bar stock up to Ø16″) |

| Coolant Systems | Through-spindle, high-pressure flood | High-pressure flood with chip management | High-pressure through-tool cooling | Closed-loop coolant with filtration |

| Inspection Support | CMM, Vision Systems, Laser Scanning, Hard Gaging | Full FAI and PPAP documentation available | AS9100 and ISO 9001:2015 compliant reporting | First-article and in-process inspection per MIL-STD-883 |

Notes on Materials:

Aluminum (6061-T6, 7075-T6): Lightweight, high strength-to-density ratio, excellent machinability. Used in aircraft housings, brackets, and weapon systems.

Steel (4140, 17-4 PH Stainless): High strength, wear resistance, and corrosion performance. Ideal for shafts, actuators, and structural components requiring durability.

ABS (Acrylonitrile Butadiene Styrene): Impact-resistant thermoplastic used for non-structural enclosures, jigs, and prototypes requiring EMI shielding or electrical insulation.

Nylon (PA6, PA66): High toughness, low friction, and chemical resistance. Commonly used for bushings, insulators, and wear components in harsh environments.

All military CNC machining operations are performed under controlled conditions with full traceability, material certifications (e.g., MIL-DTL-5541, AMS), and adherence to defense-specific quality protocols. Honyo Prototype supports rapid prototyping and low-to-medium volume production runs with fast turnaround and secure data handling.

From CAD to Part: The Process

Honyo Prototype Military CNC Machining Process Overview

Honyo Prototype executes military-grade CNC machining through a rigorously controlled workflow designed for defense sector compliance, precision, and traceability. All processes adhere to ITAR, AS9100 Rev D, and NADCAP standards, with end-to-end documentation for audit readiness. Below is the structured sequence:

CAD Upload & Secure Data Handling

Customers submit 3D CAD models via Honyo’s ITAR-compliant portal, featuring AES-256 encryption and geo-fenced server access. Military-specific metadata (e.g., DFARS clause references, material pedigree requirements) is auto-tagged upon upload. Non-disclosure agreements are digitally embedded, and data isolation protocols prevent cross-client exposure. Legacy formats (e.g., IGES for legacy systems) undergo validation to ensure geometric fidelity against source specifications.

AI-Powered Quoting with Military Parameter Integration

Our AI engine analyzes CAD geometry against a defense-specific historical database, incorporating MIL-STD-883 material allowances, ITAR-controlled alloy costs (e.g., 7075-T7351 aluminum), and CMMC-level cybersecurity overhead. The system flags potential compliance gaps (e.g., missing REACH exemptions for cadmium plating) and generates tiered quotes: standard, expedited (72-hour), and classified (requiring onsite review). Human engineers validate all AI outputs, with final quotes including PPAP documentation costs and first-article testing (FAT) scope.

Defense-Optimized DFM Analysis

DFM reviews prioritize military-critical factors beyond commercial standards. A dual-expertise team (AS9100-certified engineer + veteran machinist with defense OEM experience) conducts the assessment, focusing on:

| DFM Parameter | Military-Specific Requirement | Honyo Action |

|---|---|---|

| Material Certification | AMS 4928 (titanium), MIL-DTL-46100 (steel) full traceability | Reject non-certified vendors; verify mill certs |

| Geometric Tolerancing | ASME Y14.5-2009 GD&T with military addenda (e.g., MIL-STD-3046) | Enforce true position ≤ 0.0005″ for flight surfaces |

| Surface Finish | MIL-PRF-13830B for optical components; Ra ≤ 8 μin for hydraulic | Specify diamond turning vs. grinding processes |

| Environmental Testing | MIL-STD-810H shock/vibe prep integrated into fixture design | Simulate 20G loads in CAM path optimization |

Revised designs include annotated deviations with engineering change proposals (ECPs) routed for client approval via secure channels.

Production Execution Under Defense Controls

Machining occurs in ISO Class 7 cleanrooms with ITAR-restricted access. Key protocols include:

Tooling: Only NIST-traceable carbide inserts (e.g., ISO S-grade for Inconel 718) with wear monitoring via IoT sensors.

Process Validation: In-process CMM checks per MIL-STD-45662 at 50% and 100% completion; thermal compensation for aerospace alloys.

Documentation: Real-time digital logs capturing operator IDs, machine calibration certs, and environmental conditions (humidity/temperature) for full lot traceability.

Quality Gates: First-article inspection reports (FAIR) aligned with AS9102B, including cross-section microscopy for critical features.

Delivery & Compliance Handover

Final delivery includes:

Physical shipment via DHL Secure Logistics (chain-of-custody tracking to DoD facility gates).

Digital package: Complete PPAP Level 3 documentation, material test reports (MTRs) with melt chemistry, and non-destructive testing (NDT) records (e.g., X-ray per MIL-STD-271).

Certificate of Conformance (CoC) signed by Honyo’s ITAR compliance officer, affirming adherence to DFARS 252.204-7012 cyber safeguards.

All records are archived for 10+ years per defense contract requirements, with blockchain-verified audit trails available upon request.

This end-to-end process ensures military components meet stringent reliability demands while minimizing program risk through embedded compliance and transparent data continuity. For classified projects, Honyo implements facility clearance protocols under client-supervised workflows.

Start Your Project

For precision military CNC machining solutions, contact Susan Leo at [email protected]. Our ISO-compliant manufacturing facility in Shenzhen delivers high-reliability components meeting stringent defense and aerospace standards. From rapid prototyping to low-volume production, we specialize in tight-tolerance machining of aluminum, titanium, and hardened alloys for critical defense applications.

Capabilities Overview:

| Feature | Specification |

|——–|—————|

| Materials | Aluminum (6061, 7075), Titanium (Gr2, Gr5), Stainless Steel (17-4PH, 303), Inconel |

| Tolerances | ±0.0002″ (5µm) |

| Max Work Envelope | 22.8″ x 16.5″ x 11.8″ (580 x 420 x 300 mm) |

| Secondary Operations | Mil-spec deburring, passivation, anodizing (Type II & III), laser marking |

All parts undergo 100% first-article inspection with full CMM reporting and material traceability. ITAR-registered and NDA-protected processes ensure compliance and security.

Contact Susan Leo directly for engineering support, RFQs, or to discuss ITAR-controlled project requirements. Lead times typically 10–15 business days for prototype builds.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.